ASTM D3387-83(2003)

(Test Method)Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM)

Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM)

SCOPE

1.1 This test method covers two separate modes of operation of the Gyratory Testing Machine (GTM), namely: (1) GTM fixed roller mode; and (2) GTM oil-filled roller mode. The fixed roller mode of operation is employed in testing for compaction and strain indices only, while the oil-filled roller mode of operation is employed in testing for strength properties as well as compaction and strain indices. This test method is for use with mixtures containing asphalt cement, asphalt cut-back, asphalt emulsion, or tar and aggregate up to 1 in. (25.4 mm) maximum size in the 4-in. (101.6-mm) diameter specimen and 1.5 in. (38.1 mm) maximum size in the 6-in. (152.4-mm) diameter specimen.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3387– 83(Reapproved 2003)

Standard Test Method for

Compaction and Shear Properties of Bituminous Mixtures

by Means of the U.S. Corps of Engineers Gyratory Testing

Machine (GTM)

This standard is issued under the fixed designation D3387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 gyratory angle—a measure of the magnitude of the

gyratory strain. Three pertinent angles are defined as follows:

1.1 This test method covers two separate modes of opera-

3.1.2.1 Initial gyratory angle or shear strain (machine set-

tion of the Gyratory Testing Machine (GTM), namely: (1)

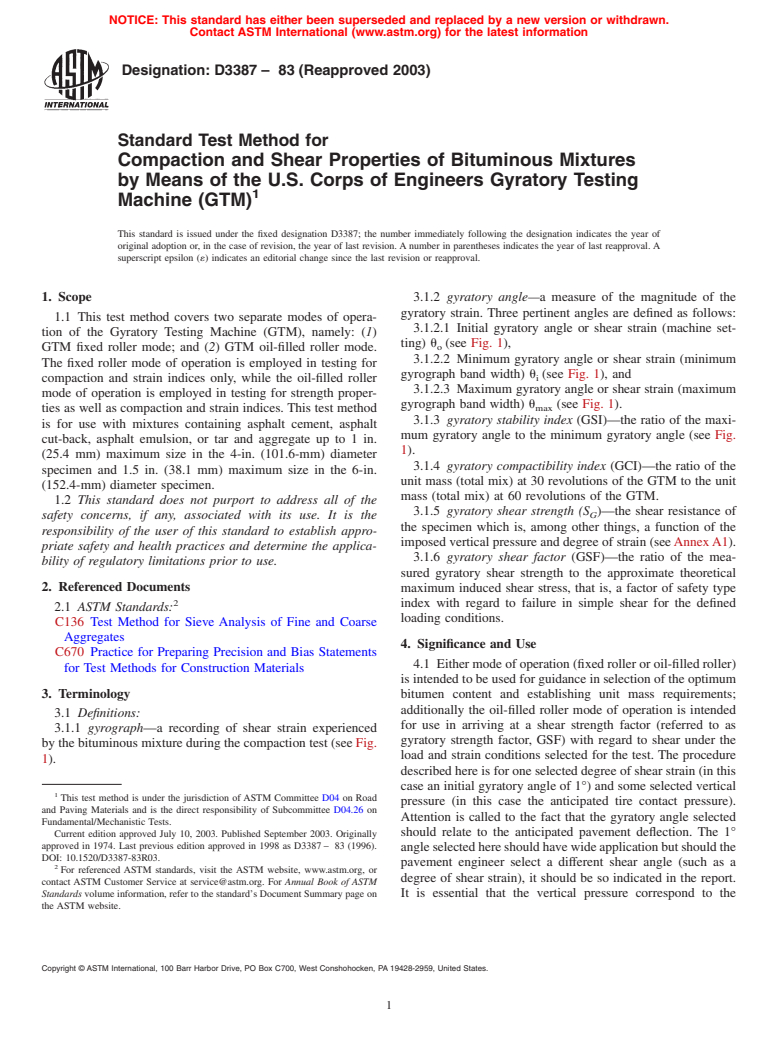

ting) u (see Fig. 1),

GTM fixed roller mode; and (2) GTM oil-filled roller mode. o

3.1.2.2 Minimum gyratory angle or shear strain (minimum

The fixed roller mode of operation is employed in testing for

gyrograph band width) u (see Fig. 1), and

compaction and strain indices only, while the oil-filled roller i

3.1.2.3 Maximum gyratory angle or shear strain (maximum

mode of operation is employed in testing for strength proper-

gyrograph band width) u (see Fig. 1).

ties as well as compaction and strain indices. This test method max

3.1.3 gyratory stability index (GSI)—the ratio of the maxi-

is for use with mixtures containing asphalt cement, asphalt

mum gyratory angle to the minimum gyratory angle (see Fig.

cut-back, asphalt emulsion, or tar and aggregate up to 1 in.

1).

(25.4 mm) maximum size in the 4-in. (101.6-mm) diameter

3.1.4 gyratory compactibility index (GCI)—the ratio of the

specimen and 1.5 in. (38.1 mm) maximum size in the 6-in.

unit mass (total mix) at 30 revolutions of the GTM to the unit

(152.4-mm) diameter specimen.

mass (total mix) at 60 revolutions of the GTM.

1.2 This standard does not purport to address all of the

3.1.5 gyratory shear strength (S )—the shear resistance of

G

safety concerns, if any, associated with its use. It is the

the specimen which is, among other things, a function of the

responsibility of the user of this standard to establish appro-

imposed vertical pressure and degree of strain (seeAnnexA1).

priate safety and health practices and determine the applica-

3.1.6 gyratory shear factor (GSF)—the ratio of the mea-

bility of regulatory limitations prior to use.

sured gyratory shear strength to the approximate theoretical

2. Referenced Documents

maximum induced shear stress, that is, a factor of safety type

index with regard to failure in simple shear for the defined

2.1 ASTM Standards:

loading conditions.

C136 Test Method for Sieve Analysis of Fine and Coarse

Aggregates

4. Significance and Use

C670 Practice for Preparing Precision and Bias Statements

4.1 Either mode of operation (fixed roller or oil-filled roller)

for Test Methods for Construction Materials

is intended to be used for guidance in selection of the optimum

3. Terminology

bitumen content and establishing unit mass requirements;

additionally the oil-filled roller mode of operation is intended

3.1 Definitions:

for use in arriving at a shear strength factor (referred to as

3.1.1 gyrograph—a recording of shear strain experienced

gyratory strength factor, GSF) with regard to shear under the

by the bituminous mixture during the compaction test (see Fig.

load and strain conditions selected for the test. The procedure

1).

described here is for one selected degree of shear strain (in this

case an initial gyratory angle of 1°) and some selected vertical

This test method is under the jurisdiction of ASTM Committee D04 on Road

pressure (in this case the anticipated tire contact pressure).

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

Attention is called to the fact that the gyratory angle selected

Fundamental/Mechanistic Tests.

should relate to the anticipated pavement deflection. The 1°

Current edition approved July 10, 2003. Published September 2003. Originally

approved in 1974. Last previous edition approved in 1998 as D3387 – 83 (1996).

angleselectedhereshouldhavewideapplicationbutshouldthe

DOI: 10.1520/D3387-83R03.

pavement engineer select a different shear angle (such as a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

degree of shear strain), it should be so indicated in the report.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on It is essential that the vertical pressure correspond to the

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3387– 83 (2003)

FIG. 1 GTM Compaction and Shear Test

D3387– 83 (2003)

FIG. 2 Gyratory Testing Machine

maximum anticipated tire contact pressure, since the theoreti- bitumen content as does the widening of the gyrograph which

cal stress for compaction and maximum induced shear used in gives a stability index in excess of unity.

determining the compaction requirements and the gyratory 4.4 The gyratory compactibility index (GCI) is an indicator

strength factor (GSF) is based on the concept of employing of the compactibility of the mix. The closer this index

realistic loads for the test. approaches unity, the easier the mix is to compact.

4.2 The gyratory strength factor (GSF) must be interpreted

5. Apparatus

with due recognition of the use of the somewhat arbitrarily

selecteddegreeofstrainandtheassumptionofplanemaximum

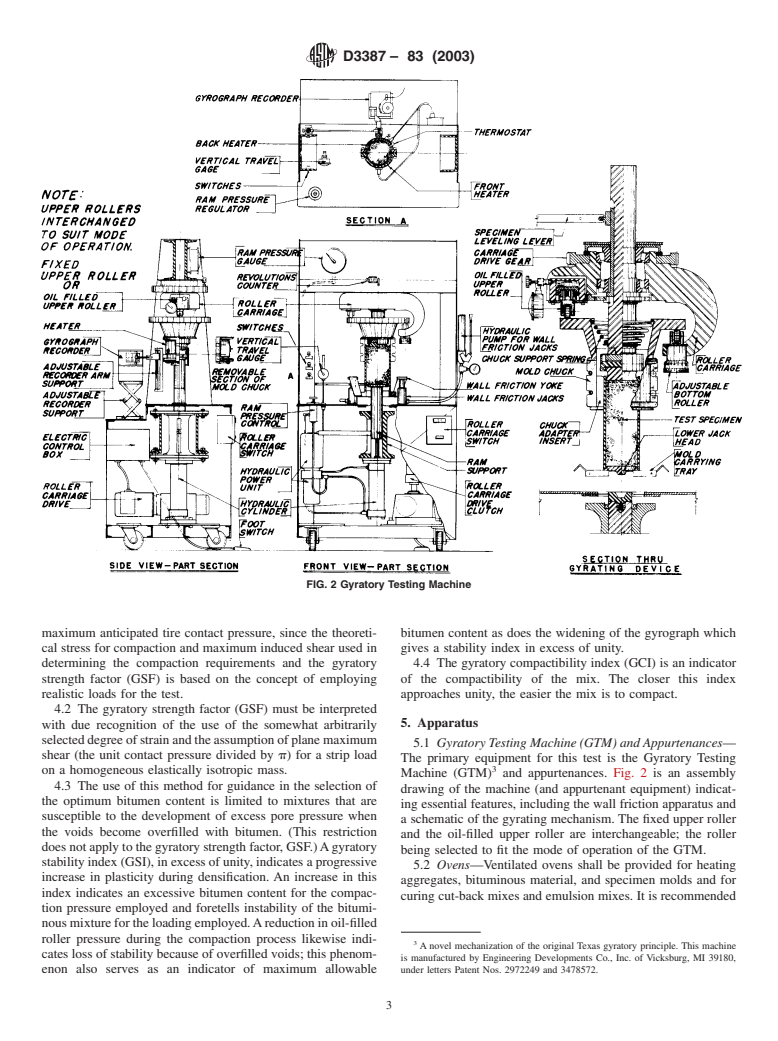

5.1 Gyratory Testing Machine (GTM) and Appurtenances—

shear (the unit contact pressure divided by p) for a strip load

The primary equipment for this test is the Gyratory Testing

on a homogeneous elastically isotropic mass.

Machine (GTM) and appurtenances. Fig. 2 is an assembly

4.3 The use of this method for guidance in the selection of

drawing of the machine (and appurtenant equipment) indicat-

the optimum bitumen content is limited to mixtures that are

ing essential features, including the wall friction apparatus and

susceptible to the development of excess pore pressure when

a schematic of the gyrating mechanism. The fixed upper roller

the voids become overfilled with bitumen. (This restriction

and the oil-filled upper roller are interchangeable; the roller

does not apply to the gyratory strength factor, GSF.)Agyratory

being selected to fit the mode of operation of the GTM.

stability index (GSI), in excess of unity, indicates a progressive

5.2 Ovens—Ventilated ovens shall be provided for heating

increase in plasticity during densification. An increase in this

aggregates, bituminous material, and specimen molds and for

index indicates an excessive bitumen content for the compac-

curing cut-back mixes and emulsion mixes. It is recommended

tion pressure employed and foretells instability of the bitumi-

nousmixturefortheloadingemployed.Areductioninoil-filled

roller pressure during the compaction process likewise indi-

A novel mechanization of the original Texas gyratory principle. This machine

cates loss of stability because of overfilled voids; this phenom-

is manufactured by Engineering Developments Co., Inc. of Vicksburg, MI 39180,

enon also serves as an indicator of maximum allowable under letters Patent Nos. 2972249 and 3478572.

D3387– 83 (2003)

FIG. 3 GTM Shear Test

that the heating units be thermostatically controlled so as to extremely critical mixes, lower the incremental change of

maintain the required temperature within 5°F (2.8°C).

bitumen content to 0.3 % and for highly absorptive aggregates,

5.3 Balances, one having a capacity of 5 kg or more,

increase the incremental change of bitumen content to 1.0 %.

sensitive to 1.0 g; and one having a capacity of 2 kg, sensitive

Tests on additional bitumen contents should be conducted as

to 0.1 g.

necessary when check tests are needed.

5.4 Thermometers—Armored glass or dial-type thermom-

6.2 Preparation of Aggregates—In accordance with Test

eters with metal stems are recommended. A range from 50 to

Method C136, obtain a sieve analysis on the fine and coarse

400°F (9.9 to 20.4°C) with sensitivity of 5°F (2.8°C) is

aggregate (aggregate shall be separated by means of a No. 4

required.

(4.75-mm) sieve). Separate the aggregate into the various size

5.5 Spacer Blocks, two metal spacer blocks for use in

fractions necessary for accurately recombining into test mix-

zeroing the specimen height measuring equipment. These shall

tures conforming to specified grading requirements.

all be of 2-in. (50.8-mm) diameter with one each of the

6.3 Preparation of Mixtures—Combine the moisture-free

following lengths: 2.50 6 0.005 in. (63.50 6 0.013 mm) and

aggregates into batches sufficiently large to make specimens

3.75 6 0.005 in. (95.25 6 0.013 mm).

approximately 2.50 in. (63.5 mm) long in the 4-in. (101.6-mm)

5.6 Miscellaneous Apparatus—Trowels, spatulas, scoops,

diameter mold and 3.75 in. (95.3 mm) long in the 6-in.

gloves, rubber gloves, metal pans, 4-in. (101.6-mm) diameter

(152.4-mm) diameter mold. For normal aggregates, this will

paper disks, and 6-in. (152.4-mm) diameter paper disks.

require approximately 1200 g for the 4-in. (101.6-mm) diam-

6. Test Specimens

eter specimens and approximately 4050 g for the 6-in. (152.4-

mm) diameter specimens. Heat the aggregate to the proper

6.1 Selection of Bitumen Content for Specimens—Conduct

mixing temperature; then weigh the required amount of bitu-

laboratory tests for one specimen each at a minimum of three

men at the proper temperature into the aggregate mixture.

bitumen contents, one above, one below, and one at the

estimated optimum content (see Note 1). The incremental Mixing of the aggregate and bitumen shall be as thorough and

change of bitumen content should generally be 0.5 %. For rapid as possible; mechanical mixing is recommended.

D3387– 83 (2003)

FIG. 4 Compaction and Shear Properties vs. Bitumen Content

NOTE 1—A first approximation of the optimum amount of bitumen for

should be dried to constant weight at 221 to 230°F (105 to

the aggregate may be determined by any method commonly employed by

110°C). The liquid asphalt should be combined with the

the laboratory.Amethod that has been found suitable in some laboratories

aggregate at room temperature. Following mixing, cure the

is the centerfuge kerosene equivalent method.

loose mixture in a ventilated oven maintained at 221 to 230°F

6.3.1 For mixes employing penetration/viscosity grades of

(105 to 110°C) for at least 12 h prior to compaction at this

asphalt, the temperature of the aggregate and asphalt at the

temperature. The mix may be stirred occasionally during

time of mixing should correspond to the temperatures antici-

curing to accelerate loss of volatiles.

pated to be used at the plant during manufacture of the paving

6.4 Size of Specimens—The 4-in. (101.6-mm) diameter

mix. These temperatures will generally be somewhere in the

specimensshallbeapproximately2.50in.(63.5mm)long.The

range of 250 to 325°F (121 to 149°C). Once the mixing

6-in. (152.4-mm) diameter specimens shall be approximately

temperature is selected, it should be so controlled that the

3.75 in. (95.3 mm) long.

viscosity of the bitumen will not vary more than 650 cSt

7. Calibration

during the mixing process.

7.1 See Annex A2.

6.3.2 For tar mixtures, the temperature of the aggregate and

tar at the time of mixing should correspond to the temperatures

8. Procedure

to be used at the plant during manufacture of the paving mix.

8.1 General—The GTM-fixed roller is employed when the

This temperature will generally not exceed 225°F (107°C).

compaction test only is required. The GTM oil-filled roller is

Once the mixing temperature is specified, it should be so

employed when both the compaction test and the shear test are

controlled that the viscosity of the tar will not vary more than

required. The oil-filled roller procedure is accomplished in

65 Engler specific viscosity during the mixing process.

sequential steps including the compaction test, shear test, and

6.3.3 For mixtures employing liquid asphalts (cut backs or

wall friction test as outlined in this section. (The procedure for

emulsions), the asphalt need not be heated but the aggregate

determining the machine correction for S is presented in

G

Annex A2.) When using the fixed roller, inapplicable portions

California Highways and Public Works, Vol 20, No. 7, July 1942, pp. 14-17. of the following instructions are ignored.

D3387– 83 (2003)

8.2 Compaction or Compaction and Shear Test—Fig. 1 and assembly drawing, Fig. 2. With the vertical load acting on the

Fig.3illustratedatasheetswhicharesuitableforrecordingand specimen, the force required to overcome wall friction and

move the mold with respect to the specimen shall be deter-

calculating compaction or compaction and shear test results

and for displaying the gyrograph (shear strain) recording. The mined by observing the pressure gage of the jack while

actuating the jack. The pressure reading will be found to

gyratory strain angles u , u, and u are indicated on the

o i max

increase with each thrust of the jack until there is sufficient

gyrograph displayed in Fig. 1. For this test, set the initial

force to move the mold with respect to the specimen. The

gyratory angle, u , at 1°. Roller positions 2 and 4 (Fig. 1) are

o

pressure reading will then stabilize to about the same value

usedinsettingtheinitialgyratoryangle, u .Atrialbatchofmix

o

after each thrust of the jack. The reading of the wall friction

is used in making the initial gyratory angle adjustment. Make

gage shall be recorded in the space provided as illustrated in

certain that the specimen molds are thoroughly clean and free

Fig. 3. Immediately after completion of the wall friction test,

of defects. Excessive wear or grooving in the molds in the area

the test specimen should be removed from the GTM and the

of contact with the upper and lower plates will have an adverse

lower roller brought back to the 1° setting so that the machine

effect upon the compaction as well as the gyrograph (shear

is ready for the next test specimen.

strain) recording. Instructions for the compaction temperatures

for the laboratory specimens are presented in 6.3.1 through

9. Calculations

6.3.3. Set the GTM heater at 140°F (60°C) at least 15 min

9.1 Calculations for Compaction—Calculate the following

before starting the compaction test. Preheat the mold and base

compaction properties for each specimen, as illustrated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.