ASTM F2321-03

(Specification)Standard Specification for Flexible Insulated Temporary By-Pass Jumpers

Standard Specification for Flexible Insulated Temporary By-Pass Jumpers

SCOPE

1.1 These specifications cover the equipment making up the flexible insulated temporary bypass jumpers (bypass jumpers) used on energized power lines and equipment.

1.2 It is common practice for the user of this protective equipment to prepare complete instructions and safety regulations to govern in detail the correct and safe use of such equipment.

1.3 The use and maintenance of this equipment are beyond the scope of these specifications.

1.4 These specifications for a system of bypass jumpers is covered in four parts as follows:TitleSectionsClamps for Bypass JumpersFerrules for Bypass JumpersCable for Bypass JumpersBypass Jumpers (complete assemblywith clamps, ferrules, and cable)

1.5 Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification.

1.6 The values stated in SI units are to be regarded as the standard. See ASTM SI 10.

1.7 The following precautionary caveat pertains only to the test method portions, Sections 13, 26, and of these specifications.This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2321 – 03

Standard Specification for

Flexible Insulated Temporary By-Pass Jumpers

This standard is issued under the fixed designation F 2321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 173 Specification for Rope-Lay-Stranded Copper Con-

ductors Having Concentric-Stranded Members, for Elec-

1.1 These specifications cover the equipment making up the

trical Conductors

flexible insulated temporary bypass jumpers (bypass jumpers)

D 2768 Specification for General-Purpose Ethylene-

used on energized power lines and equipment.

Propylene Rubber Jacket for Wire and Cable

1.2 It is common practice for the user of this protective

D 2770 Specification for Ozone-Resisting Ethylene-

equipment to prepare complete instructions and safety regula-

Propylene Rubber Integral Insulation and Jacket for Wire

tions to govern in detail the correct and safe use of such

and Cable

equipment.

E 8 Test Methods for Tension Testing of Metallic Materials

1.3 The use and maintenance of this equipment are beyond

F 819 Terminology Relating to Electrical Protective Equip-

the scope of these specifications.

ment for Workers

1.4 These specifications for a system of bypass jumpers is

SI 10 Practice for Use of the International System of Units

covered in four parts as follows:

(SI) (the Modernized Metric System)

Title Sections

2.2 ANSI Standard:

Clamps for Bypass Jumpers 5-17

Ferrules for Bypass Jumpers 18-31

ANSI C119.4 American National Standard for Electrical

Cable for Bypass Jumpers 32-40

Connectors

Bypass Jumpers (complete assembly 41-53

with clamps, ferrules, and cable) 2.3 NEMA Standard:

WC 8 Ethylene-Propylene-Rubber Insulated Wire and

1.5 Each of the four parts is an entity of itself, but is listed

Cable for the Transmission and Distribution of Electrical

as a part of the system for completeness and clarification.

Energy (formerly ICEA S-68-516)

1.6 The values stated in SI units are to be regarded as the

standard. See ASTM SI 10.

3. Terminology

1.7 The following precautionary caveat pertains only to the

3.1 Definitions:

test method portions, Sections 13, 26, and 48 of these specifi-

3.1.1 flexible insulated temporary bypass jumpers—devices

cations. This standard does not purport to address all of the

designed and used to keep electric supply circuits effectively

safety concerns, if any, associated with its use. It is the

continuous (electrically bridged) for short periods of time at

responsibility of the user of this standard to establish appro-

work locations when conductors or equipment may otherwise

priate safety and health practices and determine the applica-

be opened or made electrically discontinuous during work

bility of regulatory requirements prior to use.

operations.

3.1.1.1 Discussion—The devices are normally installed,

2. Referenced Documents

used, and removed as part of a protective insulating system

2.1 ASTM Standards:

composed of insulating covers and/or observances of required

B 172 Specification for Rope-Lay-Stranded Copper Con-

minimum safe approach distances for workers.

ductors Having Bunch-Stranded Members, for Electric

3.2 For definitions of other terms, refer to Terminology

Conductors

F 819.

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.45 on Mechanical Equipment.

Current edition approved Nov. 1, 2003. Published January 2004.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from National Electrical Manufacturers Association (NEMA), 1300

the ASTM website. N. 17th St., Suite 1847, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2321–03

4. Significance and Use

4.1 These specifications cover the minimum electrical and

physical properties designated by the manufacturer and the

detailed procedures by which such properties are to be deter-

mined. The purchaser may at his option perform or have

performed any of these tests in order to verify the manufactur-

er’sdesignation.Claimsforfailuretomeetthespecificationare

subject to verification by the manufacturer.

4.2 Bypass jumpers are devices designed and used to keep

electrical circuits effectively continuous (electrically bridged)

for short periods of time at work locations when conductors or

equipment may otherwise be opened or made discontinuous

during work operations. Bypass jumpers are insulated to

temporarily protect personnel from brush or accidental contact

only; therefore, when authorizing their use, a margin of safety

should be provided between the maximum voltage used on,

and the proof-test voltage at which they are tested. The

relationship between proof-test voltage and the maximum

FIG.1StyleIClamp

voltage at which bypass jumpers are used is shown in Table 1.

Warning—Portions of these devices (clamps and ferrules) are

not insulated and offer no protection from accidental contact.

CLAMPS FOR BYPASS JUMPERS

5. Scope

5.1 Thisspecificationcoversclampsusedintheassemblyof

bypass jumpers.

6. Classification

6.1 Clamps are furnished in, but not limited to, two styles

according to their function and method of installation.

6.1.1 Style I—Clamps equipped with insulated handles for

installation on energized conductors with rubber gloves. See

Fig. 1.

6.1.1.1 Insulated handles may be either clear or opaque.

6.1.1.2 Insulating materials used in this specification in-

FIG. 2 Style II “C” Shape Clamp

clude thermo-set plastic, elastomers, elastomer compounds,

thermoplastic polymers or any combination, regardless of

origin.

7. Sizes

6.1.2 Style II—Clamps equipped with eyes for installation

7.1 Clamp size is the combination of the main contact and

on energized conductors with live line tools. See Figs. 2-4.

cable size ranges as listed by the manufacturers.

6.1.2.1 Clamps are furnished according to mechanical

strength and current rating. See Table 2.

6.2 Clamps are furnished in two classes according to the 8. Ordering Information

characteristics of the main contact jaws.

8.1 Orders for clamps under this specification shall include

6.2.1 Class A—Clamp jaws with smooth contact surfaces.

this ASTM designation and the following information:

6.2.2 Class B—Clamp jaws with serrations, crosshatching

8.1.1 Quantity,

or other means intended to abrade or bite through corrosion

8.1.2 Name (Bypass Jumper Clamp),

products on the surface of the conductor being clamped.

8.1.3 Main contact size ranges, conductor descriptions, and

type of materials which are to be clamped,

TABLE 1 Proof Test/Use Voltage Relationship

8.1.4 Cable size, material, and description by which clamps

Maximum Nominal AC Proof DC Proof

are to be assembled,

Voltage

Use Voltage Test Voltage Test Voltage

Rating

(rms) V (rms) V (avg) V 8.1.5 Style (see 6.1),

15 kV 15 000 20 000 50 000 8.1.6 Class (see 6.2), and

25 kV 25 000 30 000 60 000

8.1.7 Clamps for bypass jumpers, at the customer’s request,

35 kV 35 000 40 000 70 000

shall meet ANSI C119.4.

F2321–03

accordance with Test Methods E 8.

10. Electrical and Mechanical Properties

10.1 Materials used shall meet the requirements of 9.1.

10.2 Electrical and mechanical properties shall conform to

the requirements prescribed in Tables 1-3 and with the follow-

ing:

10.2.1 Clamps shall accept hand assembly of all cables

fitted with compatible ferrules as rated per Table 2.

10.2.2 Main contacts shall accept and clamp all conductors

according to the manufacturer’s recommendation.

10.2.3 Style II clamps shall have the following properties:

10.2.3.1 In the event the clamp is over-torqued during

installation, normal fracture shall be such that the attached

cableremainsundercontrolbybeingretainedwiththeliveline

tool. Clamps with an ultimate torque strength exceeding 45

N-m (400 lbf in.) are exempt from this provision.

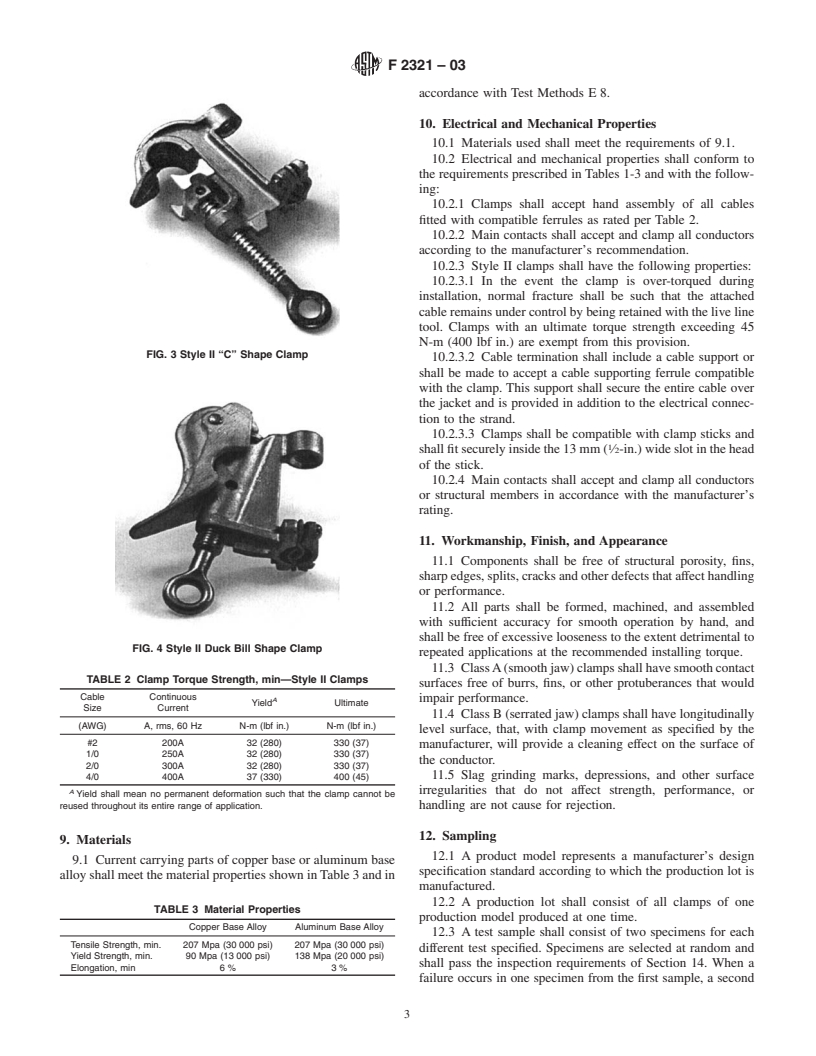

FIG. 3 Style II “C” Shape Clamp

10.2.3.2 Cable termination shall include a cable support or

shall be made to accept a cable supporting ferrule compatible

with the clamp. This support shall secure the entire cable over

the jacket and is provided in addition to the electrical connec-

tion to the strand.

10.2.3.3 Clamps shall be compatible with clamp sticks and

shallfitsecurelyinsidethe13mm( ⁄2-in.)wideslotinthehead

of the stick.

10.2.4 Main contacts shall accept and clamp all conductors

or structural members in accordance with the manufacturer’s

rating.

11. Workmanship, Finish, and Appearance

11.1 Components shall be free of structural porosity, fins,

sharpedges,splits,cracksandotherdefectsthataffecthandling

or performance.

11.2 All parts shall be formed, machined, and assembled

with sufficient accuracy for smooth operation by hand, and

shall be free of excessive looseness to the extent detrimental to

FIG. 4 Style II Duck Bill Shape Clamp

repeated applications at the recommended installing torque.

11.3 ClassA(smoothjaw)clampsshallhavesmoothcontact

TABLE 2 Clamp Torque Strength, min—Style II Clamps

surfaces free of burrs, fins, or other protuberances that would

Cable Continuous

A impair performance.

Yield Ultimate

Size Current

11.4 Class B (serrated jaw) clamps shall have longitudinally

(AWG) A, rms, 60 Hz N-m (lbf in.) N-m (lbf in.)

level surface, that, with clamp movement as specified by the

#2 200A 32 (280) 330 (37)

manufacturer, will provide a cleaning effect on the surface of

1/0 250A 32 (280) 330 (37)

the conductor.

2/0 300A 32 (280) 330 (37)

11.5 Slag grinding marks, depressions, and other surface

4/0 400A 37 (330) 400 (45)

A irregularities that do not affect strength, performance, or

Yield shall mean no permanent deformation such that the clamp cannot be

reused throughout its entire range of application.

handling are not cause for rejection.

12. Sampling

9. Materials

12.1 A product model represents a manufacturer’s design

9.1 Current carrying parts of copper base or aluminum base

specification standard according to which the production lot is

alloyshallmeetthematerialpropertiesshowninTable3andin

manufactured.

12.2 A production lot shall consist of all clamps of one

TABLE 3 Material Properties

production model produced at one time.

Copper Base Alloy Aluminum Base Alloy

12.3 A test sample shall consist of two specimens for each

Tensile Strength, min. 207 Mpa (30 000 psi) 207 Mpa (30 000 psi)

different test specified. Specimens are selected at random and

Yield Strength, min. 90 Mpa (13 000 psi) 138 Mpa (20 000 psi)

shall pass the inspection requirements of Section 14. When a

Elongation, min 6 % 3 %

failure occurs in one specimen from the first sample, a second

F2321–03

sample from the same lot shall be selected and tested. If the tested, and inspected in accordance with this specification and

second sample (two specimens) passes, the lot shall be ac- have been found to meet the requirements. When specified in

cepted. If one specimen from the second sample fails, the lot the purchase order or contract, a report of design test shall be

shall be rejected. furnished.

13. Design Tests

17. Packaging and Package Marking

13.1 The design tests that follow shall be made on test 17.1 Clamps shall be marked with the name or logo of the

samples of each product model to verify that the requirements

manufacturer, identity number, and date code to indicate year

of this specification are met. of manufacture.

13.2 Mechanical Torque Strength:

17.2 Apacking list indicating manufacturer’s product num-

13.2.1 Install the clamp on the main conductor of the bers and quantities of each different clamp shall be provided

minimum and maximum size for which the clamp is rated and with each shipment.

apply torsion force to the main screw. Force may be applied to 17.3 Each shipment shall be packaged to provide protection

other devices designed to secure the clamp on the conductor. of the contents appropriate for the mode of transportation.

13.2.2 Measure torque by a torque wrench that indicates

CABLE FERRULES FOR BYPASS JUMPERS

torque directly or by other manner easily convertible.

13.2.3 The main conductor is defined as the material(s) on

18. Scope

which the clamp is rated to be used.

18.1 This specification covers ferrules used with bypass

13.2.4 Yield and ultimate strength shall equal or exceed the

jumpers.

values shown in Table 2.

18.2 Two styles of ferrules are available and are designated

13.3 Continuous Current Rating:

as shrouded or unshrouded.

13.3.1 Test the clamp at the continuous current level for

which it is rated. The temperature shall be measured at the

19. Classification

warmest spot on clamp and on the metal strand at the midpoint

19.1 Ferrules are furnished in four types as follows:

of an attached cable, which is a minimum of 1.5 m (5 ft.) in

19.1.1 Type I—Compression ferrule is cylindrical and made

length. The maximum temperature of the clamp shall be lower

for installation on cable stranding by compression.

than the midpoint temperature of the maximum size copper

19.1.2 Type III—Plain stud-shrouded compression ferrule

main or tap cable for which the clamp is rated.

has a stepped bore that accepts entire cable and jacket. (See

14. Inspection and Product Testing

Fig. 5.)

19.1.3 Type IV—Threaded stud shrouded compression fer-

14.1 The clamps shall be inspected and tested as follows:

rulehasasteppedborethatacceptsentirecableoverjacketand

14.1.1 Verification of the main contact and cable capacities

has male threads at forward end. (See Fig. 6.)

are in accordance with 10.2.2 and 10.2.3.

19.1.4 Type VI—Threaded stud compression ferrule has

14.1.2 Visualinspectionandhandoperationshallbedoneto

male threads at forward end. (See Fig. 7.)

verify workmanship, finish, and appearance, which shall be in

accordance with Section 11.

20. Size

14.1.3 Torque test on a test sample shall be in accordance

20.1 Ferrule size is the combination of cable capacity, stud

with 13.2.

description, and size after installation of cable.

15. Acceptance, Rejection and Rehearing

21. Ordering Information

15.1 At the option of the purchaser, a production lot may be

21.1 Orders for ferrules under this specification should

subjected to the following:

include thisASTM designation and the following information:

15.1.1 Inspection in accordance with 14.1 for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.