ASTM F2389-15

(Specification)Standard Specification for Pressure-rated Polypropylene (PP) Piping Systems

Standard Specification for Pressure-rated Polypropylene (PP) Piping Systems

ABSTRACT

This specification establishes the requirements for polypropylene (PP) piping system components such as pipe, fittings, valves, and manifolds used in water service lines, hot-and-cold water distribution, hydronic heating, and irrigation systems to transport industrial process fluids, effluents, slurries, municipal sewage, etc. The piping system components covered here are made to metric sizes and IPS schedule 80 sizes, and pressure rated for water service and distribution supply. When tested according to the procedures provided herein, the piping components shall adhere to specified requirements for workmanship, dimensions, longitudinal reversion, melt flow rate, impact resistance, thermal stability and oxidative induction time (OIT), hydrostatic pressure, thermocycling, and oxidative stability in potable chlorinated water.

SCOPE

1.1 This specification establishes requirements for polypropylene (PP) piping system components made to metric sizes and IPS schedule 80 sizes, and pressure rated for water service and distribution supply (see Appendix X1). Included are criteria for materials, workmanship, dimensions and tolerances, product tests, and marking for polypropylene (PP) piping system components such as pipe, fittings, valves, and manifolds.

1.2 The components governed by this specification shall be permitted for use in water service lines, hot-and-cold water distribution, hydronic heating, and irrigation systems.

1.3 The pipe and fittings produced under this specification shall be permitted to be used to transport industrial process fluids, effluents, slurries, municipal sewage, etc. The user shall consult the manufacturer to determine whether the material being transported is compatible with the polypropylene piping system and will not affect the service life beyond limits acceptable to the user.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2389 −15 An American National Standard

Standard Specification for

1

Pressure-rated Polypropylene (PP) Piping Systems

This standard is issued under the fixed designation F2389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1238 Test Method for Melt Flow Rates of Thermoplastics

by Extrusion Plastometer

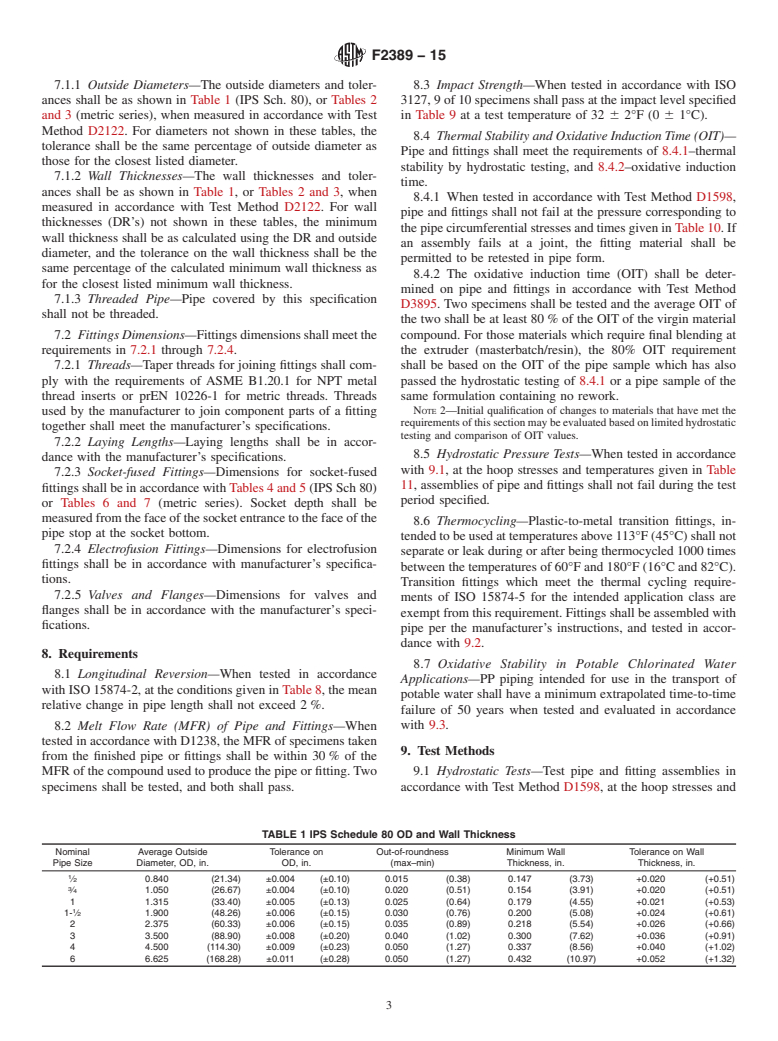

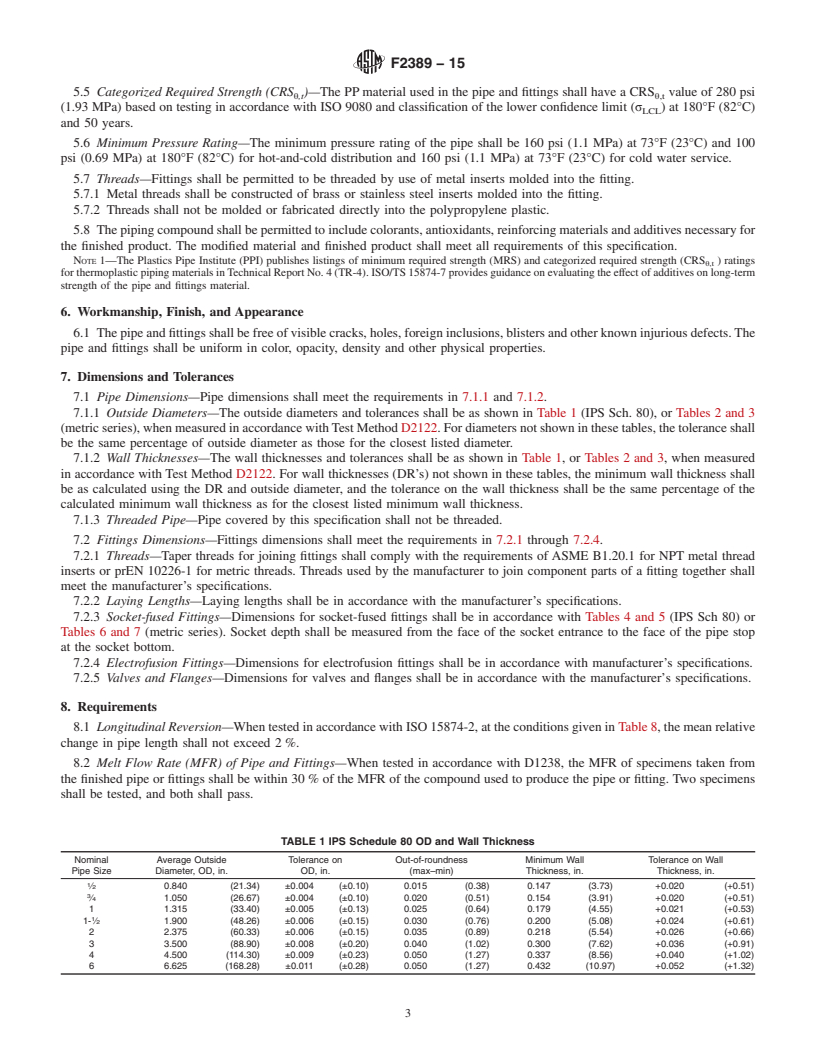

1.1 This specification establishes requirements for polypro-

D1505 Test Method for Density of Plastics by the Density-

pylene (PP) piping system components made to metric sizes

Gradient Technique

and IPS schedule 80 sizes, and pressure rated for water service

D1598 Test Method for Time-to-Failure of Plastic Pipe

and distribution supply (see Appendix X1). Included are

Under Constant Internal Pressure

criteria for materials, workmanship, dimensions and

D1600 Terminology forAbbreviatedTerms Relating to Plas-

tolerances, product tests, and marking for polypropylene (PP)

tics

piping system components such as pipe, fittings, valves, and

D2122 Test Method for Determining Dimensions of Ther-

manifolds.

moplastic Pipe and Fittings

1.2 The components governed by this specification shall be

D2749 Symbols for Dimensions of Plastic Pipe Fittings

permitted for use in water service lines, hot-and-cold water

D3895 Test Method for Oxidative-Induction Time of Poly-

distribution, hydronic heating, and irrigation systems.

olefins by Differential Scanning Calorimetry

1.3 The pipe and fittings produced under this specification

D4101 Specification for Polypropylene Injection and Extru-

shall be permitted to be used to transport industrial process

sion Materials

fluids, effluents, slurries, municipal sewage, etc. The user shall F412 Terminology Relating to Plastic Piping Systems

consult the manufacturer to determine whether the material

F2023 Test Method for Evaluating the Oxidative Resistance

being transported is compatible with the polypropylene piping of Crosslinked Polyethylene (PEX) Pipe, Tubing and

system and will not affect the service life beyond limits

Systems to Hot Chlorinated Water

acceptable to the user.

2.2 International Organization for Standardization (ISO)

1.4 Units—The values stated in inch-pound units are to be

Standards:

regarded as standard. The values given in parentheses are ISO 3127 Thermoplastic Pipes—Determination of Resis-

3

mathematical conversions to SI units that are provided for

tance to External Blows—Round the Clock Method

information only and are not considered standard.

ISO 4065 Thermoplastics Pipes—Universal Wall Thickness

3

Table

1.5 This standard does not purport to address all of the

ISO 9080 Plastics Piping and Ducting Systems—

safety concerns, if any, associated with its use. It is the

Determination of the Long-Term Hydrostatic Strength of

responsibility of the user of this standard to establish appro-

3

Thermoplastics Materials in Pipe Form by Extrapolation

priate safety and health practices and determine the applica-

ISO 9393–2 Thermoplastics valves for industrial applica-

bility of regulatory requirements prior to use.

tions - Pressure test methods and requirements - Part 2:

Test conditions and basic requirements

2. Referenced Documents

ISO 15874-2:2002 Plastics Piping Systems for Hot and Cold

2

2.1 ASTM Standards:

3

Water Installations—Polypropylene (PP)—Part 2: Pipes

D792 Test Methods for Density and Specific Gravity (Rela-

ISO 15874-3:2002 Plastics Piping Systems for Hot and Cold

tive Density) of Plastics by Displacement

Water Installations—Polypropylene (PP)—Part 3: Fit-

3

tings

ISO/TS 15874-7 Plastics Piping Systems for Hot and Cold

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Water Installations—Polypropylene (PP)—Part 7: Guid-

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

3

ance for the Assessment of Conformity

Current edition approved Aug. 1, 2015. Published August 2015. Originally

approved in 2004. Last previous edition approved in 2010 as F2389-10. DOI:

10.1520/F2389-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2389 − 10 F2389 − 15

Standard Specification for

1

Pressure-rated Polypropylene (PP) Piping Systems

This standard is issued under the fixed designation F2389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification establishes requirements for polypropylene (PP) piping system components made to metric sizes and IPS

schedule 80 sizes, and pressure rated for water service and distribution supply (see Appendix X1). Included are criteria for

materials, workmanship, dimensions and tolerances, product tests, and marking for polypropylene (PP) piping system components

such as pipe, fittings, valves, and manifolds.

1.2 The components governed by this specification shall be permitted for use in water service lines, hot-and-cold water

distribution, hydronic heating, and irrigation systems.

1.3 The pipe and fittings produced under this specification shall be permitted to be used to transport industrial process fluids,

effluents, slurries, municipal sewage, etc. The user shall consult the manufacturer to determine whether the material being

transported is compatible with the polypropylene piping system and will not affect the service life beyond limits acceptable to the

user.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2749 Symbols for Dimensions of Plastic Pipe Fittings

D3895 Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry

D4101 Specification for Polypropylene Injection and Extrusion Materials

F412 Terminology Relating to Plastic Piping Systems

F2023 Test Method for Evaluating the Oxidative Resistance of Crosslinked Polyethylene (PEX) Tubing and Systems to Hot

Chlorinated Water

2.2 International Organization for Standardization (ISO) Standards:

3

ISO 3127 Thermoplastic Pipes—Determination of Resistance to External Blows—Round the Clock Method

3

ISO 4065 Thermoplastics Pipes—Universal Wall Thickness Table

ISO 9080 Plastics Piping and Ducting Systems—Determination of the Long-Term Hydrostatic Strength of Thermoplastics

3

Materials in Pipe Form by Extrapolation

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

Current edition approved Feb. 1, 2010Aug. 1, 2015. Published February 2010August 2015. Originally approved in 2004. Last previous edition approved in 20072010 as

ε1

F2389-07-10. . DOI: 10.1520/F2389-10.10.1520/F2389-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2389 − 15

ISO 9393–2 Thermoplastics valves for industrial applications - Pressure test methods and requirements - Part 2: Test conditions

and basic requirements

3

ISO 15874-2:2002 Plastics Piping Systems for Ho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.