ASTM A646/A646M-04

(Specification)Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

SCOPE

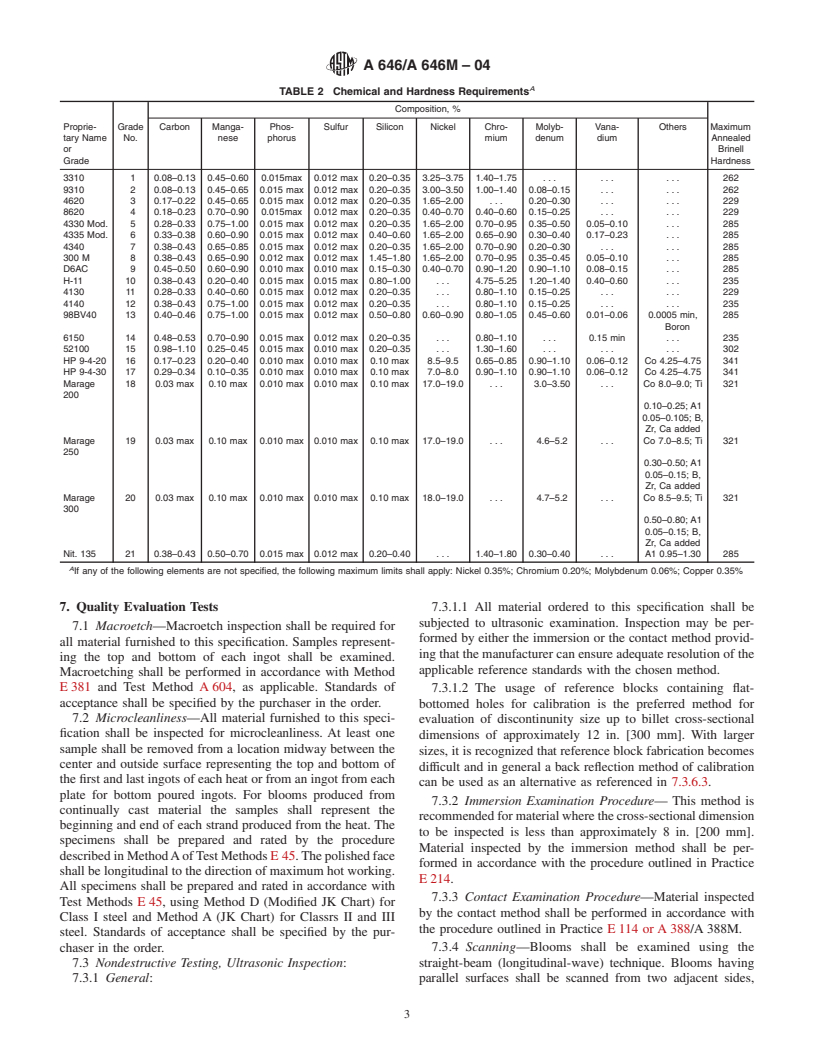

1.1 This specification covers premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into critical parts such as aircraft landing-gear forgings.

1.2 Blooms and billets, hereinafter referred to as blooms, are semifinished steel products, hot rolled or forged to approximate cross-sectional dimensions. Blooms may be square, round, hexagonal, octagonal, or rectangular in section. For the purposes of this specification, minimum bloom section size will be 16 in.² (103 cm²).

1.3 This specification covers two basic classifications of steel:

1.3.1 Class I—Vacuum-induction melted or consumable-electrode vacuum melted, or other suitable processes which will satisfy the quality requirements of this specification.

1.3.2 Class II—Air-melted vacuum degassed.

1.3.3 Class III—Air melted electric furnace ladle refined and vacuum degassed

1.4 The values stated in either inch-pound or SI (metric) units are to be regarded separately as standards. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Unless the order specifies the applicable "M" specification the material shall be furnished to the inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 646/A 646M – 04

Standard Specification for

Premium Quality Alloy Steel Blooms and Billets for Aircraft

1

and Aerospace Forgings

This standard is issued under the fixed designationA646/A646M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* A 788 Specification for Steel Forgings, General Require-

ments

1.1 This specification covers premium quality alloy steel

A 604 Test Method for Macroetch Testing of Consumable

semifinished rolled or forged blooms and billets for reforging

Electrode Remelted Steel Bars and Billets

into critical parts such as aircraft landing-gear forgings.

E45 Test Methods for Determining the Inclusion Content

1.2 Blooms and billets, hereinafter referred to as blooms,

of Steel

are semifinished steel products, hot rolled or forged to approxi-

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

mate cross-sectional dimensions. Blooms may be square,

Testing by the Contact Method

round, hexagonal, octagonal, or rectangular in section. For the

E 214 Practice for Immersed Ultrasonic Examination by the

purposes of this specification, minimum bloom section size

2 2 Reflection Method Using Pulsed Longitudinal Waves

will be 16 in. (103 cm ).

E 381 Method for Macroetch Testing, Inspection, and Rat-

1.3 This specification covers two basic classifications of

ing Steel Products, Comprising Bars, Billets, Blooms, and

steel:

Forgings

1.3.1 Class I—Vacuum-induction melted or consumable-

3

2.2 AMS Standards:

electrode vacuum melted, or other suitable processes which

AMS 2300 Steel Cleanliness, Premium-Quality

will satisfy the quality requirements of this specification.

AMS 2301 Steel Cleanliness, Aircraft-Quality

1.3.2 Class II—Air-melted vacuum degassed.

AMS 2304 Steel Cleanliness, Special Aircraft-Quality

1.3.3 Class III—Air melted electric furnace ladle refined

4

2.3 Government Standard:

and vacuum degassed

MIL-STD-430A Macrograph Standards for Steel Bars,

1.4 The values stated in either inch-pound or SI (metric)

Billets, and Blooms

units are to be regarded separately as standards.Within the text

andtables,theSIunitsareshowninbrackets.Thevaluesstated

3. Terminology

in each system are not exact equivalents; therefore, each

3.1 In addition to the terminology requirements of Specifi-

system must be used independent of the other. Combining

cation A 788, the following terms that are specific to this

values from the two systems may result in nonconformance

specification apply:

with the specification.

3.2 Definitions:

1.5 Unless the order specifies the applicable “M” specifica-

3.2.1 air-melted vacuum-degassed steel—arc- or induction-

tion the material shall be furnished to the inch-pound units.

furnace-melted steel that is vacuum treated immediately prior

2. Referenced Documents to or during the operation of pouring the ingot.

2 3.2.2 consumable-electrode vacuum-remelted steel—metal

2.1 ASTM Standards:

that has been remelted into a crucible in vacuum from single or

A 255 Test Method of End-Quench Test for Hardenability

multiple electrodes.

of Steel

3.2.3 electroslag-melted steel—metal that has been re-

A 388/A 388M Practice for Ultrasonic Examination of

melted into a crucible from single or multiple electrodes

Heavy Steel Forgings

utilizinganelectricaldischargethroughmoltenslagasasource

of heat.

3.2.3.1 Discussion—For the purposes of this specification

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

the parent heat from which any electrode for remelting by the

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

CurrenteditionapprovedSeptember1,2004.PublishedOctober2004.Originally

approved in 1971. Last previous edition approved in 1999 as A 646 – 94 (1999).

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Society of Automotive Engineers, 400 Commonwealth Drive,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Warrendale, PA 15096.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 646/A 646M – 04

electroslag process has been produced shall have been either 5.1.1.3 Class III material shall be manufactured by the

melted unde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.