ASTM E452-02(2007)

(Test Method)Standard Test Method for Calibration of Refractory Metal Thermocouples Using a Radiation Thermometer

Standard Test Method for Calibration of Refractory Metal Thermocouples Using a Radiation Thermometer

SIGNIFICANCE AND USE

This test method is intended to be used by wire producers and thermocouple manufacturers for certification of refractory metal thermocouples. It is intended to provide a consistent method for calibration of refractory metal thermocouples referenced to a calibrated radiation thermometer. Uncertainty in calibration and operation of the radiation thermometer, and proper construction and use of the test furnace are of primary importance.

Calibration establishes the temperature-emf relationship for a particular thermocouple under a specific temperature and chemical environment. However, during high temperature calibration or application at elevated temperatures in vacuum, oxidizing, reducing or contaminating environments, and depending on temperature distribution, local irreversible changes may occur in the Seebeck Coefficient of one or both thermoelements. If the introduced inhomogeneities are significant, the emf from the thermocouple will depend on the distribution of temperature between the measuring and reference junctions.

At high temperatures, the accuracy of refractory metal thermocouples may be limited by electrical shunting errors through the ceramic insulators of the thermocouple assembly. This effect may be reduced by careful choice of the insulator material, but above approximately 2100 °C, the electrical shunting errors may be significant even for the best insulators available.

SCOPE

1.1 This test method covers the calibration of refractory metal thermocouples using a radiation thermometer as the standard instrument. This test method is intended for use with types of thermocouples that cannot be exposed to an oxidizing atmosphere. These procedures are appropriate for thermocouple calibrations at temperatures above 800 °C (1472 °F).

1.2 The calibration method is applicable to the following thermocouple assemblies:

1.2.1 Type 1 - Bare-wire thermocouple assemblies in which vacuum or an inert or reducing gas is the only electrical insulating medium between the thermoelements.

1.2.2 Type 2 - Assemblies in which loose fitting ceramic insulating pieces, such as single-bore or double-bore tubes, are placed over the thermoelements.

1.2.3 Type 2A - Assemblies in which loose fitting ceramic insulating pieces, such as single-bore or double-bore tubes, are placed over the thermoelements, permanently enclosed and sealed in a loose fitting metal or ceramic tube.

1.2.4 Type 3 - Swaged assemblies in which a refractory insulating powder is compressed around the thermoelements and encased in a thin-walled tube or sheath made of a high melting point metal or alloy.

1.2.5 Type 4 - Thermocouple assemblies in which one thermoelement is in the shape of a closed-end protection tube and the other thermoelement is a solid wire or rod that is coaxially supported inside the closed-end tube. The space between the two thermoelements can be filled with an inert or reducing gas, or with ceramic insulating materials, or kept under vacuum.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E452 − 02(Reapproved 2007)

Standard Test Method for

Calibration of Refractory Metal Thermocouples Using a

Radiation Thermometer

This standard is issued under the fixed designation E452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the calibration of refractory

E344Terminology Relating to Thermometry and Hydrom-

metal thermocouples using a radiation thermometer as the

etry

standard instrument. This test method is intended for use with

E563Practice for Preparation and Use of an Ice-Point Bath

types of thermocouples that cannot be exposed to an oxidizing

as a Reference Temperature

atmosphere. These procedures are appropriate for thermo-

E988Temperature-Electromotive Force (EMF) Tables for

couple calibrations at temperatures above 800°C (1472°F).

Tungsten-Rhenium Thermocouples (Withdrawn 2011)

1.2 The calibration method is applicable to the following

E1256Test Methods for Radiation Thermometers (Single

thermocouple assemblies:

Waveband Type)

1.2.1 Type 1—Bare-wire thermocouple assemblies in which

E1751Guide for Temperature Electromotive Force (EMF)

vacuum or an inert or reducing gas is the only electrical

Tables for Non-Letter Designated Thermocouple Combi-

insulating medium between the thermoelements. 3

nations (Withdrawn 2009)

1.2.2 Type 2—Assemblies in which loose fitting ceramic

3. Terminology

insulatingpieces,suchassingle-boreordouble-boretubes,are

placed over the thermoelements.

3.1 Definitions:

1.2.3 Type 2A—Assemblies in which loose fitting ceramic

3.1.1 For definitions of terms used in this test method see

insulatingpieces,suchassingle-boreordouble-boretubes,are

Terminology E344.

placed over the thermoelements, permanently enclosed and

3.1.2 radiation thermometer, n—radiometer calibrated to

sealed in a loose fitting metal or ceramic tube.

indicate the temperature of a blackbody.

1.2.4 Type 3—Swaged assemblies in which a refractory

3.1.2.1 Discussion—Radiationthermometersincludeinstru-

insulating powder is compressed around the thermoelements

ments having the following or similar names: (1) optical

and encased in a thin-walled tube or sheath made of a high

radiation thermometer, (2) photoelectric pyrometer, ( 3) single

melting point metal or alloy.

wavelength automatic thermometer, (4) disappearing filament

1.2.5 Type 4—Thermocouple assemblies in which one ther- pyrometer, (5) dual wavelength pyrometer or ratio radiation

moelement is in the shape of a closed-end protection tube and thermometer, (6) visual optical thermometer, (7) infrared

the other thermoelement is a solid wire or rod that is coaxially thermometer, (8) infrared pyrometer, and permutations on the

supported inside the closed-end tube. The space between the terms above as well as some manufacturer-specific names.

twothermoelementscanbefilledwithaninertorreducinggas,

3.2 Definitions of Terms Specific to This Standard:

or with ceramic insulating materials, or kept under vacuum.

3.2.1 automatic radiation thermometer, n— radiation ther-

1.3 This standard does not purport to address all of the

mometer whose temperature reading is determined by elec-

safety concerns, if any, associated with its use. It is the tronic means.

responsibility of the user of this standard to establish appro-

3.2.2 disappearing filament pyrometer, n— radiation ther-

priate safety and health practices and determine the applica-

mometer that requires an observer to match visually the

bility of regulatory limitations prior to use.

brightness of a heated filament mounted inside the radiation

thermometer to that of the measured object.

1 2

This test method is under the jurisdiction of ASTM Committee E20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Temperature Measurementand is the direct responsibility of Subcommittee E20.04 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Thermocouples. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2007. Published June 2007. Originally the ASTM website.

approved in 1972. Last previous edition approved in 2002 as E452–02. DOI: The last approved version of this historical standard is referenced on

10.1520/E0452-02R07. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E452 − 02 (2007)

3.2.3 equalizing block, n—object, usually metal, that when 5. Significance and Use

placed in a nonuniform temperature region, has greater tem-

5.1 This test method is intended to be used by wire

perature uniformity (due to its relatively high thermoconduc-

producers and thermocouple manufacturers for certification of

tivity and mass) than the medium surrounding the object.

refractory metal thermocouples. It is intended to provide a

3.2.4 spectral emissivity, n—ratio of the spectral radiance at consistent method for calibration of refractory metal thermo-

a point on a particular specimen and in a particular direction couples referenced to a calibrated radiation thermometer.

from that point to that emitted by a blackbody at the same Uncertainty in calibration and operation of the radiation

temperature. thermometer, and proper construction and use of the test

furnace are of primary importance.

3.2.5 spectral radiance, n—powerradiatedbyaspecimenin

a particular direction, per unit wavelength, per unit projected 5.2 Calibration establishes the temperature-emf relationship

area of the specimen, and per unit solid angle. for a particular thermocouple under a specific temperature and

chemical environment. However, during high temperature

3.2.6 spectral response, n—signal detected by a radiometer

calibration or application at elevated temperatures in vacuum,

at a particular wavelength of incident radiation, per unit power

oxidizing, reducing or contaminating environments, and de-

of incident radiation.

pending on temperature distribution, local irreversible changes

3.2.7 test thermocouple, n—thermocouple that is to have its

may occur in the Seebeck Coefficient of one or both thermo-

temperature-emf relationship determined by reference to a

elements.Iftheintroducedinhomogeneitiesaresignificant,the

temperature standard.

emf from the thermocouple will depend on the distribution of

3.2.8 thermocouple calibration point, n— temperature, es- temperature between the measuring and reference junctions.

tablished by a standard, at which the emf developed by a

5.3 At high temperatures, the accuracy of refractory metal

thermocouple is determined.

thermocouples may be limited by electrical shunting errors

through the ceramic insulators of the thermocouple assembly.

4. Summary of Test Method

This effect may be reduced by careful choice of the insulator

material, but above approximately 2100°C, the electrical

4.1 The thermocouple is calibrated by determining the

shunting errors may be significant even for the best insulators

temperature of its measuring junction with a radiation ther-

available.

mometer and recording the emf of the thermocouple at that

temperature. The measuring junction of the thermocouple is

6. Sources of Error

placed in an equalizing block containing a cavity which

6.1 The most prevalent sources of error (Note 2) in this

approximates blackbody conditions. The radiation thermom-

eter is sighted on the cavity in the equalizing block and the method of calibration are: (1) improper design of the black-

bodyenclosure,(2)severetemperaturegradientsinthevicinity

blackbody temperature or true temperature of the block,

including the measuring junction, is determined. of the blackbody enclosure, ( 3) heat conduction losses along

the thermoelements, and ( 4) improper alignment of the

4.2 Since the spectral emissivity of the radiation emanating

radiationthermometerwithrespecttotheblackbodycavityand

from a properly designed blackbody is considered unity (one)

unaccounted transmission losses along the optical path of the

for all practical purposes, no spectral emissivity corrections

radiation thermometer.

need be applied to optical pyrometer determinations of the

NOTE 2—These are exclusive of any errors that are made in the

blackbody temperature.

radiation thermometer measurements or the thermocouple-emf measure-

4.3 Although the use of a radiation thermometer (Note 1)is

ments.

less may require more effort and more complex apparatus to

achieve a sensitivity equivalent to that of commonly used 7. Apparatus

thermocouples, a radiation thermometer has the advantage of

7.1 Furnace:

being physically separated from the test assembly; thus, its

7.1.1 Thecalibrationfurnaceshouldbedesignedsothatany

calibration is not influenced by the temperatures and atmo-

temperature within the desired calibration temperature range

spheres in the test chamber. By comparison, a standard

can be maintained constant within a maximum change of 1°C

thermocouple that is used to calibrate another thermocouple

(1.8°F) per minute in the equalizing block over the period of

mustbesubjectedtothetemperaturesatwhichthecalibrations

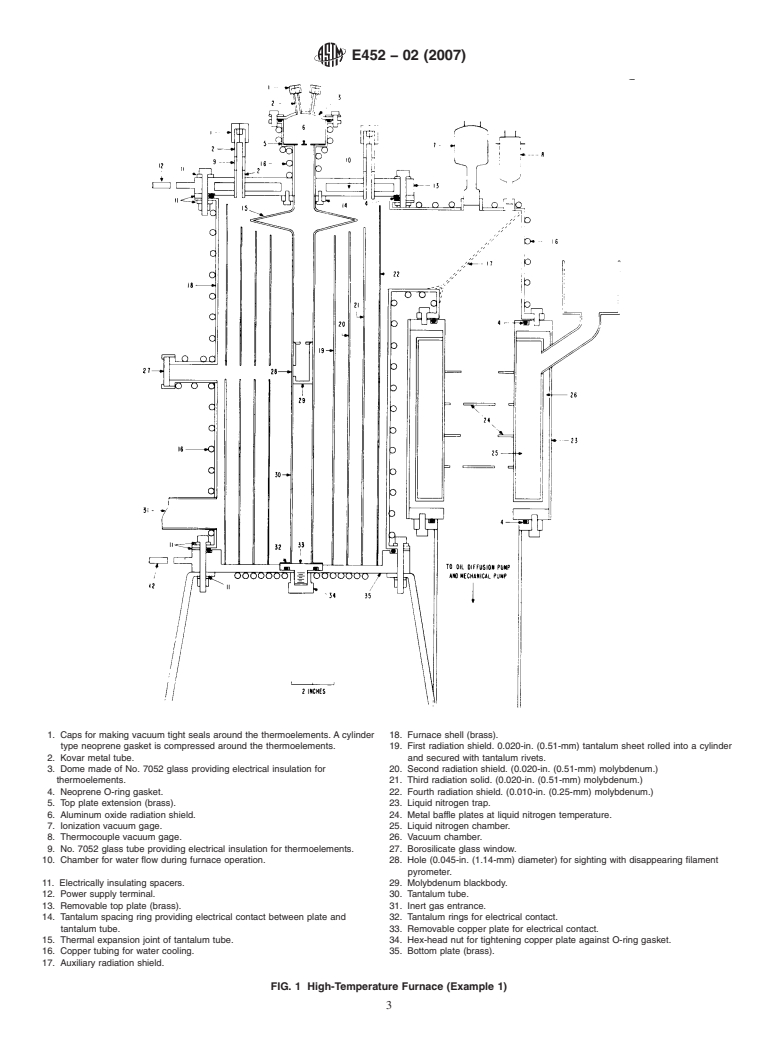

any observation. Figs. 1-3 show three types of furnaces (1 and

are performed and in some cases must be exposed to the 4

2) that can be used for calibrating refractory-metal thermo-

environment that is common to the test thermocouple. If a

couples.Fig.4isadetaileddrawingoftheuppersectionofthe

standard thermocouple is exposed to high temperatures or

furnace in Fig. 3.An equalizing block containing a blackbody

contaminating environments, or both, for long periods of time,

cavity is suspended in the central region of the furnace by

its calibration becomes questionable and the uncertainty in the

means of support rods or wires. The mass of the support rods

bias of the calibration increases.

or wires should be kept to a minimum to reduce heat losses by

conduction. When the furnace is in operation, a sufficiently

NOTE1—Disappearingfilamentpyrometersaresomewhatlesssensitive

than many of the thermocouples used above 800°C (1472°F). The

advantages of physical separation of the disappearing filament pyrometer

from the test assembly may still justify its use over use of a standard Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

thermocouple. this standard.

E452 − 02 (2007)

1. Caps for making vacuum tight seals around the thermoelements. A cylinder 18. Furnace shell (brass).

type neoprene gasket is compressed around the thermoelements. 19. First radiation shield. 0.020-in. (0.51-mm) tantalum sheet rolled into a cylinder

2. Kovar metal tube. and secured with tantalum rivets.

3. Dome made of No. 7052 glass providing electrical insulation for 20. Second radiation shield. (0.020-in. (0.51-mm) molybdenum.)

thermoelements. 21. Third radiation solid. (0.020-in. (0.51-mm) molybdenum.)

4. Neoprene O-ring gasket. 22. Fourth radiation shield. (0.010-in. (0.25-mm) molybdenum.)

5. Top plate extension (brass). 23. Liquid nitrogen trap.

6. Aluminum oxide radiation shield. 24. Metal baffle plates at liquid nitrogen temperature.

7. Ionization vacuum gage. 25. Liquid nitrogen chamber.

8. Thermocouple vacuum gage. 26. Vacuum chamber.

9. No. 7052 glass tube providing electrical insulation for thermoelements. 27. Borosilicate glass window.

10. Chamber for water flow during furnace operation. 28. Hole (0.045-in. (1.14-mm) diameter) for sighting with disappearing filament

pyrometer.

11. Electrically insulating spacers. 29. Molybdenum blackbody.

12. Power supply terminal. 30. Tantalum tube.

13. Removable top plate (brass). 31. Inert gas entrance.

14. Tantalum spacing ring providing electrical contact between plate and 32. Tantalum rings for electrical contact.

tantalum tube. 33. Removable copper plate for electrical contact.

15. Thermal expansion joint of tantalum tube. 34. Hex-head nut for tightening copper plate against O-ring gasket.

16. Copper tubing for water cooling. 35. Bottom plate (brass).

17. Auxiliary radiation shield.

FIG. 1 High-Temperature Furnace (Example 1)

E452 − 02 (2007)

(a) Nylon bushing, ( b) stainless steel support, (c) rectangular stainless steel shutter, (d) borosilicate glass window, (e) brass shutter support, ( f) shutter rotation

mechanism,(g) copperlead,(h) steelhousing,(i) brassplate,(j) coppercoilspring,(k) aluminaclosed-endtube,(l) port,(m) O-ringgaskets,(n) copperwater-cooled

electrode, (o) tantalum heater element, ( p) tantalum radiation shields, (q) water-cooling coils, (r) ceramic insulator, ( s) tantalum radiation shield, (t) adjustable clamp,

(u) water out, (v) electrical leads, (w) water in, and ( x) to vacuum system.

FIG. 2 High-Temperature Furnace (Example 2)

large region in the center of the furnace should be at a uniform internalgeometrycanhaveanappreciableeffectonthespectral

temperature to ensure that the temperature throughout the emissivity of the cavity.

equalizingblock(whenalltestthermocoupleassembliesarein 7.1.3 Figs. 5-7 show three typical equalizing block designs

position in the block) is uniform.At temperatures greater than that are used in thermocouple calibrating furnaces. The design

2000°C, furnace parts made from tantalum may introduce in Fig. 5 is used in furnaces where the standard radiation

contamination of exposed thermoelements. In this case, it may thermometerissightedhorizontallyintotheblackbodythrough

be desirable to fabricate heated furnace components from the hole in the side of the block. This design is particularly

tungsten. useful in the calibration of bare-wire thermocouples since the

7.1.2 The blackbody cavity in the equalizing block should lid on the blackbody (or the entire blackbody) can be an

be designed in accordance with established criteria set forth in electrically insulating material such ashafnium oxide or beryl-

the literature (4-8). Such factors as interior surface texture, lium oxide. Thus, if the bare thermocouple wires should come

diameter-to-depth ratio of the blackbody cavity opening, and in contact with the equalizing block, the wires will not be

E452 − 02 (2007)

FIG. 4 Upper Section of Furnace (Example 3)

(A) Disappearing filament pyrometer

(B) Sight window

(C) Gas inlet

(D) Water cooling

(E) Stainless steel shell

(F) Tungsten heat shield

(G) Tungsten heater

(H) Support rods

(J) Equalizer block (blackbody)

(K) Refractory brick

(L) Gallium alloy electrical contact

(M) Gas outlet

(N) Copper electrode

FIG. 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.