ASTM D4577-19

(Test Method)Standard Test Method for Compression Resistance of a Container Under Constant Load

Standard Test Method for Compression Resistance of a Container Under Constant Load

SIGNIFICANCE AND USE

4.1 In the distribution system for many products there is a phase wherein the packaged product may be stored for a period of time in a manner such that one or more containers are superimposed one upon the other. Failure can occur in any layer4 (see Fig. 1 and Fig. 3).

FIG. 1 Containers Under Constant Load of Dead Weights Imposed by Other Containers

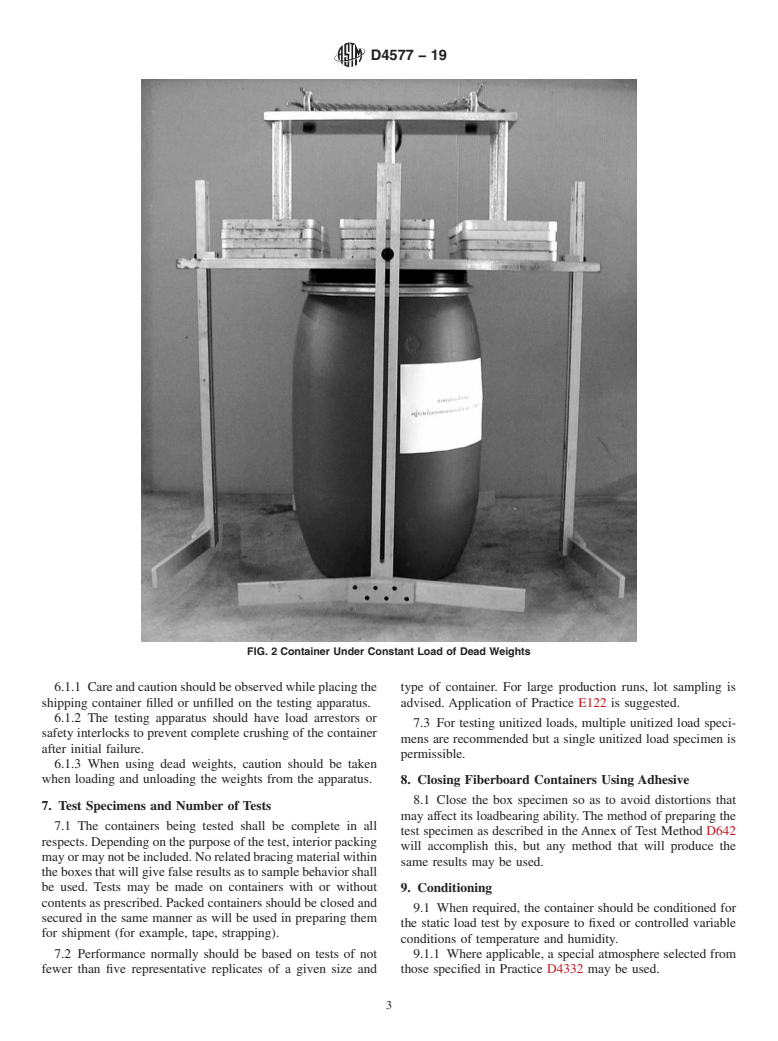

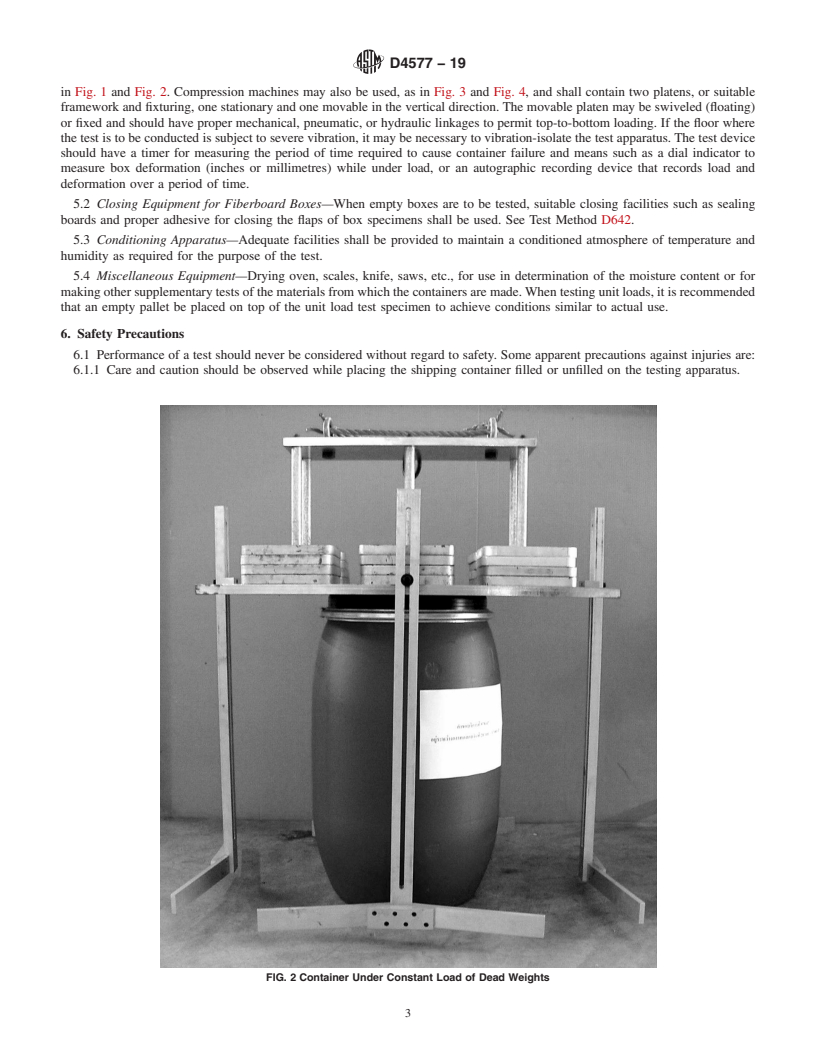

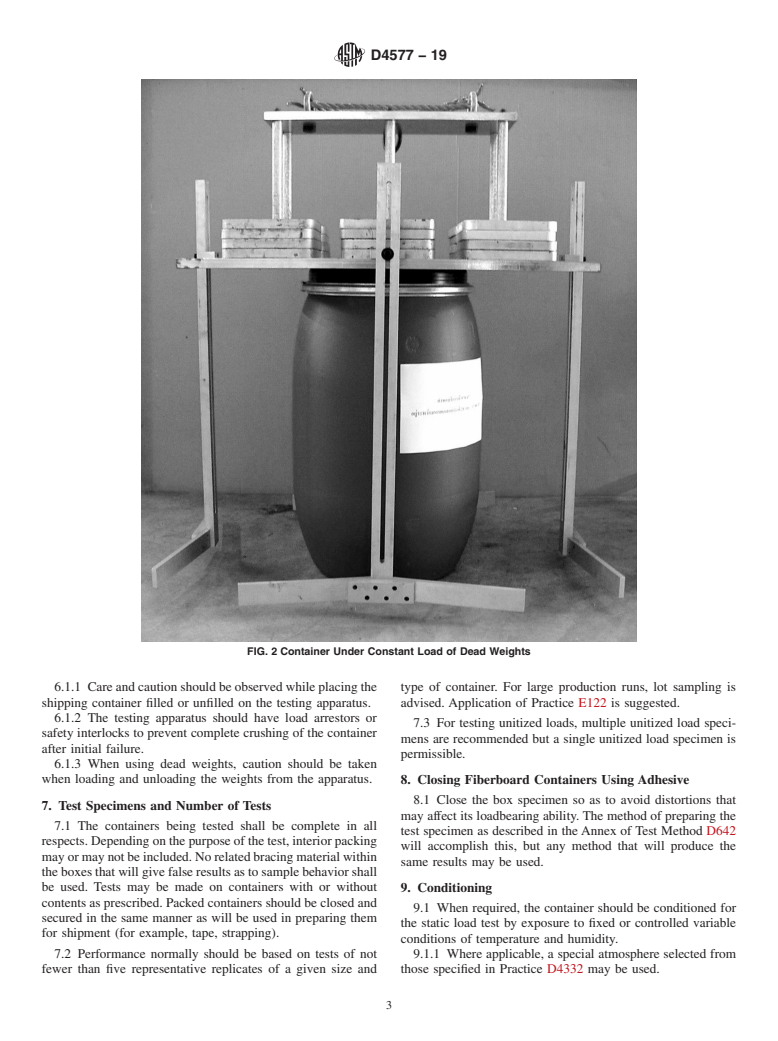

FIG. 2 Container Under Constant Load of Dead Weights

FIG. 3 Containers Under Constant Load in Compression Test Machine With Fixed Platen

4.2 This test method subjects a container, empty or filled, to a predetermined static load, and to specified atmospheric conditions, if required.

SCOPE

1.1 This test method is designed to determine the resistance of a shipping container to a vertically applied constant load for either a specified time or to failure. The test method may also be used for palletized or unitized load configurations.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4577 − 19

Standard Test Method for

Compression Resistance of a Container Under Constant

1

Load

This standard is issued under the fixed designation D4577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 TAPPI Standard

T412 Moisture in pulp, paper and paperboard

1.1 This test method is designed to determine the resistance

of a shipping container to a vertically applied constant load for

3. Terminology

either a specified time or to failure. The test method may also

3.1 Definitions—General definitions for the packaging and

be used for palletized or unitized load configurations.

distribution environments are found in Terminology D996.

1.2 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 load—the force applied to a body, lbf or N.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.2.2 constant load—a load that is invariable or unchanging

mine the applicability of regulatory limitations prior to use.

3.2.3 static load—an imposed stationary force, constant in

For specific precautionary statements, see Section 6.

magnitude, direction, and sense

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4. Significance and Use

ization established in the Decision on Principles for the

4.1 In the distribution system for many products there is a

Development of International Standards, Guides and Recom-

phasewhereinthepackagedproductmaybestoredforaperiod

mendations issued by the World Trade Organization Technical

of time in a manner such that one or more containers are

Barriers to Trade (TBT) Committee.

superimposed one upon the other. Failure can occur in any

4

layer (see Fig. 1 and Fig. 3).

2. Referenced Documents

2

4.2 This test method subjects a container, empty or filled, to

2.1 ASTM Standards:

a predetermined static load, and to specified atmospheric

D642 Test Method for Determining Compressive Resistance

conditions, if required.

of Shipping Containers, Components, and Unit Loads

D685 Practice for Conditioning Paper and Paper Products

5. Apparatus

for Testing

5.1 The testing apparatus shall be capable of imposing a

D996 Terminology of Packaging and Distribution Environ-

constant load on the test specimen and may be hydraulically,

ments

pneumatically, or mechanically activated. A test apparatus

D4332 Practice for Conditioning Containers, Packages, or

employing dead weights to impose the constant load may be

Packaging Components for Testing

used, as in Fig. 1 and Fig. 2. Compression machines may also

D4442 Test Methods for Direct Moisture Content Measure-

be used, as in Fig. 3 and Fig. 4, and shall contain two platens,

ment of Wood and Wood-Based Materials

or suitable framework and fixturing, one stationary and one

E122 Practice for Calculating Sample Size to Estimate,With

movable in the vertical direction. The movable platen may be

Specified Precision, the Average for a Characteristic of a

swiveled (floating) or fixed and should have proper

Lot or Process

mechanical, pneumatic, or hydraulic linkages to permit top-to-

bottom loading. If the floor where the test is to be conducted is

1

This test method is under the jurisdiction of ASTM Committee D10 on

subject to severe vibration, it may be necessary to vibration-

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

Containers and Systems - Application of Performance Test Methods. isolate the test apparatus. The test device should have a timer

Current edition approved April 1, 2019. Published June 2019. Originally

approved in 1986. Last previous edition approved in 2018 as D4577 – 05(2018).

3

DOI: 10.1520/D4577-19. Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Frank, B., Gilgenbach, M., and Maltenfort, M., “Compression Testing to

Standards volume information, refer to the standard’s Document Summary page on Simulate Real-World Stresses,” Packaging Technology and Science, 2010; 23:

the ASTM website. 275-282.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Bo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4577 − 05 (Reapproved 2018) D4577 − 19

Standard Test Method for

Compression Resistance of a Container Under Constant

1

Load

This standard is issued under the fixed designation D4577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is designed to determine the resistance of a shipping container to a vertically applied constant load for

either a specified time or to failure. The test method may also be used for palletized or unitized load configurations.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D642 Test Method for Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads

3

D644 Test Method for Moisture Content of Paper and Paperboard by Oven Drying (Withdrawn 2010)

D685 Practice for Conditioning Paper and Paper Products for Testing

D996 Terminology of Packaging and Distribution Environments

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

3

2.2 TAPPI Standard

T412 Moisture in pulp, paper and paperboard

3. Terminology

3.1 Definitions—General definitions for the packaging and distribution environments are found in Terminology D996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 load—the force applied to a body, lbf or N.

3.2.2 constant load—a load that is invariable or unchanging

3.2.3 static load—an imposed stationary force, constant in magnitude, direction, and sense

1

This test method is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems - Application of Performance Test Methods.

Current edition approved Oct. 1, 2018April 1, 2019. Published November 2018June 2019. Originally approved in 1986. Last previous edition approved in 20102018 as

D4577 – 05(2010).(2018). DOI: 10.1520/D4577-05R18.10.1520/D4577-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.Available from Technical Association of the Pulp and Paper Industry (TAPPI), 15

Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4577 − 19

4. Significance and Use

4.1 In the distribution system for many products there is a phase wherein the packaged product may be stored for a period of

time in a manner such that one or more containers are superimposed one upon the other. The bottom package is thus

4

continuallyFailure can occur in any layer stressed with(see Fig. 1 aand Fig. 3constant load.).

4.2 This test method subjects a container, empty or filled, to a predetermined static load, and to specified atmospheric

conditions, if required.

5. Apparatus

5.1 The testing apparatus shall be capable of imposing a constant load on the test specimen and may be hydraulically,

pneumatically, or mechanically activated. A test apparatus employing dead weights to impose the constant load may be used, as

FIG. 1 Containers Under Constant Load of Dead Weights Imposed by Other Containers

4

Kellicut, K. Q., and Landt, E. F., “S

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4577 − 19

Standard Test Method for

Compression Resistance of a Container Under Constant

1

Load

This standard is issued under the fixed designation D4577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 TAPPI Standard

T412 Moisture in pulp, paper and paperboard

1.1 This test method is designed to determine the resistance

of a shipping container to a vertically applied constant load for

3. Terminology

either a specified time or to failure. The test method may also

3.1 Definitions—General definitions for the packaging and

be used for palletized or unitized load configurations.

distribution environments are found in Terminology D996.

1.2 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 load—the force applied to a body, lbf or N.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.2.2 constant load—a load that is invariable or unchanging

mine the applicability of regulatory limitations prior to use.

3.2.3 static load—an imposed stationary force, constant in

For specific precautionary statements, see Section 6.

magnitude, direction, and sense

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Significance and Use

ization established in the Decision on Principles for the

4.1 In the distribution system for many products there is a

Development of International Standards, Guides and Recom-

phase wherein the packaged product may be stored for a period

mendations issued by the World Trade Organization Technical

of time in a manner such that one or more containers are

Barriers to Trade (TBT) Committee.

superimposed one upon the other. Failure can occur in any

4

layer (see Fig. 1 and Fig. 3).

2. Referenced Documents

2

4.2 This test method subjects a container, empty or filled, to

2.1 ASTM Standards:

a predetermined static load, and to specified atmospheric

D642 Test Method for Determining Compressive Resistance

conditions, if required.

of Shipping Containers, Components, and Unit Loads

D685 Practice for Conditioning Paper and Paper Products

5. Apparatus

for Testing

5.1 The testing apparatus shall be capable of imposing a

D996 Terminology of Packaging and Distribution Environ-

constant load on the test specimen and may be hydraulically,

ments

pneumatically, or mechanically activated. A test apparatus

D4332 Practice for Conditioning Containers, Packages, or

employing dead weights to impose the constant load may be

Packaging Components for Testing

used, as in Fig. 1 and Fig. 2. Compression machines may also

D4442 Test Methods for Direct Moisture Content Measure-

be used, as in Fig. 3 and Fig. 4, and shall contain two platens,

ment of Wood and Wood-Based Materials

or suitable framework and fixturing, one stationary and one

E122 Practice for Calculating Sample Size to Estimate, With

movable in the vertical direction. The movable platen may be

Specified Precision, the Average for a Characteristic of a

swiveled (floating) or fixed and should have proper

Lot or Process

mechanical, pneumatic, or hydraulic linkages to permit top-to-

bottom loading. If the floor where the test is to be conducted is

1

This test method is under the jurisdiction of ASTM Committee D10 on

subject to severe vibration, it may be necessary to vibration-

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

isolate the test apparatus. The test device should have a timer

Containers and Systems - Application of Performance Test Methods.

Current edition approved April 1, 2019. Published June 2019. Originally

approved in 1986. Last previous edition approved in 2018 as D4577 – 05(2018).

3

DOI: 10.1520/D4577-19. Available from Technical Association of the Pulp and Paper Industry (TAPPI),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Frank, B., Gilgenbach, M., and Maltenfort, M., “Compression Testing to

Standards volume information, refer to the standard’s Document Summary page on Simulate Real-World Stresses,” Packaging Technology and Science, 2010; 23:

the ASTM website. 275-282.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4577 − 19

FI

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.