ASTM D2014-97

(Test Method)Standard Test Method for Expansion or Contraction of Coal by the Sole-Heated Oven

Standard Test Method for Expansion or Contraction of Coal by the Sole-Heated Oven

SCOPE

1.1 This test method covers a large-scale laboratory test for obtaining information on the expansion or contraction of coal or coal blends during carbonization under specified conditions. This test method is applicable in the examination of coals or coal blends intended for use in the manufacture of coke.

1.2 The values stated in SI units shall be regarded as standard. Inch-pound units shall be accepted on an equivalent basis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2014 – 97

Standard Test Method for

Expansion or Contraction of Coal by the Sole-Heated Oven

This standard is issued under the fixed designation D 2014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope pertinent experience with other coals and coal blends and

processing conditions used in commercial-type coke ovens.

1.1 This test method covers a large-scale laboratory test for

obtaining information on the expansion or contraction of coal

5. Apparatus

or coal blends during carbonization under specified conditions.

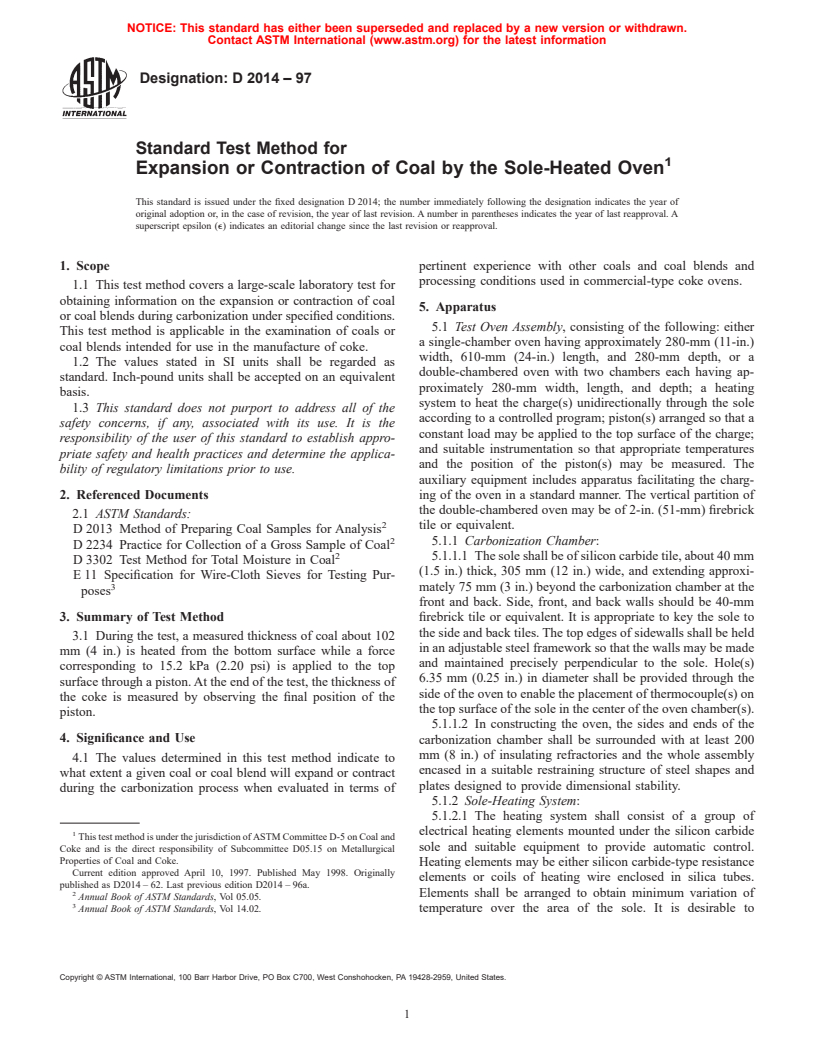

5.1 Test Oven Assembly, consisting of the following: either

This test method is applicable in the examination of coals or

a single-chamber oven having approximately 280-mm (11-in.)

coal blends intended for use in the manufacture of coke.

width, 610-mm (24-in.) length, and 280-mm depth, or a

1.2 The values stated in SI units shall be regarded as

double-chambered oven with two chambers each having ap-

standard. Inch-pound units shall be accepted on an equivalent

proximately 280-mm width, length, and depth; a heating

basis.

system to heat the charge(s) unidirectionally through the sole

1.3 This standard does not purport to address all of the

according to a controlled program; piston(s) arranged so that a

safety concerns, if any, associated with its use. It is the

constant load may be applied to the top surface of the charge;

responsibility of the user of this standard to establish appro-

and suitable instrumentation so that appropriate temperatures

priate safety and health practices and determine the applica-

and the position of the piston(s) may be measured. The

bility of regulatory limitations prior to use.

auxiliary equipment includes apparatus facilitating the charg-

2. Referenced Documents ing of the oven in a standard manner. The vertical partition of

the double-chambered oven may be of 2-in. (51-mm) firebrick

2.1 ASTM Standards:

tile or equivalent.

D 2013 Method of Preparing Coal Samples for Analysis

5.1.1 Carbonization Chamber:

D 2234 Practice for Collection of a Gross Sample of Coal

5.1.1.1 The sole shall be of silicon carbide tile, about 40 mm

D 3302 Test Method for Total Moisture in Coal

(1.5 in.) thick, 305 mm (12 in.) wide, and extending approxi-

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

3 mately 75 mm (3 in.) beyond the carbonization chamber at the

poses

front and back. Side, front, and back walls should be 40-mm

3. Summary of Test Method firebrick tile or equivalent. It is appropriate to key the sole to

the side and back tiles. The top edges of sidewalls shall be held

3.1 During the test, a measured thickness of coal about 102

in an adjustable steel framework so that the walls may be made

mm (4 in.) is heated from the bottom surface while a force

and maintained precisely perpendicular to the sole. Hole(s)

corresponding to 15.2 kPa (2.20 psi) is applied to the top

6.35 mm (0.25 in.) in diameter shall be provided through the

surface through a piston. At the end of the test, the thickness of

side of the oven to enable the placement of thermocouple(s) on

the coke is measured by observing the final position of the

the top surface of the sole in the center of the oven chamber(s).

piston.

5.1.1.2 In constructing the oven, the sides and ends of the

4. Significance and Use

carbonization chamber shall be surrounded with at least 200

mm (8 in.) of insulating refractories and the whole assembly

4.1 The values determined in this test method indicate to

encased in a suitable restraining structure of steel shapes and

what extent a given coal or coal blend will expand or contract

plates designed to provide dimensional stability.

during the carbonization process when evaluated in terms of

5.1.2 Sole-Heating System:

5.1.2.1 The heating system shall consist of a group of

electrical heating elements mounted under the silicon carbide

This test method is under the jurisdiction of ASTM Committee D-5 on Coal and

sole and suitable equipment to provide automatic control.

Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

Properties of Coal and Coke.

Heating elements may be either silicon carbide-type resistance

Current edition approved April 10, 1997. Published May 1998. Originally

elements or coils of heating wire enclosed in silica tubes.

published as D2014 – 62. Last previous edition D2014 – 96a.

Elements shall be arranged to obtain minimum variation of

Annual Book of ASTM Standards, Vol 05.05.

Annual Book of ASTM Standards, Vol 14.02. temperature over the area of the sole. It is desirable to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2014–97

incorporate a maximum number of supports for the silicon 6. Instrumentation

carbide sole tile. The brickwork and steelwork beneath the

6.1 Piston Movement—The excursion of the piston from an

heating flues shall be of appropriate design to maintain rigidity

initial reference position may be measured either manually, by

of the oven under the temperature and load stresses of

observing the movement of an indicator, or automatically by

operation.

means of an appropriate transducer and recording system. A

5.1.2.2 The thermocouple used for temperature control is

preferred form of indicator is a witness point on a silica rod

located in a position which enables the sole to be heated in

mounted on the upper surface of the lower piston plate and not

accordance with the sole temperature program shown in Table

connected in any way to the remaining piston structure. When

1. The heating system shall be capable of reachieving the initial

using this design of indicator, no corrections need be made for

set point temperature of 554°C within 10 min of charging the

expansion of the piston structure itself. Alternatively, the basic

oven and of heating the sole in accordance with the sole

indicator may be mounted on the upper steel structure of the

temperature program shown in Table 1.

piston. In this event, any correction for piston expansion during

5.1.2.3 The temperature control thermocouple may be in-

a test, if necessary, shall be determined by appropriate prelimi-

stalled in the heating flue or in contact with the sole plate.

nary calibration. Measurements of the position of the indicator

5.1.3 Piston—The piston assembly shall include a massive

may be made by directly observing the witness point with a

bottom plate of metal to which an upper steel assembly is

cathetometer or by using a suitable mechanical or electrical

rigidly attached. The bottom plate shall be 19- or 25-mm (0.75-

system of magnifying movement. Apparatus of the latter type

or 1-in.) cast steel or cast iron in one piece with square edges.

should be calibrated with an accurate cathetometer. Whatever

Dimensions are to be so chosen that the clearances between

type of indicator is used it shall be placed as close to the

piston edges and chamber walls, ends, and sides, at the

geometric center of the piston as possible.

conclusion of a test (upper surface of coal at 500°C) are at least

6.1.1 Thermocouples shall be provided for measuring both

3.2 mm (0.125 in.) but not as much as 9.5 mm (0.375 in.). A10-

the temperature of the top surface of the sole (maximum of

to 130-mm (4.5- to 5-in.) layer of insulating refractory shall be

about 950°C) and the temperature of the top surface of the coal

formed upon the steel plate, the sides being recessed somewhat

(maximum about 500°C) (Note 2). The thermowell containing

within the piston edges. The upper steel assembly shall be

the sole couple shall be placed horizontally through the hole in

rigidly fastened to the corners of the lower plate with steel

the sidewall or endwall tile so that the thermowell lies flat with

supports. The upper steel assembly and corner supports shall

its tip near the geometric center of the sole. The thermowell

be of adequate strength to permit application of the desired

containing the top surface thermocouple shall be placed in the

load and shall be fitted with appropriate hardware to permit

vertical hole in the piston and adjusted so that its lowest point

ready placement into or removal from the carbonization

is flush with the lower surface of the piston plate.

chamber. A vertical hole, 13 mm (0.5 in.) in diameter, piercing

NOTE 1—Type K Chromel-Alumel thermocouples have proven satis-

the piston assembly, including lower plate shall be provided on

factory in these applications. Quartz or porcelain is a satisfactory material

the longitudinal center line for a thermocouple, about 200 mm

for thermocouple protection tubing. Mild steel or stainless tubing may also

(8 in.) from either the front or rear edge of the piston.

be used but will require frequent replacement.

5.1.4 Apparatus for Loading Piston—Apparatus shall be

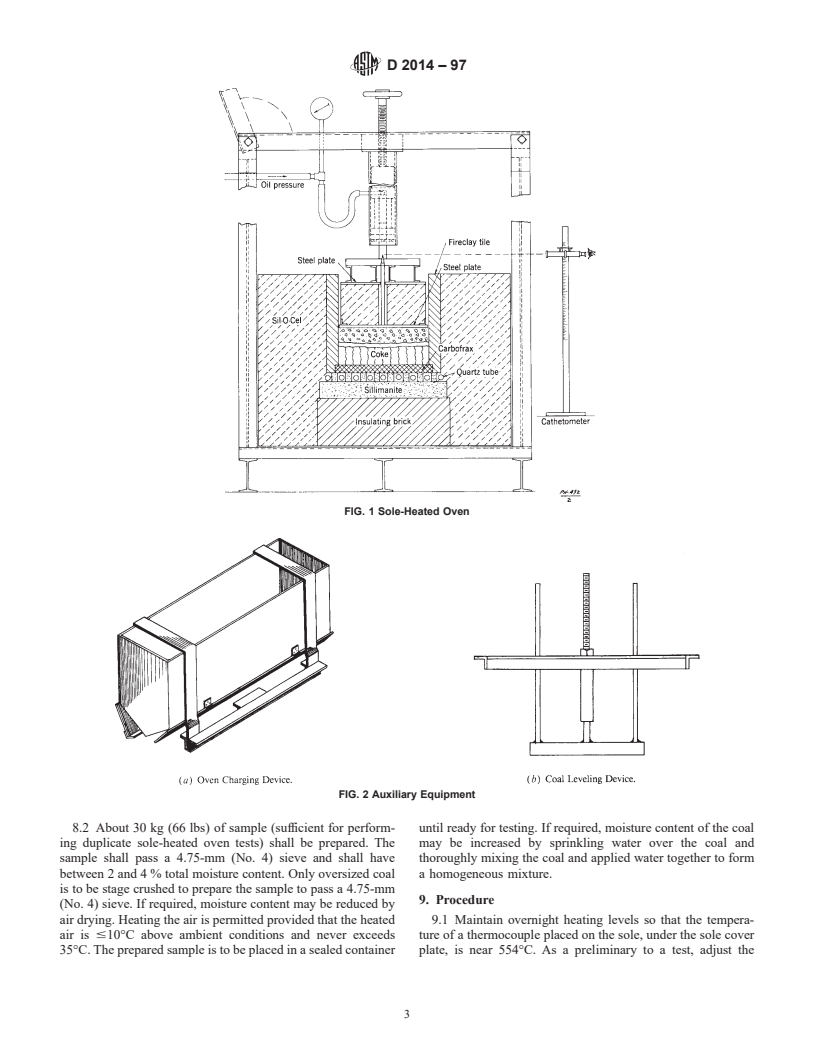

7. Accessory Equipment

provided so that a constant load of 15.17 6 0.35 kPa (2.20 6

0.05 psi) calculated over the measured area of the piston plate, 7.1 Auxiliary Apparatus—Necessary auxiliary apparatus in-

may be applied to the piston during the test. The manner of

cludes a sole cover plate, a charging hopper, and an adjustable

applying this load is not critical. Examples of suitable proce- leveling device:

dures are (1) use of a hydraulic piston as shown in Fig. 1, (2)

7.1.1 Sole Cover Plate, conforming to the dimensions of the

use of a hinged lever-arm system bearing on a fulcrum piston plate and consisting of a suitable metal framework

mounted on the upper steelwork of the piston structure, and (3)

containing either a layer of insulating brick or an equivalent

placement of sufficient additional dead weights on the piston layer of ins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.