ASTM E823-81(2001)

(Practice)Standard Practice for Nonoperational Exposure and Inspection of a Solar Collector (Withdrawn 2010)

Standard Practice for Nonoperational Exposure and Inspection of a Solar Collector (Withdrawn 2010)

SIGNIFICANCE AND USE

Exposure in a nonoperational mode provides for conditioning and assessment of the physical appearance of a solar collector resulting from moderately severe solar irradiation, ambient temperature, and effects of moisture on the various materials or construction.

This practice describes actual exposure conditions that have a high probability of occurring sometime during the installation of a solar collector, or during operation, or malfunction of a solar energy system.

This practice shall be considered to be a limited aging test in that it does not address those aging effects resulting from fluid-to-collector interfaces.

This practice applies to all solar thermal collector types.

SCOPE

1.1 This practice defines the procedure to expose a solar thermal collector to an outdoor or simulated outdoor environment in a nonoperational model. The procedure provides for periodic inspections and a post-exposure disassembly and inspection of the collector.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice defines the procedure to expose a solar thermal collector to an outdoor or simulated outdoor environment in a nonoperational model. The procedure provides for periodic inspections and a post-exposure disassembly and inspection of the collector.

Formerly under the jurisdiction of Committee E44 on Solar, Geothermal and Alternative Engergy Sources and the direct responsibility of Subcommittee E44.05 on Solar Heating and Cooling Subsystems and Systems, this practice was withdrawn in January 2010 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E823–81 (Reapproved 2001)

Standard Practice for

Nonoperational Exposure and Inspection of a Solar

Collector

This standard is issued under the fixed designation E823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope installation of a solar collector, or during operation, or mal-

function of a solar energy system.

1.1 This practice defines the procedure to expose a solar

3.3 This practice shall be considered to be a limited aging

thermal collector to an outdoor or simulated outdoor environ-

testinthatitdoesnotaddressthoseagingeffectsresultingfrom

ment in a nonoperational model. The procedure provides for

fluid-to-collector interfaces.

periodic inspections and a post-exposure disassembly and

3.4 This practice applies to all solar thermal collector types.

inspection of the collector.

1.2 This standard does not purport to address all of the

4. Test Specimen

safety concerns, if any, associated with its use. It is the

4.1 The exposure specimen shall consist of a complete

responsibility of the user of this standard to establish appro-

collector. The collector specimens may be equipped with

priate safety and health practices and determine the applica-

self-contained, self-actuated protective devices.

bility of regulatory limitations prior to use.

5. Collector Mounting

2. Referenced Documents

2 5.1 Theexposurespecimenshallconsistofacompleteairor

2.1 ASTM Standards:

liquid solar collector undergoing the nonoperational mode

E772 Terminology Relating to Solar Energy Conversion

exposure. Cap (not seal) all inlet, outlet, and vent ports not

E892 Tables for Terrestrial Solar Spectral Irradiance at Air

normally exposed to rain.

Mass 1.5 for a 37° Tilted Surface

5.2 Locate the exposure rack such that it is clear of

2.2 ASHRAE Standard:

obstruction that may cause shadows or nonuniform reflections

93-77 Methods of Testing to Determine the Thermal Perfor-

3 on the collector.

mance of Solar Collectors

5.3 During exposure, mount the collector to the exposure

3. Significance and Use rack in accordance with the manufacturer’s instructions. When

specific exposure mounting instructions are not provided,

3.1 Exposure in a nonoperational mode provides for condi-

mount the collector to permit air movement on all sides and

tioning and assessment of the physical appearance of a solar

edges. Cover the collector for protection from the weather

collector resulting from moderately severe solar irradiation,

elements until the exposure period commences.

ambient temperature, and effects of moisture on the various

materials or construction.

6. Nonoperational Mode Exposure

3.2 This practice describes actual exposure conditions that

6.1 Mount the collector securely to an adjustable rack,

have a high probability of occurring sometime during the

prepare for nonoperational mode, and expose at the following

conditions:

6.1.1 Aminimum of 30 days during which, for each day, the

This practice is under the jurisdiction of ASTM Committee E44 on Solar,

cumulative minimum radiant exposure, measured in the plane

Geothermal,andOtherAlternativeEnergySourcesandisthedirectresponsibilityof

2 2

Subcommittee E44.05 on Solar Heating and Cooling Subsystems and Systems. of the collector, shall be 17 000 kJ/m ·day (1500 Btu/ft ·day).

Current edition approved May 29, 1981. Published July 1981. DOI: 10.1520/

Minimum conditions do not need to be met for 30 consecutive

E0823-81R01.

days.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.2 Simulated Solar Radiation:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.1.2.1 For solar simulation, one solar exposure day is

the ASTM website.

defined as the exposure for5htoa minimum solar irradiance

Available from American Society of Heating, Refrigerating, and Air-

2 2 2

of950W/m (300Btu/ft ·h)andnottoexceed1150W/m (365

Conditioning Engineers, Inc. (ASHRAE), Publications Sales Dept., 1791 Tullie

Circle, N.E., Atlanta, GA 30329. Btu/ft ·h) at an ambient temperature characteristic of outdoor

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E823–81 (2001)

exposure (nominal range from 15 to 35°C (70 to 95°F)). 6.2 Thermal Shock/Water Spray Penetration—This test is

Simulator exposure is to be followed by setting the collector intended to induce the thermal stresses that will occur when

outdoors overnight in accordance with 5.2.

rain impinges on a heated collector in order to determine the

6.1.2.2 The simulated solar spectrum shall generally con- penetration of rain into the collector and the effect of such

form to the Air Mass 1.5 global distribution as described in

penetration or moisture condensation, if any, on collector

Standard E892.

performance.

6.1.3 The energy distribution in the 0.3 to 0.4-µm range

6.2.1 PeriodofTest—Performthetestthreetimesduringthe

shall not deviate more than 625 % from the Air Mass 1.5

nonoperational mode exposure period; once during the first 10

spectrum as measured in 0.05-µm bands. The energy distribu-

days of the exposure period as defined in 6.1.1, and once each

tion from 0.4 to 2.5 µm shall not deviate by more than 615 %

during the second and third 10 days of the exposure period.

from theAir Mass 1.5 spectrum as measured in 0.10-µm bands.

6.2.2 Pre-Test Exposure—Conduct the spray test after at

6.1.4 A minimum continuous period of 1 h exposure at a

least1hof radiant exposure with a minimum solar irradi-

2 2

solar irradiance greater than 950 W/m (300 Btu/h·ft ). This

2 2

ance of 850 W/m (270 Btu/ft ·h) measured in the plane of the

condition must be experienced in the exposure day in order to

collector.

qualifytheexposuretimeaspartofthe30-hrequirement.Once

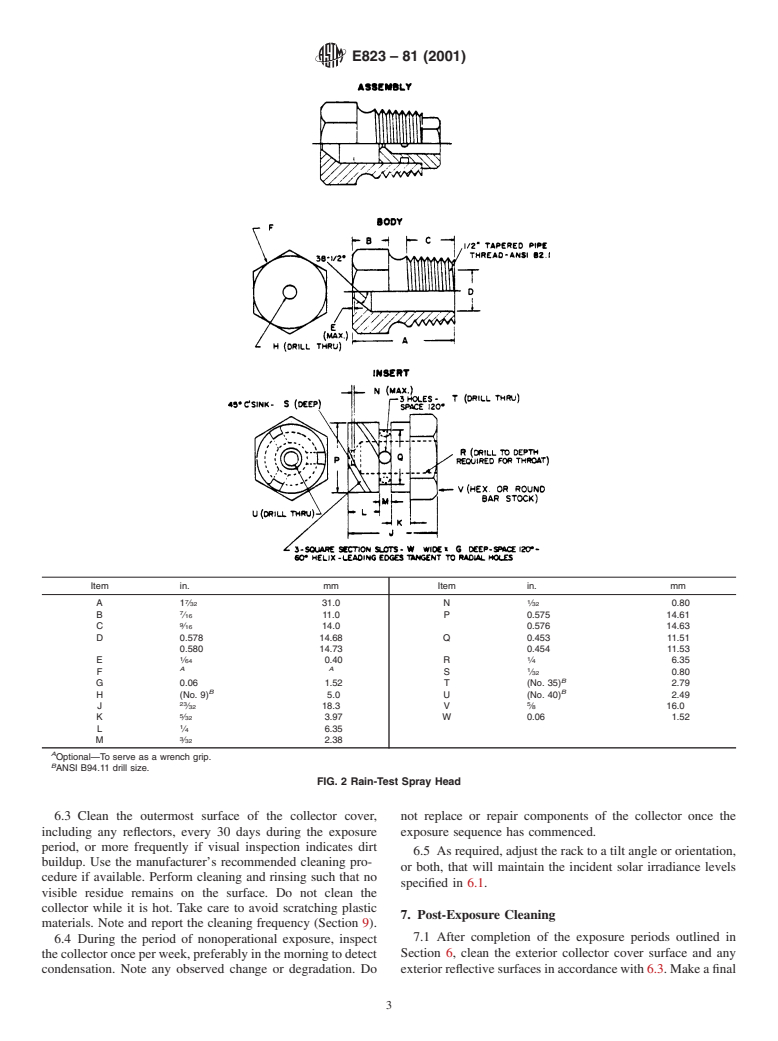

6.2.3 Apparatus—The test apparatus shall consist of three

the minimum 1-h exposure period is met, all exposure time

or more spray heads mounted in a water supply rack as shown

(including the 1-h period) above the minimum solar irradiance

in Fig. 1 and Fig. 2. Spray heads shall be constructed in

and ambient temperature requirement during the same expo-

accordance with Fig. 1 and Fig. 2. The water pressure for all

sure day may be included in the 30-h requirement of 6.1.4.

tests shall be maintained at 35 kPa (5 psi) at each spray head.

6.1.5 A minimum of 30 h accumulated radiant exposure

2 2

Thispressurewillprovideabout0.3m/h(12in./h)ofrainatthe

with a solar irradiance not less than 950 W/m (300 Btu/h·ft )

water flow of 190 L/h (50 gal/h) per nozzle. The supply water

concurrent with an ambient temperature of at least 25°C

temperature shall not exceed 30°C (86°F).

(80°F). Measure the solar irradiance in the plane of the

6.2.4 Procedure—Position the spray apparatus to direct a

collector aperture with a pyranometer. The average air velocity

downward spray from a distance of 1.0 m (3 ft) at an angle of

at the test station, measured at a height corresponding to the

45 6 5° with the collector cover plate surface, as illustrated in

mid-height of the collector, should be less than 4.5 m/s (10

Fig. 3. Direct the spray onto the cover plate surface and the top

mph). Record air velocity as part of the test data.

6.1.6 The nonoperational mode exposure is only concluded and side edges of the collector which have been exposed as

described in 6.2. Adjust the water pressure at each spray head

after the requirements of 6.1.1 and 6.1.4 have been met.

Exposure times under 6.1.1 and 6.1.4 shall be accumulated to 35 kPa (5 psi). Maintain the water spray for 15 min per test

period. Observe and record occurrence of water penetratio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.