ASTM D7527-10

(Test Method)Standard Test Method for Measurement of Antioxidant Content in Lubricating Greases by Linear Sweep Voltammetry

Standard Test Method for Measurement of Antioxidant Content in Lubricating Greases by Linear Sweep Voltammetry

SIGNIFICANCE AND USE

The quantitative determination of antioxidants in new greases measures the amount of the chemical compounds that were added to the base oil as protection against grease oxidation. For in-service oil greases, the voltammetric test method measures the amount of original (individual) antioxidants remaining after grease oxidation have reduced its concentration. Before making final judgment on the remaining useful life of the in-service grease, which might result in the replacement of the grease reservoir, it is advised to perform additional analytical techniques, such as Test Method D942 and D5483, which may be used to measure the remaining oxidative life of the used grease.

4.1.1 This test method is applicable to mineral oil-based and synthetic oil-based greases, based on all type of applied thickeners. This test method is applicable to greases containing at least one type of antioxidant. The presence of other types of additives like corrosion inhibitors or metal deactivators will not interfere with this test method.

SCOPE

1.1 This test method covers the voltammetric determination of antioxidants in new or in-service lubricating greases in concentrations from 0.0075 weight percent up to concentrations found in new greases by measuring the amount of current flow at a specified voltage in the produced voltammogram.

1.2 This test method is intended to monitor the antioxidant content in lubricating greases; it cannot be applied for lubricating greases that do not contain antioxidants.

1.3 This test method is designed to allow the user to monitor the antioxidant depletion rate of in-service greases through its life cycle as part of condition monitoring programs. This test method is performed in order to collect and trend early signs of deteriorating lubricant grease, and it may be used as a guide for the direction of any required maintenance activities. This will ensure a safe, reliable, and cost-effective operation of the monitored plant equipment.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7527 − 10

Standard Test Method for

Measurement of Antioxidant Content in Lubricating Greases

by Linear Sweep Voltammetry

This standard is issued under the fixed designation D7527; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope catingGreasesbyPressureDifferentialScanningCalorim-

etry

1.1 This test method covers the voltammetric determination

D6810 Test Method for Measurement of Hindered Phenolic

of antioxidants in new or in-service lubricating greases in

Antioxidant Content in Non-Zinc Turbine Oils by Linear

concentrations from 0.0075 weight percent up to concentra-

Sweep Voltammetry

tions found in new greases by measuring the amount of current

D6971 Test Method for Measurement of Hindered Phenolic

flow at a specified voltage in the produced voltammogram.

and Aromatic Amine Antioxidant Content in Non-zinc

1.2 This test method is intended to monitor the antioxidant

Turbine Oils by Linear Sweep Voltammetry

content in lubricating greases; it cannot be applied for lubri-

cating greases that do not contain antioxidants.

3. Summary of Test Method

1.3 Thistestmethodisdesignedtoallowtheusertomonitor

3.1 A measured quantity of sample is weighed into a vial

the antioxidant depletion rate of in-service greases through its

containing a measured quantity of acetone based electrolyte

life cycle as part of condition monitoring programs. This test

solution and containing a layer of sand. When the vial is

methodisperformedinordertocollectandtrendearlysignsof

shaken, the dissolved antioxidants and other solution soluble

deterioratinglubricantgrease,anditmaybeusedasaguidefor

oil components present in the sample are extracted into the

the direction of any required maintenance activities. This will

solution, and the remaining droplets suspended in the solution

ensure a safe, reliable, and cost-effective operation of the

are agglomerated by the sand. The sand/droplet suspension is

monitored plant equipment.

allowed to settle out, and the antioxidants dissolved in the

1.4 The values stated in SI units are to be regarded as solution are quantified by voltammetric analysis.

standard. No other units of measurement are included in this

NOTE 1—Voltages are listed with respect to reference electrode. The

standard.

voltammograms shown in Figs. 1 and 2 were obtained with a platinum

reference electrode and a voltage scan rate of 0.1 V/s.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 The quantitative determination of antioxidants in new

bility of regulatory limitations prior to use.

greases measures the amount of the chemical compounds that

were added to the base oil as protection against grease

2. Referenced Documents

oxidation. For in-service oil greases, the voltammetric test

2.1 ASTM Standards:

method measures the amount of original (individual) antioxi-

D942 Test Method for Oxidation Stability of Lubricating dants remaining after grease oxidation have reduced its con-

Greases by the Oxygen Pressure Vessel Method centration. Before making final judgment on the remaining

D1193 Specification for Reagent Water

useful life of the in-service grease, which might result in the

D5483 Test Method for Oxidation Induction Time of Lubri- replacement of the grease reservoir, it is advised to perform

additional analytical techniques, such as Test Method D942

and D5483, which may be used to measure the remaining

This test method is under the jurisdiction of ASTM Committee D02 on

oxidative life of the used grease.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

4.1.1 Thistestmethodisapplicabletomineraloil-basedand

Subcommittee D02.G0.07 on Research Techniques.

synthetic oil-based greases, based on all type of applied

Current edition approved May 1, 2010. Published June 2010. DOI: 10.1520/

D7527-10.

thickeners.This test method is applicable to greases containing

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

at least one type of antioxidant. The presence of other types of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

additiveslikecorrosioninhibitorsormetaldeactivatorswillnot

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. interfere with this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7527 − 10

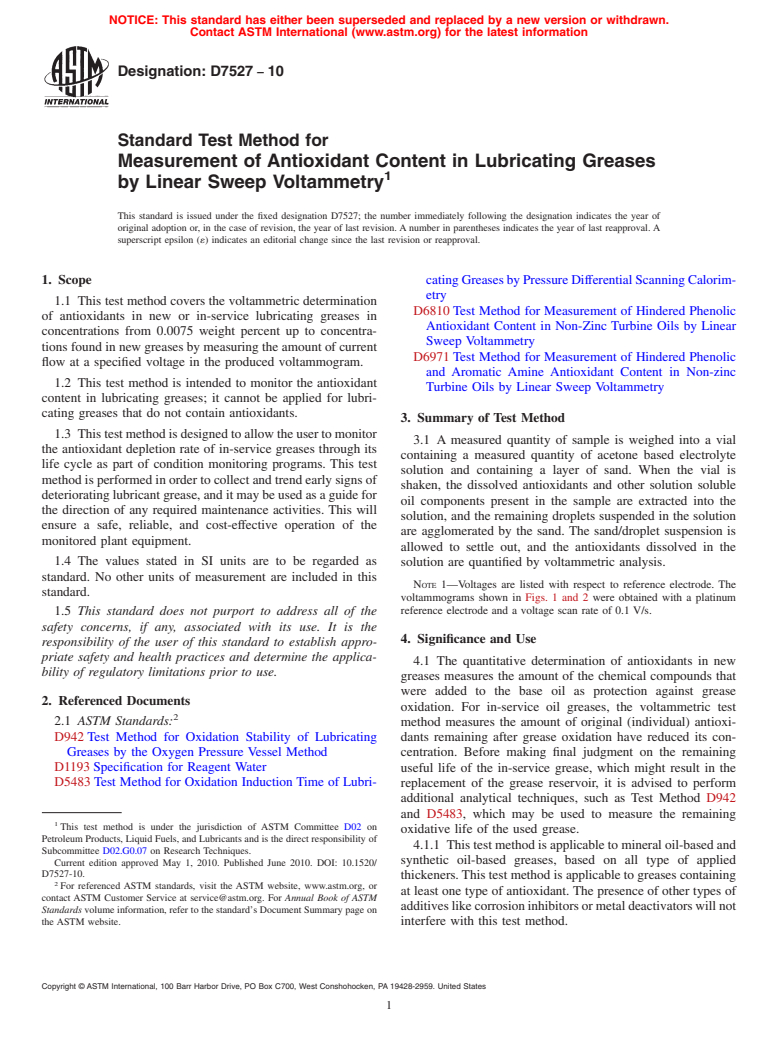

NOTE 1—X-axis represents time (seconds) andY-axis represents current (arbitrary units). Upper line curve in Fig. 1 is voltammogram of a fresh Li-OH

mineral grease showing valley indicators (dotted lines) before and after a antioxidant additives.

FIG. 1 Aromatic Amine and Hindered Phenol Voltammetric Response in Neutral Test Solution with Blank Response Zeroed

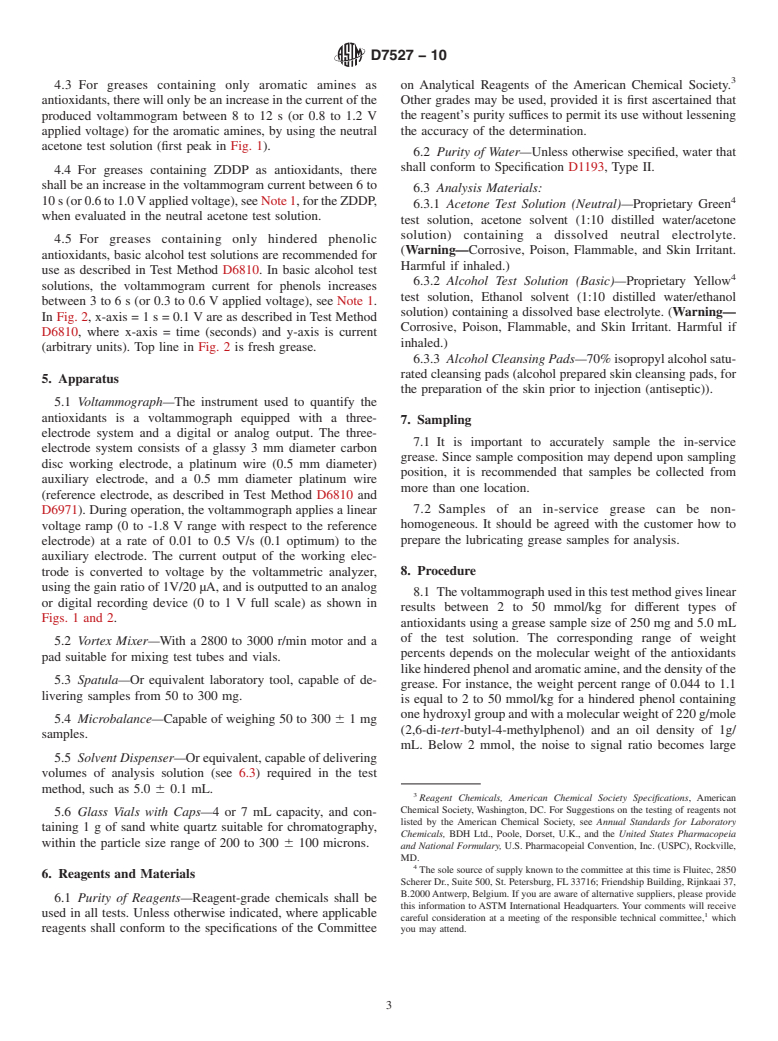

FIG. 2 Hindered Phenol Voltammetric Response in Basic Alcohol Test Solution with Blank Response Zeroed

4.2 When a voltammetric analysis is obtained using a Hindered phenol antioxidants detected by voltammetric analy-

neutral acetone test solution for a grease inhibited with a sis include, but are not limited to, 2,6-di-tert-butyl-4- methyl-

typical synergistic mixture of hindered phenol and aromatic

phenol; 2,6-di-tert-butylphenol and 4,4’-Methylenebis(2,6-di-

amine antioxidants, there is an increase in the voltammogram

tertbutylphenol). Aromatic amine antioxidants detected by

current between 8 to 12 s (or 0.8 to 1.2 V applied voltage), see

voltammetric analysis include, but are not limited to, phenyl

Note 1, for the aromatic amines, and an increase in the

alpha naphthylamines, and alkylated diphenylamines.

voltammogram current of the produced voltammogram be-

tween 13 to 16 s (or 1.3 to 1.6 V applied voltage), see Note 1,

for the hindered phenols. In Fig. 1, x-axis=1s=0.1V.

D7527 − 10

4.3 For greases containing only aromatic amines as on Analytical Reagents of the American Chemical Society.

antioxidants, there will only be an increase in the current of the Other grades may be used, provided it is first ascertained that

produced voltammogram between 8 to 12 s (or 0.8 to 1.2 V the reagent’s purity suffices to permit its use without lessening

applied voltage) for the aromatic amines, by using the neutral the accuracy of the determination.

acetone test solution (first peak in Fig. 1).

6.2 Purity of Water—Unless otherwise specified, water that

shall conform to Specification D1193, Type II.

4.4 For greases containing ZDDP as antioxidants, there

shall be an increase in the voltammogram current between 6 to

6.3 Analysis Materials:

10s(or0.6to1.0Vappliedvoltage),seeNote1,fortheZDDP,

6.3.1 Acetone Test Solution (Neutral)—Proprietary Green

when evaluated in the neutral acetone test solution.

test solution, acetone solvent (1:10 distilled water/acetone

solution) containing a dissolved neutral electrolyte.

4.5 For greases containing only hindered phenolic

(Warning—Corrosive, Poison, Flammable, and Skin Irritant.

antioxidants, basic alcohol test solutions are recommended for

Harmful if inhaled.)

use as described in Test Method D6810. In basic alcohol test

6.3.2 Alcohol Test Solution (Basic)—Proprietary Yellow

solutions, the voltammogram current for phenols increases

test solution, Ethanol solvent (1:10 distilled water/ethanol

between 3 to 6 s (or 0.3 to 0.6 V applied voltage), see Note 1.

solution) containing a dissolved base electrolyte. (Warning—

In Fig. 2, x-axis=1s=0.1Vareas described in Test Method

Corrosive, Poison, Flammable, and Skin Irritant. Harmful if

D6810, where x-axis = time (seconds) and y-axis is current

inhaled.)

(arbitrary units). Top line in Fig. 2 is fresh grease.

6.3.3 Alcohol Cleansing Pads—70%isopropylalcoholsatu-

rated cleansing pads (alcohol prepared skin cleansing pads, for

5. Apparatus

the preparation of the skin prior to injection (antiseptic)).

5.1 Voltammograph—The instrument used to quantify the

antioxidants is a voltammograph equipped with a three-

7. Sampling

electrode system and a digital or analog output. The three-

7.1 It is important to accurately sample the in-service

electrode system consists of a glassy 3 mm diameter carbon

grease. Since sample composition may depend upon sampling

disc working electrode, a platinum wire (0.5 mm diameter)

position, it is recommended that samples be collected from

auxiliary electrode, and a 0.5 mm diameter platinum wire

more than one location.

(reference electrode, as described in Test Method D6810 and

7.2 Samples of an in-service grease can be non-

D6971). During operation, the voltammograph applies a linear

homogeneous. It should be agreed with the customer how to

voltage ramp (0 to -1.8 V range with respect to the reference

prepare the lubricating grease samples for analysis.

electrode) at a rate of 0.01 to 0.5 V/s (0.1 optimum) to the

auxiliary electrode. The current output of the working elec-

8. Procedure

trode is converted to voltage by the voltammetric analyzer,

using the gain ratio of 1V/20 µA, and is outputted to an analog

8.1 Thevoltammographusedinthistestmethodgiveslinear

or digital recording device (0 to 1 V full scale) as shown in

results between 2 to 50 mmol/kg for different types of

Figs. 1 and 2.

antioxidants using a grease sample size of 250 mg and 5.0 mL

of the test solution. The corresponding range of weight

5.2 Vortex Mixer—With a 2800 to 3000 r/min motor and a

percents depends on the molecular weight of the antioxidants

pad suitable for mixing test tubes and vials.

likehinderedphenolandaromaticamine,andthedensityofthe

5.3 Spatula—Or equivalent laboratory tool, capable of de-

grease. For instance, the weight percent range of 0.044 to 1.1

livering samples from 50 to 300 mg.

is equal to 2 to 50 mmol/kg for a hindered phenol containing

onehydroxylgroupandwithamolecularweightof220g/mole

5.4 Microbalance—Capable of weighing 50 to 300 61mg

(2,6-di-tert-butyl-4-methylphenol) and an oil density of 1g/

samples.

mL. Below 2 mmol, the noise to signal ratio becomes large

5.5 Solvent Dispenser—Orequivalent,capableofdelivering

volumes of analysis solution (see 6.3) required in the test

method, such as 5.0 6 0.1 mL.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

5.6 Glass Vials with Caps—4 or 7 mL capacity, and con-

listed by the American Chemical Society, see Annual Standards for Laboratory

taining1gof sand white quartz suitable for chromatography,

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

within the particle size range of 200 to 300 6 100 microns.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

The sole source of supply known to the committee at this time is Fluitec, 2850

6. Reagents and Materials

Scherer Dr., Suite 500, St. Petersburg, FL 33716; Friendship Building, Rijnkaai 37,

B.2000Antwerp, Belgium. If you are aware of alternative suppliers, please provide

6.1 Purity of Reagents—Reagent-grade chemicals shall be

this information to ASTM International Headquarters. Your comments will receive

used in all tests. Unless otherwise indicated, where applicable 1

careful consideration at a meeting of the responsible technical committee, which

reagents shall conform to the specifications of the Committee you may attend.

D7527 − 10

decreasing the accuracy of the measurements. For measure- antioxidant peaks (as shown in Fig. 1), the software (R-DMS )

ments below 2 mmol or for fresh oils with high noise to signal will automatically identify and calculate the area above the

ratios, the sample size should be increased to 600 mg. baseline between the two valley indicators. This calculated

area is then used for the sample reading (in-service or oxidized

8.2 General Voltammetric Test Procedure—The test proce-

grease), which will be established by comparing the in-service

dureforvoltammetricanalysiswillconsistoftheblankreading

grease area to its standard (see Fig. 3) and makes the necessary

(calibration), followed by a standard reading (fresh grease) and

calculations of remaining antioxidant concentration (see Sec-

finally the reading of the (in-service or oxidized grease)

tion 9).

sample.

8.2.1 Blank Reading—(0 mmol/kg = 0 mass percent). The 8.4 Calibration (Blank Reading):

blank reading (voltammetric number) is a measurement of the 8.4.1 Pipette 5.0 mLof analysis solution intoa7mLvial or

testsolutionbyitself.Theblankmeasurementgivesareference other suitable container containing1gof sand.

number with no antioxidant present (the zero baseline). 8.4.2 Insert the electrode of the voltammetric analyzer into

8.2.2 Standard Reading—(30-150 mmol/kg). Concentration theanalysissolutiontowetthebottomsurfaceoftheelectrode,

dependent on density of fresh oil and molecular weight of remove, and rub the bottom electrode surface dry with a lint

antioxidant).The standard reading is a measurement of a fresh, free paper towel. Insert the electrode into the vial so that the

unused grease (containing one or more different types of bottom of the electrode is submerged in the analysis solution

antioxidants) mixed with an appropriate analysis solvent. This without resting on the sand layer on the bottom of the vial.

measurementgivesyouthevoltammetricreadingthatindicates Placethevial/probeuprightintorackorfoamblockfortesting.

the response for the concentration of antioxidants in the fresh 8.4.3 Perform the voltammetric analysis (see 5.1). Record

grease being tested. the voltammetric reading in the voltage range of aromatic

8.2.3 Sample Reading—(Of in-service grease). The sample amines, 0.8 to 1.2 V, see Note 1, and the phenols, 1.3 to 1.6 V,

reading is a measurement of an in-service/ oxidized grease see Note 1, in neutral test solution (Fig. 1).

mixed with the same type of analysis solvent as the standard. 8.4.4 Remove the combination electrode from the blank

This measurement will provide voltammetric readings that solution, and rub the bottom surface dry of the electrode with

normally range between the Blank and Standard a lint-free paper towel.

measurements, and reflects the concentration of one or more 8.4.5 Runatleasttwotestsoftheanalysissolutiontoensure

different types of antioxidants present (fresh grease) or remain- the electrode is clean and the cor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.