ASTM A512-18

(Specification)Standard Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

Standard Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

ABSTRACT

This specification covers cold-drawn buttweld carbon steel tubes for use as round, square, rectangular or special shape mechanical tubing. The carbon steel can be made unless a specific type of melting process is required by the purchaser. Heat and product analysis shall be made to determine the specified percentages of chemical elements to which steel tubes shall conform to. The tubing shall be free of injurious defects and shall have a workmanlike finish. Unless otherwise specified, both outside and inside surfaces of the tubing shall be coated with a film of rust-retarding oil before shipping.

SCOPE

1.1 This specification covers cold-drawn buttweld carbon steel tubes for use as mechanical tubing.

1.2 This specification covers round, square, rectangular, and special shape mechanical tubing.

1.3 Round tube size ranges covered are outside diameters up to 3 1/2 in. (88.9 mm) and wall thickness from 0.035 to 0.500 in. (0.89 to 12.70 mm).

1.4 Optional supplementary requirements are provided and, when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This product is available in various grades (Section 6 Tables 1 and 2 and conditions (Section 5).

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A512 −18

Standard Specification for

1

Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

This standard is issued under the fixed designation A512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Compositions for Wrought Carbon, Low-Alloy, andAlloy

Steels

1.1 This specification covers cold-drawn buttweld carbon

3

2.2 Military Standards:

steel tubes for use as mechanical tubing.

MIL-STD-129 Marking for Shipment and Storage

1.2 This specification covers round, square, rectangular, and

2.3 Federal Standard:

special shape mechanical tubing.

3

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

1.3 Roundtubesizerangescoveredareoutsidediametersup

1

to3 ⁄2 in.(88.9mm)andwallthicknessfrom0.035to0.500in.

3. Ordering Information

(0.89 to 12.70 mm).

3.1 Orders for material under this specification should

1.4 Optional supplementary requirements are provided and,

include the following, as required, to describe the required

when desired, shall be so stated in the order.

material adequately:

1.5 The values stated in inch-pound units are to be regarded 3.1.1 Quantity(feet,weight(Note1),ornumberoflengths),

as standard. The values given in parentheses are mathematical

NOTE 1—The term “weight” is temporarily used in this specification

conversions to SI units that are provided for information only

because of established trade usage.The word is used to mean both “force”

and are not considered standard.

and “mass,” and care must be taken to determine which is meant in each

case (SI unit for force = newton and for mass = kilogram).

1.6 This product is available in various grades (Section 6

3.1.2 Name of material (buttweld carbon steel mechanical

Tables 1 and 2 and conditions (Section 5).

tubing),

1.7 This international standard was developed in accor-

3.1.3 Form (round, square, rectangular, special shape),

dance with internationally recognized principles on standard-

3.1.4 Condition, description and code letters (Section 5),

ization established in the Decision on Principles for the

3.1.5 Grade, if required (Section 6),

Development of International Standards, Guides and Recom-

3.1.6 Dimensions (round, Section 9 or square and

mendations issued by the World Trade Organization Technical

rectangular, Section 10),

Barriers to Trade (TBT) Committee.

3.1.7 Length (round length, 9.2; square and rectangular

length, 10.5),

2. Referenced Documents

3.1.8 Burr removal (Section 11),

2

2.1 ASTM Standards:

3.1.9 Report of chemical analysis and products analysis, if

A370 Test Methods and Definitions for Mechanical Testing

required,

of Steel Products

3.1.10 Individual supplementary requirements if required

A751 Test Methods, Practices, and Terminology for Chemi-

(S1 through S5),

cal Analysis of Steel Products

3.1.11 Special requirements,

A1040 Guide for Specifying Harmonized Standard Grade

3.1.12 End use,

3.1.13 Specification designation,

3.1.14 Special marking (Section 15), and

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, 3.1.15 Special packaging (Section 16).

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

4. Materials and Manufacture

Current edition approved Sept. 1, 2018. Published September 2018. Originally

approved in 1964. Last previous edition approved in 2017 as A512 – 17. DOI:

4.1 The steel shall be made by any process.

10.1520/A0512-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

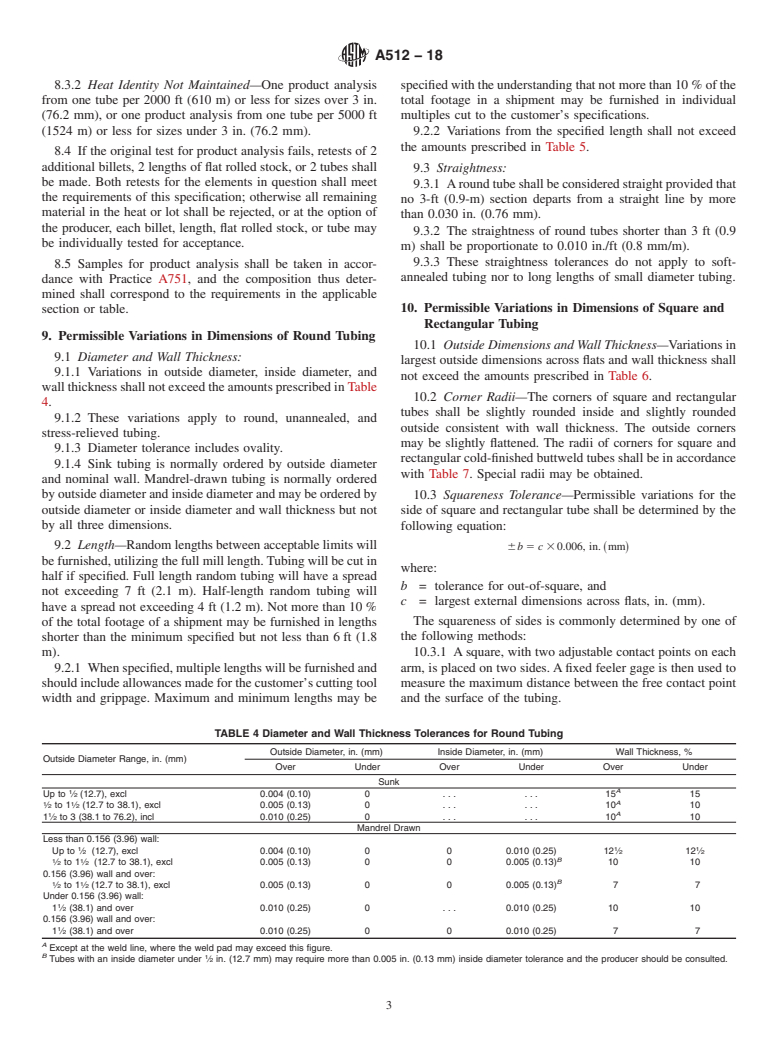

A512−18

A

TABLE 1 Chemical Requirements

SDSR—Sink Drawn and Stress Relieved

Chemical Composition Limits, %

MDSA—Mandrel Drawn and SoftAnnealed or normalized

Grade

Phospho-

SDSA—Sink Drawn and Soft Annealed or normalized

Designation

Carbon Manganese Sulfur, max

rus, max

NORM-MD-SR—Normalized, Mandrel Drawn, and Stress

MT 1010 0.05–0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A512 − 17 A512 − 18

Standard Specification for

1

Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

This standard is issued under the fixed designation A512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers cold-drawn buttweld carbon steel tubes for use as mechanical tubing.

1.2 This specification covers round, square, rectangular, and special shape mechanical tubing.

1

1.3 Round tube size ranges covered are outside diameters up to 3 ⁄2 in. (88.9 mm) and wall thickness from 0.035 to 0.500 in.

(0.89 to 12.70 mm).

1.4 Optional supplementary requirements are provided and, when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This product is available in various grades (Section 6 Tables 1 and 2 and conditions (Section 5).

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A1040 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

3

2.2 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

2.3 Federal Standard:

3

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required, to describe the required material

adequately:

3.1.1 Quantity (feet, weight (Note 1), or number of lengths),

NOTE 1—The term “weight” is temporarily used in this specification because of established trade usage. The word is used to mean both “force” and

“mass,” and care must be taken to determine which is meant in each case (SI unit for force = newton and for mass = kilogram).

3.1.2 Name of material (buttweld carbon steel mechanical tubing),

3.1.3 Form (round, square, rectangular, special shape),

3.1.4 Condition, description and code letters (Section 5),

3.1.5 Grade, if required (Section 6),

3.1.6 Dimensions (round, Section 9 or square and rectangular, Section 10),

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved Nov. 1, 2017Sept. 1, 2018. Published November 2017September 2018. Originally approved in 1964. Last previous edition approved in 20122017

as A512 – 06 (2012).A512 – 17. DOI: 10.1520/A0512-17.10.1520/A0512-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

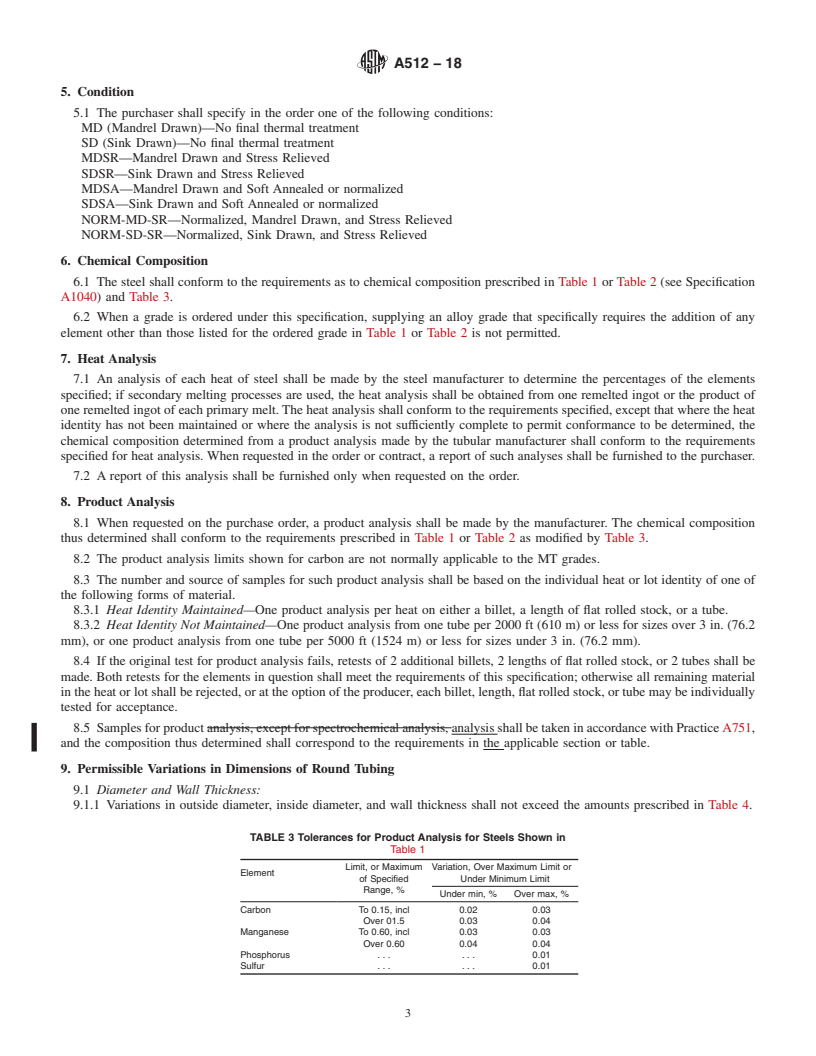

A512 − 18

A

TABLE 1 Chemical Requirements

Chemical Composition Limits, %

Grade

Phospho-

Designation

Carbon Manganese Sulfur, max

rus, max

MT 1010 0.05–0.15 0.30–0.60 0.04 0.045

MT 1015 0.10–0.20 0.30–0.60 0.04 0.045

MT X 1015 0.10–0.20 0.60–0.90 0.04 0.045

MT 1020 0.15–0.25 0.30–0.60 0.04 0.045

MT X 1020 0.15–0.25 0.70–1.00 0.04 0.045

A

Rimmed or capped steels which may be used for the above grades are

characterized by a lack of uniformity in their chemical composition, and for this

reason product analysis is not technologically appropriate unless misapplication is

clearly ind

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.