Standard Test Method for Measurement of Thermal Stability of Aviation Turbine Fuels under Turbulent Flow Conditions (HiReTS Method) <a href="#fn00002"></a> (Withdrawn 2013)

SIGNIFICANCE AND USE

The thermal stresses experienced by aviation fuel in modern jet engines may lead to the formation of undesirable and possibly harmful insoluble materials, such as lacquers, on heat exchangers and control surfaces, that reduce efficiency and require extra maintenance.

Aircraft fuel systems operate mainly under turbulent flow conditions. Most large-scale realistic test rigs operate in the turbulent flow regime but fuel volumes are very large and test times are very long.

This test method tests fuel under turbulent flow (high Reynolds number) conditions, and it gives a quantitative result under standard operating conditions of 65 or 125 min. Continuous analysis of results during the test allows performance of the fuel to be monitored in real time thus enabling the test time to be reduced manually or automatically, if required.

The results of this test method are not expected to correlate with existing test methods for all fuels, since the test methods and operating conditions are different (see Appendix X2).

SCOPE

1.1 This test method covers a laboratory thermal process, using a specified apparatus for measuring the tendencies of aviation turbine fuels to deposit insoluble materials and decomposition products, such as lacquers, within a fuel system. This test method provides a quantitative result for fuel under turbulent flow conditions in 65 or 125 min.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers a laboratory thermal process, using a specified apparatus for measuring the tendencies of aviation turbine fuels to deposit insoluble materials and decomposition products, such as lacquers, within a fuel system. This test method provides a quantitative result for fuel under turbulent flow conditions in 65 or 125 min.

This test method was balloted for withdrawal with no replacement because the apparatus is no longer being manufactured and the existing apparatus has limited use.

Formerly under the jurisdiction of Committee D02 on Petroleum Products and Lubricants, this test method was withdrawn in May 2013.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6811 − 02(Reapproved 2007)

Standard Test Method for

Measurement of Thermal Stability of Aviation Turbine Fuels

1,2

under Turbulent Flow Conditions (HiReTS Method)

This standard is issued under the fixed designation D6811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Removed all instances of the acronym for Jet Fuel Thermal Oxidation Tester editorially in April 2010.

1. Scope E128Test Method for Maximum Pore Diameter and Perme-

3 ability of Rigid Porous Filters for Laboratory Use

1.1 This test method covers a laboratory thermal process,

using a specified apparatus for measuring the tendencies of

3. Terminology

aviation turbine fuels to deposit insoluble materials and de-

composition products, such as lacquers, within a fuel system. 3.1 Definitions of Terms Specific to This Standard:

This test method provides a quantitative result for fuel under

3.1.1 capillary tube, n—a coated resistively heated stainless

turbulent flow conditions in 65 or 125 min. steel tube through which fuel is pumped and controlled to give

a predefined constant fuel exit temperature.

1.2 The values stated in SI units are to be regarded as the

3.1.2 deposits, n—oxidative products, such as lacquers, laid

standard.

downpredominantlyatthefuelexitend(hottest),ontheinside

1.3 This standard does not purport to address all of the

of the heated capillary tube.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.3 HiReTS, n—high Reynolds number thermal stability.

priate safety and health practices and determine the applica-

3.1.4 HiReTSPeak(P)numberandTotal(T)number,n—the

bility of regulatory limitations prior to use.

quantitative results of the test.

3.1.5 tubeways, n—plastic and metal tubes through which

2. Referenced Documents

fuel flows during cleaning and the test.

2.1 ASTM Standards:

D3241Test Method for Thermal Oxidation Stability of

4. Summary of Test Method

Aviation Turbine Fuels

4.1 Fuel is pumped, at pressure, through an electrically

D4057Practice for Manual Sampling of Petroleum and

heated capillary tube at a constant rate. The heating of the

Petroleum Products

capillary tube is controlled to maintain a constant fuel tem-

D4177Practice for Automatic Sampling of Petroleum and

perature of 290 6 3°C at the exit of the capillary tube.Aflow

Petroleum Products

rate of greater than 20 mL/min and the specified capillary bore

D4306Practice for Aviation Fuel Sample Containers for

oflessthan0.300mmensuresthatturbulentflowismaintained

Tests Affected by Trace Contamination

(see Appendix X1) within the capillary. The formation of

lacquers and fuel degradation products act as a thermal

insulator between the cooler fuel and hotter capillary tube,

This test method is under the jurisdiction of ASTM Committee D02 on

resulting in an increase in temperature of the capillary tube

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

which is measured at a number of positions by a contactless

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved Nov. 1, 2007. Published January 2008. Originally pyrometer. The HiReTS Total (T) number is displayed during

approved in 2002. Last previous edition approved in 2002 as D6811–02. DOI:

andattheendofthetest.TheHiReTSPeak(P)numbercanbe

10.1520/D6811-02R07E01.

determined from analysis of the results.

This test method is being jointly developed with the Institute of Petroleum,

where it is designated IP 482.

This process is covered by a patent. Interested parties are invited to submit

5. Significance and Use

information regarding the identification of an alternative(s) to this patented item to

5.1 The thermal stresses experienced by aviation fuel in

the ASTM Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

modern jet engines may lead to the formation of undesirable

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and possibly harmful insoluble materials, such as lacquers, on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

heat exchangers and control surfaces, that reduce efficiency

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and require extra maintenance.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6811 − 02 (2007)

5.2 Aircraft fuel systems operate mainly under turbulent 7.2 Trisolvent, for cleaning sampling vessels. (Warning—

flow conditions. Most large-scale realistic test rigs operate in Each of the components and the trisolvent is flammable;

the turbulent flow regime but fuel volumes are very large and harmful if inhaled; irritating to skin, eyes and mucous mem-

test times are very long. branes.) It consists of equal volumes of the following:

7.2.1 Acetone, CH ·CO·CH , technical grade, 95%

3 3

5.3 This test method tests fuel under turbulent flow (high

purity.

Reynolds number) conditions, and it gives a quantitative result

7.2.2 Toluene, C H ·CH , technical grade, 95% purity.

under standard operating conditions of 65 or 125 min. Con- 6 5 3

7.2.3 Propan-2-ol, (CH ) ·CH·OH,technicalgrade,95%

tinuous analysis of results during the test allows performance

3 2

purity.

of the fuel to be monitored in real time thus enabling the test

time to be reduced manually or automatically, if required.

7.3 Cleaning Solvent, technical grade, 95% purity, for

5.4 The results of this test method are not expected to cleaning sampling vessels. (Warning—Extremely flammable;

harmful if inhaled.) It consists of one of the following:

correlate with existing test methods for all fuels, since the test

methods and operating conditions are different (see Appendix 7.3.1 2-methylpentane.

X2).

7.3.2 3-methylpentane.

7.3.3 2,2,4-trimethylpentane.

6. Apparatus (see Annex A1)

7.4 Drying Components, to dry the air used for aeration and

6.1 General—(See Fig.A1.2.) Fuel contained in the sample

to indicate the absorption of water by changes from blue to

vessel is drawn through the sample filter by a pump. The

pink color. Use a mix, by volume or weight of the following:

temperature of the fuel is checked by the input fuel electronic

7.4.1 Calcium Sulfate Anhydrous Powder, CaSO (97%).

thermometer.Thefuelispumpedataconstantrate,atpressure

7.4.2 Cobalt Chloride Anhydrous, CoCl (3%) granules.

set by the back pressure valve, through an electrically heated

capillary tube which has a blackened outer surface to give a

7.5 Air, 1.5 L/min for aeration of the test sample.

high thermal emissivity. The heating of the capillary tube is

controlledtomaintainaconstantfueltemperature,asmeasured

8. Sampling and Sample Containers

by the capillary exit electronic thermometer, at the exit of the

8.1 Obtain samples for testing in accordance with Practices

capillary tube. The waste fuel is then cooled to a temperature

D4057 or D4177, with the following additional requirements:

oflessthan20°Caboveambient,asmeasuredbythewastefuel

8.1.1 Containers shall be fully epoxy lined or made of

electronic thermometer, before being discharged to a waste

polytetrafluoroethylene (PTFE). See Note 2 and Practice

container.Duringthetest,thetemperatureoftheoutsideofthe

D4306.

capillary tube is scanned, checked and recorded every 5 min at

8.1.2 Prior to sampling, all containers and their closures

12 points along the exit end of the capillary tube using a

shallberinsedatleastthreetimeswiththefuelbeingsampled.

contactless pyrometer which is located on a computer-

8.1.3 Test samples as soon as possible after sampling.

controlled elevating platform.

NOTE 2—Test methods for measuring thermal stability are known to be

5 5

6.2 The thermal stability apparatus and capillary tube is

sensitive to trace contamination during the sampling operation and from

specified in detail in Annex A1. samplecontainers.Newcontainersarerecommended,butwhenonlyused

containers are available, a thorough rinse with trisolvent (see 7.2)

6.3 Sparger, of porosity 40 to 80 µm, which allows an air

followed by cleaning solvent (see 7.1 and 7.3), and drying with a stream

flow of approximately 1.5 L/min.

of air is recommended.

NOTE1—TheporosityofthespargercanbecheckedusingTestMethod

8.2 Aeration of Test Sample—Aerate the test sample, with

E128.

dry air, through the sparger at an air flow rate of 1 to 2 L/min

6.4 Sample Filter, 20-µm stainless steel.

for 10 min.

6.5 Aeration Dryer, glass or other suitable transparent

8.3 Sample Size—Standardoperatingconditionsare:3Lfor

material,minimumheight250mm,minimumdiameter50mm,

13 scans (65–min test) and 5 L for 25 scans (125-min test).

filled with dry calcium sulfate and cobalt chloride (see 7.4),

whichisusedinconjunctionwithanairsupplyandthesparger

9. Preparation of Apparatus

(see 6.3) to aerate the test sample.

9.1 Prepare the instrument for operation in accordance with

7. Reagents and Materials

the manufacturer’s instructions. (Warning—Installing and re-

moving the capillary tube may result in exposure to fuel or

7.1 Heptane, CH ·(CH ) ·CH ,technicalgrade95%purity,

3 2 5 3

solvent.Itisrecommendedthatimpermeableglovesandsafety

for cleaning the apparatus tubeways, and sampling vessels.

glasses are worn.)

(Warning—Extremely flammable; harmful if inhaled.)

9.2 Remove the sample filter and inlet tubing and clean by

rinsing with heptane and then by back flushing with heptane,

The equipment, as listed in the research report being prepared, was used to

and then refit.

develop the precision statement. The apparatus and capillary tubes described in

AnnexA1arebothsuppliedbyStanhope-Seta,Chertsey,SurreyKT168AP,UK.To

9.3 SettheinstrumentinaccordancewithTable1andcheck

datenootherequipmenthasdemonstratedthroughASTMinterlaboratorytestingthe

thatthecorrectstandardoperatingconditionsareinaccordance

ability to meet the precision of this test. This is not an endorsement or certification

by ASTM. A research report is being prepared. with Section 10.

´1

D6811 − 02 (2007)

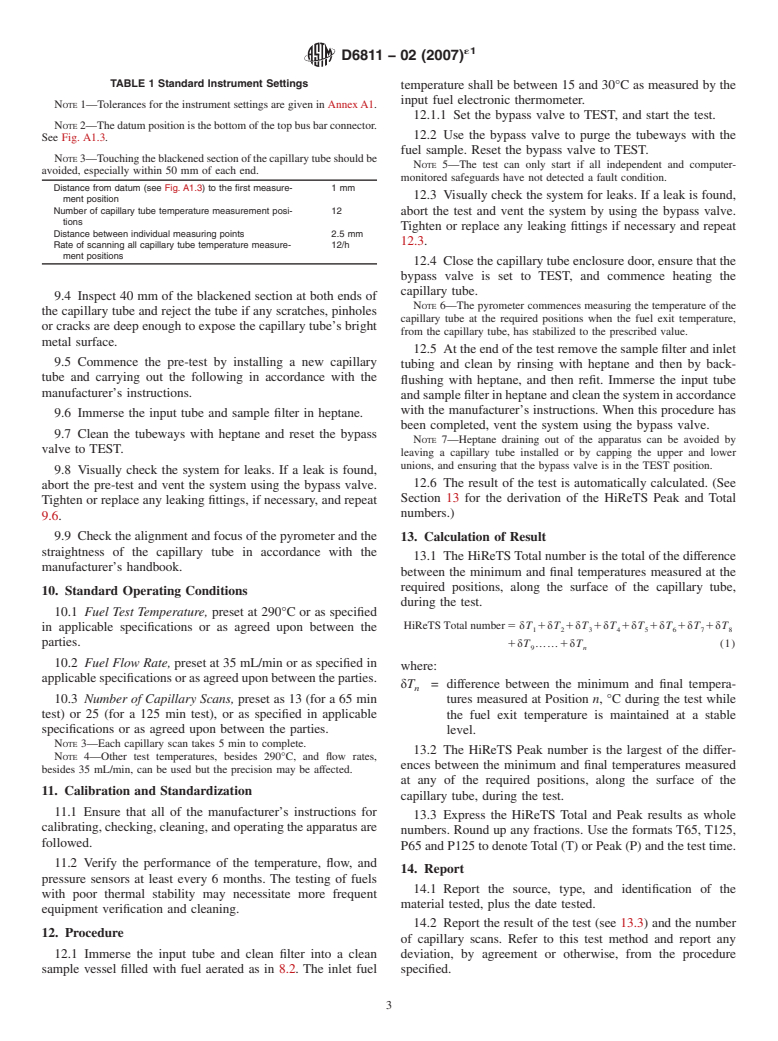

TABLE 1 Standard Instrument Settings

temperature shall be between 15 and 30°C as measured by the

input fuel electronic thermometer.

NOTE 1—Tolerances for the instrument settings are given in AnnexA1.

12.1.1 Set the bypass valve to TEST, and start the test.

NOTE2—Thedatumpositionisthebottomofthetopbusbarconnector.

12.2 Use the bypass valve to purge the tubeways with the

See Fig. A1.3.

fuel sample. Reset the bypass valve to TEST.

NOTE3—Touchingtheblackenedsectionofthecapillarytubeshouldbe

NOTE 5—The test can only start if all independent and computer-

avoided, especially within 50 mm of each end.

monitored safeguards have not detected a fault condition.

Distance from datum (see Fig. A1.3) to the first measure- 1mm

12.3 Visually check the system for leaks. If a leak is found,

ment position

Number of capillary tube temperature measurement posi- 12

abort the test and vent the system by using the bypass valve.

tions

Tighten or replace any leaking fittings if necessary and repeat

Distance between individual measuring points 2.5 mm

12.3.

Rate of scanning all capillary tube temperature measure- 12/h

ment positions

12.4 Closethecapillarytubeenclosuredoor,ensurethatthe

bypass valve is set to TEST, and commence heating the

capillary tube.

9.4 Inspect 40 mm of the blackened section at both ends of

NOTE 6—The pyrometer commences measuring the temperature of the

the capillary tube and reject the tube if any scratches, pinholes

capillary tube at the required positions when the fuel exit temperature,

or cracks are deep enough to expose the capillary tube’s bright

from the capillary tube, has stabilized to the prescribed value.

metal surface.

12.5 Attheendofthetestremovethesamplefilterandinlet

9.5 Commence the pre-test by installing a new capillary

tubing and clean by rinsing with heptane and then by back-

tube and carrying out the following in accordance with the

flushing with heptane, and then refit. Immerse the input tube

manufacturer’s instructions.

andsamplefilterinheptaneandcleanthesysteminaccordance

with the manufacturer’s instructions. When this procedure has

9.6 Immerse the input tube and sample filter in heptane.

been completed, vent the system using the bypass valve.

9.7 Clean the tubeways with heptane and reset the bypass

NOTE 7—Heptane draining out of the apparatus can be avoided by

valve to TEST.

leaving a capillary tube installed or by capping the upper and lower

unions, and ensuring that the bypass valve is in the TEST position.

9.8 Visually check the system for leaks. If a leak is found,

12.6 The result of the test is automatically calculated. (See

abort the pre-test and vent the system using the bypass valve.

Section 13 for the derivation of the HiReTS Peak and Total

Tighten or replace any leaking fittings, if necessary, and repeat

numbers.)

9.6.

9.9 Checkthealignmentandfocusofthepyrometerandthe

13. Calculation of Result

straightness of the capillary tube in accordance with the

13.1 The HiReTSTotal number is the total of the difference

manufacturer’s handbook.

between the minimum and final temperatures measured at the

required positions, along the surface of the capillary tube,

10. Standard Operating Conditions

during the test.

10.1 Fuel Test Temperature, preset at 290°C or as specified

HiReTSTotalnumber 5 δT 1δT 1δT 1δT 1δT 1δT 1δT 1δT

in applicable specifications or as agreed upon between the

1 2 3 4 5 6 7 8

parties.

1δT ……1δT (1)

9 n

10.2 Fuel Flow Rate, preset at 35 mL/min or as specified in

where:

applicablespecificationsorasagreeduponbetweentheparties.

δT = difference between the minimum and final tempera-

n

10.3 Number of Capillary Scans, preset as 13 (for a 65 min

tures measured at Position n, °C during the test while

test) or 25 (for a 125 min test), or as specified in applicable the fuel exit temperature is maintained at a stable

specifications or as agreed upon between the parties. level.

NOTE 3—Each capillary scan takes 5 min to complete.

13.2 The HiReTS Peak number is the largest of the differ-

NOTE 4—Other test temperatures, besides 290°C, and flow rates,

ences between the minimum and final temperatures measured

besides 35 mL/min, can be used but the precision may be affected.

at any of the required positions, along the surface of the

11. Calibration and Standardization

capillary tube, during the test.

11.1 Ensure that all of the manufacturer’s instructions for

13.3 Express the HiReTS Total and Peak results as whole

calibrating,checking,cleaning,an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.