ASTM A646-95(1999)

(Specification)Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

SCOPE

1.1 This specification covers premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into critical parts such as aircraft landing-gear forgings.

1.2 Blooms and billets, hereinafter referred to as blooms, are semifinished steel products, hot rolled or forged to approximate cross-sectional dimensions. Blooms may be square, round, hexagonal, octagonal, or rectangular in section. For the purposes of this specification, minimum bloom section size will be 16 in. (103 cm ).

1.3 This specification covers two basic classifications of steel:

1.3.1 Class I -Vacuum-induction melted or consumable-electrode vacuum melted, or other suitable processes which will satisfy the quality requirements of this specification.

1.3.2 Class II -Air-melted vacuum degassed.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 646 – 95 (Reapproved 1999)

Standard Specification for

Premium Quality Alloy Steel Blooms and Billets for Aircraft

and Aerospace Forgings

This standard is issued under the fixed designation A 646; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 114 Practice for Ultrasonic Pulse-Echo Straight-Beam

Testing by the Contact Method

1.1 This specification covers premium quality alloy steel

E 127 Practice for Fabricating and Checking Aluminum

semifinished rolled or forged blooms and billets for reforging

Alloy Ultrasonic Standard Reference Blocks

into critical parts such as aircraft landing-gear forgings.

E 214 Practice for Immersed Ultrasonic Examination by the

1.2 Blooms and billets, hereinafter referred to as blooms,

Reflection Method Using Pulsed Longitudinal Waves

are semifinished steel products, hot rolled or forged to approxi-

E 350 Test Methods for ChemicalAnalysis of Carbon Steel,

mate cross-sectional dimensions. Blooms may be square,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

round, hexagonal, octagonal, or rectangular in section. For the

Wrought Iron

purposes of this specification, minimum bloom section size

2 2 E 381 Method for Macroetch Testing, Inspection, and Rat-

will be 16 in. (103 cm ).

ing Steel Products, Comprising Bars, Billets, Blooms, and

1.3 This specification covers two basic classifications of

Forgings

steel:

2.2 AMS Standards:

1.3.1 Class I—Vacuum-induction melted or consumable-

AMS 2300 Premium Quality Steel Cleanliness, Magnetic

electrode vacuum melted, or other suitable processes which

Particle, and

will satisfy the quality requirements of this specification.

AMS 2301 Aircraft Quality Steel Cleanliness.

1.3.2 Class II—Air-melted vacuum degassed.

2.3 Government Standard:

1.4 The values stated in inch-pound units are to be regarded

MIL-STD-430A Macrograph Standards for Steel Bars,

as the standard. The values given in parentheses are for

Billets, and Blooms

information only.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2.1 ASTM Standards:

3.1.1 air-melted vacuum-degassed steel—arc- or induction-

A 255 Test Method of End-Quench Test for Hardenability

2 furnace-melted steel that is vacuum treated immediately prior

of Steel

to or during the operation of pouring the ingot.

A 388/A 388M Practice for Ultrasonic Examination of

2 3.1.2 consumable-electrode vacuum-remelted steel—metal

Heavy Steel Forgings

that has been remelted into a crucible in vacuum from single or

A 604 Test Method for Macroetch Testing of Consumable

2 multiple electrodes.

Electrode Remelted Steel Bars and Billets

3.1.3 electroslag-melted steel—metal that has been re-

E 30 Test Methods for Chemical Analysis of Steel, Cast

3 melted into a crucible from single or multiple electrodes

Iron, Open-Hearth Iron and Wrought Iron

utilizinganelectricaldischargethroughmoltenslagasasource

E 45 Test Methods for Determining the Inclusion Content

of heat.

of Steel

3.1.4 heat—for the purpose of this specification, if consum-

able electrode remelting is employed, all of the remelted ingots

produced one parent arc- or induction-melted heat.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

Current edition approved July 15, 1995. Published September 1995. Originally Annual Book of ASTM Standards, Vol 03.03.

published as A 646 – 71. Last previous edition A 646 – 94. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 01.05. Warrendale, PA 15096.

3 7

Annual Book of ASTM Standards, Vol 03.05. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 03.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 646 – 95 (1999)

3.1.5 vacuum induction melted steel—metal that has been 5.3.2 When specified, the material may be ordered annealed

melted, refined, and poured from a furnace operating in or normalized and tempered to a maximum Brinell Hardness,

vacuum. as specified in Table 2 or by agreement.

5.3.3 Material shall be furnished in condition to withstand,

4. Ordering Information

for an indefinite time, exposure to all climatic conditions

4.1 When this specification is to be applied to an inquiry,

withoutdevelopinganyexternalorinternalcracks.Themethod

contract, or order, the purchaser shall so state, and shall also

of cooling or of treatment before shipment shall be optional

furnish the following information:

with the manufacturer, but he shall be responsible (in the same

4.1.1 Class designation (see 1.3),

manner as for discontinuities disclosed after delivery) for

4.1.2 Quality level (Table 1), grade designation (Table 2), or

cracks which may develop before material is subjected to

detailed chemistry (Table 3) for nonstandard grades,

reheating.Whenanyotherspecifictreatmentorconditioningof

4.1.3 Desired billet or bloom size,

materialisspecifiedbythepurchaser,themanufacturershallbe

4.1.4 Weight or quantity and length,

responsible only for carrying out those specific operations.

4.1.5 Minimum forging reduction required if ordered size

2 2

exceeds 225 in. (1450 cm ) (see 5.2.2),

6. Chemical Requirements

4.1.6 Annealing, if required (see 5.3.2),

6.1 General Requirements:

4.1.7 Macroetch standards of acceptance (see 7.1),

4.1.8 Microcleanliness standards of acceptance (see 7.2),

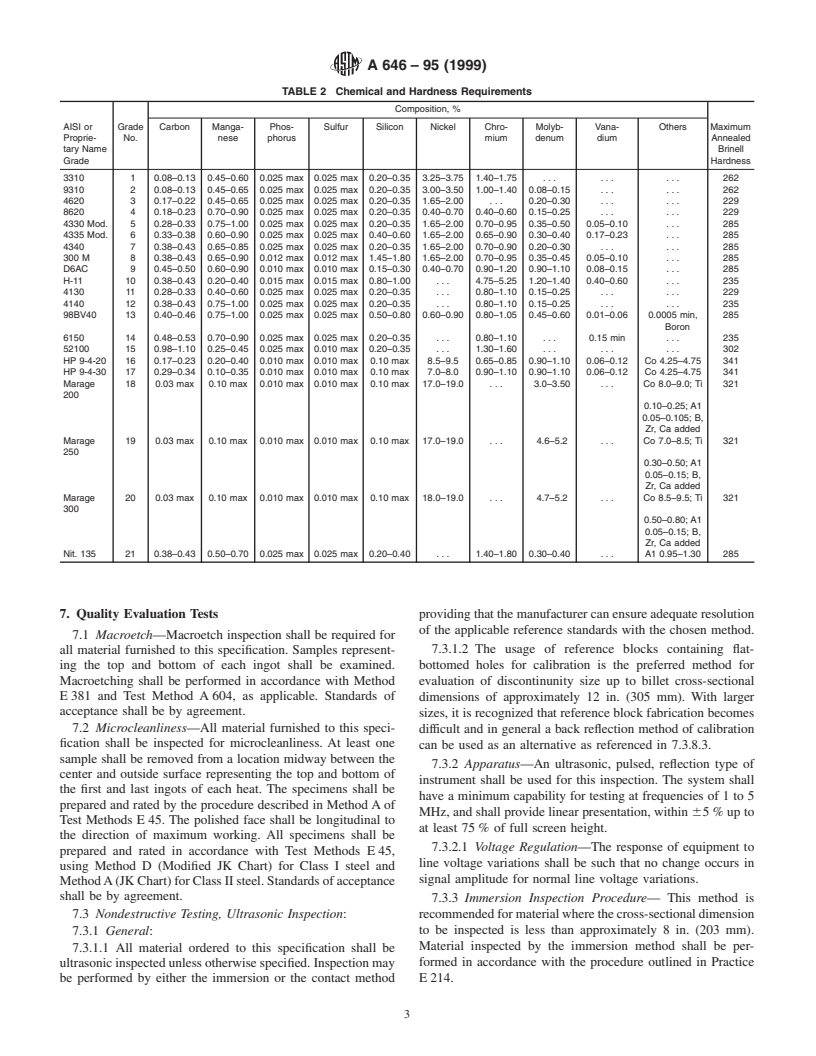

6.1.1 Table 2 lists 21 standard grades of alloy steel which

4.1.9 Ultrasonic quality level required (see 7.3.7.1),

are currently produced in premium quality; however, it is not

4.1.9.1 Also any further restrictions on ultrasonic, such as

the intent of this specification to restrict application only to the

transducer type and size, whether contact or immersion pre-

materials listed in Table 2.

ferred, level of reportable discontinuities and any special

6.1.2 When a standard grade is ordered, the analysis shall

surface finish requirements.

conform to the requirements as to chemical composition

4.1.10 Hardenability standards of acceptance (see 8.1), and

prescribed in Table 2 for the respective grades.

4.1.11 Any supplementary requirements desired.

6.1.3 The steel when ordered to other than standard analysis

shall conform to the requirements as to chemical ranges and

5. Manufacture

limits prescribed in Table 3.

5.1 Melting Practice:

6.1.4 Small quantities of certain elements are present in

5.1.1 Class I material shall be manufactured by the vacuum-

alloy steels which are neither specified nor required. These

induction-melting process or by the consumably-electrode

elements are residual and may be present up to the following

vacuum-melting process. By agreement other processes such

amounts: copper, 0.35 %; nickel, 0.25 %; chromium, 0.20 %;

as electroslag or electron-beam melting may be considered

and molybdenum, 0.06 %.

acceptable.

5.1.2 Class II material shall be manufactured by an electric- 6.2 Heat Analysis:

furnace vacuum-degassed process.

6.2.1 Each heat of steel shall be analyzed by the manufac-

5.2 Hot-Working Procedure:

turer to determine the percentage of elements prescribed in

5.2.1 Blooms may be either hot rolled or forged.

Table 2. This analysis shall be made on a sample taken during

5.2.2 Blooms having cross-sectional areas ranging from 16

the pouring of the heat, except that in the event mechanical

2 2

to 225 in. (103 to 1450 cm ) when made from air-melt ingots

difficulties prevent obtaining samples from the ladle, that may

shall have at least 2 to 1 reduction of area from ingot to bloom.

be obtained from suitable portions of the ingots or product.

On blooms exceeding 225 in. , forging reduction requirements

6.2.2 If consumable-electrode remelting is employed, the

shall be by agreement. Ingot-to-final forging reduction is not

analysis of each resulting ingot shall conform to the require-

included in this requirement.

ments of Table 2. Samples for these analyses shall be removed

5.3 Heat Treatment:

from the top end of the ingot after adequate discard at any area

5.3.1 Unless otherwise specified all material purchased to

midway between the center and surface of the ingot or bloom.

this specification will be furnished in the untreated condition.

One complete analysis from the master heat or from one remelt

In this condition some grades may not be soft enough for cold

ingot plus carbon and manganese analysis from each remelt

sawing.

ingot are required.

6.3 Product Analysis:

TABLE 1 Maximum Permissible Discontinuities

6.3.1 Analysis may be made by the purchaser from material

NOTE 1—See 7.3.

representing each heat or lot. The chemical composition thus

Quality Response, Stringers,

determined shall not vary from the ranges or limits as specified

Level in. (mm) Length in. (mm)

in Table 2 or Table 3 by more than the amount specified in

Single Multiple

Table 4, unless otherwise agreed.

Discontinuities Discontinuities

3 2 2 1 6.3.2 Samples for product analyses shall be taken from a

AA ⁄64 (1.2) ⁄64 (0.8) ⁄64 – ⁄2 (0.8–12.7)

5 3 3

A ⁄64 (2.0) ⁄64 (1.2) ⁄64 –1 (1.2–25.4)

location midway between center and surface of the bloom.

8 5 5

B ⁄64 (3.2) ⁄64 (2.0) ⁄64 –1 (2.0–25.4)

6.4 Method ofAnalysis—TestMethodsE 30andE 350shall

12 8 8

C ⁄64 (4.8) ⁄64 (3.2) ⁄64 –1 (3.2–25.4)

be used for referee purposes.

A 646 – 95 (1999)

TABLE 2 Chemical and Hardness Requirements

Composition, %

AISI or Grade Carbon Manga- Phos- Sulfur Silicon Nickel Chro- Molyb- Vana- Others Maximum

Proprie- No. nese phorus mium denum dium Annealed

tary Name Brinell

Grade Hardness

3310 1 0.08–0.13 0.45–0.60 0.025 max 0.025 max 0.20–0.35 3.25–3.75 1.40–1.75 . . . . . . . . . 262

9310 2 0.08–0.13 0.45–0.65 0.025 max 0.025 max 0.20–0.35 3.00–3.50 1.00–1.40 0.08–0.15 . . . . . . 262

4620 3 0.17–0.22 0.45–0.65 0.025 max 0.025 max 0.20–0.35 1.65–2.00 . . . 0.20–0.30 . . . . . . 229

8620 4 0.18–0.23 0.70–0.90 0.025 max 0.025 max 0.20–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . . . . . 229

4330 Mod. 5 0.28–0.33 0.75–1.00 0.025 max 0.025 max 0.20–0.35 1.65–2.00 0.70–0.95 0.35–0.50 0.05–0.10 . . . 285

4335 Mod. 6 0.33–0.38 0.60–0.90 0.025 max 0.025 max 0.40–0.60 1.65–2.00 0.65–0.90 0.30–0.40 0.17–0.23 . . . 285

4340 7 0.38–0.43 0.65–0.85 0.025 max 0.025 max 0.20–0.35 1.65–2.00 0.70–0.90 0.20–0.30 . . . . . . 285

300 M 8 0.38–0.43 0.65–0.90 0.012 max 0.012 max 1.45–1.80 1.65–2.00 0.70–0.95 0.35–0.45 0.05–0.10 . . . 285

D6AC 9 0.45–0.50 0.60–0.90 0.010 max 0.010 max 0.15–0.30 0.40–0.70 0.90–1.20 0.90–1.10 0.08–0.15 . . . 285

H-11 10 0.38–0.43 0.20–0.40 0.015 max 0.015 max 0.80–1.00 . . . 4.75–5.25 1.20–1.40 0.40–0.60 . . . 235

4130 11 0.28–0.33 0.40–0.60 0.025 max 0.025 max 0.20–0.35 . . . 0.80–1.10 0.15–0.25 . . . . . . 229

4140 12 0.38–0.43 0.75–1.00 0.025 max 0.025 max 0.20–0.35 . . . 0.80–1.10 0.15–0.25 . . . . . . 235

98BV40 13 0.40–0.46 0.75–1.00 0.025 max 0.025 max 0.50–0.80 0.60–0.90 0.80–1.05 0.45–0.60 0.01–0.06 0.0005 min, 285

Boron

6150 14 0.48–0.53 0.70–0.90 0.025 max 0.025 max 0.20–0.35 . . . 0.80–1.10 . . . 0.15 min . . . 235

52100 15 0.98–1.10 0.25–0.45 0.025 max 0.010 max 0.20–0.35 . . . 1.30–1.60 . . . . . . . . . 302

HP 9-4-20 16 0.17–0.23 0.20–0.40 0.010 max 0.010 max 0.10 max 8.5–9.5 0.65–0.85 0.90–1.10 0.06–0.12 Co 4.25–4.75 341

HP 9-4-30 17 0.29–0.34 0.10–0.35 0.010 max 0.010 max 0.10 max 7.0–8.0 0.90–1.10 0.90–1.10 0.06–0.12 Co 4.25–4.75 341

Marage 18 0.03 max 0.10 max 0.010 max 0.010 max 0.10 max 17.0–19.0 . . . 3.0–3.50 . . . Co 8.0–9.0; Ti 321

0.10–0.25; A1

0.05–0.105; B,

Zr, Ca added

Marage 19 0.03 max 0.10 max 0.010 max 0.010 max 0.10 max 17.0–19.0 . . . 4.6–5.2 . . . Co 7.0–8.5; Ti 321

0.30–0.50; A1

0.05–0.15; B,

Zr, Ca added

Marage 20 0.03 max 0.10 max 0.010 max 0.010 max 0.10 max 18.0–19.0 . . . 4.7–5.2 . . . Co 8.5–9.5; Ti 321

0.50–0.80; A1

0.05–0.15; B,

Zr, Ca added

Nit. 135 21 0.38–0.43 0.50–0.70 0.025 max 0.025 max 0.20–0.40 . . . 1.40–1.80 0.30–0.40 . . . A1 0.95–1.30 285

7. Quality Evaluation Tests providing that the manufacturer can ensure adequate resolution

of the applicable reference standards with the chosen method.

7.1 Macroetch—Macroetch inspection shall be required for

7.3.1.2 The usage of reference blocks containing flat-

all material furnished to this specification. Samples represent-

bottomed holes for calibration is the preferred method for

ing the top and bottom of each ingot shall be examined.

Macroetching shall be performed in accordance with Method evaluation of discontinunity size up to billet cross-sectional

E 381 and Test Method A 604, as applicable. Standards of dimensions of approximately 12 in. (305 mm). With larger

acceptance shall be by agreement.

sizes, it is recognized that reference block fabrication becomes

7.2 Microcleanliness—All material furnished to this speci- difficult and in general a back reflection method of calibration

fication shall be inspected for microcleanliness. At least one

can be used as an alternative as referenced in 7.3.8.3.

sample shall be removed from a location midway between the

7.3.2 Apparatus—An ultrasonic, pulsed, reflection type of

center and outside surface representing the top and bottom of

instrument shall be used for this inspection. The system shall

the first and last ingots of each heat. The specimens shall be

have a minimum capability for testing at frequencies of 1 to 5

prepared and rated by the procedure described in MethodAof

MHz, and shall provide linear presentation, within 65 % up to

Test Methods E 45. The polished face shall be longitudinal to

at least 75 % of full screen height.

the direction of maximum working. All specimens shall be

7.3.2.1 Voltage Regulation—The response of equipment to

prepared and rated in accordance with Test Methods E 45,

line voltage variations shall be such that no change occurs in

using Method D (Modified JK Chart) for Class I steel and

signal amplitude for normal line voltage variations.

MethodA(JKChart)forClassIIsteel.Standardsofacceptance

shall be by agreement.

7.3.3 Immersion Inspection Procedure— This method is

7.3 Nondestructive Testing, Ultrasonic Inspection: recommendedformaterialwherethecross-sectionaldimension

7.3.1 General: to be inspected is less than approximately 8 in. (203 mm).

Material inspected by the immersion method shall be per-

7.3.1.1 All material ordered to this specification shall be

formed in accordance with the procedure outlined in Practic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.