ASTM D3159-22

(Specification)Standard Specification for Modified ETFE Fluoropolymer Molding and Extrusion Materials

Standard Specification for Modified ETFE Fluoropolymer Molding and Extrusion Materials

ABSTRACT

This specification covers melt processible molding and extrusion materials of modified ETFE-fluoropolymer. The ETFE resin is a copolymer of ethylene containing approximately 75 mass% of tetrafluoroethylene. This specification addresses virgin materials only as performance requirements cannot be met with recycled material. Modified ETFE-fluoropolymers shall be supplied in pellet form and classified into five types according to their specific gravity. Furthermore, the resins of each type are divided into three grades according to their melt flow rate. Materials shall be sampled, prepared, and conditioned as appropriate for testing, wherein the following performance requirements must be met: melting point and flow rate; melting endotherm peak temperature; specific gravity; tensile properties (tensile strength and elongation); and dielectric constant and dissipation factor.

SCOPE

1.1 This specification covers molding and extrusion materials of modified ETFE fluoropolymer. The ETFE resin is a copolymer of ethylene and tetrafluoroethylene. Modified ETFE resin contains no more than 5 mole % of other fluoromonomers.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI-10 are to be regarded as standard. The values given in parentheses are for information only.

Note 1: Although this specification and ISO 20568-1 and ISO 20568-2 differ in approach or detail, data obtained using either are technically equivalent.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 Recycled material is not appropriate for this specification because performance requirements cannot be met with recycled material. Therefore, this specification is for virgin material only.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3159 −22

Standard Specification for

Modified ETFE Fluoropolymer Molding and Extrusion

1

Materials

This standard is issued under the fixed designation D3159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers molding and extrusion mate-

D150 Test Methods forAC Loss Characteristics and Permit-

rials of modified ETFE fluoropolymer. The ETFE resin is a

tivity (Dielectric Constant) of Solid Electrical Insulation

copolymerofethyleneandtetrafluoroethylene.ModifiedETFE

D618 Practice for Conditioning Plastics for Testing

resin contains no more than 5 mole % of other fluoromono-

D638 Test Method for Tensile Properties of Plastics

mers.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 The values stated in SI units as detailed in IEEE/ASTM

tive Density) of Plastics by Displacement

SI-10 are to be regarded as standard. The values given in

D883 Terminology Relating to Plastics

parentheses are for information only.

D1238 Test Method for Melt Flow Rates of Thermoplastics

by Extrusion Plastometer

NOTE 1—Although this specification and ISO 20568-1 and ISO

D1600 Terminology forAbbreviatedTerms Relating to Plas-

20568-2 differ in approach or detail, data obtained using either are

technically equivalent. tics

D3418 Test Method for Transition Temperatures and En-

1.3 The following safety hazards caveat pertains only to the

thalpies of Fusion and Crystallization of Polymers by

test method portion, Section 11, of this specification. This

Differential Scanning Calorimetry

standard does not purport to address all of the safety concerns,

D3892 Practice for Packaging/Packing of Plastics

if any, associated with its use. It is the responsibility of the user

E177 Practice for Use of the Terms Precision and Bias in

of this standard to establish appropriate safety, health, and

ASTM Test Methods

environmental practices and determine the applicability of

IEEE/ASTM SI-10 Use of the International System of Units

regulatory limitations prior to use.

(SI): The Modern Metric System

1.4 Recycled material is not appropriate for this specifica-

2.2 ISO Standards:

tion because performance requirements cannot be met with

ISO 20568-1 Plastics—Fluoropolymer Dispersions and

recycled material. Therefore, this specification is for virgin

Moulding and Extrusion Materials—Part 1

material only.

ISO 20568-2 Plastics—Fluoropolymer Dispersions and

Moulding and Extrusion Materials—Part 2

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3.1 Definitions:

3.1.1 General—The terminology given in Terminology

mendations issued by the World Trade Organization Technical

D883 is applicable to this specification.

Barriers to Trade (TBT) Committee.

3.1.2 lot, n—one production run or a uniform blend of two

or more production runs.

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials (Section D20.15.12). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2022. Published March 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1973. Last previous edition approved in 2020 as D3159 - 20. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3159-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3159−22

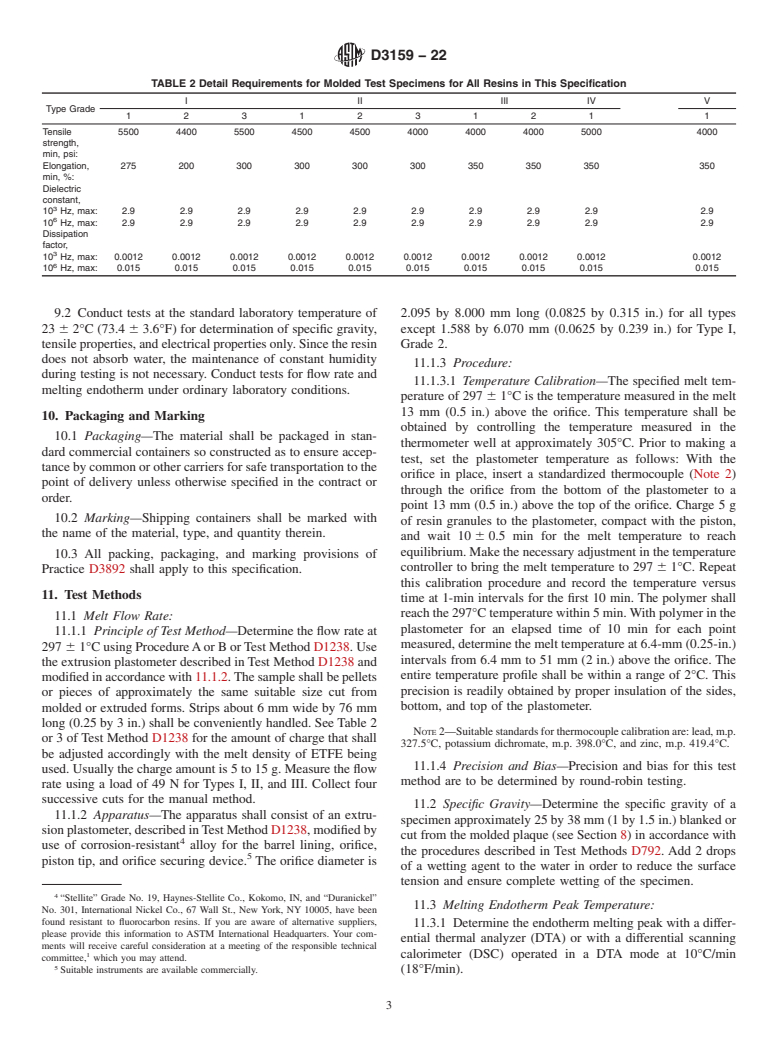

TABLE 1 Specific Gravity, Melting Point, and Flow Rate Requirements

I II III IV V

Type Grade

123123121 1

Specific

gravity,

min: 1.69 1.69 1.69 1.75 1.75 1.75 1.83 1.83 1.74 1.74

max: 1.76 1.76 1.76 1.84 1.84 1.84 1.89 1.89 1.78 1.80

Melting point,

°C,

min: 255 255 250 220 220 220 218 218 220 250

max: 280 280 280 259 259 259 230 230 240 260

Flow rate,

g/10 min,

min: 2.0 8.0 25 2.0 10.1 25 9.0 25.0 10 15

A

max: 16.0 28.0 45 10.0 19.0 40 18.0 35.0 40 30

A

Measured with 1.588-mm (0.062

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3159 − 20 D3159 − 22

Standard Specification for

Modified ETFE Fluoropolymer Molding and Extrusion

1

Materials

This standard is issued under the fixed designation D3159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers molding and extrusion materials of modified ETFE fluoropolymer. The ETFE resin is a copolymer

of ethylene and tetrafluoroethylene. Modified ETFE resin contains no more than 5 mole % of other fluoromonomers.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI-10 are to be regarded as standard. The values given in parentheses

are for information only.

NOTE 1—Although this specification and ISO 20568-1 and ISO 20568-2 differ in approach or detail, data obtained using either are technically equivalent.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.4 Recycled material is not appropriate for this specification because performance requirements cannot be met with recycled

material. Therefore, this specification is for virgin material only.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1600 Terminology for Abbreviated Terms Relating to Plastics

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials

(Section D20.15.12).

Current edition approved July 1, 2020March 15, 2022. Published July 2020March 2022. Originally approved in 1973. Last previous edition approved in 20152020 as

D3159 - 15.D3159 - 20. DOI: 10.1520/D3159-20.10.1520/D3159-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

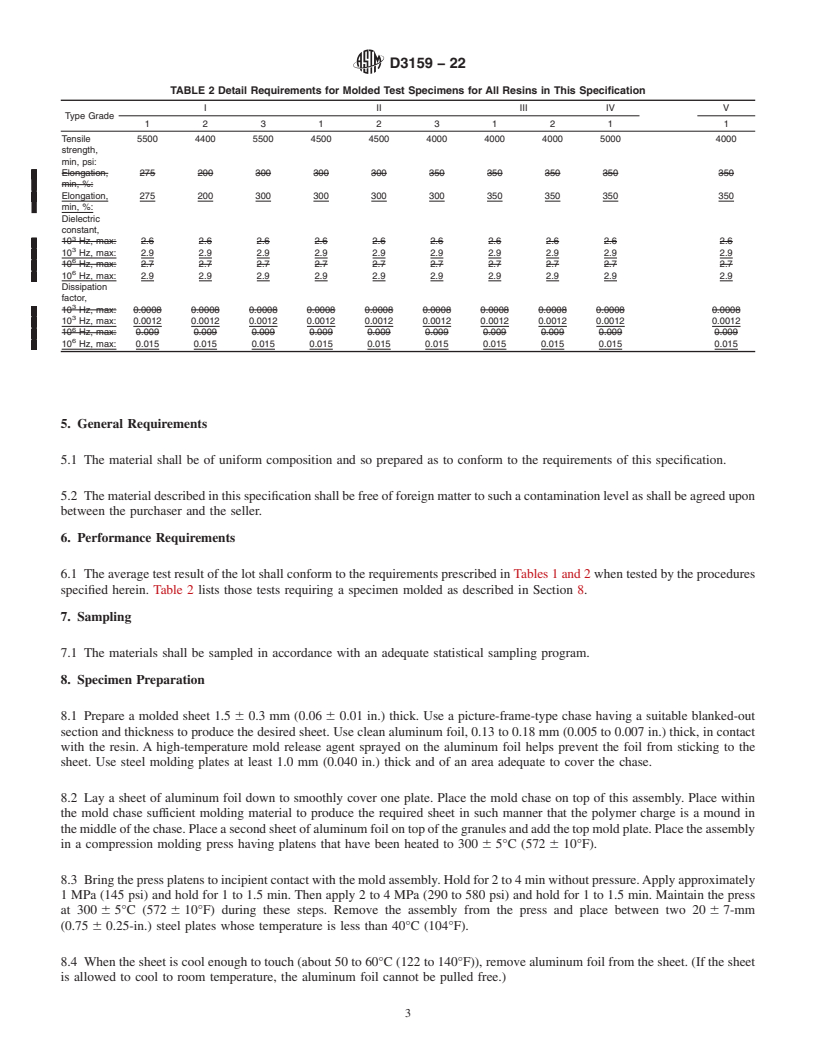

D3159 − 22

TABLE 1 Specific Gravity, Melting Point, and Flow Rate Requirements

I II III IV V

Type Grade

1 2 3 1 2 3 1 2 1 1

Specific

gravity,

min: 1.69 1.69 1.69 1.75 1.75 1.75 1.83 1.83 1.74 1.74

max: 1.76 1.76 1.76 1.84 1.84 1.84 1.88 1.88 1.78 1.80

max: 1.76 1.76 1.76 1.84 1.84 1.84 1.89 1.89 1.78 1.80

Melting point,

°C,

min: 255 255 250 220 220 220 218 218 220 250

max: 280 280 280 259 259 259 230 230 240 260

Flow rate,

g/10 min,

min: 2.0 8.0 25 2.0 10.1 25 9.0 25.0 10 15

A

max: 16.0 28.0 45 10.0 19.0 40 18.0 35.0 40 30

A

Measured with 1.588-mm (0.0625-in.) orifice; other values measured with 2.095-mm (0.0825-in.) orifice.

D3418 Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential

Scanning Calorimetry

D3892 Practice for Packaging/Packing of Plastics

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

IEEE/ASTM SI-10 Use of the International System of Units (SI): The Modern Metric System

2.2 ISO Standards:

ISO 20568-1 Plastics—Fluoropolymer Dispersions and Moulding and Extrusion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.