ASTM B505/B505M-04

(Specification)Standard Specification for Copper-Base Alloy Continuous Castings

Standard Specification for Copper-Base Alloy Continuous Castings

SCOPE

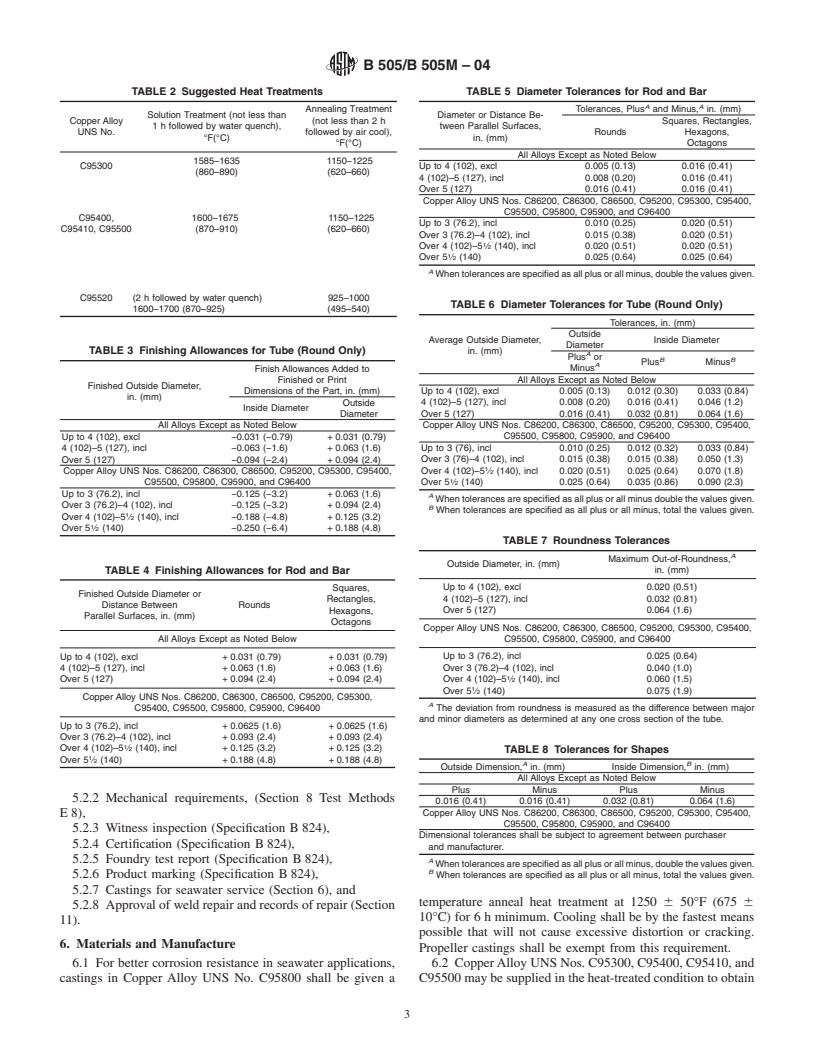

1.1 This specification establishes requirements for continuously cast rod, bar, tube, and shapes produced from copper alloys with nominal compositions as listed in .

1.2 Castings produced to this specification may be manufactured for and supplied from stock. In such cases the manufacturer shall maintain heat traceability to specific manufacturing date and chemical analysis.

1.3 The values stated in inch/pound or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 505/B 505M – 04

Standard Specification for

1

Copper Alloy Continuous Castings

This standard is issued under the fixed designation B 505/B 505M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B 846 Terminology for Copper and Copper Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

1.1 This specification establishes requirements for continu-

E 8M Test Methods for Tension Testing of Metallic Mate-

ously cast rod, bar, tube, and shapes produced from copper

2 rials (Metric)

alloys with nominal compositions as listed in Table 1.

E 10 Test Method for Brinell Hardness of Metallic Materi-

1.2 Castings produced to this specification may be manu-

als

factured for and supplied from stock. In such cases the

E 18 Test Methods for Rockwell Hardness and Rockwell

manufacturer shall maintain heat traceability to specific manu-

Superficial Hardness of Metallic Materials

facturing date and chemical analysis.

E 255 Practice for Sampling of Copper and Copper Alloys

1.3 The values stated in inch/pound or SI units are to be

for the Determination of Chemical Composition

regarded separately as standard. The values stated in each

E 527 Practice for Numbering Metals and Alloys (UNS)

system may not be exact equivalents; therefore, each system

shall be used independently of the other. Combining values

3. Terminology

from the two systems may result in nonconformance with the

3.1 For definitions of terms related to copper and copper

specification.

alloys, refer to Terminology B 846.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. General Requirements

responsibility of the user of this standard to establish appro-

4.1 The following sections of Specification B 824 form a

priate safety and health practices and determine the applica-

part of this specification. The definition of a casting lot as

bility of regulatory limitations prior to use.

defined in Section 12, Sampling, takes precedence over Speci-

fication B 824.

2. Referenced Documents

4.1.1 Terminology (Section 3),

2.1 The following documents in the current issue of the

4.1.2 Other Requirements (Section 7),

Annual Book of ASTM Standards form a part of this specifi-

4.1.3 Workmanship, Finish, and Appearance (Section 9),

cation to the extent referenced herein:

3 4.1.4 Number of Tests and Retests (Section 11),

2.2 ASTM Standards:

4.1.5 Specimen Preparation (Section 12),

B 208 Practice for Preparing Tension Test Specimens for

4.1.6 Test Methods (Section 13),

CopperAlloys for Sand, Permanent Mold, Centrifugal and

4.1.7 Significance of Numerical Limits (Section 14),

Continuous Castings

4.1.8 Inspection (Section 15),

B 824 Specification for General Requirements for Copper

4.1.9 Rejection and Rehearing (Section 16),

Alloy Castings

4.1.10 Certification (Section 17),

4.1.11 Test Report (Section 18),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper 4.1.12 Product Marking (Section 19),

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

4.1.13 Packaging and Package Marking (Section 20),

Castings and Ingots for Remelting.

4.1.14 Keywords (Section 21), and

Current edition approved Oct. 1, 2004. Published October 2004. Originally

4.1.15 Supplementary Requirements.

approved in 1970. Last previous edition approved in 2002 as B 505/B 505M – 02.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple

expansion of the former standard designation system accomplished by the addition 5. Ordering Information

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate

5.1 Include the following information in orders for product:

composition variations of the base alloy.

3

5.1.1 ASTM designation and year of issue (for example,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

B 505/B 505M – 04),

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 505/B 505M – 04

TABLE 1 Nominal Composition

Composition, %

Copper Alloy UNS

Designation

No.

Copper Tin Lead Zinc Nickel Aluminum Iron Manganese

C83600 leaded red brass 85 5 5 5 . . . .

C83800 leaded red brass 82.9 3.8 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.