ASTM F2711-08(2012)

(Test Method)Standard Test Methods for Bicycle Frames

Standard Test Methods for Bicycle Frames

SIGNIFICANCE AND USE

5.1 These tests are used to verify the durability and strength of a bicycle frame.

SCOPE

1.1 These test methods establish procedures for conducting tests to determine the structural performance properties of bicycle frames.

1.2 These test methods describe mechanical tests for determining the following performance properties:

1.2.1 Frame Fatigue—Horizontal Loading,

1.2.2 Frame Fatigue—Vertical Loading, and

1.2.3 Frame Impact Strength.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2711 − 08 (Reapproved 2012) An American National Standard

Standard Test Methods for

Bicycle Frames

This standard is issued under the fixed designation F2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope via the head tube for the fork and lower connection for the

crank/pedal assembly.

1.1 These test methods establish procedures for conducting

tests to determine the structural performance properties of 3.1.4 bottom bracket shell, n—structural member of the

bicycle frames. frame that houses the assembly that supports the bearings,

which support the cranks.

1.2 These test methods describe mechanical tests for deter-

mining the following performance properties: 3.1.5 crank, n—lever arm that receives human energy as

torque to convert into bicycle motion.

1.2.1 Frame Fatigue—Horizontal Loading,

1.2.2 Frame Fatigue—Vertical Loading, and

3.1.6 crown race seat, n—position on the fork where the

1.2.3 Frame Impact Strength.

lower steering axis bearing sits.

1.3 The values stated in SI units are to be regarded as

3.1.7 down tube, n—lower structural connection between

standard. No other units of measurement are included in this

the head tube and the bottom bracket shell.

standard.

3.1.8 dropout centerline, n—hub-mounting axis that passes

1.4 This standard does not purport to address all of the

through both right and left dropouts.

safety concerns, if any, associated with its use. It is the

3.1.9 front dropout, n—area where the front wheel hub

responsibility of the user of this standard to establish appro-

connects to the fork.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.1.10 head tube, n—forward most structural member of the

frame, which provides an interface through top, and bottom

2. Referenced Documents

bearings for the fork.

3.1.10.1 Discussion—The head tube is connected to the seat

2.1 ASTM Standards:

tube through the top tube and the down tube.

E4 Practices for Force Verification of Testing Machines

3.1.11 initial running displacement, n—average displace-

3. Terminology

ment between approximately 500 and 1000 cycles during a

durability fatigue test.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bicycle, n—two-wheeled, single track, articulated ve-

3.1.12 normal attitude, n—intended position of the bicycle

hicle that is solely human powered.

framewhenincontinuousstraight-linemotiononaflatsurface.

3.1.2 bicycle fork, n—structural connection between the

3.1.13 rake, n—straight-line distance from the front axle

front wheel and the frame.

center to the perpendicular of the steering axis.

3.1.2.1 Discussion—Theforktransmitssteeringtorquefrom

3.1.14 rear dropout, n—area where the rear wheel hub

the handlebars to the front wheel.

connects to the lower rear and the upper rear frame members.

3.1.3 bicycle frame, n—structural member that supports the

3.1.15 sag, n—amount of compression in a suspension unit,

seat with rear connection for the rear wheel, front connection

given in a percentage.

3.1.16 seat post, n—structural component that connects the

This test method is under the jurisdiction of ASTM Committee F08 on Sports

seat to the seat tube.

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

3.1.17 seat tube, n—structural member of the frame into

Subcommittee F08.10 on Bicycles.

Current edition approved Nov. 1, 2012. Published December 2012. Originally which the seat post inserts.

approved in 2008. Last previous edition approved in 2008 as F2711 – 08. DOI:

3.1.18 steerer tube, n—section of the bicycle fork that is

10.1520/F2711-08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or housed within the head tube and bearing assemblies.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.19 top tube, n—upper structural connection between the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. head tube and the seat tube.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2711 − 08 (2012)

3.2 Acronyms: the dropout position when the suspension fork is compressed

3.2.1 OEM, n—original equipment from manufacturer no more than 20 % of its maximum amount of travel.

6.1.3 The deflection of a test fork is measured at the front

3.3 Symbols:

axle center, resulting from the application of a vertical 1200 N

L = fork length, a straight-line measure from the crown race

load at that point. The fork is fixed in position only at the

seat to the center of the front axle.

steerer tube by a v-block with minimum length of 76 mm. The

δ = deflection of test fork.

steerer tube is fixed horizontally with the crown race seat

adjacent to the v-block.

4. Summary of Test Methods

6.1.4 ThedeflectionratiofortheTestforkfortheHorizontal

4.1 Horizontal Loading Durability Fatigue Test—This test

LoadingFatiguetestandtheVerticalLoadingFatiguetestshall

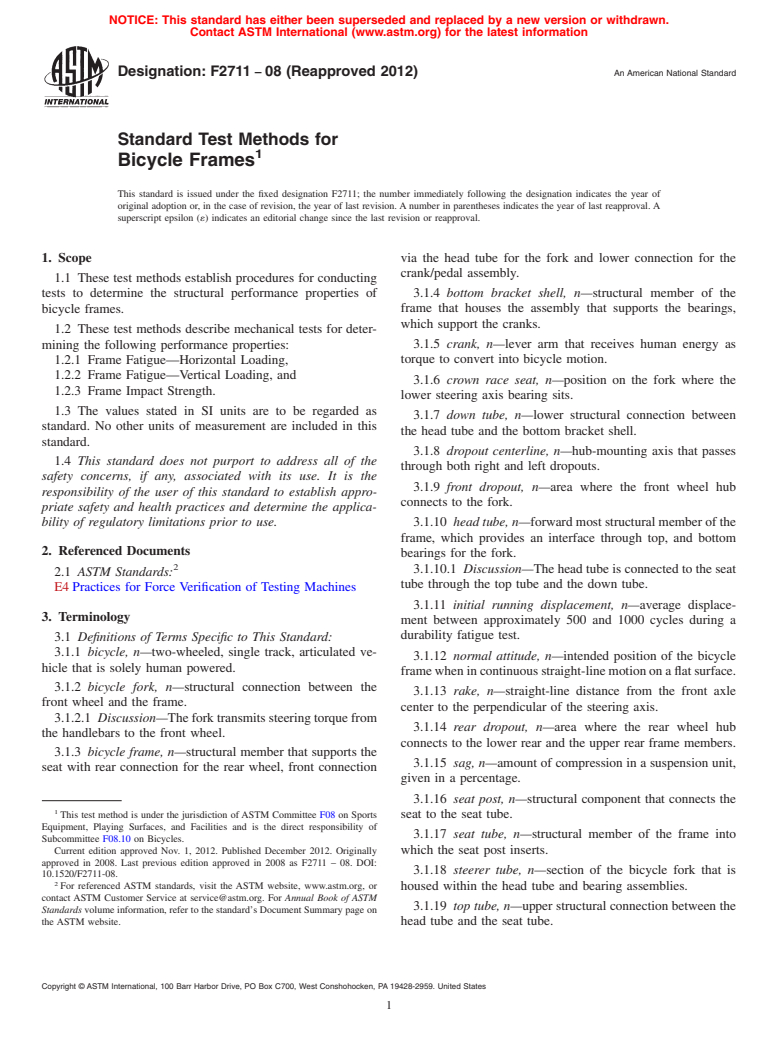

method restrains the frame at the rear dropouts (see Fig. 1). A

not exceed the value of 1.0 when computed as follows:

cyclicloadisappliedalongthex-axisatthefrontdropouts.The

K 310 000 3δ

number of cycles is measured. The magnitude of the load, and

Deflection ratio 5

L

the minimum number of cycles, are determined by the speci-

fication standard.

Where:

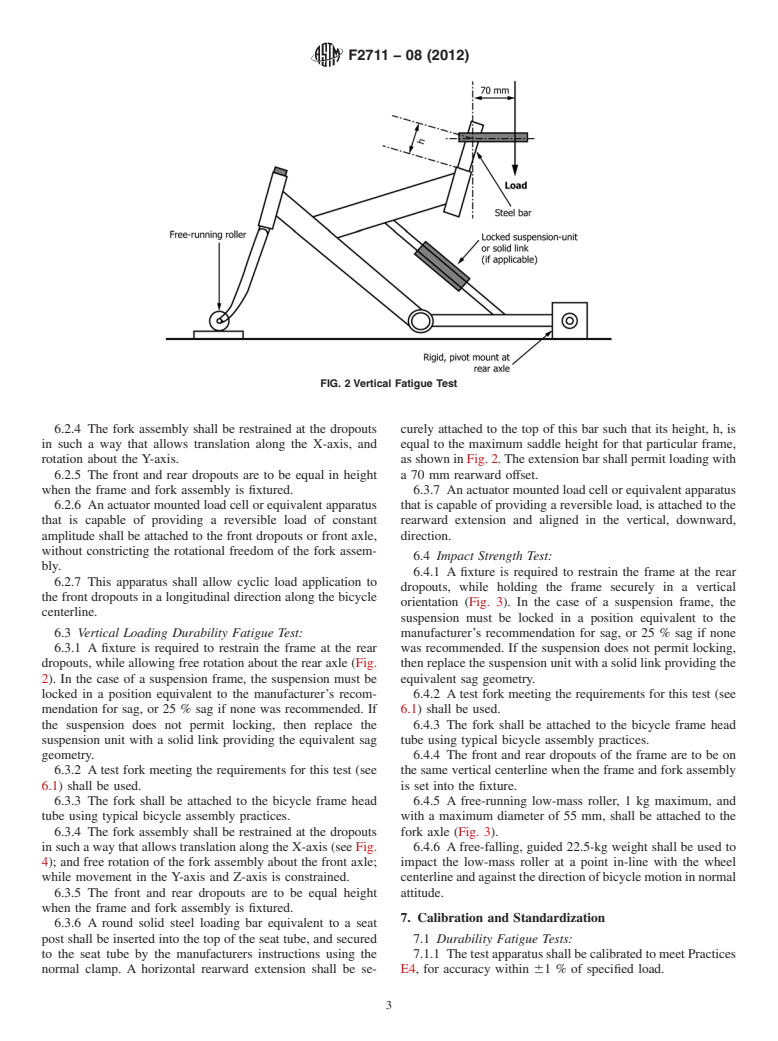

4.2 Vertical Loading Durability Fatigue Test—This test

K (a constant) = 1417 for L and δ in millimetres.

method restrains the frame at the rear dropouts, and allows free

(For example, a fork length of 460 mm, the maximum

rollingatthefork(seeFig.2).Acyclicloadisappliedalongthe

acceptable fork deflection (δ) would be 6.9 mm. Similarly for

Z-axis behind the seat post.The number of cycles is measured.

a fork length of 330 mm, the maximum deflection is 2.5 mm.)

Themagnitudeoftheload,andtheminimumnumberofcycles,

6.1.5 The deflection ratio for the Test fork for the Impact

are determined by the specification standard.

test shall not exceed the value of 1.0 when computed as

4.3 Impact Strength Test—This test method restrains the follows:

frame vertically at the rear dropouts (see Fig. 3). A mass is

K 310 000 3δ

Deflection ratio 5

dropped onto a roller assembly attached to the fork. Permanent

L

set is measured. The height of the drop is determined by the

Where:

specification standard.

K = 709 for L and δ in millimetres.

5. Significance and Use

6.2 Horizontal Loading Durability Fatigue Test:

5.1 These tests are used to verify the durability and strength

6.2.1 A fixture is required to restrain the frame at the rear

of a bicycle frame.

dropouts, while allowing free rotation about the axle (see Fig.

1). In the case of a suspension frame, the suspension must be

6. Apparatus

locked in a position equivalent to the manufacturer’s recom-

6.1 Requirements for Test Forks: mendation for sag, or 25 % sag if none was recommended. If

6.1.1 The test forks shall be designed to mount in a manner the suspension does not permit locking, then replace the

similar to the OEM fork, or in a manner using typical bicycle suspension unit with a solid link providing the equivalent sag

assembly procedures. geometry.

6.1.2 The test forks, when mounted, shall be the same 6.2.2 A test fork meeting the requirements for this test (see

length, L, as the longest fork designed for use with the frame 6.1) shall be used.

and have a rake of 45 6 6 mm. When the test fork is used in 6.2.3 The fork shall be attached to the bicycle frame head

place of an OEM Suspension fork, the length is determined by tube using typical bicycle assembly practices.

FIG. 1 Horizontal Fatigue Test

F2711 − 08 (2012)

FIG. 2 Vertical Fatigue Test

6.2.4 The fork assembly shall be restrained at the dropouts curely attached to the top of this bar such that its height, h, is

in such a way that allows translation along the X-axis, and equal to the maximum saddle height for that particular frame,

rotation about the Y-axis. as shown in Fig. 2.The extension bar shall permit loading with

6.2.5 The front and rear dropouts are to be equal in height a 70 mm rearward offset.

when the frame and fork assembly is fixtured. 6.3.7 An actuator mounted load cell or equivalent apparatus

6.2.6 An actuator mounted load cell or equivalent apparatus that is capable of providing a reversible load, is attached to the

that is capable of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.