ASTM A673/A673M-05

(Specification)Standard Specification for Sampling Procedure for Impact Testing of Structural Steel

Standard Specification for Sampling Procedure for Impact Testing of Structural Steel

SCOPE

1.1 This specification establishes the procedure for longitudinal Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as rolled, control rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide assurance all plates, bars, or shapes of the same heat as processed will be identical in toughness with the product tested. Normalizing or quenching and tempering the product will reduce the degree of variation.

1.2 This specification is intended to supplement specifications for structural steel when so specified.

1.3 This specification does not necessarily apply to all product specifications; therefore, the manufacturer or processor should be consulted for energy absorption levels and minimum testing temperatures that can be expected or supplied.

1.4 Two frequencies of testing (P and H) are prescribed.

1.5 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

American Association State Highway

Designation: A 673/A673M – 05 and Transportation Officials

Standard AASHTO No.: T 243

Standard Specification for

1

Sampling Procedure for Impact Testing of Structural Steel

This standard is issued under the fixed designationA673/A673M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. Ordering Information

1.1 This specification establishes the procedure for longitu- 3.1 The inquiry and order shall indicate the following:

dinal Charpy V-notch testing of structural steel and contains 3.1.1 Frequency of testing, (P) or (H),

two frequencies of testing. The impact properties of steel can 3.1.2 Test temperature (see 4.5 and 4.6),

vary within the same heat and piece, be it as rolled, control 3.1.3 Minimum average absorbed energy value (see 4.1 and

rolled, or heat treated. The purchaser should, therefore, be 4.6),

aware that testing of one plate, bar, or shape does not provide 3.1.4 Alternate core location (see 4.3), if applicable, and

assurance all plates, bars, or shapes of the same heat as 3.1.5 Condition (as-rolled, stress relieved, normalized, nor-

processed will be identical in toughness with the product malized and stress relieved, or quenched and tempered).

tested. Normalizing or quenching and tempering the product

4. Tests

will reduce the degree of variation.

1.2 This specification is intended to supplement specifica- 4.1 Impact testing shall be in accordance with Test Methods

and Definitions A 370. An impact test shall consist of testing

tions for structural steel when so specified.

1.3 This specification does not necessarily apply to all three specimens taken from a single test coupon or test

location, the average result of which shall be not less than the

productspecifications;therefore,themanufacturerorprocessor

should be consulted for energy absorption levels and minimum minimum average absorbed energy specified in the purchase

order, which in no case shall be less than 7 ft·lbf [10 J] for full

testing temperatures that can be expected or supplied.

1.4 Two frequencies of testing (P and H) are prescribed. size specimens.

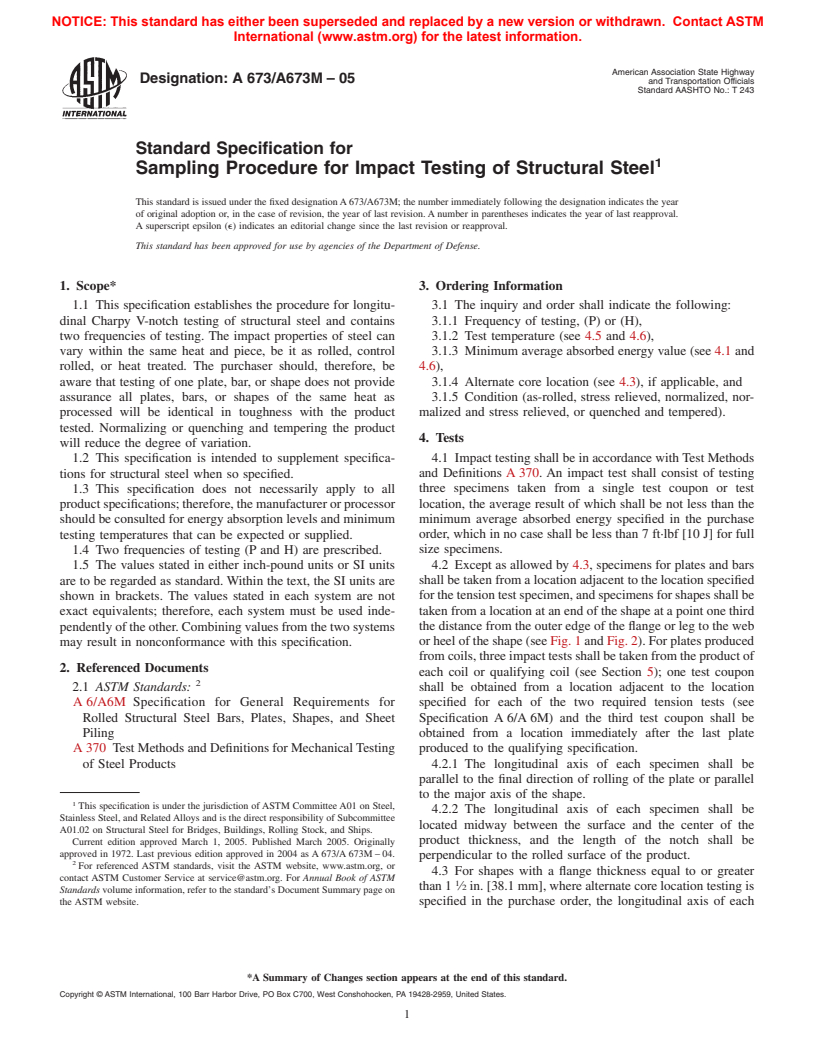

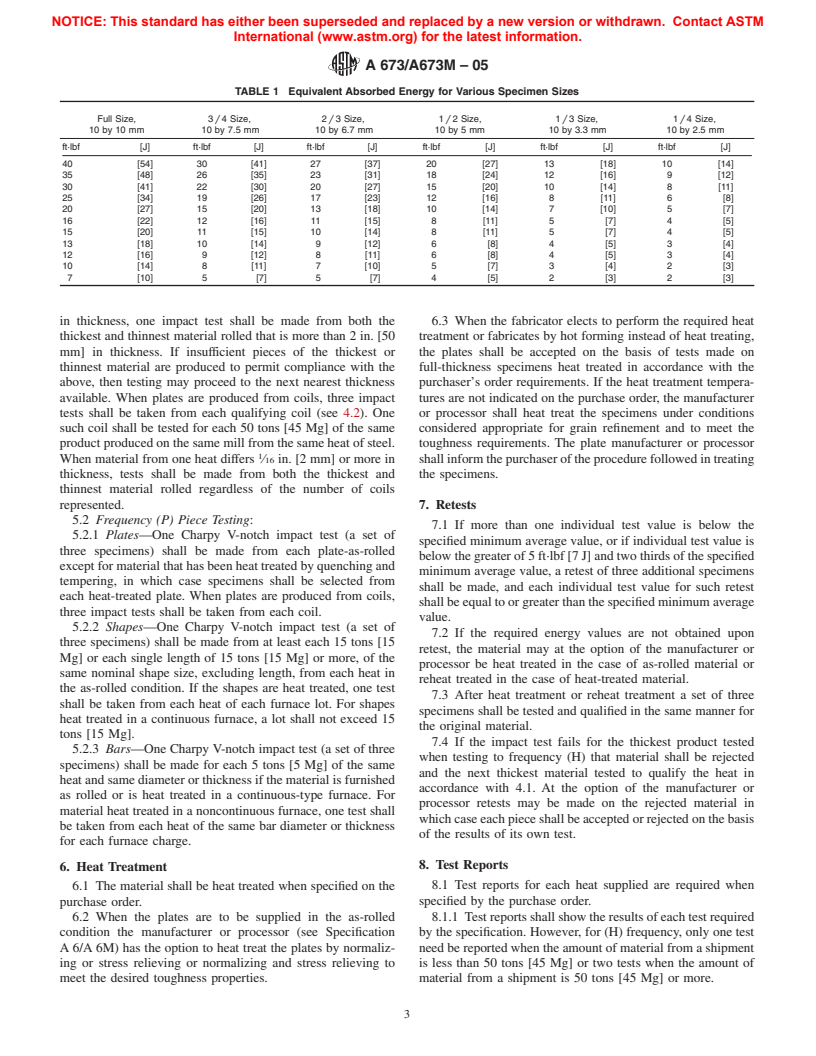

4.2 Except as allowed by 4.3, specimens for plates and bars

1.5 The values stated in either inch-pound units or SI units

shall be taken from a location adjacent to the location specified

are to be regarded as standard. Within the text, the SI units are

shown in brackets. The values stated in each system are not forthetensiontestspecimen,andspecimensforshapesshallbe

taken from a location at an end of the shape at a point one third

exact equivalents; therefore, each system must be used inde-

pendentlyoftheother.Combiningvaluesfromthetwosystems the distance from the outer edge of the flange or leg to the web

or heel of the shape (see Fig. 1 and Fig. 2). For plates produced

may result in nonconformance with this specification.

from coils, three impact tests shall be taken from the product of

2. Referenced Documents

each coil or qualifying coil (see Section 5); one test coupon

2

2.1 ASTM Standards: shall be obtained from a location adjacent to the location

A 6/A6M Specification for General Requirements for specified for each of the two required tension tests (see

Rolled Structural Steel Bars, Plates, Shapes, and Sheet Specification A 6/A 6M) and the third test coupon shall be

Piling obtained from a location immediately after the last plate

A 370 Test Methods and Definitions for MechanicalTesting produced to the qualifying specification.

of Steel Products 4.2.1 The longitudinal axis of each specimen shall be

parallel to the final direction of rolling of the plate or parallel

to the major axis of the shape.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.2.2 The longitudinal axis of each specimen shall be

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

located midway between the surface and the center of the

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships.

product thickness, and the length of the notch shall be

Current edition approved March 1, 2005. Published March 2005. Originally

approved in 1972. Last previous edition approved in 2004 as A 673/A 673M – 04.

perpendicular to the rolled surface of the product.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 For shapes with a flange thickness equal to or greater

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

than 1 ⁄2 in. [38.1 mm], where alternate core location testing i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.