ASTM E477-99

(Test Method)Standard Test Method for Measuring Acoustical and Airflow Performance of Duct Liner Materials and Prefabricated Silencers

Standard Test Method for Measuring Acoustical and Airflow Performance of Duct Liner Materials and Prefabricated Silencers

SCOPE

1.1 This test method covers the laboratory testing of duct liner materials, integral ducts, and in-duct absorptive silencers used in the ventilation systems of buildings. Procedures are described for the measurement of acoustical insertion loss, airflow generated noise, and pressure drop as a function of airflow.

1.2 Excluded from the scope are reactive mufflers and those designed for uses other than in ventilation systems, such as automobile mufflers.

1.3 This test method includes a provision for a simulated semi-reflective plenum to fit around thin-walled duct and silencer test specimens, since the acoustical environments around such thin-walled specimens can affect the measured insertion loss.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 477 – 99

Standard Test Method for

Measuring Acoustical and Airflow Performance of Duct

Liner Materials and Prefabricated Silencers

This standard is issued under the fixed designation E477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standards:

S1.1 Acoustical Terminology

1.1 This test method covers the laboratory testing of duct

S1.11 Octave, Half-Octave and Third-Octave Band Filter

liner materials, integral ducts, and in-duct absorptive straight

Sets

and elbow silencers used in the ventilation systems of build-

S1.13 Measurement of Sound Pressure Levels

ings. Procedures are described for the measurement of acous-

S12.31-1990, Precision Methods for the Determination of

tical insertion loss, airflow generated noise, and pressure drop

Sound Power Levels of Broad-Band Noise Sources in

as a function of airflow.

Reverberation Rooms

1.2 Excluded from the scope are reactive mufflers and those

2.3 ASME Test Codes:

designed for uses other than in ventilation systems, such as

ANSI/ASME PTC 11-1984 (R1990) Fans

automobile mufflers.

ASME MFC-3M (1989)

1.3 This test method includes a provision for a simulated

ASME 19.5-72

semi-reflective plenum to fit around thin-walled duct and

2.4 AMCA Standards:

silencer test specimens, since the acoustical environments

ANSI/AMCA 210-85

around such thin-walled specimens can affect the measured

AMCA 300

insertion loss.

2.5 ASHRAE Documents and Standards:

1.4 This standard does not purport to address all of the

ASHRAE Handbook, Fundamentals Volume (current edi-

safety concerns, if any, associated with its use. It is the

tion), Chapter on Measurement and Instruments

responsibility of the user of this standard to establish appro-

ANSI/ASHRAE 41.2-1987 (RA92) Standard Methods for

priate safety and health practices and determine the applica-

Laboratory Airflow Measurement

bility of regulatory limitations prior to use.

2.6 ISO Standards:

2. Referenced Documents

ISO 3741

ISO 7235

2.1 ASTM Standards:

C423 Test Method for Sound Absorption and Sound Ab-

3. Terminology

sorption Coefficients by the Reverberation Room Method

2 3.1 Definitions—The acoustical terms used in this method

C634 Terminology Relating to Environmental Acoustics

are consistent with Terminology C634,ANSI S1.1, andANSI

E90 Test Method for Laboratory Measurement ofAirborne

2 S1.13.

Sound Transmission Loss of Building Partitions

3.2 Definitions of Terms Specific to This Standard:

E548 Guide for General Criteria Used for Evaluating

3 3.2.1 acoustical duct liner material—a material that has

Laboratory Competence

soundabsorptivepropertiesandisattachedtotheinsidewallof

E717 Guide for Preparation of the Accreditation Annex of

a duct to attenuate the sound that propagates down that section

Acoustical Test Standards

of duct.

E 795 Practices for Mounting Test Specimens During

Sound Absorption Tests

Available from American National Standards Institute, 11 W. 42nd St., 13th

This test method is under the jurisdiction of ASTM Committee E-33 on Floor, New York, NY 10036.

EnvironmentalAcousticsandisthedirectresponsibilityofSubcommitteeE33.08on Available fromAmerican Society of Mechanical Engineers, 345 East 47th St.,

Mechanical and Electrical System Noise. New York, NY 10017.

Current edition approved October 10, 1999. Published January 2000. Originally Available from Air Movement and Control Association, 30 W. University Dr.,

published as E477–73. Last previous edition E477–96. Arlington Heights, IL 60004.

2 7

Annual Book of ASTM Standards, Vol 04.06. Available from ASHRAE, 1791 Tullie Circle, NE, Atlanta, GA 30329.

3 8

Annual Book of ASTM Standards, Vol 14.02. Available from ISO, Case Postale 56, CH-1211, Genève 20, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 477

3.2.2 airflow generated noise—the noise generated by air 3.2.19 velocity pressure at a plane of traverse, P , Pa (in.

v

flowing through a device. water)—the square of the average of the square roots of the

velocity pressures at that point.

3.2.3 background noise—the total of all noise sources of

interference in a system used for the production, detection, 3.2.20 velocity pressure at a point, P8 , Pa (in. water)—the

v

measurement, or recording of a signal, independent of the pressure measured by the differential reading of a pitot tube

presence of the signal. pointed upstream at that point.

3.2.4 empty duct measurements—the sound pressure levels 3.3 Symbols:Symbols—see ASHRAE Fundamentals Hand-

measured in the reverberation room as a result of the noise

book, Measurement and Instruments chapter:

3 3

generated by the sound sources in the source chamber and

3.3.1 D =air density in reverberation room, kg/m (lb/ft ).

transmitted through the empty duct system without the test

3.3.2 BP =barometric pressure, kPa (in. Hg).

specimen inserted.

3.3.3 t =dry bulb temperature, °C(°F).

d

3.2.5 equivalent diameter of rectangular ducts—

3.3.4 T =absolutetemperatureofairinreverberationroom,

1/2

{4(W 3H)/P} , where W and H are the width and height of

K(°C+273) or [°R=(°F+460)].

the duct, respectively.

3.3.5 P =velocity pressure at a plane of transverse, Pa (in.

v

3.2.6 forward flow (+)—noise that propagates in the same

water).

direction as airflow.

3.3.6 P =static pressure at a plane of transverse, Pa (in.

s

3.2.7 in-duct sound-attenuating devices—units specifically

water).

designed to be installed in a ventilating duct system for the

3.3.7 V =average velocity in the duct across the plane of

purpose of attenuating the sound that transmits through the

traverse, m/min (ft/min).

in-duct sound-attenuating device.

3.3.8 DP =pressure differential or pressure drop across the

3.2.8 insertion loss (IL)—the reduction in sound power

in-duct sound attenuating device, Pa (in. water).

level, in decibels, at a given location due solely to the

3.3.9 Q =discharge rate, L/s (ft /s).

placement of a sound-attenuating device in the path of trans-

mission between the sound source and the given location. The 3.3.10 K =values of constant K.

2 2

path of transmission in this case is within the test duct system.

3.3.11 A =orifice area, m (ft ).

3.2.9 integral duct—a duct formed from an integral com-

G =gravitational conversion factor, 9.806 m/s (32.174 ft/

c

posite of materials, typically having a porous inner layer to

s ).

provide sound absorption, with an impervious outer surface.

3.3.12 hf =pressure drop obtained by the pressure taps, Pa

3.2.10 reverse flow (−)—noise that propagates in the oppo-

(lbf/ft ).

site direction to airflow.

3.2.11 signalsourcechamber—anenclosureattheupstream

4. Summary of Test Method

endoftheductsysteminwhichoneormoresoundsourcesare

4.1 To measure the insertion loss of a test specimen, two

located for the purpose of generating sound to be transmitted

separate measurements must be made. The sound pressure

through the duct system and discharged into the receiving

level in the reverberation room is measured while sound is

reverberation room.

entering the room through a length of straight or elbow empty

3 3

3.2.12 standard air density (d )—1.202 kg/m (0.075 lb/ft ).

s

duct with a sound source at the far end. The sound pressure

This corresponds approximately to dry air at 21°C (70°F) and

level in the reverberation room is measured again after a

101.3 kPa (29.92 in. Hg).

section of the empty duct has been replaced with the test

3.2.13 static pressure at a plane of traverse, P , Pa (in.

s

specimen.The insertion loss is equal to the difference between

water)—the arithmetic average of the static pressure at points

thetwomeasuredsoundpressurelevels.Thesectionofstraight

in the plane of traverse.

empty duct is designed to have negligible attenuation at all

3.2.14 static pressure at a point, P8 , Pa (in. water)—the

s measurement frequencies. The construction of the test facility

pressure measured by the static connection of a pitot tube

duct system and the shape of the test elbow silencer determine

pointed upstream at that point.

thegeometryoftheelbowemptyduct.Theelbowductmustbe

3.2.15 test run—pertains to all readings and calculations at

fully described in all test reports to include information on the

any one setting of the throttling device. shape, angle, radius, centerline, and so on, due to different

elbow constructions having various attenuation properties.

3.2.16 thin-walledduct—aductorsilencerwhosewallmass

or stiffness are low enough to allow significant energy to

4.2 The airflow generated noise is measured in terms of

escape into the environment about it (low STC). This term

frequency band sound power levels while air, originally quiet,

applies to ducts whose walls are thinner than 24 gage, or are

is passing through the system with the test specimen installed.

flexible, or are of rigid fiberglass construction.

4.3 Pressuredropperformanceisobtainedbymeasuringthe

3.2.17 total pressure at a plane of traverse, P, Pa (in.

static pressure at designated locations upstream and down-

t

water)—the algebraic sum of the velocity pressure at the plane

stream of the test specimen at various airflow settings. The

of traverse and the static pressure at the plane of traverse.

pressure drop and airflow may be measured with a variety of

3.2.18 traverse—a series of readings made with a pitot tube standard acceptable instrumentation such as piezometer rings,

inside a duct in accordance with ASHRAE Fundamentals flow nozzles, orifices, etc. However, the method described

Handbook, Measurement and Instruments chapter. herein is the pitot tube and manometer method.

E 477

5. Significance and Use turally isolated from the chamber and duct system. This

enclosure should be joined to the duct system through an

5.1 The procedures described are for measurement of the

opening in the chamber having dimensions the same as or

properties of silencing elements as installed in a laboratory

greater than the duct. In the latter case, a tapered transition

facility of the type described herein.The insertion loss, airflow

piece is placed between the duct and the opening in the

generated noise, and pressure drop of a silencer in an actual

chamber.

installation may differ from the values obtained from this test

6.2.1 The signal source chamber should be constructed of

methodduetointeractionwithotherelementsoftheventilation

material having sufficient sound transmission loss and be

system. Provisions have been included for surrounding a

adequately isolated to reduce the possibility of sound entering

thin-walled test specimen with a simulated semi-reflective

the reverberation room by paths other than through the duct

plenum.

connecting the signal source chamber and reverberation room.

5.2 Silencersareoftendesignedtobeusedunderconditions

6.2.2 Inordertoensurethatthereactiononthesoundsource

which do not duplicate the duct-to-duct test set-up covered in

remains essentially constant with or without the test specimen

this test standard. Mock-up or specialized test set-ups for such

inplace,theinteriorwallsurfacesofthesignalsourcechamber

silencers (such as those to be used at the end of a duct) are not

must be lined with sound-absorbing material. The material

considered to be in full conformance with this standard. See

shall have a minimum NRC=0.25, as determined by Test

Annex A2 for information regarding such tests.

MethodC423andTypeAmountingperPracticesE795forall

the test frequencies but should be kept low enough so that the

6. Test Facilities

sound pressure level in the reverberation room is 10 dB above

6.1 The test facility shall consist of a signal source chamber

ambient when the test specimen is in place and the sound

and a reverberation room coupled together by means of a

source is on.

length of straight or elbow duct. Provisions shall be made in

6.2.3 Thephysicalsizeofthesignalsourcechambershallbe

theductsystemforinsertingeitheratestspecimen,orasection

suchthatnoinsidedimensionislessthanthelargestdimension

of empty duct having the same interior cross-sectional dimen-

oftheductsystemandthatthesoundsourceistotallyenclosed

sions at the duct connection points, length, and shape (for

and does not obstruct the opening into the duct.

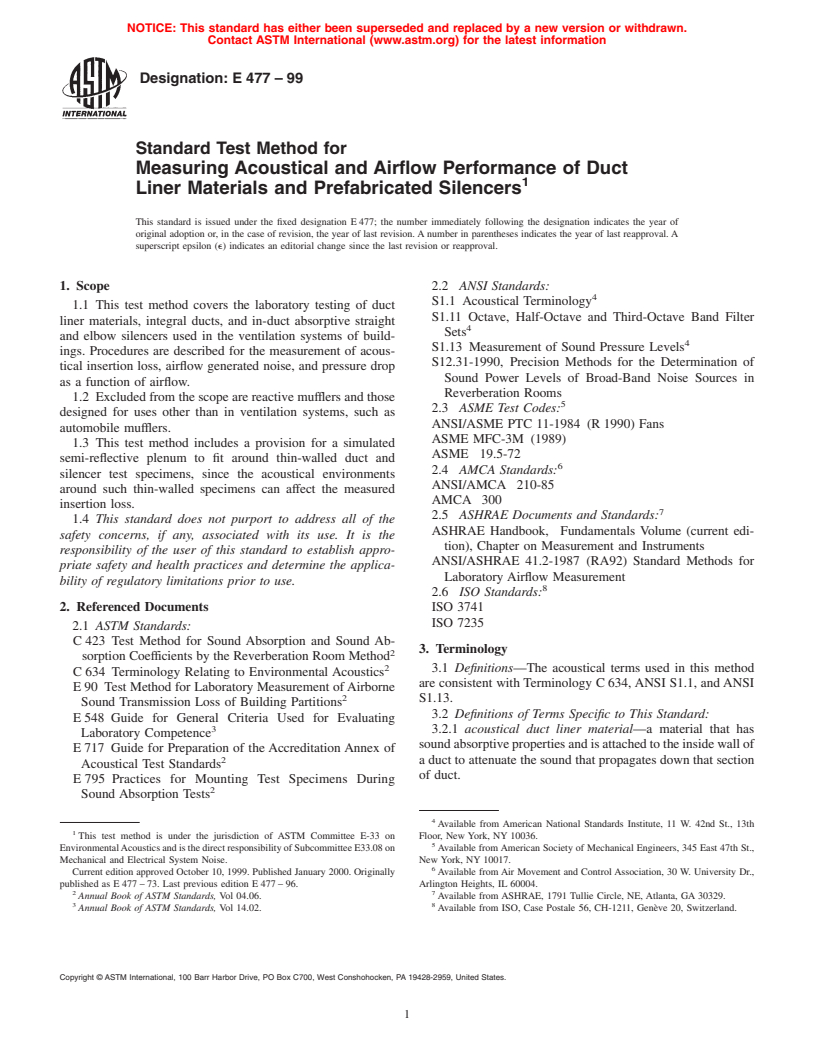

elbow testing) as the test specimen. An example of a facility

6.2.4 A second duct may be attached to the signal source

set-up to accomodate straight silencer testing is shown in Fig.

chamber through which quiet airflow can be supplied to the

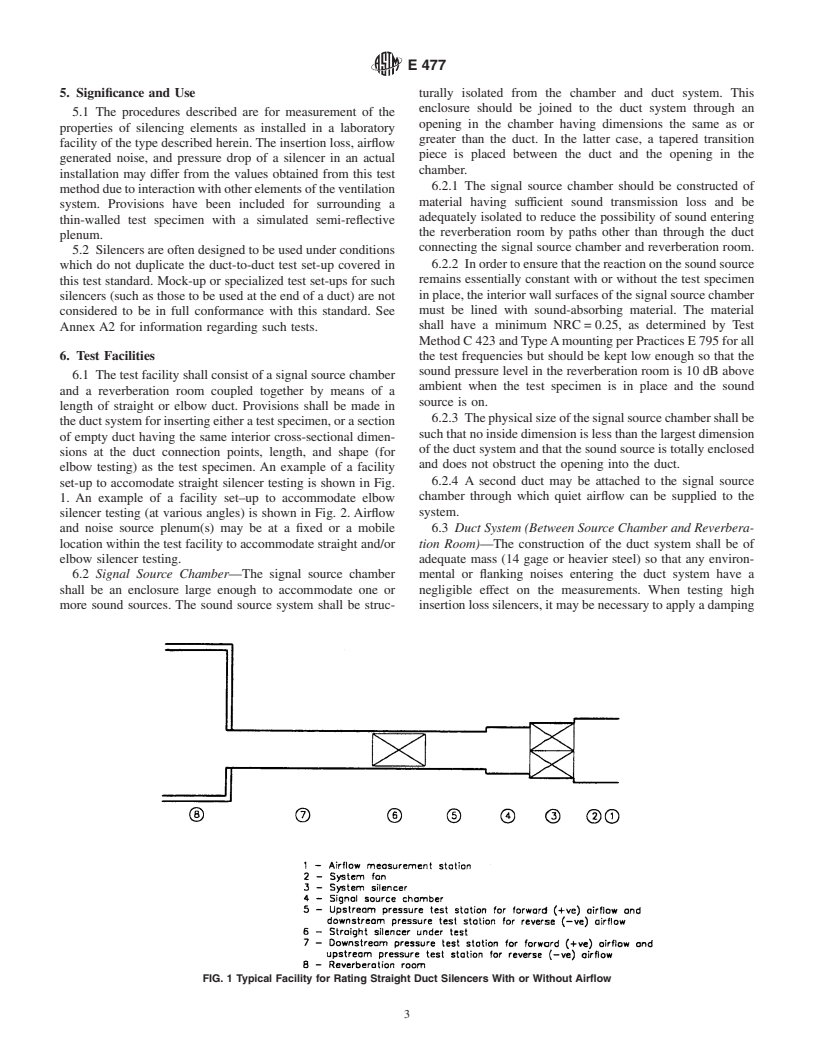

1. An example of a facility set–up to accommodate elbow

system.

silencer testing (at various angles) is shown in Fig. 2. Airflow

and noise source plenum(s) may be at a fixed or a mobile 6.3 Duct System (Between Source Chamber and Reverbera-

location within the test facility to accommodate straight and/or tion Room)—The construction of the duct system shall be of

elbow silencer testing. adequate mass (14 gage or heavier steel) so that any environ-

6.2 Signal Source Chamber—The signal source chamber mental or flanking noises entering the duct system have a

shall be an enclosure large enough to accommodate one or negligible effect on the measurements. When testing high

more sound sources. The sound source system shall be struc- insertionlosssilencers,itmaybenecessarytoapplyadamping

FIG. 1 Typical Facility for Rating Straight Duct Silencers With or Without Airflow

E 477

FIG. 2 Typical Facility for Rating Elbow Duct Silencers With or Without Airflow

material to the outside of the duct walls or increase the than 7.5°). The duct shall terminate at the reverberation room

wall abruptly with the same cross-sectional dimensions as the

transmission loss, or both, by adding one or more layers of

gypsum board to the exterior. The interior surface of the duct system duct.

system shall be smooth and have a low sound absorption

6.3.3 There are occasions when a silence, designed to be

coefficient in the frequency range of interest.

used at the termination of a duct system, must be tested.

Testing of such silencers, mounted at the termination of the

6.3.1 The length of the duct system is primarily determined

facility duct or in the reverberation room, shall be considered

by the requirements of air-flow measurements.The duct length

a special circumstance, and shall be noted as an exception to

upstream, regardless of the shape of the test specimen and

this test standard in the test report. Full details concerning the

layout of test facility, shall be not less than 5 equivalent

mounting and testing must al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.