ASTM D4554-90(1995)

(Test Method)Standard Test Method for In Situ Determination of Direct Shear Strength of Rock Discontinuities

Standard Test Method for In Situ Determination of Direct Shear Strength of Rock Discontinuities

SCOPE

1.1 This test method covers the measurement of peak and residual direct shear strength of in situ rock discontinuities as a function of stress normal to the sheared plane. This sheared plane is usually a significant discontinuity which may or may not be filled with gouge or soil-like material.

1.2 The measured shear properties are affected by scale factors. The severity of the effect of these factors must be assessed and applied to the specific problems on an individual basis.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4554 – 90 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

In Situ Determination of Direct Shear Strength of Rock

Discontinuities

This standard is issued under the fixed designation D 4554; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the tangent to the failure curve at a normal stress that is

relevant to design.

1.1 This test method covers the measurement of peak and

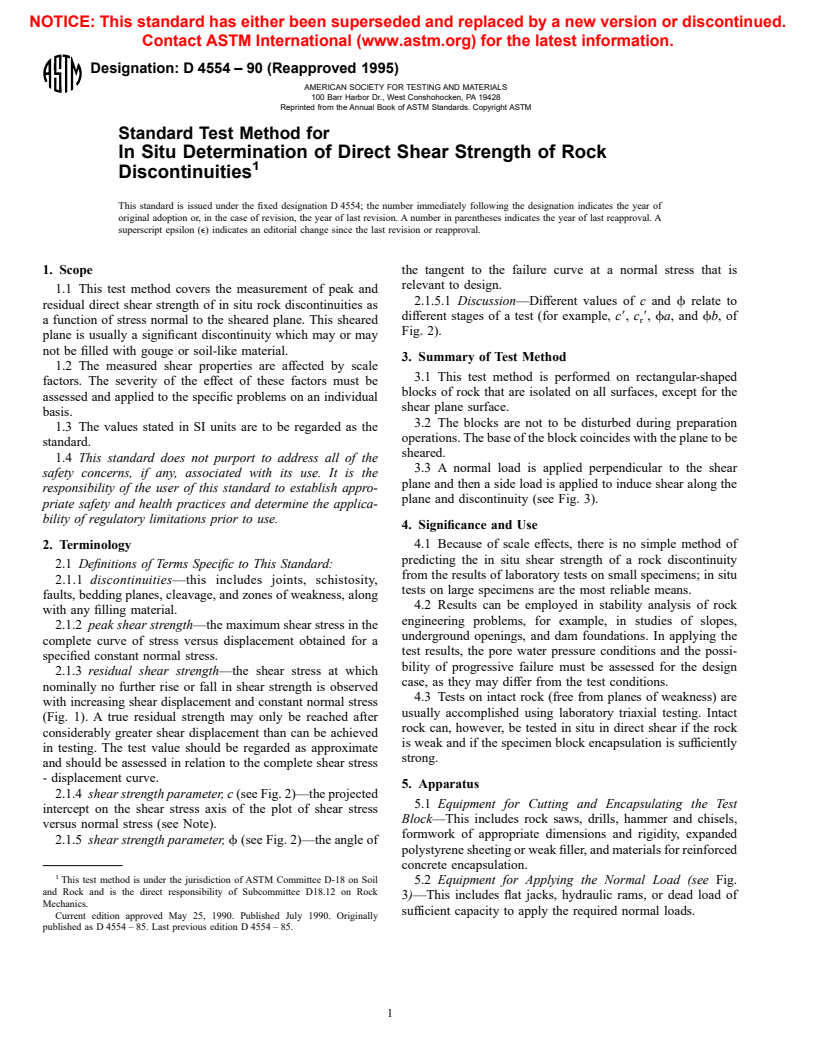

2.1.5.1 Discussion—Different values of c and f relate to

residual direct shear strength of in situ rock discontinuities as

different stages of a test (for example, c8, c 8, fa, and fb,of

r

a function of stress normal to the sheared plane. This sheared

Fig. 2).

plane is usually a significant discontinuity which may or may

not be filled with gouge or soil-like material.

3. Summary of Test Method

1.2 The measured shear properties are affected by scale

3.1 This test method is performed on rectangular-shaped

factors. The severity of the effect of these factors must be

blocks of rock that are isolated on all surfaces, except for the

assessed and applied to the specific problems on an individual

shear plane surface.

basis.

3.2 The blocks are not to be disturbed during preparation

1.3 The values stated in SI units are to be regarded as the

operations. The base of the block coincides with the plane to be

standard.

sheared.

1.4 This standard does not purport to address all of the

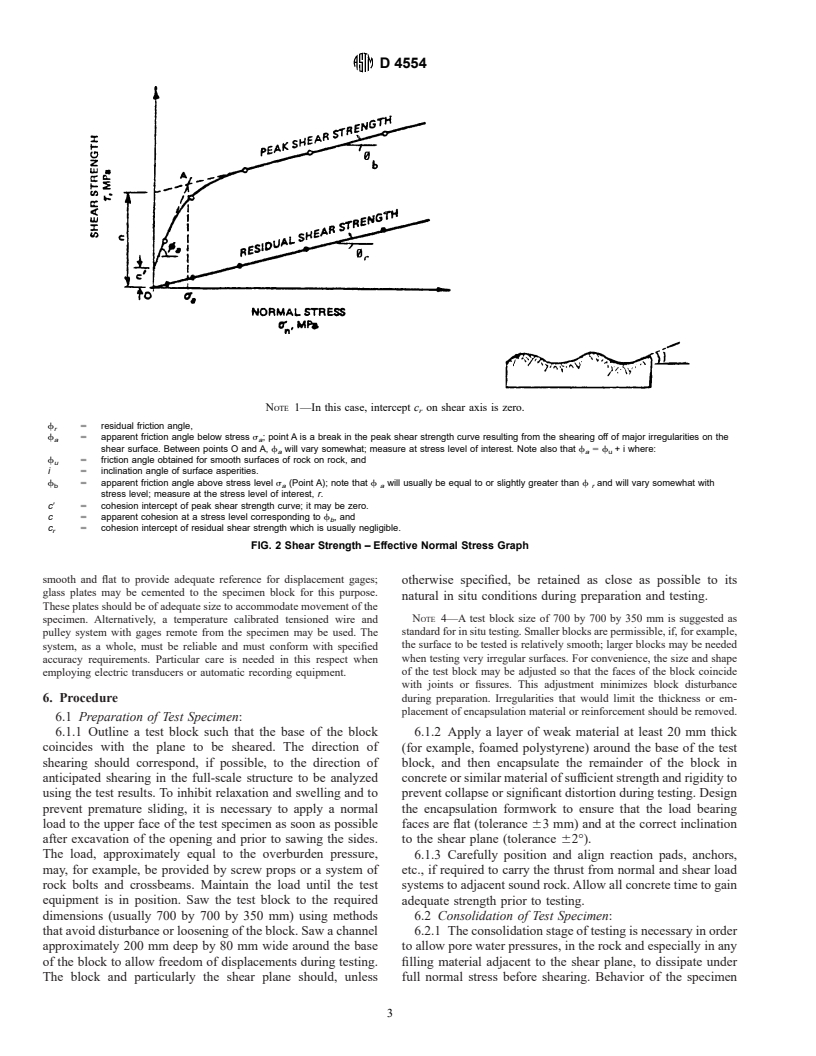

3.3 A normal load is applied perpendicular to the shear

safety concerns, if any, associated with its use. It is the

plane and then a side load is applied to induce shear along the

responsibility of the user of this standard to establish appro-

plane and discontinuity (see Fig. 3).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

2. Terminology 4.1 Because of scale effects, there is no simple method of

predicting the in situ shear strength of a rock discontinuity

2.1 Definitions of Terms Specific to This Standard:

from the results of laboratory tests on small specimens; in situ

2.1.1 discontinuities—this includes joints, schistosity,

tests on large specimens are the most reliable means.

faults, bedding planes, cleavage, and zones of weakness, along

4.2 Results can be employed in stability analysis of rock

with any filling material.

engineering problems, for example, in studies of slopes,

2.1.2 peak shear strength—the maximum shear stress in the

underground openings, and dam foundations. In applying the

complete curve of stress versus displacement obtained for a

test results, the pore water pressure conditions and the possi-

specified constant normal stress.

bility of progressive failure must be assessed for the design

2.1.3 residual shear strength—the shear stress at which

case, as they may differ from the test conditions.

nominally no further rise or fall in shear strength is observed

4.3 Tests on intact rock (free from planes of weakness) are

with increasing shear displacement and constant normal stress

usually accomplished using laboratory triaxial testing. Intact

(Fig. 1). A true residual strength may only be reached after

rock can, however, be tested in situ in direct shear if the rock

considerably greater shear displacement than can be achieved

is weak and if the specimen block encapsulation is sufficiently

in testing. The test value should be regarded as approximate

strong.

and should be assessed in relation to the complete shear stress

- displacement curve.

5. Apparatus

2.1.4 shear strength parameter, c (see Fig. 2)—the projected

5.1 Equipment for Cutting and Encapsulating the Test

intercept on the shear stress axis of the plot of shear stress

Block—This includes rock saws, drills, hammer and chisels,

versus normal stress (see Note).

formwork of appropriate dimensions and rigidity, expanded

2.1.5 shear strength parameter, f (see Fig. 2)—the angle of

polystyrene sheeting or weak filler, and materials for reinforced

concrete encapsulation.

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

5.2 Equipment for Applying the Normal Load (see Fig.

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

3)—This includes flat jacks, hydraulic rams, or dead load of

Mechanics.

sufficient capacity to apply the required normal loads.

Current edition approved May 25, 1990. Published July 1990. Originally

published as D 4554 – 85. Last previous edition D 4554 – 85.

D 4554

FIG. 1 Shear Stress – Displacement Graphs

NOTE 1—If a dead load is used for normal loading, precautions are

center of the base of the shear plane at an angle approximately

required to ensure accurate centering and stability. If two or more

15° to the shear plane with an angular tolerance of6 5°. The

hydraulic rams are used for loading, care is needed to ensure that their

exact angle should be measured to 61°.

operating characteristics are identically matched and they are in exact

parallel alignment.

NOTE 2—Tests where both shear and normal forces are provided by a

single set of jacks inclined at greater angles to the shear plane are not

5.2.1 Each ram should be provided with a spherical seat.

recommended, as it is then impractical to control shear and normal

The travel of rams, and particularly of flat jacks, should be

stresses independently.

sufficient to accommodate the full anticipated specimen dis-

5.4 Equipment for Measuring the Applied Force—This

placement. The normal displacement may be estimated from

includes one system for measuring normal force and another

the content and thickness of the filling and roughness of the

for measuring applied shearing force with an accuracy better

shear surfaces. The upper limits would be the filling thickness.

than 62 % of the maximum forces reached in the test. Load

5.2.2 Hydraulic System—A hydraulic system, if used,

cells (dynamometers) or flat jack pressure measurements may

should be capable of maintaining a normal load to within 2 %

be used. Recent calibration data applicable to the range of

of a selected value throughout the test.

testing should be appended to the test report. If possible, the

5.2.3 Reaction System—A reaction system to transfer nor-

gages should be calibrated both before and after testing.

mal loads uniformly to the test block includes rollers or a

5.5 Equipment for Measuring Shear, Normal, and Lateral

similar low friction device to ensure that at any given normal

Displacement—Displacement should be measured (for ex-

load, the resistance to shear displacement is less than 1 % of

ample, using micrometer dial gages) at eight locations on the

the maximum shear force applied in the test. Rock anchors,

specimen block or encapsulating material, as shown in Fig. 4

wire ties, and turnbuckles are usually required to install and

(Note 3). The shear displacement measuring system should

secure the equipment.

have a travel of at least 100 mm and an accuracy better than 0.1

5.3 Equipment for Applying the Shear Force (see Fig. 3):

mm. The normal and lateral displacement measuring systems

5.3.1 One or More Hydraulic Rams, of adequate total

should have a travel of at least 20 mm and an accuracy better

capacity with at least 150-mm travel.

than 0.05 mm. The measuring reference system (beams,

5.3.2 Hydraulic Pump, to pressurize the shear force system.

anchors, and clamps) should, when assembled, be sufficiently

5.3.3 Reaction System—A reaction system to transmit the

rigid to meet these requirements. Resetting of gages during the

shear force to the test block. The shear force should be

test should be avoided, if possible.

distributed uniformly along one face of the specimen. The

resultant line of applied shear forces should pass through the NOTE 3—The surface of encapsulating material is usually insufficiently

D 4554

NOTE 1—In this case, intercept c on shear axis is zero.

r

f 5 residual friction angle,

r

f 5 apparent friction angle below stress s ; point A is a break in the peak shear strength curve resulting from the shearing off of major irregularities on the

a a

shear surface. Between points O and A, f will vary somewhat; measure at stress level of interest. Note also that f 5f + i where:

a a u

f 5 friction angle obtained for smooth surfaces of rock on rock, and

u

i 5 inclination angle of surface asperities.

f 5 apparent friction angle above stress level s (Point A); note that f will usually be equal to or slightly greater than f and will vary somewhat with

b a a r

stress level; measure at the stress level of interest, r.

c8 5 cohesion intercept of peak shear strength curve; it may be zero.

c 5 apparent cohesion at a stress level corresponding to f , and

b

c 5 cohesion intercept of residual shear strength which is usually negligible.

r

FIG. 2 Shear Strength – Effective Normal Stress Graph

smooth and flat to provide adequate reference for displacement gages;

otherwise specified, be retained as close as possible to its

glass plates may be cemented to the specimen block for this purpose.

natural in situ conditions during preparation and testing.

These plates should be of adequate size to accommodate movement of the

NOTE 4—A test block size of 700 by 700 by 350 mm is suggested as

specimen. Alternatively, a temperature calibrated tensioned wire and

standard for in situ testing. Smaller blocks are permissible, if, for example,

pulley system with gages remote from the specimen may be used. The

the surface to be tested is relatively smooth; larger blocks may be needed

system, as a whole, must be reliable and must conform with specified

when testing very irregular surfaces. For convenience, the size and shape

accuracy requirements. Particular care is needed in this respect when

of the test block may be adjusted so that the faces of the block coincide

employing electric transducers or automatic recording equipment.

with joints or fissures. This adjustment minimizes block disturbance

6. Procedure during preparation. Irregularities that would limit the thickness or em-

placement of encapsulation material or reinforcement should be removed.

6.1 Preparation of Test Specimen:

6.1.1 Outline a test block such that the base of the block 6.1.2 Apply a layer of weak material at least 20 mm thick

coincides with the plane to be sheared. The direction of (for example, foamed polystyrene) around the base of the test

shearing should correspond, if possible, to the direction of block, and then encapsulate the remainder of the block in

anticipated shearing in the full-scale structure to be analyzed concrete or similar material of sufficient strength and rigidity to

using the test results. To inhibit relaxation and swelling and to

prevent collapse or significant distortion during testing. Design

prevent premature sliding, it is necessary to apply a normal the encapsulation formwork to ensure that the load bearing

load to the upper face of the test specimen as soon as possible

faces are flat (tolerance 63 mm) and at the correct inclination

after excavation of the opening and prior to sawing the sides. to the shear plane (tolerance 62°).

The load, approximately equal to the overburden pressure, 6.1.3 Carefully position and align reaction pads, anchors,

may, for example, be provided by screw props or a system of etc., if required to carry the thrust from normal and shear load

rock bolts and crossbeams. Maintain the load until the test systems to adjacent sound rock. Allow all concrete time to gain

equipment is in position. Saw the test block to the required adequate strength prior to testing.

dimensions (usually 700 by 700 by 350 mm) using methods 6.2 Consolidation of Test Specimen:

that avoid disturbance or loosening of the block. Saw a channel 6.2.1 The consolidation stage of testing is necessary in order

approximately 200 mm deep by 80 mm wide around the base to allow pore water pressures, in the rock and especially in any

of the block to allow freedom of displacements during testing. filling material adjacent to the shear plane, to dissipate under

The block and particularly the shear plane should, unless full normal stress before shearing. Behavior of the specimen

D 4554

FIG. 3 Typical Arrangement of Equipment for In Situ Direct Shear Test

during consolidation may also impose a limit on permissible Corrections to the applied normal load may be required to hold

rate of shearing (see 6.3.3). the normal stress constant (see 7.5). A shear determination

6.2.2 Check all displacement gages for rigidity, adequate should preferably be comprised of at least five tests per block,

travel, and freedom of movement, and record a preliminary set tested at different but constant normal stress. If conditions

of load and displacement readings. warrant, test more than one block for each shear plane.

6.2.3 Raise normal load to the full value specified for the 6.3.2 Apply the shear force either incrementally or continu-

test, recording any consequent normal displacements (consoli- ously.

dation) of the test block as a function of time and applied loads 6.3.3 Take approximately 10 sets of readings before reach-

(Fig. 5 and Fig. 6). ing peak strength (Fig. 1 and Fig. 3). The rate of shear

6.2.4 If consolidation occurs, it may be considered complete displacement should be less than 0.1 mm/min in the 10-min

when the rate of change in normal displacement recorded at period before taking a set of readings. This rate may be

each of the four gages is less than 0.005 mm/min for at least 10 increased to not more than 0.5 mm/min between sets of

min. Shear loading may then be applied. readings, provided that the peak strength itself is adequately

6.3 Shear Testing: recorded. For a “drained” test, particularly when testing

6.3.1 The purpose of shearing is to establish values for the clayfilled discontinuities, the total time to reach peak strength

peak and residual direct shear strengths of the test plane. should exceed 6t , as determined from the consolidation

curve (see 7.1 and Fig. 6). If necessary, the rate of shear should

be reduced and the application of later shear force increments

delayed to meet this requirement.

NOTE 5—The requirement that the total time to reach peak strength

should exceed 6t is derived from a conventional soil mechanics

consolidation theory assuming a requirement of 90 % pore water pressure

dissipation. This requirement is most import

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.