ASTM F2927-21

(Test Method)Standard Test Method for Door Systems Subject to Airblast Loadings

Standard Test Method for Door Systems Subject to Airblast Loadings

SIGNIFICANCE AND USE

5.1 This test method provides standardized procedures that must be followed to establish that a particular door assembly meets a defined damage category (Table 1). Test results can be used to specify a door assembly for a particular pressure/time loading and damage level.

5.2 When a door system is subjected to this test method, it does not imply that a door system of visually similar design will resist the same applied test load. The probability that a single door assembly will resist the specified air blast pressure for which it is certified increases with the number of test specimens used to certify the door design. See Annex A1 for additional statistical considerations.

5.3 Arena testing and shock tube testing may not translate to equivalent results from one method to the other. A specifier may require testing using one method instead of the other. The specifier should be consulted prior to the initiation of any testing.

SCOPE

1.1 This test method identifies the standard procedures that shall be followed when utilizing either an air blast simulator, shock tube, or a controlled open-air explosion to evaluate the blast capacity of a door system. This test method is designed for all types of swinging doors, including single and double doors construction. This method is used to test complete door assemblies. The door panel(s) may also contain one or more integral vision lites (part of the glazing system). The door assembly shall be arranged so that the initial blast force either acts to seat the door panel(s) into the frame or unseat the door panel(s) from the frame to simulate the blast threat. When the initial blast force acts to unseat the door(s) from the frame, the force is concentrated on the restraining hardware (that is, the latching mechanism, the hinges, and the frame connection). The results gathered from this method can be used for door installations in non-rigid wall openings. The test method may be adapted to horizontal sliding and vertical-lift doors.

1.2 When testing with an explosive charge, a charge in-contact with the test specimen or any charge resulting in high localized loading is not covered by this method. When testing with an explosive charge to this standard, to avoid brittle modes of response from the blast, the scaled range of the charge shall be (1.19 m/kg)1/3 (3 ft/lb)1/3 or greater from the test specimen, with an absolute minimum of 1 m (39 in.) standoff of the charge from the test specimen.

1.3 Swinging doors that may be required to resist or mitigate the effects of a blast shall have restraining hardware (latching mechanisms and hinges). The performance of these items is critical in determining the blast resisting or mitigating properties of a door assembly. A door assembly may also contain ancillary hardware. Although many of these critical restraining and ancillary items are mounted on what is deemed the “safe side” of the door system, the test director must verify whether these items stay affixed to the assembly or become dislodged from the assembly. Hardware items that dislodge from the door or frame during the test and become a flying debris hazard shall be assigned a door response damage category as defined in Table 1. When the test results of a door system do not include ancillary hardware as specified by the specifier, it shall be the responsibility of the test sponsor or vendor/manufacturer to determine the risk of an ancillary component becoming a flying debris hazard to the satisfaction of the specifier.

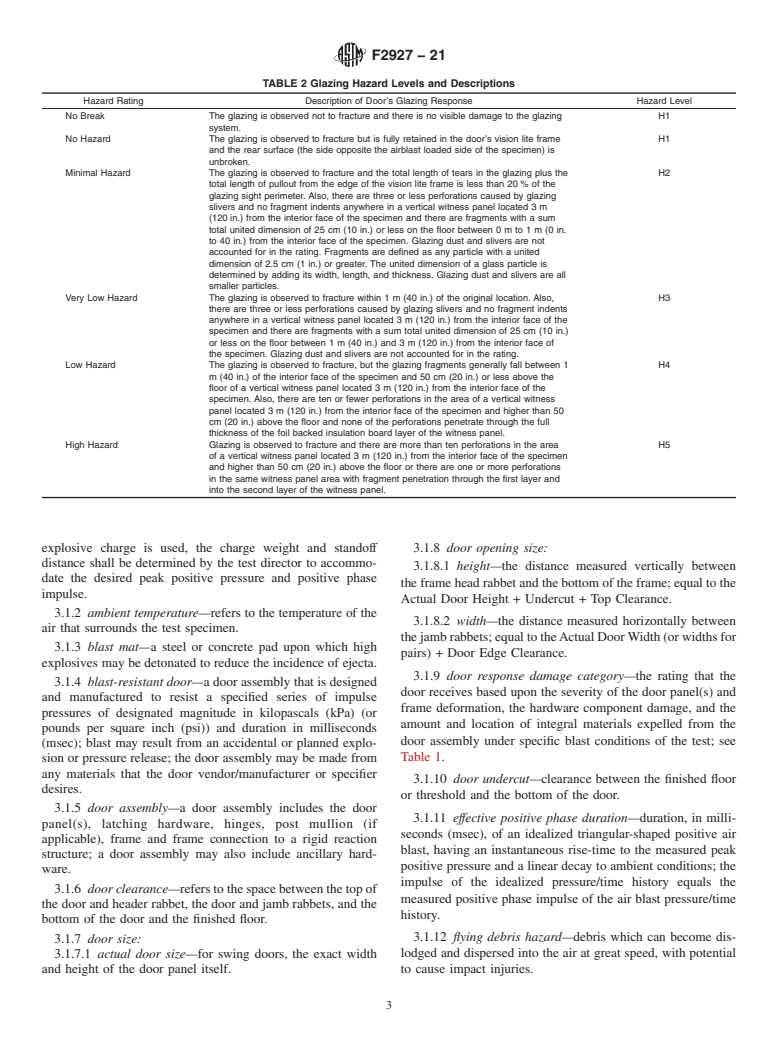

1.4 Unless otherwise specified by end user, this test method and the resulting data are valid for the door size tested, and for smaller doors of identical construction (including any ancillary hardware) with a similar (±20 %) aspect ratio up to 25 % smaller. Acceptance criteria are divided into five door response damage categories (Categories I, II, III, IV, and V). Damage Category III has two subcategories: III/U that permits an un...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2927 − 21

Standard Test Method for

1

Door Systems Subject to Airblast Loadings

This standard is issued under the fixed designation F2927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope debris hazard shall be assigned a door response damage

category as defined in Table 1. When the test results of a door

1.1 This test method identifies the standard procedures that

system do not include ancillary hardware as specified by the

shall be followed when utilizing either an air blast simulator,

specifier, it shall be the responsibility of the test sponsor or

shock tube, or a controlled open-air explosion to evaluate the

vendor/manufacturer to determine the risk of an ancillary

blast capacity of a door system. This test method is designed

component becoming a flying debris hazard to the satisfaction

for all types of swinging doors, including single and double

of the specifier.

doors construction. This method is used to test complete door

assemblies. The door panel(s) may also contain one or more

1.4 Unless otherwise specified by end user, this test method

integral vision lites (part of the glazing system). The door

and the resulting data are valid for the door size tested, and for

assembly shall be arranged so that the initial blast force either

smaller doors of identical construction (including any ancillary

acts to seat the door panel(s) into the frame or unseat the door

hardware) with a similar (620 %) aspect ratio up to 25 %

panel(s) from the frame to simulate the blast threat. When the

smaller.Acceptance criteria are divided into five door response

initial blast force acts to unseat the door(s) from the frame, the

damage categories (Categories I, II, III, IV, and V). Damage

force is concentrated on the restraining hardware (that is, the

Category III has two subcategories: III/U that permits an

latching mechanism, the hinges, and the frame connection).

unsecured door after the loading event and III/S that requires a

The results gathered from this method can be used for door

secured door after the loading event. Refer to 7.1 and Table 1

installations in non-rigid wall openings. The test method may

for a description of each category.

be adapted to horizontal sliding and vertical-lift doors.

1.5 A door assembly may also contain ancillary hardware.

1.2 When testing with an explosive charge, a charge in-

Although these hardware components may not influence blast

contact with the test specimen or any charge resulting in high

resistance performance, the specifier may wish to verify that

localized loading is not covered by this method. When testing

theseitemsdonotdislodgefromthedoororframeduringatest

with an explosive charge to this standard, to avoid brittle

and become a flying debris hazard.

modes of response from the blast, the scaled range of the

1/3 1/3

1.6 For doors equipped with a vision lite, the door shall be

charge shall be (1.19 m⁄kg) (3 ft⁄lb) or greater from the

evaluated using the door response damage categories in Table

test specimen, with an absolute minimum of 1 m (39 in.)

1, and the glazing and glazing system of the vision lite shall

standoff of the charge from the test specimen.

also be evaluated using the glazing hazard levels in Table 2

1.3 Swinging doors that may be required to resist or

(see also 7.5).

mitigate the effects of a blast shall have restraining hardware

1.7 This method is intended to test the blast capacity of a

(latching mechanisms and hinges). The performance of these

door assembly from a shock wave. It does not attempt to

items is critical in determining the blast resisting or mitigating

addressalltestingrequiredofdoorassemblies.Thesetestsmay

properties of a door assembly. A door assembly may also

include, but are not limited to, charge-in-contact blast

contain ancillary hardware. Although many of these critical

resistance, forced entry resistance, ballistic resistance, fire

restraining and ancillary items are mounted on what is deemed

resistance, sound attenuation, and gas or water leakage. These

the “safe side” of the door system, the test director must verify

types of tests are not covered by this test method.

whether these items stay affixed to the assembly or become

dislodged from the assembly. Hardware items that dislodge

1.8 This test method does not verify the blast performance

from the door or frame during the test and become a flying

of the wall that a tested door will be placed in.

1.9 The values sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.