ASTM F1594-95(1999)

(Specification)Standard Specification for Pure Aluminum (Unalloyed) Source Material for Vacuum Coating Applications

Standard Specification for Pure Aluminum (Unalloyed) Source Material for Vacuum Coating Applications

SCOPE

1.1 This specification covers pure aluminum metal (unalloyed) for use as raw material for making evaporation sources, sputtering targets, and superconducting wires.

1.2 This specification sets purity grade levels, physical attributes, analytical methods, and packaging requirements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1594 – 95 (Reapproved 1999)

Standard Specification for

Pure Aluminum (Unalloyed) Source Material for Vacuum

Coating Applications

This standard is issued under the fixed designation F 1594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

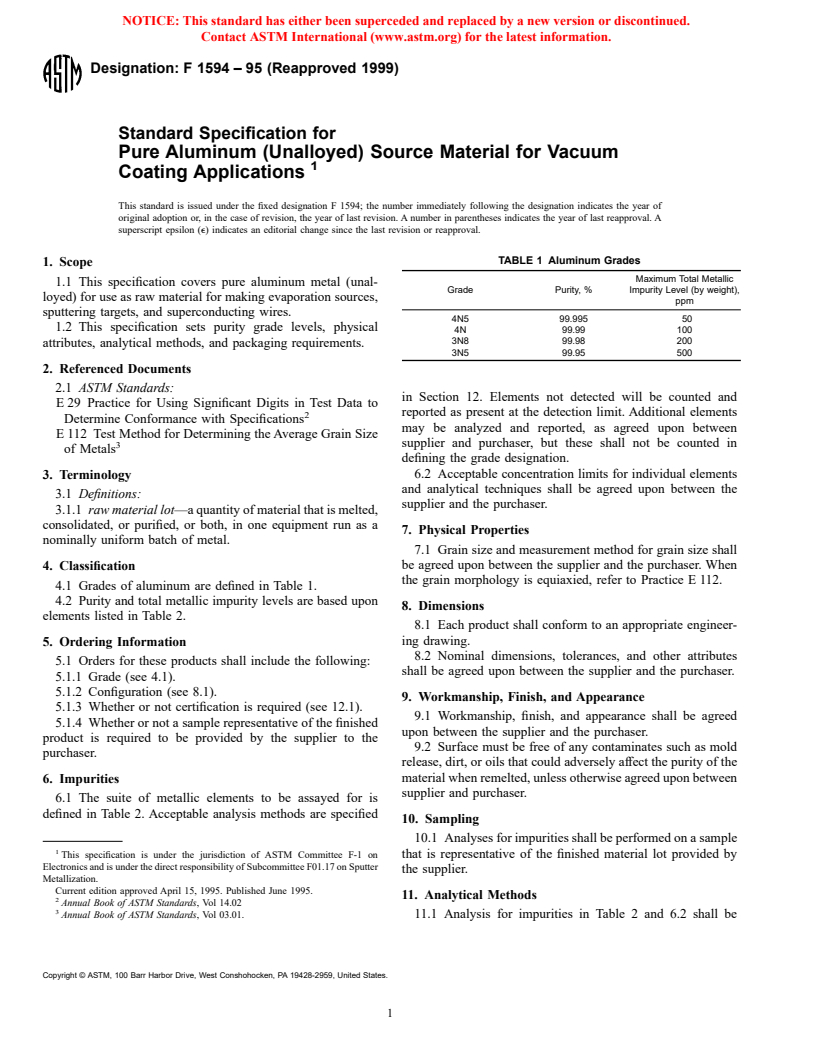

TABLE 1 Aluminum Grades

1. Scope

Maximum Total Metallic

1.1 This specification covers pure aluminum metal (unal-

Grade Purity, % Impurity Level (by weight),

loyed) for use as raw material for making evaporation sources,

ppm

sputtering targets, and superconducting wires.

4N5 99.995 50

1.2 This specification sets purity grade levels, physical

4N 99.99 100

3N8 99.98 200

attributes, analytical methods, and packaging requirements.

3N5 99.95 500

2. Referenced Documents

2.1 ASTM Standards:

in Section 12. Elements not detected will be counted and

E 29 Practice for Using Significant Digits in Test Data to

reported as present at the detection limit. Additional elements

Determine Conformance with Specifications

may be analyzed and reported, as agreed upon between

E 112 Test Method for Determining the Average Grain Size

supplier and purchaser, but these shall not be counted in

of Metals

defining the grade designation.

6.2 Acceptable concentration limits for individual elements

3. Terminology

and analytical techniques shall be agreed upon between the

3.1 Definitions:

supplier and the purchaser.

3.1.1 raw material lot—a quantity of material that is melted,

consolidated, or purified, or both, in one equipment run as a

7. Physical Properties

nominally uniform batch of metal.

7.1 Grain size and measurement method for grain size shall

be agreed upon between the supplier and the purchaser. When

4. Classification

the grain morphology is equiaxied, refer to Practice E 112.

4.1 Grades of aluminum are defined in Table 1.

4.2 Purity and total metallic impurity levels are based upon

8. Dimensions

elements listed in Table 2.

8.1 Each product shall conform to an appropriate engineer-

ing drawing.

5. Ordering Information

8.2 Nominal dimensions, tolerances, and other attributes

5.1 Orders for these products shall include the following:

shall be agreed upon between the supplier and the purchaser.

5.1.1 Grade (see 4.1).

5.1.2 Configuration (see 8.1).

9. Workmanship, Finish, and Appearance

5.1.3 Whether or not certification is required (see 12.1).

9.1 Workmanship, finish, and appearance shall be agreed

5.1.4 Whether or not a sample representative of the finished

upon between the supplier and the purchaser.

product is required to be provided by the supplier to the

9.2 Surface must be free of any contaminates such as mold

purchaser.

release, dirt, or oils that could adversely affect the purity of the

material when remelted, unless otherwise agreed upon between

6. Impurities

supplier and purchaser.

6.1 The suite of metallic elements to be assayed for is

defined in Table 2. Acceptable analysis methods are specified

10. Sampling

10.1 Analyses for impurities shall be performed on a sample

This specification is under the jurisdiction of ASTM Committee F-1 on that is representative of the finished material lot pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.