ASTM C1292-00

(Test Method)Standard Test Method for Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures

Standard Test Method for Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures

SCOPE

1.1 This test method covers the determination of shear strength of continuous fiber-reinforced ceramic composites (CFCCs) at ambient temperature. The test methods addressed are (1) the compression of a double-notched specimen to determine interlaminar shear strength and (2) the Iosipescu test method to determine the shear strength in any one of the material planes of laminated composites. Specimen fabrication methods, testing modes (load or displacement control), testing rates (load rate or displacement rate), data collection, and reporting procedures are addressed.

1.2 This test method is used for testing advanced ceramic or glass matrix composites with continuous fiber reinforcement having uni-directional (1-D) or bi-directional (2-D) fiber architecture. This test method does not address composites with (3-D) fiber architecture or discontinous fiber-reinforced, whisker-reinforced, or particulate-reinforced ceramics.

1.3 The values stated in SI units are to be regarded as the standard and are in accordance with Practice E380.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 8.1 and 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 1292–00

Standard Test Method for

Shear Strength of Continuous Fiber-Reinforced Advanced

Ceramics at Ambient Temperatures

This standard is issued under the fixed designation C 1292; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3878 Terminology for High-Modulus Reinforcing Fibers

and Their Composites

1.1 This test method covers the determination of shear

D 5379/D 5379M Test Method for Shear Properties of

strength of continuous fiber-reinforced ceramic composites

Composite Materials by the V-Notched Beam Method

(CFCCs) at ambient temperature. The test methods addressed

E 4 Practices for Force Verification of Testing Machines

are (1) the compression of a double-notched specimen to

E 6 Terminology Relating to Methods of Mechanical Test-

determine interlaminar shear strength and (2) the Iosipescu test

ing

method to determine the shear strength in any one of the

E 122 Practice for Choice of Sample Size to Estimate a

material planes of laminated composites. Specimen fabrication

Measure of Quality for a Lot or Process

methods, testing modes (load or displacement control), testing

E 177 Practice for Use of the Terms Precision and Bias in

rates (load rate or displacement rate), data collection, and

ASTM Test Methods

reporting procedures are addressed.

E 337 Test Method for Measuring Humidity with Psy-

1.2 This test method is used for testing advanced ceramic or

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

glass matrix composites with continuous fiber reinforcement

peratures)

having uni-directional (1-D) or bi-directional (2-D) fiber archi-

E 380 Practice for Use of International System of Units

tecture. This test method does not address composites with

(SI)

(3-D) fiber architecture or discontinous fiber-reinforced,

E 691 Practice for Conducting an Interlaboratory Study to

whisker-reinforced, or particulate-reinforced ceramics.

Determine the Precision of a Test Method

1.3 The values stated in SI units are to be regarded as the

standard and are in accordance with Practice E 380.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions—The definitions of terms relating to shear

safety concerns, if any, associated with its use. It is the

strength testing appearing in Terminology E 6 apply to the

responsibility of the user of this standard to establish appro-

terms used in this test method.The definitions of terms relating

priate safety and health practices and determine the applica-

to advanced ceramics appearing in Terminology C 1145 apply

bility of regulatory limitations prior to use. Specific hazard

to the terms used in this test method. The definitions of terms

statements are given in 8.1 and 8.2.

relating to fiber-reinforced composites appearing in Terminol-

2. Referenced Documents ogy D 3878 apply to the terms used in this test method.

Additional terms used in conjunction with this test method are

2.1 ASTM Standards:

defined in the following.

C 1145 Terminology of Advanced Ceramics

3.1.1 advanced ceramic—an engineered high-performance

D 695 Test Method for Compressive Properties of Rigid

predominately nonmetallic, inorganic, ceramic material having

Plastics

specific functional attributes.

D 3846 Test Method for In-Plane Shear Strength of Rein-

3.1.2 continuous fiber-reinforced ceramic matrix composite

forced Plastics

(CFCC)—a ceramic matrix composite in which the reinforcing

phase consists of a continuous fiber, continuous yarn, or a

This test method is under the jurisdiction of ASTM Committee C-28 on woven fabric.

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

Ceramic Matrix Composites.

Current edition approved April 10, 2000. Published July 2000. Originally

published as C 1292 – 95. Last previous edition C 1292 – 95a. Annual Book of ASTM Standards, Vol 15.03.

2 6

Annual Book of ASTM Standards, Vol 15.01. Annual Book of ASTM Standards, Vol 03.01.

3 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 14.02.

4 8

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1292

3.1.3 shear failure load—the maximum load required to

fracture a shear loaded test specimen.

3.1.4 shear strength—the maximum shear stress that a

material is capable of sustaining. Shear strength is calculated

from the shear fracture load and the shear loaded area.

4. Summary of Test Method

4.1 This test method addresses two methods to determine

the shear strength of CFCCs: (1) the compression of a

double-notched specimen test method to determine interlami-

nar shear strength and (2) the Iosipescu test method to

determine the shear strength in any one of the material planes

of laminated CFCCs.

4.1.1 Shear Test by Compression Loading of Double-

Notched Specimens—The interlaminar shear strength of

CFCCs, as determined by this method is measured by loading

in compression a double-notched specimen of uniform width.

Failure of the specimen occurs by shear between two centrally

located notches machined halfway through the thickness and

spaced a fixed distance apart on opposing faces. Schematics of

the test setup and the specimen are shown in Fig. 1 and Fig. 2.

4.1.2 Shear Test By the Iosipescu Method—The shear

strength of one of the different material shear planes of

laminated CFCCs may be determined by loading a coupon in

the form of a rectangular flat strip with symmetric centrally

located V-notches using a mechanical testing machine and a

four-point asymmetric fixture. The loading can be idealized as

asymmetric flexure by the shear and bending diagrams in Fig.

3. Failure of the specimen occurs by shear between the

V-notches. Different specimen configurations are addressed for

this test method. Schematics of the test setup and specimen are

shown in Fig. 4 and Fig. 5. The determination of shear

NOTE 1—All tolerances are in millimetres.

FIG. 2 Schematic of Double-Notched Compression Specimen

Whitney, J., M., “Stress Analysis of the Double Notch Shear Specimen,”

Proceedings of the American Society for Composites, 4th Technical Conference,

properties of polymer matrix composites by the Iosipescu

Blacksburg Virginia, Oct. 3–5, 1989, Technomic Publishing Co, pp. 325.

method has been presented in Test Method D 5379.

Iosipescu, N., “NewAccurate Procedure for ShearTesting of Metals,”Journal

of Materials, 2, 3, Sept. 1967, pp. 537–566.

5. Significance and Use

5.1 Continuous fiber-reinforced ceramic composites are

candidate materials for structural applications requiring high

degrees of wear and corrosion resistance, and damage toler-

ance at high temperatures.

5.2 Shear tests provide information on the strength and

deformation of materials under shear stresses.

5.3 This test method may be used for material development,

material comparison, quality assurance, characterization, and

design data generation.

5.4 For quality control purposes, results derived from stan-

dardized shear test specimens may be considered indicative of

the response of the material from which they were taken for

given primary processing conditions and post-processing heat

treatments.

6. Interferences

6.1 Test environment (vacuum, inert gas, ambient air, etc.)

including moisture content (for example, relative humidity)

FIG. 1 Schematic of Test Fixture for the Double-Notched

Compression Specimen may have an influence on the measured shear strength. In

C 1292

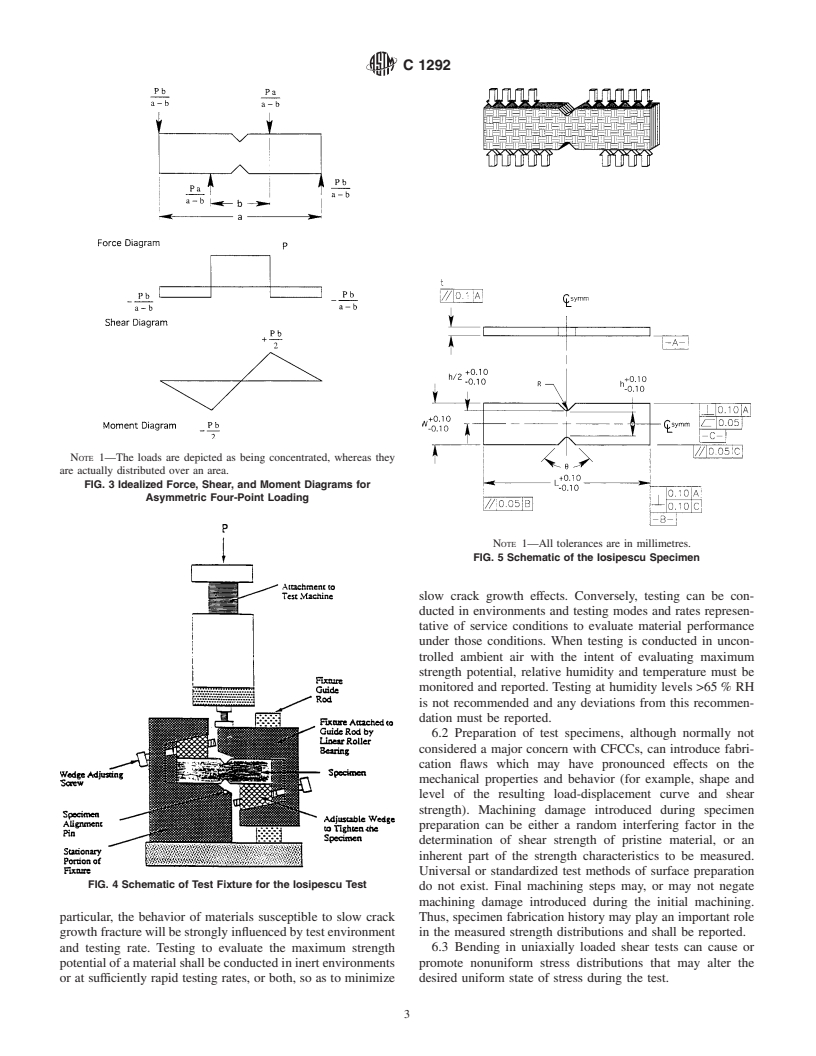

NOTE 1—The loads are depicted as being concentrated, whereas they

are actually distributed over an area.

FIG. 3 Idealized Force, Shear, and Moment Diagrams for

Asymmetric Four-Point Loading

NOTE 1—All tolerances are in millimetres.

FIG. 5 Schematic of the Iosipescu Specimen

slow crack growth effects. Conversely, testing can be con-

ducted in environments and testing modes and rates represen-

tative of service conditions to evaluate material performance

under those conditions. When testing is conducted in uncon-

trolled ambient air with the intent of evaluating maximum

strength potential, relative humidity and temperature must be

monitored and reported. Testing at humidity levels >65 % RH

is not recommended and any deviations from this recommen-

dation must be reported.

6.2 Preparation of test specimens, although normally not

considered a major concern with CFCCs, can introduce fabri-

cation flaws which may have pronounced effects on the

mechanical properties and behavior (for example, shape and

level of the resulting load-displacement curve and shear

strength). Machining damage introduced during specimen

preparation can be either a random interfering factor in the

determination of shear strength of pristine material, or an

inherent part of the strength characteristics to be measured.

Universal or standardized test methods of surface preparation

FIG. 4 Schematic of Test Fixture for the Iosipescu Test

do not exist. Final machining steps may, or may not negate

machining damage introduced during the initial machining.

particular, the behavior of materials susceptible to slow crack Thus, specimen fabrication history may play an important role

growthfracturewillbestronglyinfluencedbytestenvironment in the measured strength distributions and shall be reported.

and testing rate. Testing to evaluate the maximum strength 6.3 Bending in uniaxially loaded shear tests can cause or

potential of a material shall be conducted in inert environments promote nonuniform stress distributions that may alter the

or at sufficiently rapid testing rates, or both, so as to minimize desired uniform state of stress during the test.

C 1292

6.4 Fractures that initiate outside the uniformly stressed element that attaches to the crosshead of the testing machine,

gage section of a specimen may be due to factors such as and two jaws to fix the specimen in position. A schematic

localized stress concentrations, extraneous stresses introduced description of the test fixture is shown in Fig. 1. Asupporting

by improper loading configurations, or strength-limiting fea- jig conforming to the geometry of that shown in Fig. 1 of Test

tures in the microstructure of the specimen. Such non-gage Method D 3846 or Fig. 4 of Test Method D 695 may also be

section fractures will normally constitute invalid tests. used.

6.5 For the conduction of the Iosipescu test, thin test 7.4.2 Iosipescu Specimen—The fixture shall be a four-point

specimens (width to thickness ratio of more than ten) may asymmetric flexure fixture shown schematically in Fig.

suffer from splitting and instabilities rendering in turn invalid 4. This fixture consists of a stationary element mounted on a

test results. base plate, and a movable element capable of vertical transla-

6.6 For the evaluation of the interlaminar shear strength by tion guided by a stiff post.The movable element attaches to the

the compression of a double-notched specimen, the distance cross-head of the testing machine. Each element clamps half of

between the notches in the specimen has an effect on the the test specimen into position with a wedge action grip able to

maximum load and therefore on the shear strength. It has been compensate for minor specimen width variations.Aspan of 13

foundthatthestressdistributioninthespecimenisindependent mm is left unsupported between fixture halves. An alignment

of the distance between the notches when the notches are far tool is recommended to ensure that the specimen notch is

apart. However, when the distance between the notches is such aligned with the line-of-action of the loading fixture.

that the stress fields around the notches interact, the measured

8. Hazards

interlaminar shear strength increases. Because of the complex-

ity of the stress field around each notch and its dependence on

8.1 During the conduct of this test method, the possibility of

the properties and homogeneity of the material, it is recom- flying fragments of broken test material may be high. The

mended to conduct a series of tests on specimens with different

brittle nature of advanced ceramics and the release of strain

spacing between the notches to determine their effect on the energy contribute to the potential release of uncontrolled

measured interlaminar shear strength.

fragments upon fracture. Means for containment and retention

6.7 For the evaluation of the interlaminar shear strength by of these fragments for later fractographic reconstruction and

the compression of a double-notched specimen, excessive

analysis is highly recommended.

clamping force with the jaws will reduce the stress concentra- 8.2 Exposed fibers at the edges of CFCC specimens present

tion around the notches and therefore artificially increase the

a hazard due to the sharpness and brittleness of the ceramic

measured interlaminar shear strength. Because the purpose of fiber. All persons required to handle these materials shall be

the jaws is to maintain the specimen in place and to prevent

well informed of these conditions and the proper handling

buckling, avoid overtightening the jaws. techniques.

6.8 Most fixtures incorporate an alignment mechanism in

9. Test Specimens

the form of a guide rod and a linear roller bearing. Excessive

freeplayorexcessivefrictioninthismechanismmayintroduce

9.1 Test Specimen Geometry:

spurious moments that will alter the ideal loading conditions.

9.1.1 Double-Notched Compression Specimen—The test

specimens shall conform to the shape and tolerances shown in

7. Apparatus

Fig. 2. The specimen consists of a rectangular plate with

7.1 Testing Machines—The testing machine shall be in

notches machined on both sides.The depth of the notches shall

conformancewithPracticesE 4.Theloadsusedindetermining

be at least equal to one half of the specimen thickness, and the

shearstrengthshallbeaccuratewithin 61 %atanyloadwithin

distance between the notches shall be determined considering

the selected load range of the testing machine as defined in

the requirements to produce shear failure in the gage section.

Practices E 4.

Furthermore, because the measured interlaminar shear strength

7.2 Data Acquisition—At the minimum, autographic

may be dependent on the notch separation, it is recommended

records of applied load and cross-head displacement versus

to conduct tests with different values of notch separation to

time shall be obtained. Either analog chart recorders or digital

determine this dependence. The e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.