ASTM A1040-10(2015)e1

(Guide)Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

SIGNIFICANCE AND USE

4.1 It is anticipated that the ASTM Subcommittees A01.02, A01.03, A01.06, A01.09, A01.11, A01.15, A01.19, A01.22, and A01.28 will use the standard composition limits listed in this guide for the grades identified in their product specifications unless there is a specific technical justification for doing otherwise.

4.2 The composition limits given in this guide are to be used as guides in determining limits for each of the elements included in the total composition of each grade. The composition limits have been established with the intent that each ASTM subcommittee will find it necessary to require only a minimum number of changes to reflect specific technical effects. Section 5 lists the general guidelines followed for determining the limits for each element; the limits established in this guide are based upon these guidelines.

SCOPE

1.1 This guide covers ASTM Subcommittees A01.02, A01.03, A01.06, A01.09, A01.11, A01.15, A01.19, A01.22, and A01.28 for specifying chemical composition limits of wrought carbon, low-alloy, and alloy steels. It is intended that these recommended grade composition limits be suitable for adoption by other standardization bodies that prepare standards for carbon, low-alloy, and alloy steel products, including discontinued steels.

1.2 Included in this guide are the recommendations for determining the number of significant figures for specifying chemical composition.

1.3 The carbon and alloy steel grades in all standards overseen by the aforementioned ASTM subcommittees have been included, except those grades applicable to restricted special end uses.

1.4 Not addressed are minor composition modifications that a specific ASTM subcommittee may find necessary to accommodate effects of normal processing or to enhance fabricability by the producer or user, or both.

1.5 Also not generally addressed (except where established by ASTM subcommittees) is a complete rationalization of all limits, especially where such would conflict with long-standing practices and is not justified by special technical effect.

1.6 This guide does not address discontinued or formerly standard steel grades. A listing of such steel grades can be found in SAE J1249. Also excluded from this guide are cast materials and welding filler metals.

1.7 In 1995, the AISI made the decision to transfer the responsibility of maintaining its numbering system to the Society of Automotive Engineers (SAE) for carbon and alloy steels (SAE J403 and SAE J404) and to ASTM International for stainless steels (Guide A959 and others). To inform users of this important event, historical information is included in the appendix of this standard.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A1040 − 10 (Reapproved 2015)

Standard Guide for

Specifying Harmonized Standard Grade Compositions for

Wrought Carbon, Low-Alloy, and Alloy Steels

This standard is issued under the fixed designation A1040; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in 1.8 editorially in September 2015.

1. Scope* forstainlesssteels(GuideA959andothers).Toinformusersof

this important event, historical information is included in the

1.1 This guide covers ASTM Subcommittees A01.02,

appendix of this standard.

A01.03,A01.06,A01.09,A01.11,A01.15,A01.19,A01.22,and

A01.28 for specifying chemical composition limits of wrought 1.8 The values stated in inch-pound units are to be regarded

carbon, low-alloy, and alloy steels. It is intended that these as standard. The values given in parentheses are mathematical

recommended grade composition limits be suitable for adop- conversions to SI units that are provided for information only

tion by other standardization bodies that prepare standards for and are not considered standard.

carbon, low-alloy, and alloy steel products, including discon-

2. Referenced Documents

tinued steels.

1.2 Included in this guide are the recommendations for 2.1 ASTM Standards:

A276/A276M Specification for Stainless Steel Bars and

determining the number of significant figures for specifying

Shapes

chemical composition.

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

1.3 The carbon and alloy steel grades in all standards

Alloys, and Ferroalloys

overseen by the aforementioned ASTM subcommittees have

A959 Guide for Specifying Harmonized Standard Grade

been included, except those grades applicable to restricted

Compositions for Wrought Stainless Steels

special end uses.

2.2 SAE Standards:

1.4 Not addressed are minor composition modifications that

SAE J403 Chemical Compositions of SAE Carbon Steels

a specific ASTM subcommittee may find necessary to accom-

SAE J404 Chemical Compositions of SAE Alloy Steels

modate effects of normal processing or to enhance fabricability

SAE J1013 Measurement of Whole Body Vibration of the

by the producer or user, or both.

Seated Operator of Off-Highway Work Machines

1.5 Also not generally addressed (except where established

SAE J1249 Former SAE Standard and Former SAE EX-

by ASTM subcommittees) is a complete rationalization of all

Steels

limits,especiallywheresuchwouldconflictwithlong-standing

practices and is not justified by special technical effect.

3. Terminology

1.6 This guide does not address discontinued or formerly

3.1 Definitions of Terms Specific to This Standard:

standard steel grades. A listing of such steel grades can be

3.1.1 long product, n—generic term describing wrought

found in SAE J1249. Also excluded from this guide are cast

bars, rod, wire, rail, tubing (welded and seamless), plate, and

materials and welding filler metals.

pipe.

3.1.1.1 Discussion—Product forms such as “C” shapes,

1.7 In 1995, the AISI made the decision to transfer the

“HP” shapes, “L” shapes, “M” shapes, “MC” shapes, “S”

responsibility of maintaining its numbering system to the

shapes, “W” shapes, and sheet piling are considered long

Society of Automotive Engineers (SAE) for carbon and alloy

products. Such product forms are produced to mechanical

steels (SAE J403 and SAE J404) and to ASTM International

1 2

This guide is under the jurisdiction of ASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.15 on Bars. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2015. Published September 2015. Originally the ASTM website.

approved in 2004. Last previous edition approved in 2010 as A1040-10. DOI: Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

10.1520/A1040-10R15E01. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A1040 − 10 (2015)

properties and are not normally produced to the chemical effects. Section 5 lists the general guidelines followed for

compositions listed in this guide. determining the limits for each element; the limits established

in this guide are based upon these guidelines.

3.1.2 flat product, n—generic term describing wrought sheet

and strip.

5. General Guidelines Used for Determining Composition

3.2 Refer to Terminology A941 for additional definitions of

Limits

terms used in this guide.

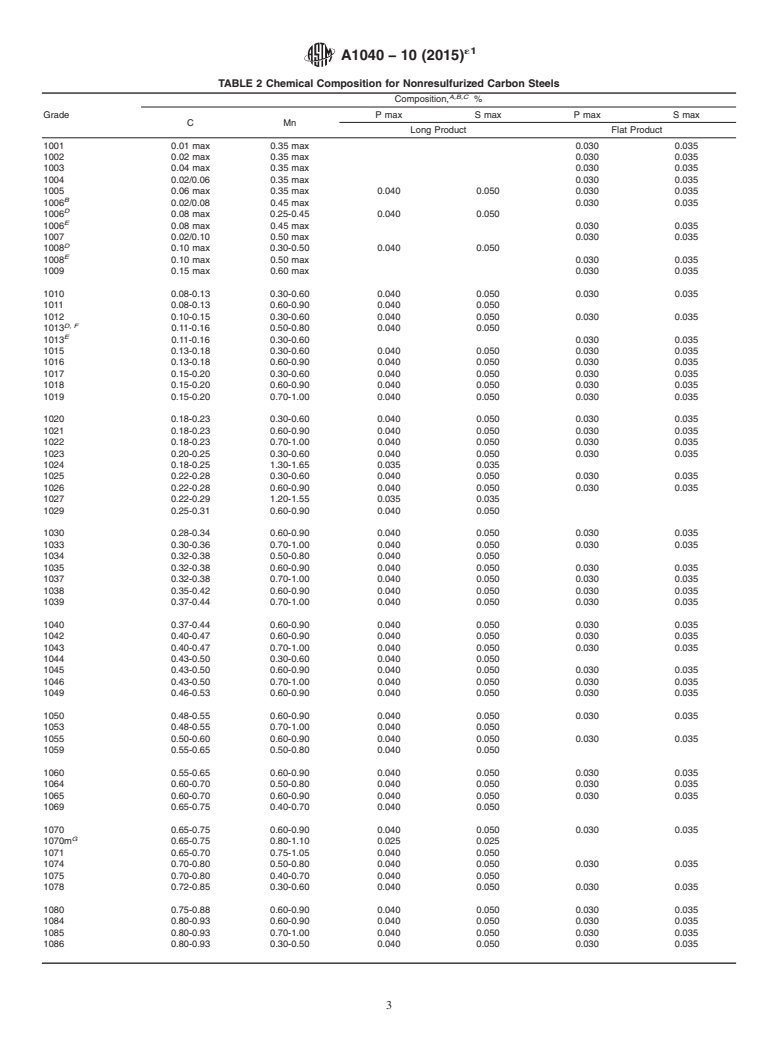

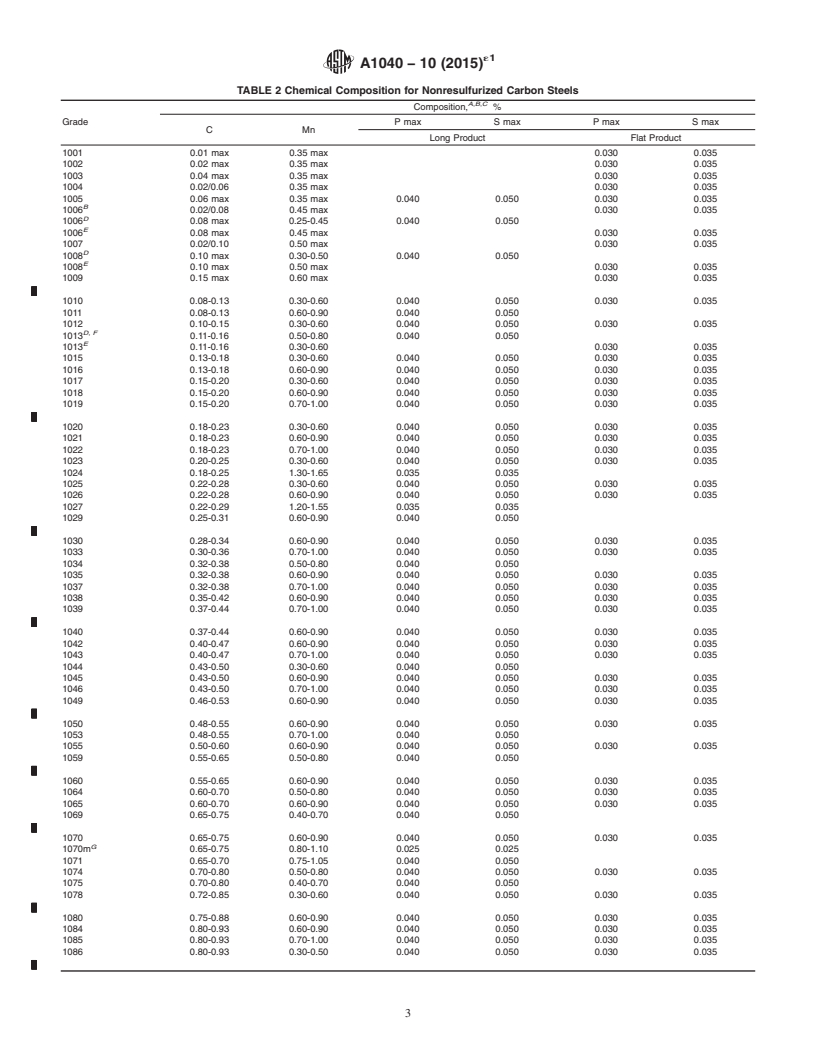

5.1 Table 1 gives typical chemical composition limits for

respective elements.

4. Significance and Use

4.1 It is anticipated that the ASTM Subcommittees A01.02,

6. Harmonized Standard Grade Wrought Carbon, Low-

A01.03,A01.06,A01.09,A01.11,A01.15,A01.19,A01.22,and Alloy, and Alloy Steel Compositions

A01.28 will use the standard composition limits listed in this

6.1 The harmonized composition limits are given in Tables

guide for the grades identified in their product specifications

2-17, grouped by metallurgical classification. Within all tables,

unless there is a specific technical justification for doing

grades are listed in numerical order.

otherwise.

6.2 Unless adopted by the appropriate product subcommit-

4.2 Thecompositionlimitsgiveninthisguidearetobeused

tee in an ASTM standard, the compositions described in this

as guides in determining limits for each of the elements

guide shall not be used for specifying an ASTM product.

included in the total composition of each grade. The compo-

6.3 Criteria for the addition of grades to the grade lists in

sition limits have been established with the intent that each

this guide are as follows: (1) New grades will be considered

ASTM subcommittee will find it necessary to require only a

based upon the grade meeting a standard grade designation and

minimum number of changes to reflect specific technical

chemistry; (2) New grades shall have an annual production or

consumption of 250 tons (225 Mg); (3) New grades shall have

TABLE 1 Expression of Chemical Composition Limits

the sponsorship of at least two individual users or producers.

Chemical Element Chemical Composition Limit

7. Keywords

C, Cr, Cu, Mn, Mo, Ni, Pb, Si Two decimal places (0.xx % ) or (1.xx %)

Al, Ca, N, Nb (Cb), P, S, Sn, Ti, V Three decimal places (0.xxx %)

7.1 alloy steels; carbon steels; harmonized carbon, low-

B Four decimal places (0.xxxx %)

alloy, and alloy steel compositions; low-alloy steels

´1

A1040 − 10 (2015)

TABLE 2 Chemical Composition for Nonresulfurized Carbon Steels

A,B,C

Composition, %

Grade P max S max P max S max

CMn

Long Product Flat Product

1001 0.01 max 0.35 max 0.030 0.035

1002 0.02 max 0.35 max 0.030 0.035

1003 0.04 max 0.35 max 0.030 0.035

1004 0.02/0.06 0.35 max 0.030 0.035

1005 0.06 max 0.35 max 0.040 0.050 0.030 0.035

B

1006 0.02/0.08 0.45 max 0.030 0.035

D

1006 0.08 max 0.25-0.45 0.040 0.050

E

1006 0.08 max 0.45 max 0.030 0.035

1007 0.02/0.10 0.50 max 0.030 0.035

D

1008 0.10 max 0.30-0.50 0.040 0.050

E

1008 0.10 max 0.50 max 0.030 0.035

1009 0.15 max 0.60 max 0.030 0.035

1010 0.08-0.13 0.30-0.60 0.040 0.050 0.030 0.035

1011 0.08-0.13 0.60-0.90 0.040 0.050

1012 0.10-0.15 0.30-0.60 0.040 0.050 0.030 0.035

D, F

1013 0.11-0.16 0.50-0.80 0.040 0.050

E

1013 0.11-0.16 0.30-0.60 0.030 0.035

1015 0.13-0.18 0.30-0.60 0.040 0.050 0.030 0.035

1016 0.13-0.18 0.60-0.90 0.040 0.050 0.030 0.035

1017 0.15-0.20 0.30-0.60 0.040 0.050 0.030 0.035

1018 0.15-0.20 0.60-0.90 0.040 0.050 0.030 0.035

1019 0.15-0.20 0.70-1.00 0.040 0.050 0.030 0.035

1020 0.18-0.23 0.30-0.60 0.040 0.050 0.030 0.035

1021 0.18-0.23 0.60-0.90 0.040 0.050 0.030 0.035

1022 0.18-0.23 0.70-1.00 0.040 0.050 0.030 0.035

1023 0.20-0.25 0.30-0.60 0.040 0.050 0.030 0.035

1024 0.18-0.25 1.30-1.65 0.035 0.035

1025 0.22-0.28 0.30-0.60 0.040 0.050 0.030 0.035

1026 0.22-0.28 0.60-0.90 0.040 0.050 0.030 0.035

1027 0.22-0.29 1.20-1.55 0.035 0.035

1029 0.25-0.31 0.60-0.90 0.040 0.050

1030 0.28-0.34 0.60-0.90 0.040 0.050 0.030 0.035

1033 0.30-0.36 0.70-1.00 0.040 0.050 0.030 0.035

1034 0.32-0.38 0.50-0.80 0.040 0.050

1035 0.32-0.38 0.60-0.90 0.040 0.050 0.030 0.035

1037 0.32-0.38 0.70-1.00 0.040 0.050 0.030 0.035

1038 0.35-0.42 0.60-0.90 0.040 0.050 0.030 0.035

1039 0.37-0.44 0.70-1.00 0.040 0.050 0.030 0.035

1040 0.37-0.44 0.60-0.90 0.040 0.050 0.030 0.035

1042 0.40-0.47 0.60-0.90 0.040 0.050 0.030 0.035

1043 0.40-0.47 0.70-1.00 0.040 0.050 0.030 0.035

1044 0.43-0.50 0.30-0.60 0.040 0.050

1045 0.43-0.50 0.60-0.90 0.040 0.050 0.030 0.035

1046 0.43-0.50 0.70-1.00 0.040 0.050 0.030 0.035

1049 0.46-0.53 0.60-0.90 0.040 0.050 0.030 0.035

1050 0.48-0.55 0.60-0.90 0.040 0.050 0.030 0.035

1053 0.48-0.55 0.70-1.00 0.040 0.050

1055 0.50-0.60 0.60-0.90 0.040 0.050 0.030 0.035

1059 0.55-0.65 0.50-0.80 0.040 0.050

1060 0.55-0.65 0.60-0.90 0.040 0.050 0.030 0.035

1064 0.60-0.70 0.50-0.80 0.040 0.050 0.030 0.035

1065 0.60-0.70 0.60-0.90 0.040 0.050 0.030 0.035

1069 0.65-0.75 0.40-0.70 0.040 0.050

1070 0.65-0.75 0.60-0.90 0.040 0.050 0.030 0.035

G

1070m 0.65-0.75 0.80-1.10 0.025 0.025

1071 0.65-0.70 0.75-1.05 0.040 0.050

1074 0.70-0.80 0.50-0.80 0.040 0.050 0.030 0.035

1075 0.70-0.80 0.40-0.70 0.040 0.050

1078 0.72-0.85 0.30-0.60 0.040 0.050 0.030 0.035

1080 0.75-0.88 0.60-0.90 0.040 0.050 0.030 0.035

1084 0.80-0.93 0.60-0.90 0.040 0.050 0.030 0.035

1085 0.80-0.93 0.70-1.00 0.040 0.050 0.030 0.035

1086 0.80-0.93 0.30-0.50 0.040 0.050 0.030 0.035

´1

A1040 − 10 (2015)

TABLE 2 Continued

A,B,C

Composition, %

Grade P max S max P max S max

CMn

Long Product Flat Product

1090 0.85-0.98 0.60-0.90 0.040 0.050 0.030 0.035

1095 0.90-1.03 0.30-0.50 0.040 0.050 0.030 0.035

A

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.15 % to 0.40 %, 0.20 % to

0.40 %, or 0.30 % to 0.60 %.

B

If required, copper can be specified as 0.20 % minimum.

C

Where boron treatment for killed steel is specified for enhanced hardenability, titanium is generally added to shield the boron from oxidation. Boron levels between

0.0005 % and 0.0030 % can be expected for this practice. If the usual titanium addition is not permitted, the steel may contain up to 0.0050 % boron for enhanced

hardenability.

D

Long product.

E

Flat product.

F

SAE J1013 has chemical limits for manganese of 0.30-0.60 %.

G

1070m has chemical limits for silicon, 0.15-0.35 %; chromium, 0.20 % maximum; nickel, 0.25 % maximum; and molybdenum, 0.10 % maximum.

TABLE 3 Chemical Composition for Resulfurized Steels

A,B

Composition, %

Grade

C Mn P max S max

1108 0.08-0.13 0.60-0.80 0.040 0.08-0.13

1109 0.08-0.13 0.60-0.90 0.040 0.08-0.13

1110 0.08-0.13 0.30-0.60 0.040 0.08-0.13

1115 0.13-0.20 0.60-0.90 0.040 0.08-0.13

1116 0.14-0.20 1.10-1.40 0.040 0.16-0.23

1117 0.14-0.20 1.00-1.30 0.040 0.08-0.13

1118 0.14-0.20 1.30-1.60 0.040 0.08-0.13

1119 0.14-0.20 1.00-1.30 0.040 0.24-0.33

1132 0.27-0.32 1.35-1.65 0.040 0.08-0.13

1137 0.32-0.39 1.35-1.65 0.040 0.08-0.13

1139 0.35-0.43 1.35-1.65 0.040 0.13-0.20

1140 0.37-0.44 0.70-1.00 0.040 0.08-0.13

1141 0.37-0.45 1.35-1.65 0.040 0.08-0.13

1144 0.40-0.48 1.35-1.65 0.040 0.24-0.33

1145 0.42-0.49 0.70-1.00 0.040 0.04-0.07

1146 0.42-0.49 0.70-1.00 0.040 0.08-0.13

1151 0.48-0.55 0.70-1.00 0.040 0.08-0.13

A

It is not common practice to produce these steels to specified limits for silicon because of its adverse effect on machinability.

B

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30%

to 0.60 %.

TABLE 4 Chemical Composition for Rephosphorized and Resulfurized Carbon Steels

A,B

Composition, %

Grade

CMn P S

1211 0.13 max 0.60-0.90 0.07-0.12 0.10-0.15

1212 0.13 max 0.70-1.00 0.07-0.12 0.16-0.23

1213 0.13 max 0.70-1.00 0.07-0.12 0.24-0.33

1215 0.09 max 0.75-1.05 0.04-0.09 0.26-0.35

A

It is not common practice to produce these steels to specified limits for silicon because of its adverse effect on machinability.

B

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30%

to 0.60 %.

´1

A1040 − 10 (2015)

TABLE 5 Chemical Composition for High-Manganese Carbon Steels

A,B,C

Composition, %

Grade P max S max P max S max

CMn

Long Product Flat Product

1513 0.10-0.16 1.10-1.40 0.040 0.050

1518 0.15-0.21 1.10-1.40 0.040 0.050

1522 0.18-0.24 1.10-1.40 0.040 0.050

1524 0.19-0.25 1.35-1.65 0.040 0.050 0.030 0.035

1525 0.23-0.29 0.80-1.10 0.040 0.050

1526 0.22-0.29 1.10-1.40 0.040 0.050

1527 0.22-0.29 1.20-1.50 0.040 0.050 0.030 0.035

1536 0.30-0.37 1.20-1.50 0.040 0.050 0.030 0.035

1541 0.36-0.44 1.35-1.65 0.040 0.050 0.030 0.035

1547 0.43-0.51 1.35-1.65 0.040 0.050

1548 0.44-0.52 1.10-1.40 0.040 0.050 0.030 0.035

1551 0.45-0.56 0.85-1.15 0.040 0.050

1552 0.47-0.55 1.20-1.50 0.040 0.050 0.030 0.035

1561 0.55-0.65 0.75-1.05 0.040 0.050

1566 0.60-0.71 0.85-1.15 0.040 0.050

1572 0.65-0.76 1.00-1.30 0.040 0.050

A

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30%

to 0.60 %.

B

If required, copper can be specified as 0.20 % minimum.

C

If lead is required as an added element to a standard steel, a range of 0.15 % to 0.35 % inclusive is specified. Such a steel is identified by inserting the letter “L” between

the second and third numerals of the grade designation, for example, 15L25. A heat analysis is not determinable where lead is added to the ladle stream.

TABLE 6 Chemical Composition for Carbon Steels with Hardenability Requirements

Composition, %

Grade

C Mn P max S max Si

1038H 0.34-0.43 0.50-1.00 0.040 0.050 0.15-0.30

1045H 0.42-0.51 0.50-1.00 0.040 0.050 0.15-0.30

1522H 0.17-0.25 1.00-1.50 0.040 0.050 0.15-0.30

1524H 0.18-0.26 1.25-1.75 0.040 0.050 0.15-0.30

1526H 0.21-0.30 1.00-1.50 0.040 0.050 0.15-0.30

1541H 0.35-0.45 1.25-1.75 0.040 0.050 0.15-0.30

1552H 0.47-0.55 1.00-1.50 0.040 0.050 0.15-0.30

TABLE 7 Chemical Composition for Standard High-Manganese Boron Carbon Steels with Hardenability Requirements

A

Composition, %

Grade

CMn P S Si

15B21H 0.17-0.24 0.70-1.20 0.040 0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1040 − 10 A1040 − 10 (Reapproved 2015)

Standard Guide for

Specifying Harmonized Standard Grade Compositions for

Wrought Carbon, Low-Alloy, and Alloy Steels

This standard is issued under the fixed designation A1040; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in 1.8 editorially in September 2015.

1. Scope*

1.1 This guide covers ASTM Subcommittees A01.02, A01.03, A01.06, A01.09, A01.11, A01.15, A01.19, A01.22, and A01.28

for specifying chemical composition limits of wrought carbon, low-alloy, and alloy steels. It is intended that these recommended

grade composition limits be suitable for adoption by other standardization bodies that prepare standards for carbon, low-alloy, and

alloy steel products, including discontinued steels.

1.2 Included in this guide are the recommendations for determining the number of significant figures for specifying chemical

composition.

1.3 The carbon and alloy steel grades in all standards overseen by the aforementioned ASTM subcommittees have been

included, except those grades applicable to restricted special end uses.

1.4 Not addressed are minor composition modifications that a specific ASTM subcommittee may find necessary to

accommodate effects of normal processing or to enhance fabricability by the producer or user, or both.

1.5 Also not generally addressed (except where established by ASTM subcommittees) is a complete rationalization of all limits,

especially where such would conflict with long-standing practices and is not justified by special technical effect.

1.6 This guide does not address discontinued or formerly standard steel grades. A listing of such steel grades can be found in

SAE J1249. Also excluded from this guide are cast materials and welding filler metals.

1.7 In 1995, the AISI made the decision to transfer the responsibility of maintaining its numbering system to the Society of

Automotive Engineers (SAE) for carbon and alloy steels (SAE J403 and SAE J404) and to ASTM International for stainless steels

(Guide A959 and others). To inform users of this important event, historical information is included in the appendix of this

standard.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A276A276/A276M Specification for Stainless Steel Bars and Shapes

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A959 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Stainless Steels

2.2 SAE Standards:

SAE J403 Chemical Compositions of SAE Carbon Steels

SAE J404 Chemical Compositions of SAE Alloy Steels

SAE J1013 Measurement of Whole Body Vibration of the Seated Operator of Off-Highway Work Machines

SAE J1249 Former SAE Standard and Former SAE EX-Steels

This guide is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.15 on

Bars.

Current edition approved April 1, 2010Sept. 1, 2015. Published April 2010September 2015. Originally approved in 2004. Last previous edition approved in 20092010 as

A1040 – 09.A1040-10. DOI: 10.1520/A1040-10.10.1520/A1040-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Society of Automotive Engineers SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A1040 − 10 (2015)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 long product, n—generic term describing wrought bars, rod, wire, rail, tubing (welded and seamless), plate, and pipe.

3.1.1.1 Discussion—

Product forms such as “C” shapes, “HP” shapes, “L” shapes, “M” shapes, “MC” shapes, “S” shapes, “W” shapes, and sheet piling

are considered long products. Such product forms are produced to mechanical properties and are not normally produced to the

chemical compositions listed in this guide.

3.1.2 flat product, n—generic term describing wrought sheet and strip.

3.2 Refer to Terminology A941 for additional definitions of terms used in this guide.

4. Significance and Use

4.1 It is anticipated that the ASTM Subcommittees A01.02, A01.03, A01.06, A01.09, A01.11, A01.15, A01.19, A01.22, and

A01.28 will use the standard composition limits listed in this guide for the grades identified in their product specifications unless

there is a specific technical justification for doing otherwise.

4.2 The composition limits given in this guide are to be used as guides in determining limits for each of the elements included

in the total composition of each grade. The composition limits have been established with the intent that each ASTM subcommittee

will find it necessary to require only a minimum number of changes to reflect specific technical effects. Section 5 lists the general

guidelines followed for determining the limits for each element; the limits established in this guide are based upon these guidelines.

5. General Guidelines Used for Determining Composition Limits

5.1 Table 1 gives typical chemical composition limits for respective elements.

6. Harmonized Standard Grade Wrought Carbon, Low-Alloy, and Alloy Steel Compositions

6.1 The harmonized composition limits are given in Tables 2-17, grouped by metallurgical classification. Within all tables,

grades are listed in numerical order.

6.2 Unless adopted by the appropriate product subcommittee in an ASTM standard, the compositions described in this guide

shall not be used for specifying an ASTM product.

6.3 Criteria for the addition of grades to the grade lists in this guide are as follows: (1) New grades will be considered based

upon the grade meeting a standard grade designation and chemistry; (2) New grades shall have an annual production or

consumption of 250 tons (225 Mg); (3) New grades shall have the sponsorship of at least two individual users or producers.

7. Keywords

7.1 alloy steels; carbon steels; harmonized carbon, low-alloy, and alloy steel compositions; low-alloy steels

TABLE 1 Expression of Chemical Composition Limits

Chemical Element Chemical Composition Limit

C, Cr, Cu, Mn, Mo, Ni, Pb, Si Two decimal places (0.xx % ) or (1.xx %)

Al, Ca, N, Nb (Cb), P, S, Sn, Ti, V Three decimal places (0.xxx %)

B Four decimal places (0.xxxx %)

´1

A1040 − 10 (2015)

TABLE 2 Chemical Composition for Nonresulfurized Carbon Steels

A,B,C

Composition, %

Grade P max S max P max S max

C Mn

Long Product Flat Product

1001 0.01 max 0.35 max 0.030 0.035

1002 0.02 max 0.35 max 0.030 0.035

1003 0.04 max 0.35 max 0.030 0.035

1004 0.02/0.06 0.35 max 0.030 0.035

1005 0.06 max 0.35 max 0.040 0.050 0.030 0.035

B

1006 0.02/0.08 0.45 max 0.030 0.035

D

1006 0.08 max 0.25-0.45 0.040 0.050

E

1006 0.08 max 0.45 max 0.030 0.035

1007 0.02/0.10 0.50 max 0.030 0.035

D

1008 0.10 max 0.30-0.50 0.040 0.050

E

1008 0.10 max 0.50 max 0.030 0.035

1009 0.15 max 0.60 max 0.030 0.035

1010 0.08-0.13 0.30-0.60 0.040 0.050 0.030 0.035

1011 0.08-0.13 0.60-0.90 0.040 0.050

1012 0.10-0.15 0.30-0.60 0.040 0.050 0.030 0.035

D, F

1013 0.11-0.16 0.50-0.80 0.040 0.050

E

1013 0.11-0.16 0.30-0.60 0.030 0.035

1015 0.13-0.18 0.30-0.60 0.040 0.050 0.030 0.035

1016 0.13-0.18 0.60-0.90 0.040 0.050 0.030 0.035

1017 0.15-0.20 0.30-0.60 0.040 0.050 0.030 0.035

1018 0.15-0.20 0.60-0.90 0.040 0.050 0.030 0.035

1019 0.15-0.20 0.70-1.00 0.040 0.050 0.030 0.035

1020 0.18-0.23 0.30-0.60 0.040 0.050 0.030 0.035

1021 0.18-0.23 0.60-0.90 0.040 0.050 0.030 0.035

1022 0.18-0.23 0.70-1.00 0.040 0.050 0.030 0.035

1023 0.20-0.25 0.30-0.60 0.040 0.050 0.030 0.035

1024 0.18-0.25 1.30-1.65 0.035 0.035

1025 0.22-0.28 0.30-0.60 0.040 0.050 0.030 0.035

1026 0.22-0.28 0.60-0.90 0.040 0.050 0.030 0.035

1027 0.22-0.29 1.20-1.55 0.035 0.035

1029 0.25-0.31 0.60-0.90 0.040 0.050

1030 0.28-0.34 0.60-0.90 0.040 0.050 0.030 0.035

1033 0.30-0.36 0.70-1.00 0.040 0.050 0.030 0.035

1034 0.32-0.38 0.50-0.80 0.040 0.050

1035 0.32-0.38 0.60-0.90 0.040 0.050 0.030 0.035

1037 0.32-0.38 0.70-1.00 0.040 0.050 0.030 0.035

1038 0.35-0.42 0.60-0.90 0.040 0.050 0.030 0.035

1039 0.37-0.44 0.70-1.00 0.040 0.050 0.030 0.035

1040 0.37-0.44 0.60-0.90 0.040 0.050 0.030 0.035

1042 0.40-0.47 0.60-0.90 0.040 0.050 0.030 0.035

1043 0.40-0.47 0.70-1.00 0.040 0.050 0.030 0.035

1044 0.43-0.50 0.30-0.60 0.040 0.050

1045 0.43-0.50 0.60-0.90 0.040 0.050 0.030 0.035

1046 0.43-0.50 0.70-1.00 0.040 0.050 0.030 0.035

1049 0.46-0.53 0.60-0.90 0.040 0.050 0.030 0.035

1050 0.48-0.55 0.60-0.90 0.040 0.050 0.030 0.035

1053 0.48-0.55 0.70-1.00 0.040 0.050

1055 0.50-0.60 0.60-0.90 0.040 0.050 0.030 0.035

1059 0.55-0.65 0.50-0.80 0.040 0.050

1060 0.55-0.65 0.60-0.90 0.040 0.050 0.030 0.035

1064 0.60-0.70 0.50-0.80 0.040 0.050 0.030 0.035

1065 0.60-0.70 0.60-0.90 0.040 0.050 0.030 0.035

1069 0.65-0.75 0.40-0.70 0.040 0.050

1070 0.65-0.75 0.60-0.90 0.040 0.050 0.030 0.035

G

1070m 0.65-0.75 0.80-1.10 0.025 0.025

1071 0.65-0.70 0.75-1.05 0.040 0.050

1074 0.70-0.80 0.50-0.80 0.040 0.050 0.030 0.035

1075 0.70-0.80 0.40-0.70 0.040 0.050

1078 0.72-0.85 0.30-0.60 0.040 0.050 0.030 0.035

1080 0.75-0.88 0.60-0.90 0.040 0.050 0.030 0.035

1084 0.80-0.93 0.60-0.90 0.040 0.050 0.030 0.035

1085 0.80-0.93 0.70-1.00 0.040 0.050 0.030 0.035

1086 0.80-0.93 0.30-0.50 0.040 0.050 0.030 0.035

´1

A1040 − 10 (2015)

TABLE 2 Continued

A,B,C

Composition, %

Grade P max S max P max S max

C Mn

Long Product Flat Product

1090 0.85-0.98 0.60-0.90 0.040 0.050 0.030 0.035

1095 0.90-1.03 0.30-0.50 0.040 0.050 0.030 0.035

A

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.15 % to 0.40 %, 0.20 % to

0.40 %, or 0.30 % to 0.60 %.

B

If required, copper can be specified as 0.20 % minimum.

C

Where boron treatment for killed steel is specified for enhanced hardenability, titanium is generally added to shield the boron from oxidation. Boron levels between

0.0005 % and 0.0030 % can be expected for this practice. If the usual titanium addition is not permitted, the steel may contain up to 0.0050 % boron for enhanced

hardenability.

D

Long product.

E

Flat product.

F

SAE J1013 has chemical limits for manganese of 0.30-0.60 %.

G

1070m has chemical limits for silicon, 0.15-0.35 %; chromium, 0.20 % maximum; nickel, 0.25 % maximum; and molybdenum, 0.10 % maximum.

TABLE 3 Chemical Composition for Resulfurized Steels

A,B

Composition, %

Grade

C Mn P max S max

1108 0.08-0.13 0.60-0.80 0.040 0.08-0.13

1109 0.08-0.13 0.60-0.90 0.040 0.08-0.13

1110 0.08-0.13 0.30-0.60 0.040 0.08-0.13

1115 0.13-0.20 0.60-0.90 0.040 0.08-0.13

1116 0.14-0.20 1.10-1.40 0.040 0.16-0.23

1117 0.14-0.20 1.00-1.30 0.040 0.08-0.13

1118 0.14-0.20 1.30-1.60 0.040 0.08-0.13

1119 0.14-0.20 1.00-1.30 0.040 0.24-0.33

1132 0.27-0.32 1.35-1.65 0.040 0.08-0.13

1137 0.32-0.39 1.35-1.65 0.040 0.08-0.13

1139 0.35-0.43 1.35-1.65 0.040 0.13-0.20

1140 0.37-0.44 0.70-1.00 0.040 0.08-0.13

1141 0.37-0.45 1.35-1.65 0.040 0.08-0.13

1144 0.40-0.48 1.35-1.65 0.040 0.24-0.33

1145 0.42-0.49 0.70-1.00 0.040 0.04-0.07

1146 0.42-0.49 0.70-1.00 0.040 0.08-0.13

1151 0.48-0.55 0.70-1.00 0.040 0.08-0.13

A

It is not common practice to produce these steels to specified limits for silicon because of its adverse effect on machinability.

B

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30 %

to 0.60 %.

TABLE 4 Chemical Composition for Rephosphorized and Resulfurized Carbon Steels

A,B

Composition, %

Grade

C Mn P S

1211 0.13 max 0.60-0.90 0.07-0.12 0.10-0.15

1212 0.13 max 0.70-1.00 0.07-0.12 0.16-0.23

1213 0.13 max 0.70-1.00 0.07-0.12 0.24-0.33

1215 0.09 max 0.75-1.05 0.04-0.09 0.26-0.35

A

It is not common practice to produce these steels to specified limits for silicon because of its adverse effect on machinability.

B

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30 %

to 0.60 %.

´1

A1040 − 10 (2015)

TABLE 5 Chemical Composition for High-Manganese Carbon Steels

A,B,C

Composition, %

Grade P max S max P max S max

C Mn

Long Product Flat Product

1513 0.10-0.16 1.10-1.40 0.040 0.050

1518 0.15-0.21 1.10-1.40 0.040 0.050

1522 0.18-0.24 1.10-1.40 0.040 0.050

1524 0.19-0.25 1.35-1.65 0.040 0.050 0.030 0.035

1525 0.23-0.29 0.80-1.10 0.040 0.050

1526 0.22-0.29 1.10-1.40 0.040 0.050

1527 0.22-0.29 1.20-1.50 0.040 0.050 0.030 0.035

1536 0.30-0.37 1.20-1.50 0.040 0.050 0.030 0.035

1541 0.36-0.44 1.35-1.65 0.040 0.050 0.030 0.035

1547 0.43-0.51 1.35-1.65 0.040 0.050

1548 0.44-0.52 1.10-1.40 0.040 0.050 0.030 0.035

1551 0.45-0.56 0.85-1.15 0.040 0.050

1552 0.47-0.55 1.20-1.50 0.040 0.050 0.030 0.035

1561 0.55-0.65 0.75-1.05 0.040 0.050

1566 0.60-0.71 0.85-1.15 0.040 0.050

1572 0.65-0.76 1.00-1.30 0.040 0.050

A

Where silicon is required, the following ranges and limits are commonly specified: 0.10 % maximum, 0.10 % to 0.20 %, 0.15 % to 0.35 %, 0.20 % to 0.40 %, or 0.30 %

to 0.60 %.

B

If required, copper can be specified as 0.20 % minimum.

C

If lead is required as an added element to a standard steel, a range of 0.15 % to 0.35 % inclusive is specified. Such a steel is identified by inserting the letter “L” between

the second and third numerals of the grade designation, for example, 15L25. A heat analysis is not determinable where lead is added to the ladle stream.

TABLE 6 Chemical Composition for Carbon Steels with Hardenability Requirements

Composition, %

Grade

C Mn P max S max Si

1038H 0.34-0.43 0.50-1.00 0.040 0.050 0.15-0.30

1045H 0.42-0.51 0.50-1.00 0.04

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.