ASTM D3348-98(2003)e1

(Test Method)Standard Test Method for Rapid Field Test for Trace Lead In Unleaded Gasoline (Colorimetric Method)

Standard Test Method for Rapid Field Test for Trace Lead In Unleaded Gasoline (Colorimetric Method)

SIGNIFICANCE AND USE

This test is used to determine trace quantities of lead in unleaded gasoline. Unwarranted amounts of lead may cause deposits in automotive pollution control equipment and poisoning of catalytic mufflers.

SCOPE

1.1 This test method is intended for use in the field by nontechnical people for the quantitative measurement of lead in unleaded gasoline in the range from 0.01 to 0.10 g Pb/U.S. gal (2.64 to 26.4 mg Pb/L). This method applies to all commercial gasolines and responds to all types of lead alkyls as well as to other organic and inorganic forms of lead.

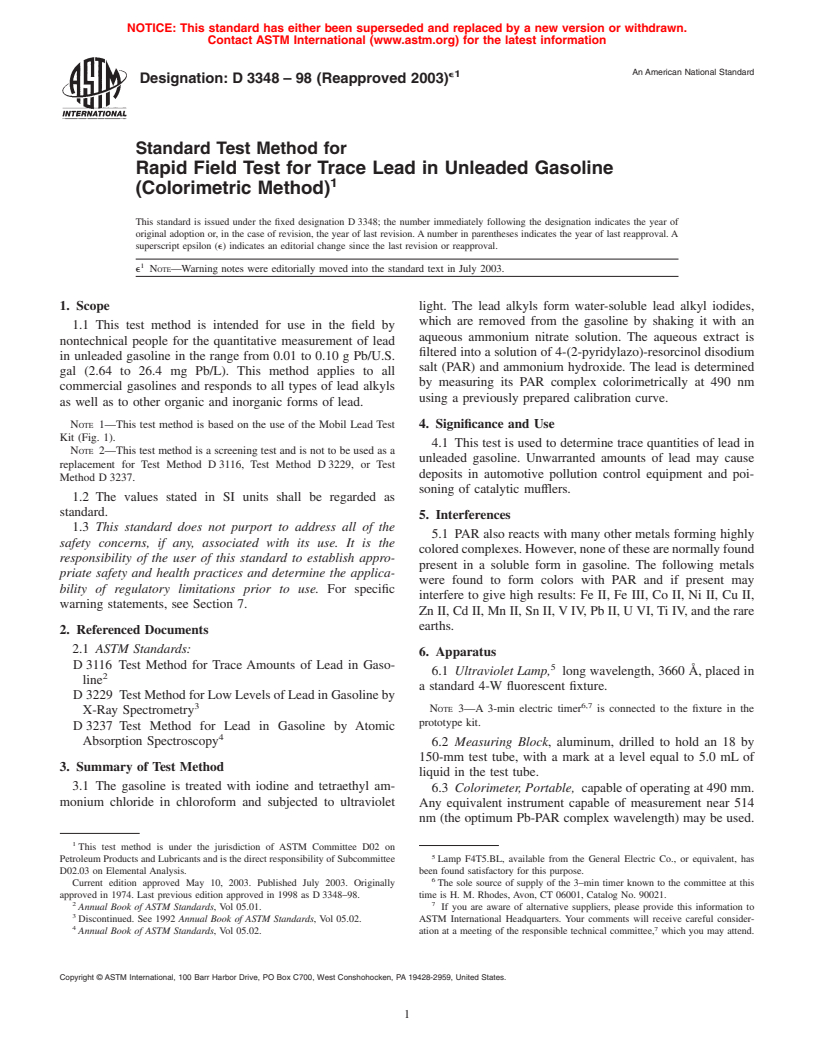

Note 1—This test method is based on the use of the Mobil Lead Test Kit (Fig. 1).

Note 2—This test method is a screening test and is not to be used as a replacement for Test Method D 3116, Test Method D 3229, or Test Method D 3237.

1.2 The values stated in SI units shall be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D3348–98 (Reapproved 2003)

Standard Test Method for

Rapid Field Test for Trace Lead in Unleaded Gasoline

(Colorimetric Method)

This standard is issued under the fixed designation D 3348; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were editorially moved into the standard text in July 2003.

1. Scope light. The lead alkyls form water-soluble lead alkyl iodides,

which are removed from the gasoline by shaking it with an

1.1 This test method is intended for use in the field by

aqueous ammonium nitrate solution. The aqueous extract is

nontechnical people for the quantitative measurement of lead

filtered into a solution of 4-(2-pyridylazo)-resorcinol disodium

in unleaded gasoline in the range from 0.01 to 0.10 g Pb/U.S.

salt (PAR) and ammonium hydroxide. The lead is determined

gal (2.64 to 26.4 mg Pb/L). This method applies to all

by measuring its PAR complex colorimetrically at 490 nm

commercial gasolines and responds to all types of lead alkyls

using a previously prepared calibration curve.

as well as to other organic and inorganic forms of lead.

NOTE 1—This test method is based on the use of the Mobil Lead Test 4. Significance and Use

Kit (Fig. 1).

4.1 This test is used to determine trace quantities of lead in

NOTE 2—This test method is a screening test and is not to be used as a

unleaded gasoline. Unwarranted amounts of lead may cause

replacement for Test Method D 3116, Test Method D 3229, or Test

deposits in automotive pollution control equipment and poi-

Method D 3237.

soning of catalytic mufflers.

1.2 The values stated in SI units shall be regarded as

standard.

5. Interferences

1.3 This standard does not purport to address all of the

5.1 PAR also reacts with many other metals forming highly

safety concerns, if any, associated with its use. It is the

coloredcomplexes.However,noneofthesearenormallyfound

responsibility of the user of this standard to establish appro-

present in a soluble form in gasoline. The following metals

priate safety and health practices and determine the applica-

were found to form colors with PAR and if present may

bility of regulatory limitations prior to use. For specific

interfere to give high results: Fe II, Fe III, Co II, Ni II, Cu II,

warning statements, see Section 7.

Zn II, Cd II, Mn II, Sn II, V IV, Pb II, U VI, Ti IV, and the rare

earths.

2. Referenced Documents

2.1 ASTM Standards:

6. Apparatus

D 3116 Test Method for Trace Amounts of Lead in Gaso-

6.1 Ultraviolet Lamp, long wavelength, 3660 Å, placed in

line

a standard 4-W fluorescent fixture.

D 3229 TestMethodforLowLevelsofLeadinGasolineby

,

6 7

NOTE 3—A 3-min electric timer is connected to the fixture in the

X-Ray Spectrometry

prototype kit.

D 3237 Test Method for Lead in Gasoline by Atomic

Absorption Spectroscopy

6.2 Measuring Block, aluminum, drilled to hold an 18 by

150-mm test tube, with a mark at a level equal to 5.0 mL of

3. Summary of Test Method

liquid in the test tube.

3.1 The gasoline is treated with iodine and tetraethyl am-

6.3 Colorimeter, Portable, capable of operating at 490 mm.

monium chloride in chloroform and subjected to ultraviolet

Any equivalent instrument capable of measurement near 514

nm (the optimum Pb-PAR complex wavelength) may be used.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Lamp F4T5.BL, available from the General Electric Co., or equivalent, has

D02.03 on Elemental Analysis. been found satisfactory for this purpose.

Current edition approved May 10, 2003. Published July 2003. Originally The sole source of supply of the 3–min timer known to the committee at this

approved in 1974. Last previous edition approved in 1998 as D 3348–98. time is H. M. Rhodes, Avon, CT 06001, Catalog No. 90021.

2 7

Annual Book of ASTM Standards, Vol 05.01. If you are aware of alternative suppliers, please provide this information to

Discontinued. See 1992 Annual Book of ASTM Standards, Vol 05.02. ASTM International Headquarters. Your comments will receive careful consider-

Annual Book of ASTM Standards, Vol 05.02. ation at a meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D3348–98 (2003)

FIG. 1 Mobil Lead Test Kit

,

7 8 10

6.4 Test Tubes, borosilicate, 18 by 150 mm. such specifications are available. Other grades may be used,

6.5 Pipets, glass, dropping, capable of delivering 2.0 mL provided it is first ascertained that the reagent is of sufficiently

with a 2-mLbulb. (Warning—Gasoline or any of the reagents high purity to permit its use without lessening the accuracy of

must not come in contact with rubber. If this happens, discard the determination.

the bulb and pipet and start again.) 7.2 Purity of Water—Unless otherwise indicated, reference

6.6 Funnel, plastic, 2 in. in inside diameter. towatershallbeunderstoodtomeandistilledwaterorwaterof

6.7 Filter Paper, ashless, hardened, smooth, very fast, 11.0 equal purity.

cm in diameter. 7.3 Ammonium Hydroxide (sp gr 0.90)—Concentrated am-

monium hydroxide (NH OH).

NOTE 4—Certain filter papers that would allow the organic layer

7.4 Ammonium Nitrate Solution (Reagent B)—Dissolve

(gasoline/chloroform) to filter through are not acceptable.

15.0 6 0.1 g of ammonium nitrate (NH NO ) in 750 mL of

4 3

6.8 Graduated Cylinder, plastic, 10-mL.

water in a 1-L volumetric flask. Dilute to the mark with water.

,

7 9

6.9 Glass Vials, with caps, disposable, 1-oz capacity.

7.5 Chloroform (CHCl )—(Warning—May be fatal if

swallowed. Harmful if inhaled. May produce toxic vapors if

7. Reagents

burned.Chronicorrepeatedexposurecancauseliverorkidney

7.1 Purity of Reagents—Reagent grade chemicals shall be

damage. Harmful if inhaled or swallowed. Carcinogen (animal

used in all tests. Unless otherwise indicated, it is intended that

positive). Skin and eye irritant. May produce toxic vapors if

all reagents conform to the specifications of the Committee on

burned. See A1.1.)

Analytical Reagents of theAmerican Chemical Society, where

Reagent Chemicals, American Chemical Society Specifications, American

The sole source of supply of the disposable culture tubes known to the Chemical Society, Washington, DC. For suggestions on the testing of reagents not

committee at this time is Sargent Welch Co., 35 SternAve., Springfield, NJ 07081, listed by the American Chemical Society, see Annual Standards for Laboratory

Catalog No. S-79523K. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Thesolesourceofsupplyoftheglassvialsknowntothecommitteeatthistime and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

is J. W. Wilson Glass Co., 501 S. ParkAve., Linden, NJ 07036, Catalog No. 60957. MD.

e1

D3348–98 (2003)

7.6 Disodium Salt of 4-(2-pyridylazo)-Resorcinol Dihydrate 8.1.4 Place a clean 18-mm test tube in the aluminum

(PAR·2H O) (Reagent C) —Dissolve 25.0 6 0.1 mg of PAR in measuring block. Add 5.0 mL of PAR solution (Reagent C) to

750 mLof water in a 1-Lvolumetric flask.Add 10.0 6 0.1 mL the test tube using the mark on the block such that the upper

of concentrated NH OH. Dilute to the mark with water. Store level of liquid in the tube is equal to the mark on the block.

this in brown bottles out of direct sunlight or in the dark. Place the plastic funnel in the test tube. Fold a piece of filter

(Warning—Low results are obtained if the monosodium or paper and place in the funnel.

unsalted PAR is used in this test. Field experience has shown

8.1.5 When the two layers of liquid in the vial have

that the PAR reagent can deteriorate within two to six months.

separated (8.1.3), pour the entire contents of the vial inside the

The PAR reagent should be tested by adding the reagent to a

filter paper. The aqueous layer will filter into the test tube; the

test tube and determining the percent transmittance. If the

gasoline/CHCl layer will remain in the filter paper. Tap the

percent transmittance is less than 80 %, the reagent should be

funnel to add any remaining drops of aqueous solution to the

discarded.)

test tube. Remove the funnel and discard its contents. Swirl the

7.7 Gasoline, Lead-Free—Gasoline containing less than

test tube gently using a wrist action to obtain a uniform color.

0.05 g Pb/gal (13.0 mg Pb/L). (Warning—Extremely flam-

NOTE 6—The lead-PAR complex formed in 8.1.5 must be measured

mable. Harmful if inhaled. Vapors may cause flash fire. See

within 10 min after starting 8.1.5.

A1.2.)

NOTE 7—Afew drops of the organic layer may come through the filter

7.8 Iodine.

paper. This will not alter the results and can therefore be tolerated.

7.9 Iodine/TEAC/CHCl Solution (Reagent A)—Dissolve

However, if more than 10 drops do come through, refilter the aqueous

1.000 g 6 1 mg of iodine in 75 mL of chloroform (CHCl)in

3 layer through a fr

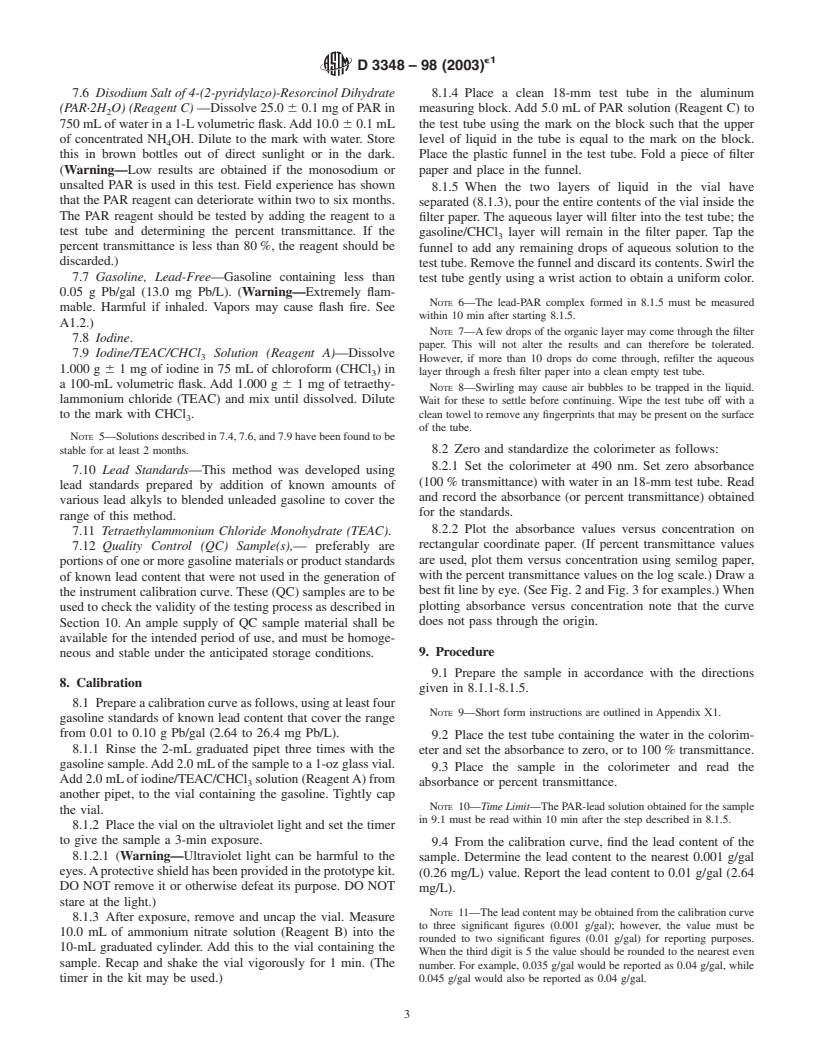

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.