ASTM D1263-94(2005)e1

(Test Method)Standard Test Method for Leakage Tendencies of Automotive Wheel Bearing Greases (Withdrawn 2010)

Standard Test Method for Leakage Tendencies of Automotive Wheel Bearing Greases (Withdrawn 2010)

SIGNIFICANCE AND USE

The test method provides a screening device that permits differentiation among products having distinctly different leakage characteristics (Note 1). It is not the equivalent of longtime service tests, nor is it intended to distinguish between wheel bearing greases showing similar or borderline leakage.

Note 1—It is possible for skilled operators to observe significant changes in other important grease characteristics that occurred during the test. Such additional information can be of special interest to individual operators. The observations, however, are subject to differences in personal judgment among operators, and cannot be used effectively for quantitative rating.

SCOPE

1.1 This test method covers the evaluation of the leakage tendencies of wheel bearing greases when tested under prescribed laboratory conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard information see 8 and Annex A2.

WITHDRAWN RATIONALE

This test method covers the evaluation of the leakage tendencies of wheel bearing greases when tested under prescribed laboratory conditions.

This test method is being balloted for withdrawal with no replacement because it is not actively supported within Subcommittee D02.G0 (it has only been reapproved with editorial changes since 1994). Subcommittee D02.G0 also considers that this Test Method D1263 was superseded by Test Method D4290 on Leakage Tendencies of Automotive Wheel Bearing Greases Under Accelerated Conditions.

Formally under the jurisdiction of Committee D02 on Petroleum Products and Lubricants, this test method was withdrawn in May 2010.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:D1263–94 (Reapproved 2005)

Standard Test Method for

Leakage Tendencies of Automotive Wheel Bearing Greases

This standard is issued under the fixed designation D1263; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Warning notes were editorially moved into text in May 2005.

1. Scope 3. Terminology

1.1 This test method covers the evaluation of the leakage 3.1 Definitions:

tendencies of wheel bearing greases when tested under pre- 3.1.1 lubricating grease, n—asemi-fluidtosolidproductof

scribed laboratory conditions. a dispersion of a thickener in a liquid lubricant.

1.2 The values stated in SI units are to be regarded as the 3.1.1.1 Discussion—Thedispersionofthethickenerformsa

standard. The values given in parentheses are for information two-phase system and immobilizes the liquid lubricant by

only. surfacetensionandotherphysicalforces.Otheringredientsare

1.3 This standard does not purport to address all of the commonly included to impart special properties. D217

safety concerns, if any, associated with its use. It is the 3.1.2 lubricant, n—any material interposed between two

responsibility of the user of this standard to establish appro- surfaces that reduces the friction or wear between them.

priate safety and health practices and determine the applica- D4175

bility of regulatory limitations prior to use. For specific hazard 3.1.3 thickener, n—in lubricating grease, a substance com-

information see 8 and Annex A2. posed of finely-divided particles dispersed in a liquid lubricant

to form the product’s structure.

2. Referenced Documents

3.1.3.1 Discussion—The solid thickener can be fibers (such

2.1 ASTM Standards: as various metallic soaps) or plates or spheres (such as certain

D217 Test Methods for Cone Penetration of Lubricating

non-soap thickeners) which are insoluble or, at the most, only

Grease very sightly soluble in the liquid lubricant. The general

D3527 Test Method for Life Performance of Automotive requirements are that the solid particles be extremely small,

Wheel Bearing Grease

uniformlydispersed,andcapableofformingarelativelystable,

D4175 Terminology Relating to Petroleum, Petroleum gel-like structure with the liquid lubricant. D217

Products, and Lubricants

3.2 Definitions of Terms Specific to This Standard:

D4290 Test Method for Determining the Leakage Tenden- 3.2.1 automotive wheel bearing grease, n—a lubricating

cies ofAutomotive Wheel Bearing Grease UnderAcceler-

grease specifically formulated to lubricate automotive wheel

ated Conditions bearings at relatively high grease temperatures and bearing

E1 Specification for ASTM Liquid-in-Glass Thermometers

speed. D3527

E77 Test Method for Inspection and Verification of Ther- 3.2.2 leakage, n—of wheel bearing grease, separation and

mometers

overflow of grease or oil from the bulk grease charge, induced

by high temperature and bearing rotation. D4290

This test method is under the jurisdiction of ASTM Committee D02 on

4. Summary of Test Method

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

4.1 The grease is distributed in a modified front-wheel hub

D02.G0 on Lubricating Grease.

Current edition approved May 1, 2005. Published May 2005. Originally

and spindle assembly. The hub is rotated at a speed of 660 6

approved in 1953. Last previous edition approved in 1999 as D1263–94(1999).

30 rpm for 6 h 6 5 min, at a spindle temperature which is

DOI: 10.1520/D1263-94R05E01.

raised to and then maintained at 105 6 1.2°C (220 6 2.5°F).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Leakage of grease or oil, or both, is measured, and the

Standards volume information, refer to the standard’s Document Summary page on

condition of the bearing surface is noted at the end of the test.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D1263–94 (2005)

6.3 Machines furnished with 660-W heaters have been

found suitable, and these will usually provide the proper heat

input to attain the temperatures in the specified time intervals.

However, if it is found that proper balance cannot be obtained,

heaters of the required wattage can be substituted.

7. Test Bearings

7.1 The inner bearing (tapered roller) isTimken 15118.The

corresponding cup is No. 15250.The smaller, outer bearing, is

Timken 09074, with corresponding cup No. 09196.

8. Reagent

8.1 ASTM n-Heptane—99.87 % purity SRM 1815.

(Warning—Flammable. Harmful if inhaled.)

9. Procedure

9.1 Weigh 90 6 1 g of sample on a flat plate. Using a

spatula, pack 2 6 0.1 g of grease in the small bearing and 36

0.1ginthelargebearing(Note2).Distributethebalanceofthe

test grease (85 g) in a uniform layer on the inside of the hub

(Note3).Applyathinfilmofgreasetothebearingracesinthe

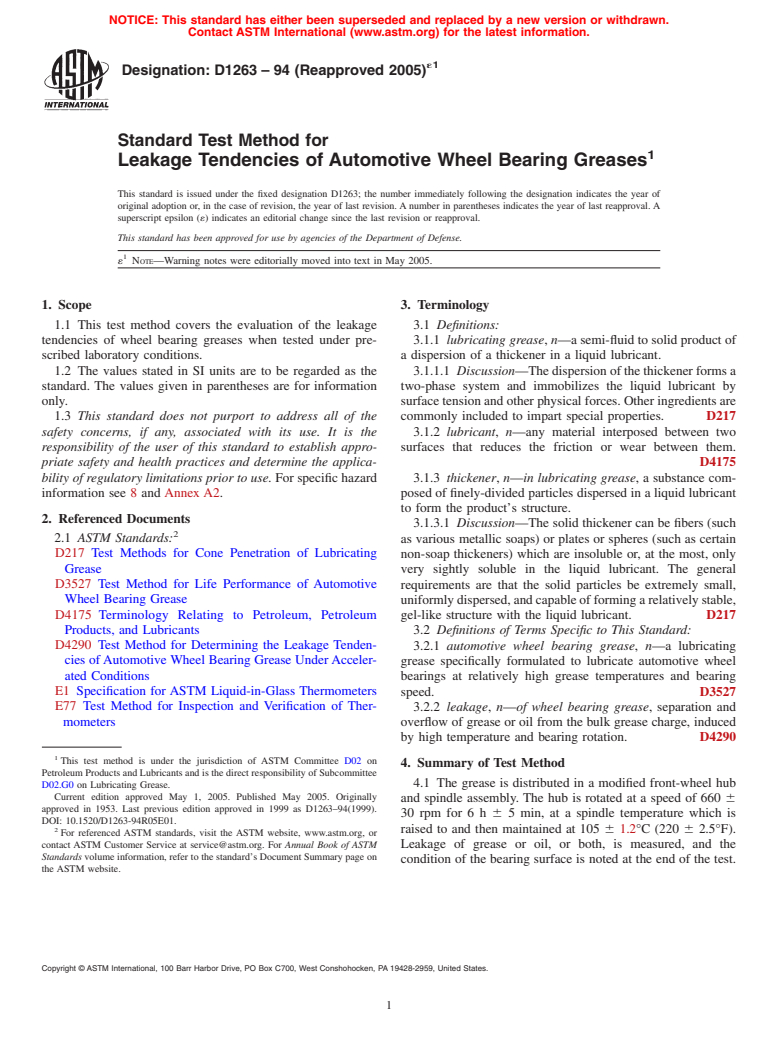

FIG. 1 Apparatus for Testing Leakage Tendencies of Wheel hub.

Bearing Greases

NOTE 2—A narrow, wedge-cut spatula has been found of considerable

aid in packing the bearings.

NOTE 3—Thebalanceofthetestgreasewillfillthehubpracticallyeven

5. Significance and Use

with the races, and, with the exception of very fibrous greases, can be

5.1 The test method provides a screening device that per- distributed readily and uniformly by use of a spatula having a 150-mm

(6-in.) blade.

mits differentiation among products having distinctly different

leakage characteristics (Note 1). It is not the equivalent of

9.2 Weigh separately the leakage collector and the hub cap

longtimeservicetests,norisitintendedtodistinguishbetween

to the nearest 0.1 g. Place the leakage collector and the large

wheel bearing greases showing similar or borderline leakage.

(inner) bearing in the proper position on the spindle . Put the

hub and small (outer) bearing on the spindle, followed by the

NOTE 1—It is possible for skilled operators to observe significant

loose-fitting retainer ring . With the torque wrench, tighten the

changes in other important grease characteristics that occurred during the

test. Such additional information can be of special interest to individual

hexagonalnutwhichholdsthehubassemblyinplace,applying

operators. The observations, however, are subject to differences in

a torque of 6.8 6 0.1 N·m (60 6 2 lbf·in.). Then back off the

personal judgment among operators, and cannot be used effectively for

hexagonalnut60 65°(oroneflat),andlockitinpositionwith

quantitative rating.

a second hexagonal nut. Screw on the hub cap, put the V-belt

on the pulleys, and close the cabinet. (Caution: All grease

6. Apparatus

collectors should be inspected carefully to make sure that the

6.1 TheapparatusshowninFig.1andFig.2hasbeenfound

inner lip is flush with the sealing face. Otherwise, this lip will

suitable and is described in detail in Annex A1. The tester

interfere with the correct seating of the inner bearing. In

consists of a special front wheel hub and spindle assembly, the

assemblingthepackedhubonthespindle,careshouldbetaken

hub being rotated by an electric motor through a V-belt drive.

topreventcontactbetweengreasepackandspindle.Fromtime

The assembly is encased in a thermostatically controlled air

to time, the drive pulley and the driven pulley should be

bath. Means of measuring both ambient (cabinet) and spindle

checked for alignment. Misalignment can introduce leakage

temperaturesareprovided.Atorquewrench,suitableforuseon

variations.)

31.75-mm (1 ⁄4-in.) hexagonal nuts, is also required.

6.2 The apparatus (spindle, case, and motor) must be NOTE 4—Excessive end play of the hub assembly is sometimes due to

worn bearings. Therefore new bearings, both cups and cones, should be

electrically grounded, otherwise the thermocouples will not

installed after each 250 tests, or sooner if inspection indicates wear or

function due to accumulated static charges. Provision is made

other damage to the bearings.

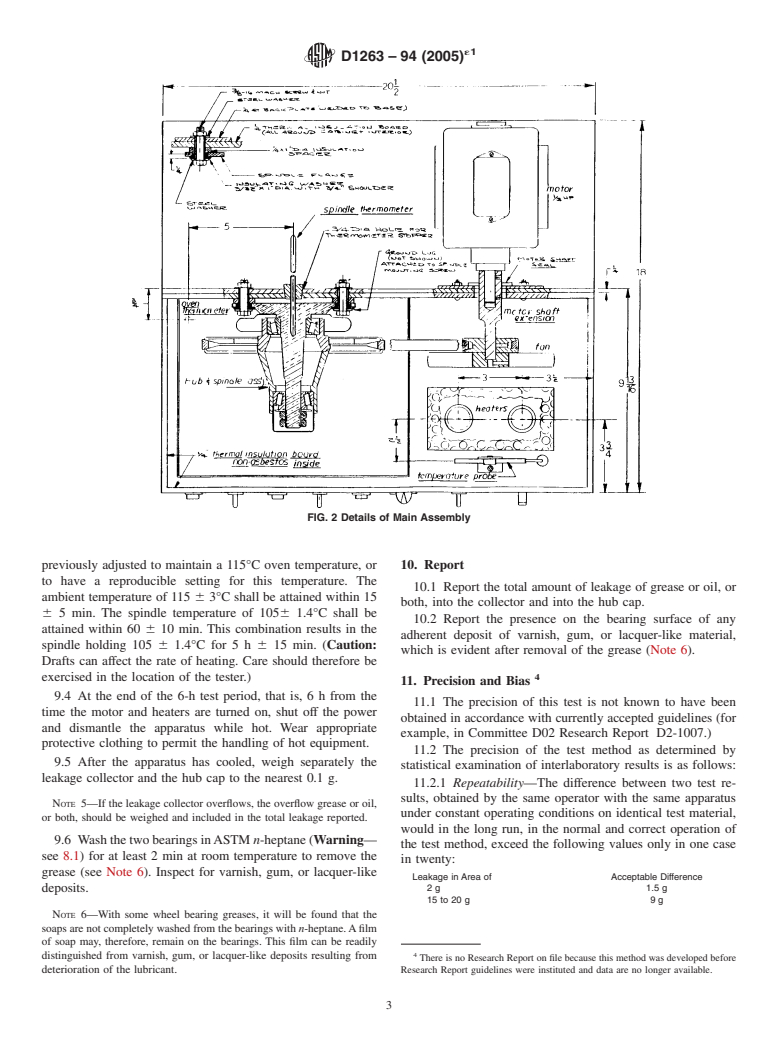

for this, as shown in Fig. 2.

9.3 After closing the cabinet turn on the motor and both

heaters. Operate at a speed of 660 6 30 rpm for 6 h 6 5 min,

3 the spindle temperature being raised to 1056 1.4°C (220 6

Wrenches meeting these requirements are available from a number of compa-

2.5°F) then maintained for the balance of the test period. The

nies. One example is listed in the catalog of the Snap-On Tools Corp., 8028 28th

Ave., Kenosha, WI, as No. TQ 12A. A suitable adapter and socket are required to

spindletemperatureof105 61.4°Cisobtainedbymaintaining

match this type wrench and nut. If you are aware of alternative suppliers, please

an ambient temperature of 115 6 3°C (235 6 5°F). Leave the

provide this information toASTM International Headquarters.Your comments will

auxiliary heater on only until an ambient or oven temperature

receive careful consideration at a meeting of the responsible technical committee ,

which you may attend. of115°Cisattained.Itisdesirabletohavethethermoregulator

´1

D1263–94 (2005)

FIG. 2 Details of Main Assembly

previously adjusted to maintain a 115°C oven temperature, or 10. Report

to have a reproducible setting for this temperature. The

10.1 Report the total amount of leakage of grease or oil, or

ambient temp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.