ASTM C841-03(2013)

(Specification)Standard Specification for Installation of Interior Lathing and Furring

Standard Specification for Installation of Interior Lathing and Furring

ABSTRACT

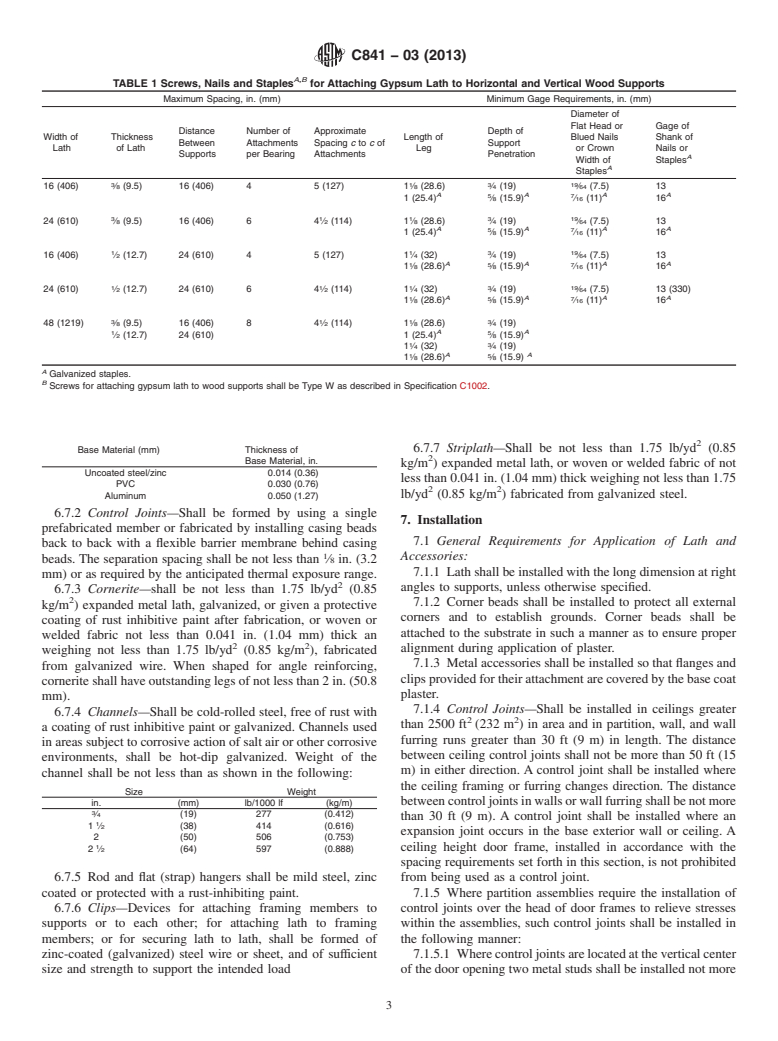

This specification covers the minimum requirements for, and the methods of application of, interior lathing and furring to receive gypsum plaster applied. Other materials are not prohibited from being used provided that their physical characteristics and durability under conditions of usage are at least equal in performance to those described. All materials shall be kept dry, preferably by being stored inside. Where necessary to be stored outside, materials shall be stacked off the ground, supported on a level platform, and protected from the weather and surface contamination. Materials shall be neatly stacked flat with care taken to avoid damage to edges, ends, or surfaces. The materials to be used are the following: tie wire and hanger wire, gypsum lath, expanded metal lath, welded wire lath, woven wire lath, nails, screws, staples, paper, and accessories such as control joints, cornerite, channels, rod and flat hangers, clips, and striplath. In general, during installation, the following shall be required: application of gypsum lath to supports, application of gypsum lath to wood supports, application of gypsum lath to metal supports, studless solid partitions (gypsum lath and plaster), application of metal plaster bases to framing members, studless solid partitions (metal lath and plaster), suspended and furred ceilings (metal lath and gypsum lath construction), main runners, cross furring, and metal furring for walls.

SCOPE

1.1 This specification covers the minimum requirements for, and the methods of application of, interior lathing and furring to receive gypsum plaster applied in accordance with Specification C842. Other materials are not prohibited from being used provided that their physical characteristics and durability under conditions of usage are at least equal in performance to those described.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Details of construction for a specific assembly to achieve the required fire resistance shall be obtained from reports of fire-resistance tests, engineering evaluations, or listings from recognized fire testing laboratories.

1.4 Where a specific degree of sound control is required for plastered assemblies and constructions, details of construction shall be obtained from reports of sound tests of assemblies that have met the requirements of Test Method E492.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C841 −03 (Reapproved 2013)

Standard Specification for

1

Installation of Interior Lathing and Furring

This standard is issued under the fixed designation C841; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C514 Specification for Nails for the Application of Gypsum

Board

1.1 Thisspecificationcoverstheminimumrequirementsfor,

C754 Specification for Installation of Steel Framing Mem-

and the methods of application of, interior lathing and furring

bers to Receive Screw-Attached Gypsum Panel Products

to receive gypsum plaster applied in accordance with Specifi-

C842 Specification forApplication of Interior Gypsum Plas-

cation C842. Other materials are not prohibited from being

ter

used provided that their physical characteristics and durability

C847 Specification for Metal Lath

under conditions of usage are at least equal in performance to

C933 Specification for Welded Wire Lath

those described.

C954 SpecificationforSteelDrillScrewsfortheApplication

1.2 The values stated in inch-pound units are to be regarded

of Gypsum Panel Products or Metal Plaster Bases to Steel

as standard. The values given in parentheses are mathematical

Studs from 0.033 in. (0.84 mm) to 0.112 in. (2.84 mm) in

conversions to SI units that are provided for information only

Thickness

and are not considered standard.

C1002 Specification for Steel Self-Piercing Tapping Screws

1.3 Details of construction for a specific assembly to for Application of Gypsum Panel Products or Metal

achieve the required fire resistance shall be obtained from

Plaster Bases to Wood Studs or Steel Studs

reports of fire-resistance tests, engineering evaluations, or

C1007 Specification for Installation of Load Bearing (Trans-

listings from recognized fire testing laboratories.

verse and Axial) Steel Studs and Related Accessories

C1032 Specification for Woven Wire Plaster Base

1.4 Where a specific degree of sound control is required for

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

plastered assemblies and constructions, details of construction

Compounds and Chlorinated Poly(Vinyl Chloride)

shall be obtained from reports of sound tests of assemblies that

(CPVC) Compounds

have met the requirements of Test Method E492.

D3678 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Interior-Profile Extrusions

2. Referenced Documents

E492 Test Method for Laboratory Measurement of Impact

2

2.1 ASTM Standards:

Sound Transmission Through Floor-Ceiling Assemblies

A641/A641M Specification for Zinc–Coated (Galvanized)

Using the Tapping Machine

Carbon Steel Wire

2.2 National Association of Architectural Metal Manufac-

C11 Terminology Relating to Gypsum and Related Building

turers Standard

Materials and Systems

HMMA 840 Installation and Storage of Hollow Metal Doors

C37/C37M Specification for Gypsum Lath (Withdrawn

4

3

and Frames

2004)

3. Terminology

1

This specification is under the jurisdiction of ASTM Committee C11 on

3.1 Definitions—For definitions relating to ceilings and

Gypsum and Related Building Materials and Systems and is the direct responsibility

walls see Terminology C11.

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther

3.2 Definitions of Terms Specific to This Standard:

Products in Assemblies.

Current edition approved Oct. 1, 2013. Published October 2013. Originally

3.2.1 base coat, n—the sum of the scratch and brown coats

approved in 1976. Last previous edition approved in 2008 as C841 – 03 (2008)ε1.

or the total coats in place prior to application of finish coats.

DOI: 10.1520/C0841-03R13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Available from National Association of Architectural Metal Manufacturers

3

The last approved version of this historical standard is referenced on (NAAMM), 800 Roosevelt Road, Bldg. C, Suite 312, Glen Ellyn, IL 60137,

www.astm.org. http://www.naamm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C841−03 (2013)

3.2.2 contact ceiling, n—a ceiling in which the lath is

Wire Gage (U.S. Steel

A

Diameter, in. (mm) Wire Gage)

attached in direct contact with the construction above, without

0.0800 (2.03) No. 14

the use of main runners or cros

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.