ASTM D6436-02

(Guide)Standard Guide for Reporting Properties for Plastics and Thermoplastic Elastomers

Standard Guide for Reporting Properties for Plastics and Thermoplastic Elastomers

SIGNIFICANCE AND USE

This guide is intended to provide ready access to the recommended property name, test method reference, maximum number of significant digits,5 and appropriate units for commonly used plastics and thermoplastic elastomer tests.

It is particularly useful for those involved in the writing and proofreading of documents containing data for a large number of tests since the need to go to each individual test method should be greatly minimized.

SI units are to be regarded as the standard. U.S. Customary units and conversion factors are provided to accommodate those situations where it is necessary to report both. U.S. Customary refers to units commonly used in the United States and is not always the same as inch-pound units.

SCOPE

1.1 This guide provides recommendations for reporting the results of property values for plastics and thermoplastic elastomers in published literature, data sheets, presentations, comparative analysis, and so forth. It is intended to minimize confusion when comparing the data from several sources.

1.2 This standard is not intended to replace recommendations within the test methods for reporting data. Refer to the test method or use other guidance to determine the number of significant figures for reporting laboratory test results.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6436–02

Standard Guide for

Reporting Properties for Plastics and Thermoplastic

1

Elastomers

This standard is issued under the fixed designation D 6436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * 4. Significance and Use

1.1 This guide provides recommendations for reporting the 4.1 This guide is intended to provide ready access to the

results of property values for plastics and thermoplastic elas- recommendedpropertyname,testmethodreference,maximum

5

tomers in published literature, data sheets, presentations, com- number of significant digits, and appropriate units for com-

parative analysis, and so forth. It is intended to minimize monly used plastics and thermoplastic elastomer tests.

confusion when comparing the data from several sources. 4.2 It is particularly useful for those involved in the writing

1.2 This standard is not intended to replace recommenda- and proofreading of documents containing data for a large

tions within the test methods for reporting data. Refer to the number of tests since the need to go to each individual test

test method or use other guidance to determine the number of method should be greatly minimized.

significant figures for reporting laboratory test results. 4.3 SI units are to be regarded as the standard. U.S.

Customaryunitsandconversionfactorsareprovidedtoaccom-

NOTE 1—There is no similar or equivalent ISO standard.

modate those situations where it is necessary to report both.

U.S. Customary refers to units commonly used in the United

2. Referenced Documents

States and is not always the same as inch-pound units.

2.1 Due to the large number of ASTM test methods refer-

enced in this guide, they will not be identified individually in

5. Procedure

this section.

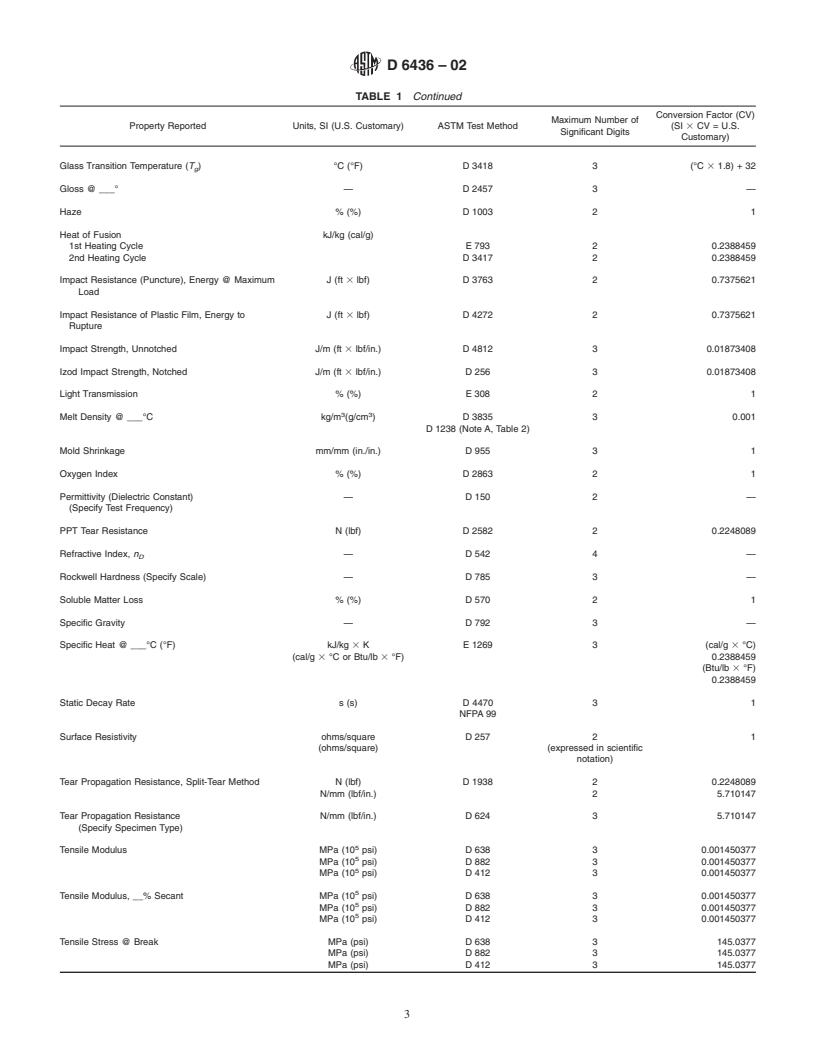

5.1 Refer toTable 1 for the recommended nomenclature and

2.2 ASTM Standards (other than test methods):

2 units for physical properties and the recommended number of

D 883 Terminology Relating to Plastics

significant digits for test data associated with each property.

D 1600 Terminology for Abbreviated Terms Relating to

5.2 Abbreviations not shown in Table 1 that may be

2

Plastics

necessary to further clarify the conditions of testing, such as

IEEE/ ASTM SI-10 Standard for Use of the International

MHz and kHz for electrical tests, can be found in IEEE/ASTM

3

System of Units (SI): The Modern Metric System

SI–10.

2.3 NFPA Standard:

4

NFPA 99 Standard for Health Care Facilities

6. Keywords

6.1 conversion factors; decimal places; properties reporting;

3. Terminology

reporting guide; significant figures

3.1 Definitions—The terminology used in this guide is in

accordance with Terminologies D 883, D 1600, and IEEE/

ASTM SI-10.

1

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and

is the direct responsibility of Subcommittee D20.94 on Government/Industry

Standards.

Current edition approved November 10, 2002. Published January 2003. Origi-

nally approved in 1999. Last previous edition approved in 1999 as D 6436 - 99.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 14.02.

4 5

Available from National Fire Protection Association, 1 Batterymarch Park, The recommended maximum number of significant digits is based on experi-

Quincy, MA 02269–9101. ence of experts in the plastics industry.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6436–02

TABLE 1 Reference Guide for Properties Reported

Conversion Factor (CV)

Maximum Number of

Property Reported Units, SI (U.S. Customary) ASTM Test Method (SI 3CV=U.S.

Significant Digits

Customary)

Arc Resistance s (s) D 495 2 1

3 3

Bulk Density kg/m (lb/ft ) D 1895 3 0.06242797

Coefficient of Friction — D 1894 2 —

Coefficient of Linear Thermal Expansion mm/mm 3 °C (in./in. 3 °F) D 696 2 0.5555556

(expressed in scientific

notation)

Color, CIE, L*, a*, b* — E 308 3 —

Crystalline Peak Melting Point (T ) °C (°F) D 3418 3 (°C 3 1.8) + 32

m

2nd Heating Cycle

Dart Impact g (g) D 1709 2 1

(1 if value is <100)

Deflection Temperature °C (°F) D 648 3 (°C 3 1.8) + 32

@ 1.82 MPa (264 psi)

@ 0.455 MPa (66 psi)

3 3

Density kg/m (g/cm ) D 792 3 0.001

3 3

g/cm (g/cm ) D 1505 3 1

3 3

g/cm (g/cm ) D 4883 3 1

Dielectric Strength (Specify Method Used) V/mm (V/mil) D 149 3 0.0254

Dissipation Factor (Specify Test Frequency) — D 150 2 —

Durometer Hardness — D 2240 2 —

Shore A

Shore D

Elmendorf Tear Resistance N (gf) D 1922 3 101.9716

Elongation @ Brea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.