ASTM F2247-11(2017)

(Test Method)Standard Test Method for Metal Doors Used in Blast Resistant Applications (Equivalent Static Load Method)

Standard Test Method for Metal Doors Used in Blast Resistant Applications (Equivalent Static Load Method)

SIGNIFICANCE AND USE

5.1 Blast resistant doors are designed to protect against the problems and dangers created by a planned or accidental explosion or pressure leak. This test method will provide reasonable assurance to the specifier of the reliability of a door's structure, the restraining hardware, the frame, and the frame anchors when used in a blast resistant application.

SCOPE

1.1 This test method covers the structural performance of metal doors and frames and their restraining hardware (such as latches and hinges) used as a blast resistant barrier. This method involves applying an equivalent static pressure based on the characteristics of the specified blast pressure and structural properties of the door panel design.

1.2 The static tests are valid for the unit size tested or for smaller units of analogous construction. Extrapolation of test results for units larger than the test specimen are not permitted.

1.3 This standard test method is not applicable to tests where the forces are created by explosive charges, forced air from a shock tube apparatus, or any other method used to generate a dynamic load.

1.4 The proper use of this method requires knowledge of the principles of pressure, deflection, and when applicable, strain gauge measurement.

1.5 Using this method, specimens may be tested to determine ultimate static capacity or tested to specific static test loads.

1.5.1 Procedure A shall be used when a load-deflection curve is not required and a single load is applied.

1.5.2 Procedure B shall be used when a load-deflection curve is required and a single or multiple loads are applied.

1.6 The values stated in SI units are to be regarded as the standard. The values provided in parenthesis are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2247 − 11 (Reapproved 2017)

Standard Test Method for

Metal Doors Used in Blast Resistant Applications

(Equivalent Static Load Method)

This standard is issued under the fixed designation F2247; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the structural performance of 2.1 ASTM Standards:

E330/E330M Test Method for Structural Performance of

metal doors and frames and their restraining hardware (such as

latches and hinges) used as a blast resistant barrier. This Exterior Windows, Doors, Skylights and Curtain Walls by

method involves applying an equivalent static pressure based Uniform Static Air Pressure Difference

on the characteristics of the specified blast pressure and

2.2 Other Standard:

structural properties of the door panel design.

UFC 3-340-02 Unified Facilities Criteria (UFC), Structures

to Resist the Effects of Accidental Explosions

1.2 The static tests are valid for the unit size tested or for

smaller units of analogous construction. Extrapolation of test

3. Terminology

results for units larger than the test specimen are not permitted.

3.1 Definitions:

1.3 This standard test method is not applicable to tests

3.1.1 metal door—a term used in reference to doors which

where the forces are created by explosive charges, forced air

are built from steel sheets, internally stiffened with cold-

from a shock tube apparatus, or any other method used to

formed shapes or structural steel shapes. Materials can be

generate a dynamic load.

carbon or stainless steel. The materials may be joined together

1.4 Theproperuseofthismethodrequiresknowledgeofthe

by any fabrication technique (that is, welding, bolting, struc-

principles of pressure, deflection, and when applicable, strain

tural adhesive, etc.). The material voids may be filled with

gauge measurement.

insulation.

1.5 Using this method, specimens may be tested to deter-

3.1.2 permanent deformation—the permanent displacement

mine ultimate static capacity or tested to specific static test

from an original position that remains after an applied load has

loads.

been removed. Measured in millimetres (mm) (inches (in.)).

1.5.1 Procedure A shall be used when a load-deflection

3.1.3 rebound—stress reversal in the material of the door.

curve is not required and a single load is applied.

3.1.4 seating pressure—an applied pressure that causes the

1.5.2 Procedure B shall be used when a load-deflection

door panel to seat against the frame that is expressed in pascals

curve is required and a single or multiple loads are applied.

(Pa) (pounds-force per square foot (psf) or pounds-force per

1.6 The values stated in SI units are to be regarded as the

square inch (psi)).

standard. The values provided in parenthesis are for informa-

3.1.5 specifier—individual or party requesting that a metal

tion only.

door assembly meet specific blast resistance criteria.

1.7 This standard does not purport to address all of the

3.1.6 specimen—the entire assembly unit submitted for test

safety concerns, if any, associated with its use. It is the

as described in Section 6.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.7 steady state pressure—a test pressure held for a

bility of regulatory limitations prior to use. minimum of 3 min.

1 2

This test method is under the jurisdiction ofASTM Committee F12 on Security For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Systems Products and Services. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2017. Published March 2017. Originally the ASTM website.

approved in 2003. Last previous edition approved in 2011 as F2247 – 11. DOI: Available from National Institute of Building Sciences, 1090 VermontAvenue,

10.1520/F2247-11R17. NW, Suite 700, Washington, DC 20005, http://www.wbdg.org/index.php.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2247 − 11 (2017)

3.1.8 test director—the individual identified as being re- installation. The door frame will be attached to the test fixture

sponsible to complete the specified tests as required and to using the same quantity, size, and spacing of fasteners or

document the results. anchors that the specifier or door manufacturer intends to use

in the actual door installation.

3.1.9 test load—the specified static pressure differential

(positive or negative) for which the specimen is to be tested,

7. Apparatus

expressedinpascals(Pa)(pounds-forcepersquarefoot(psf)or

pounds-force per square inch (psi)). 7.1 Equipment capable of performing the test procedure

described in this standard within the allowable tolerances is

3.1.10 ultimate load—the pressure (positive or negative) at

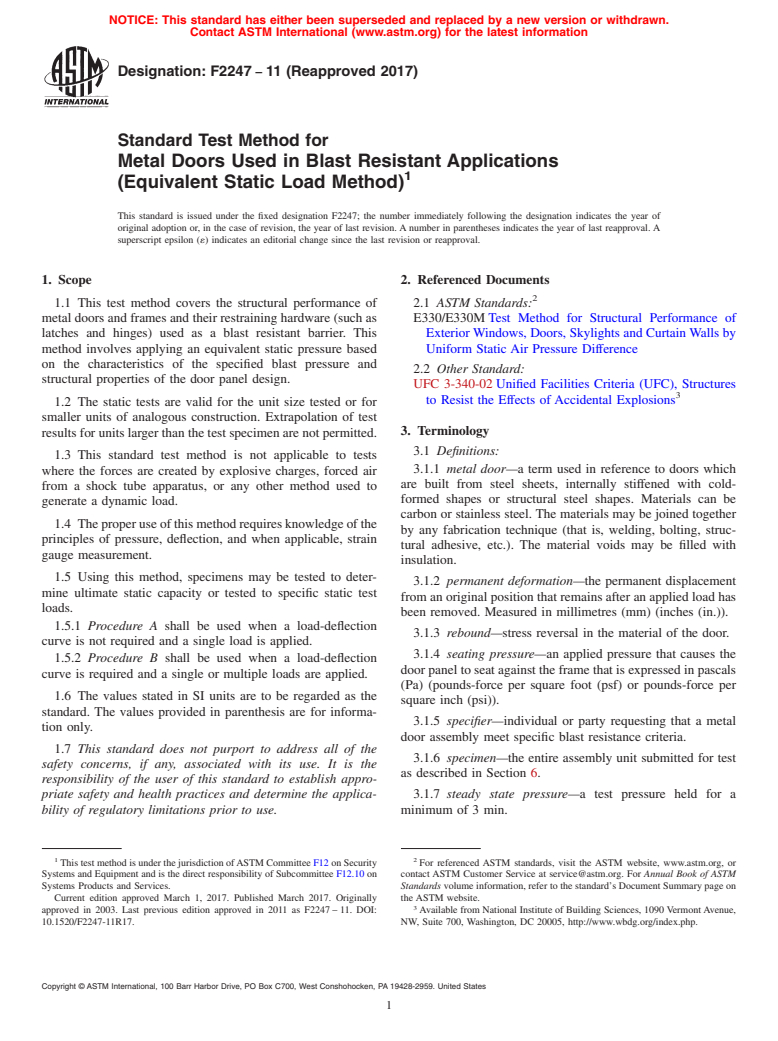

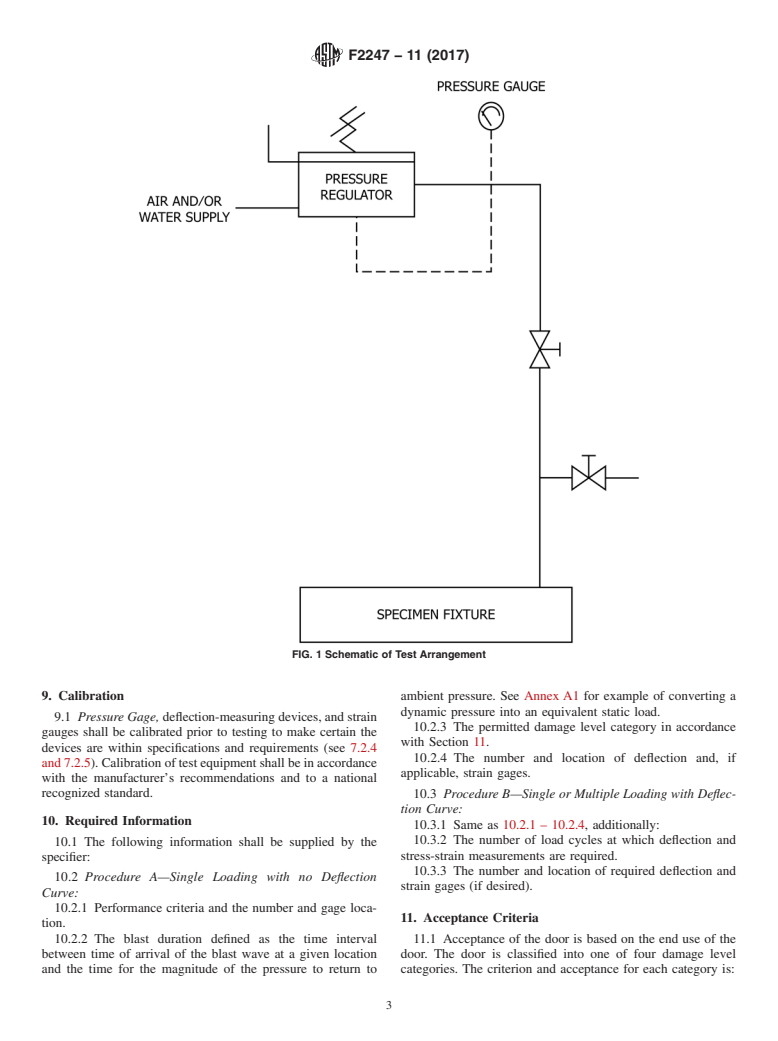

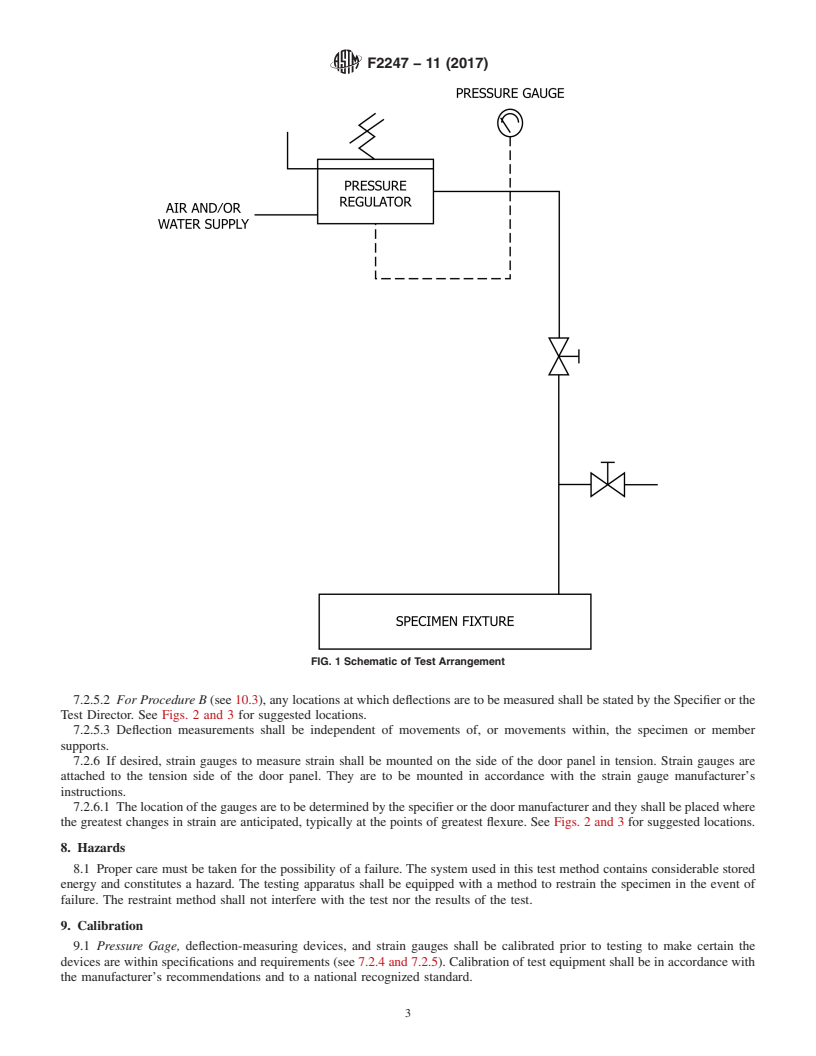

acceptable. Figs. 1-4 are examples of apparatus layout.

which failure of the specimen occurs expressed in Pa (psf or

psi). 7.2 Major Components:

7.2.1 Test Chamber—A chamber or box with an opening

3.1.11 unseating pressure—an applied pressure that tends

and a removable mounting panel, into which the specimen is

the door panel to unseat from the frame so that the door

installed.Atleastonepressuretapshallbeprovidedtomeasure

reactions must be resisted by the restraining hardware, that is

the chamber pressure and shall be so located that the reading is

expressedinpascals(Pa)(pounds-forcepersquarefoot(psf)or

unaffected by the velocity of the fluid supply to or from the

pounds-force per square inch (psi)).

chamber or any other fluid movement. A means of access is

permitted to be provided to facilitate adjustments and obser-

4. Summary of Test Method

vations after the specimen is installed. The test chamber must

4.1 This test method consists of sealing the test specimen

not deflect under the test load in such a manner that the

into or against one face of a test chamber, supplying air to the

performance of the specimen will be affected.

chamber at a ratio required to maintain the test pressure

7.2.2 Air System—A controllable blower or a compressed

difference across the specimen, and observing, measuring, and

air supply, designed to provide the required air-pressure

recording the deflection, deformations, stresses (if recorded),

difference across the specimen. The system shall provide a

and nature of any failures of principal or critical members or

constant air pressure difference for the duration of the test.

the entire specimen.

7.2.3 Combined Air/Water System—A combined air and

water (fluid) system (See Fig. 1).

5. Significance and Use

7.2.4 Pressure-Measuring Apparatus—A device to measure

5.1 Blast resistant doors are designed to protect against the

the test pressure difference with accuracy of 62 % of the

problems and dangers created by a planned or accidental

reading over the full range of test pressures.

explosion or pressure leak. This test method will provide

7.2.5 Deflection-Measuring System—Ameans of measuring

reasonable assurance to the specifier of the reliability of a

deflections with an accuracy of 60.25 mm (60.01 in.).

door’s structure, the restraining hardware, the frame, and the

7.2.5.1 For Procedure A (see 10.2), any locations at which

frame anchors when used in a blast resistant application.

deflections are to be measured shall be stated by the Specifier

or the Test Director. See Figs. 2 and 3 for suggested locations.

6. Specimen Preparation

7.2.5.2 For Procedure B (see 10.3), any locations at which

deflections are to be measured shall be stated by the Specifier

6.1 Construction—The door panel shall meet the general

or the Test Director. See Figs. 2 and 3 for suggested locations.

definition of a metal door as outlined in 3.1.1. The test method

7.2.5.3 Deflection measurements shall be independent of

isgeneralanddoesnotlimitthedoormanufacturertoaspecific

movements of, or movements within, the specimen or member

door panel construction or fabrication process. Ultimately, the

supports.

designofthedoorpanelisbaseduponthetargetpressurerating

7.2.6 If desired, strain gauges to measure strain shall be

established by the specifier or door manufacturer.

mounted on the side of the door panel in tension. Strain gauges

6.1.1 The size of the specimen (door panel and frame) shall

are attached to the tension side of the door panel. They are to

be representative or larger than the application under investi-

bemountedinaccordancewiththestraingaugemanufacturer’s

gation.

instructions.

6.1.2 Configuration and spacing of the door panel’s internal

7.2.6.1 The location of the gauges are to be determined by

stiffeners will be as designed by the specifier or the door

the specifier or the door manufacturer and they shall be placed

manufacturer. Space between stiffeners may be filled with

where the greatest changes in strain are anticipated, typically at

insulation.

the points of greatest flexure. See Figs. 2 and 3 for suggested

6.1.3 The typical door panel shall be considered as a three

locations.

side supported, one edge free loading condition for a seating

load case. Generally, the bottom edge of the door panel is free

8. Hazards

(no structural threshold). If the door assembly does have a

structuralthreshold,thedoorpanelmaybeconsideredasafour 8.1 Proper care must be taken for the possibility of a failure.

sidesupportedconditionforaseatingloadcase.Thedoorpanel The system used in this test method contains considerable

is supported by the restraining hardware during the unseating stored energy and constitutes a hazard. The testing apparatus

loadcase.Thedoorpanelwillbeattachedtotheframewiththe shall be equipped with a method to restrain the specimen in the

same quantity and size of hinge fasteners that the specifier or event of failure. The restraint method shall not interfere with

the door manufacturer intends to use in the actual door the test nor the results of the test.

F2247 − 11 (2017)

FIG. 1 Schematic of Test Arrangement

9. Calibration ambient pressure. See Annex A1 for example of converting a

dynamic pressure into an equivalent static load.

9.1 Pressure Gage, deflection-measuring devices, and strain

10.2.3 The permitted damage level category in accordance

gauges shall be calibrated prior to testing to make certain the

with Section 11.

devices are within specifications and requirements (see 7.2.4

10.2.4 The number and location of deflection and, if

and7.2.5).Calibrationoftestequipmentshallbeinaccordance

applicable, strain gages.

with the manufacturer’s recommendations and to a national

recognized standard.

10.3 Procedure B—Single or Multiple Loading with Deflec-

tion Curve:

10. Required Information

10.3.1 Same as 10.2.1 – 10.2.4, additionally:

10.3.2 The number of load cycles at which deflection and

10.1 The following information shall be supplied by the

stress-strain measurements are required.

specifier:

10.3.3 The number and location of required deflection and

10.2 Procedure A—Single Loading with no Deflection

strain gages (if desired).

Curve:

10.2.1 Performance criteria and the number and gage loca-

11. Acceptance Criteria

tion.

10.2.2 The blast duration defined as the time interval 11.1 Acceptance of the door is based on the end use of the

between time of arrival of the blast wave at a given location door. The door is classified into one of four damage level

and the time for the magnitude of the pressure to return to categories. The criterion and acceptance for each category is:

F2247 − 11 (2017)

FIG. 2 Test Fixture Elevation—Unseating Load Case

11.1.1 Category I—The specimen is unchanged (no perma- (1) After the specimen has been unloaded, verify that the

nent deformation) after the loading incident and the door is deflection gages have returned to zero reading with a tolerance

fully operable. The specimen remains intact and responds of +2 mm ( ⁄64 in.).

elastically. (2) Verify that the door is operable by unlatching the door

11.1.1.1 Acceptance: and swinging the panel.

F2247 − 11 (2017)

FIG. 3 Test Fixture Elevation—Seating Load Case

(3) If strain gages are used, check that the recorded stresses (5) Verify that the external portions of the latch and hinges

are within acceptable limits of door material. have not suffered any permanent set.

(4) Verify that the door can be latched.

F2247 − 11 (2017)

FIG. 4 Horizontal Section—Unseating Load Case

11.1.2 Category II—The door is operable but measurable; providing a barrier to blast wave propagation. However, the

permanent deformation to the door panel exceeding the toler- specimen is permanently deformed and the door panel is

ance listed in 11.1.1.1 has been experienced. The specimen

inoperable.

remains as an integral system.

11.1.3.1 Acceptance:

11.1.2.1 Acceptance:

(1) After the specimen has been unloaded, verify that the

(1) After the specimen has been unloaded, verify that the

measurable deformation is acceptable to the end use of the

measurable deformation is acceptable to the end use of the

door.

door.

(2) Verify that the specimen remains an integral system.

(2) Verify that the specimen remains an integral system.

11.1.4 Category IV—The door panel is severely deformed.

(3) If strain gages are used, check that the recorded stresses

For a seating load test, the deformation of the door panel must

are within acceptable limits of door material.

be limited to a level that does not cause the door panel to be

(4) Verify that the door is operable by unlatching the door

forced through the door frame opening. For an unseating load

and swinging the panel.

test, the latching mechanism is permitted to fail, allowing the

11.1.3 Category III—Non-catastrophicfailure.Nostructural

failure occurs to the specimen that prevents the specimen from door to swing open; however, the door panel shall remain

F2247 − 11 (2017)

supported by the hinges and it is evident that the door panel 12.4 Procedure B—Use Procedure B when a load-deflection

will not become a flying debris hazard. curve is required:

11.1.4.1 Acceptance: 12.4.1 Follow 12.3.1 and 12.3.2.

(1) After the specimen has been unloaded, verify that the

12.4.2 Apply the load in the number of increment

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2247 − 11 F2247 − 11 (Reapproved 2017)

Standard Test Method for

Metal Doors Used in Blast Resistant Applications

(Equivalent Static Load Method)

This standard is issued under the fixed designation F2247; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the structural performance of metal doors and frames and their restraining hardware (such as latches

and hinges) used as a blast resistant barrier. This method involves applying an equivalent static pressure based on the characteristics

of the specified blast pressure and structural properties of the door panel design.

1.2 The static tests are valid for the unit size tested or for smaller units of analogous construction. Extrapolation of test results

for units larger than the test specimen are not permitted.

1.3 This standard test method is not applicable to tests where the forces are created by explosive charges, forced air from a shock

tube apparatus, or any other method used to generate a dynamic load.

1.4 The proper use of this method requires knowledge of the principles of pressure, deflection, and when applicable, strain

gauge measurement.

1.5 Using this method, specimens may be tested to determine ultimate static capacity or tested to specific static test loads.

1.5.1 Procedure A shall be used when a load-deflection curve is not required and a single load is applied.

1.5.2 Procedure B shall be used when a load-deflection curve is required and a single or multiple loads are applied.

1.6 The values stated in SI units are to be regarded as the standard. The values provided in parenthesis are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E330E330/E330M Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by

Uniform Static Air Pressure Difference

2.2 Other Standard:

UFC 3-340-02 Unified Facilities Criteria (UFC), Structures to Resist the Effects of Accidental Explosions

3. Terminology

3.1 Definitions:

3.1.1 metal door—a term used in reference to doors which are built from steel sheets, internally stiffened with cold-formed

shapes or structural steel shapes. Materials can be carbon or stainless steel. The materials may be joined together by any fabrication

technique (that is, welding, bolting, structural adhesive, etc.). The material voids may be filled with insulation.

3.1.2 permanent deformation—the permanent displacement from an original position that remains after an applied load has been

removed. Measured in millimetres (mm) (inches (in.)).

3.1.3 rebound—stress reversal in the material of the door.

This test method is under the jurisdiction of ASTM Committee F12 on Security Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on

Systems Products and Services.

Current edition approved March 1, 2011March 1, 2017. Published April 2011March 2017. Originally approved in 2003. Last previous edition approved in 20102011 as

F2247 – 03 (2010).F2247 – 11. DOI: 10.1520/F2247-11.10.1520/F2247-11R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from National Institute of Building Sciences, 1090 Vermont Avenue, NW, Suite 700, Washington, DC 20005, http://www.wbdg.org/index.php.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2247 − 11 (2017)

3.1.4 seating pressure—an applied pressure that causes the door panel to seat against the frame that is expressed in pascals (Pa)

(pounds-force per square foot (psf) or pounds-force per square inch (psi)).

3.1.5 specifier—individual or party requesting that a metal door assembly meet specific blast resistance criteria.

3.1.6 specimen—the entire assembly unit submitted for test as described in Section 6.

3.1.7 steady state pressure—a test pressure held for a minimum of 3 min.

3.1.8 test director—the individual identified as being responsible to complete the specified tests as required and to document

the results.

3.1.9 test load—the specified static pressure differential (positive or negative) for which the specimen is to be tested, expressed

in pascals (Pa) (pounds-force per square foot (psf) or pounds-force per square inch (psi)).

3.1.10 ultimate load—the pressure (positive or negative) at which failure of the specimen occurs expressed in Pa (psf or psi).

3.1.11 unseating pressure—an applied pressure that tends the door panel to unseat from the frame so that the door reactions must

be resisted by the restraining hardware, that is expressed in pascals (Pa) (pounds-force per square foot (psf) or pounds-force per

square inch (psi)).

4. Summary of Test Method

4.1 This test method consists of sealing the test specimen into or against one face of a test chamber, supplying air to the chamber

at a ratio required to maintain the test pressure difference across the specimen, and observing, measuring, and recording the

deflection, deformations, stresses (if recorded), and nature of any failures of principal or critical members or the entire specimen.

5. Significance and Use

5.1 Blast resistant doors are designed to protect against the problems and dangers created by a planned or accidental explosion

or pressure leak. This test method will provide reasonable assurance to the specifier of the reliability of a door’s structure, the

restraining hardware, the frame, and the frame anchors when used in a blast resistant application.

6. Specimen Preparation

6.1 Construction—The door panel shall meet the general definition of a metal door as outlined in 3.1.1. The test method is

general and does not limit the door manufacturer to a specific door panel construction or fabrication process. Ultimately, the design

of the door panel is based upon the target pressure rating established by the specifier or door manufacturer.

6.1.1 The size of the specimen (door panel and frame) shall be representative or larger than the application under investigation.

6.1.2 Configuration and spacing of the door panel’s internal stiffeners will be as designed by the specifier or the door

manufacturer. Space between stiffeners may be filled with insulation.

6.1.3 The typical door panel shall be considered as a three side supported, one edge free loading condition for a seating load

case. Generally, the bottom edge of the door panel is free (no structural threshold). If the door assembly does have a structural

threshold, the door panel may be considered as a four side supported condition for a seating load case. The door panel is supported

by the restraining hardware during the unseating load case. The door panel will be attached to the frame with the same quantity

and size of hinge fasteners that the specifier or the door manufacturer intends to use in the actual door installation. The door frame

will be attached to the test fixture using the same quantity, size, and spacing of fasteners or anchors that the specifier or door

manufacturer intends to use in the actual door installation.

7. Apparatus

7.1 Equipment capable of performing the test procedure described in this standard within the allowable tolerances is acceptable.

FiguresFigs. 1-4 1 through 4 are examples of apparatus layout.

7.2 Major Components:

7.2.1 Test Chamber—A chamber or box with an opening and a removable mounting panel, into which the specimen is installed.

At least one pressure tap shall be provided to measure the chamber pressure and shall be so located that the reading is unaffected

by the velocity of the fluid supply to or from the chamber or any other fluid movement. A means of access is permitted to be

provided to facilitate adjustments and observations after the specimen is installed. The test chamber must not deflect under the test

load in such a manner that the performance of the specimen will be affected.

7.2.2 Air System—A controllable blower or a compressed air supply, designed to provide the required air-pressure difference

across the specimen. The system shall provide a constant air pressure difference for the duration of the test.

7.2.3 Combined Air/Water System—A combined air and water (fluid) system (See Fig. 1).

7.2.4 Pressure-Measuring Apparatus—A device to measure the test pressure difference with accuracy of 62 % of the reading

over the full range of test pressures.

7.2.5 Deflection-Measuring System—A means of measuring deflections with an accuracy of 60.25 mm (60.01 in.).

7.2.5.1 For Procedure A (see 10.2), any locations at which deflections are to be measured shall be stated by the Specifier or the

Test Director. See Figs. 2 and 3 for suggested locations.

F2247 − 11 (2017)

FIG. 1 Schematic of Test Arrangement

7.2.5.2 For Procedure B (see 10.3), any locations at which deflections are to be measured shall be stated by the Specifier or the

Test Director. See Figs. 2 and 3 for suggested locations.

7.2.5.3 Deflection measurements shall be independent of movements of, or movements within, the specimen or member

supports.

7.2.6 If desired, strain gauges to measure strain shall be mounted on the side of the door panel in tension. Strain gauges are

attached to the tension side of the door panel. They are to be mounted in accordance with the strain gauge manufacturer’s

instructions.

7.2.6.1 The location of the gauges are to be determined by the specifier or the door manufacturer and they shall be placed where

the greatest changes in strain are anticipated, typically at the points of greatest flexure. See Figs. 2 and 3 for suggested locations.

8. Hazards

8.1 Proper care must be taken for the possibility of a failure. The system used in this test method contains considerable stored

energy and constitutes a hazard. The testing apparatus shall be equipped with a method to restrain the specimen in the event of

failure. The restraint method shall not interfere with the test nor the results of the test.

9. Calibration

9.1 Pressure Gage, deflection-measuring devices, and strain gauges shall be calibrated prior to testing to make certain the

devices are within specifications and requirements (see 7.2.4 and 7.2.5). Calibration of test equipment shall be in accordance with

the manufacturer’s recommendations and to a national recognized standard.

F2247 − 11 (2017)

FIG. 2 Test Fixture Elevation—Unseating Load Case

10. Required Information

10.1 The following information shall be supplied by the specifier:

10.2 Procedure A—Single Loading with no Deflection Curve:

10.2.1 Performance criteria and the number and gage location.

F2247 − 11 (2017)

FIG. 3 Test Fixture Elevation—Seating Load Case

10.2.2 The blast duration defined as the time interval between time of arrival of the blast wave at a given location and the time

for the magnitude of the pressure to return to ambient pressure. See Annex A1 for example of converting a dynamic pressure into

an equivalent static load.

10.2.3 The permitted damage level category in accordance with Section 11.

F2247 − 11 (2017)

FIG. 4 Horizontal Section—Unseating Load Case

10.2.4 The number and location of deflection and, if applicable, strain gages.

10.3 Procedure B—Single or Multiple Loading with Deflection Curve:

10.3.1 Same as 10.2.1 – 10.2.4, additionally:

10.3.2 The number of load cycles at which deflection and stress-strain measurements are required.

10.3.3 The number and location of required deflection and strain gages (if desired).

11. Acceptance Criteria

11.1 Acceptance of the door is based on the end use of the door. The door is classified into one of four damage level categories.

The criterion and acceptance for each category is:

11.1.1 Category I—The specimen is unchanged (no permanent deformation) after the loading incident and the door is fully

operable. The specimen remains intact and responds elastically.

11.1.1.1 Acceptance:

(1) After the specimen has been unloaded, verify that the deflection gages have returned to zero reading with a tolerance of

+2 mm ( ⁄64 in.).

(2) Verify that the door is operable by unlatching the door and swinging the panel.

F2247 − 11 (2017)

(3) If strain gages are used, check that the recorded stresses are within acceptable limits of door material.

(4) Verify that the door can be latched.

(5) Verify that the external portions of the latch and hinges have not suffered any permanent set.

11.1.2 Category II—The door is operable but measurable; permanent deformation to the door panel exceeding the tolerance

listed in 11.1.1.1 has been experienced. The specimen remains as an integral system.

11.1.2.1 Acceptance:

(1) After the specimen has been unloaded, verify that the measurable deformation is acceptable to the end use of the door.

(2) Verify that the specimen remains an integral system.

(3) If strain gages are used, check that the recorded stresses are within acceptable limits of door material.

(4) Verify that the door is operable by unlatching the door and swinging the panel.

11.1.3 Category III—Non-catastrophic failure. No structural failure occurs to the specimen that prevents the specimen from

providing a barrier to blast wave propagation. However, the specimen is permanently deformed and the door panel is inoperable.

11.1.3.1 Acceptance:

(1) After the specimen has been unloaded, verify that the measurable deformation is acceptable to the end use of the door.

(2) Verify that the specimen remains an integral system.

11.1.4 Category IV—The door panel is severely deformed. For a seating load test, the deformation of the door panel must be

limited to a level that does not cause the door panel to be forced through the door frame opening. For an unseati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.