ASTM F1975-15(2023)

(Specification)Standard Specification for Nonpowered Bicycle Trailers Designed for Human Passengers

Standard Specification for Nonpowered Bicycle Trailers Designed for Human Passengers

ABSTRACT

This specification covers nonpowered trailers intended to be pulled behind bicycles to transport one or two children with accessory loads with a prescribed maximum weight. It includes methods for strength, impact drop, structural integrity in rollover, tipover resistance, single-occupant trailer, double-occupant trailer, coupling security, and system fatigue tests. The tests confirm that this specification is satisfied. The specification also prescribes colors, reflectors, and flags for conspicuity.

SCOPE

1.1 This specification covers a nonpowered trailer intended to be pulled behind a bicycle in order to transport one or two children with an accessory load of a maximum weight of 45.4 kg (100 lb). It includes test methods for confirming that this specification is satisfied.

1.2 The values stated in SI units are to be regarded as the standard. The units given in parentheses are for information only.

1.3 The following caveat pertains only to the test methods portion, Section 5, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1975 − 15 (Reapproved 2023) An American National Standard

Standard Specification for

Nonpowered Bicycle Trailers Designed for Human

Passengers

This standard is issued under the fixed designation F1975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of Nonmetallic Materials (Withdrawn 2000)

1.1 This specification covers a nonpowered trailer intended 2.2 ANSI Standard:

ANSI Z535.4, Product Safety Signs and Labels

to be pulled behind a bicycle in order to transport one or two

children with an accessory load of a maximum weight of 45.4

2.3 Federal Standards:

kg (100 lb). It includes test methods for confirming that this

Title 16, CFR 1500.3(b)(4)(i) Hazardous Substance

specification is satisfied.

Title 16, CFR 1500.3(c)(6)(vi) Flame Testing

Title 16, CFR 1500.44 Flammability

1.2 The values stated in SI units are to be regarded as the

Title 16, CFR 1500.48 Sharp Points

standard. The units given in parentheses are for information

Title 16, CFR 1500.49 Sharp Edges

only.

Title 16, CFR 1501 Small Parts

1.3 The following caveat pertains only to the test methods

Title 16, CFR 1303 Lead in Coatings

portion, Section 5, of this specification: This standard does not

Title 16, CFR 1512 Requirements for Bicycles, Sections:

purport to address all of the safety concerns, if any, associated

1512.18(n), Reflector Test

with its use. It is the responsibility of the user of this standard

to establish appropriate safety, health, and environmental

3. Terminology

practices and determine the applicability of regulatory limita-

3.1 Definitions of Terms Specific to This Standard:

tions prior to use.

3.1.1 backrest, n—the segment of the seat that is designed to

1.4 This international standard was developed in accor-

support the occupant’s back. This may or may not include

dance with internationally recognized principles on standard-

support for the upper body, including the head and neck.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.2 bicycle trailer (trailer), n—a transporting device de-

mendations issued by the World Trade Organization Technical

signed for towing behind a bicycle, which provides a restrained

Barriers to Trade (TBT) Committee.

seating position to one or more occupants, with fastening

arrangements for attaching the device.

2. Referenced Documents

3.1.3 hard horizontal surface, n—a surface, perpendicular to

2.1 ASTM Standards:

the direction of gravity, such as level ground or building floor,

B117 Practice for Operating Salt Spray (Fog) Apparatus

whose surface is either concrete, pavement, or similar rigid

D1230 Test Method for Flammability of Apparel Textiles

material whose deflection, while carrying the weight of a fully

D4329 Practice for Fluorescent Ultraviolet (UV) Lamp Ap-

loaded trailer, does not exceed 12.7 mm (0.5 in.) from the

paratus Exposure of Plastics

unloaded horizontal plane at any point.

G23 Practice for Operating Light-Exposure Apparatus

3.1.4 normal use, n—applications described as intended use

(Carbon-Arc Type) With and Without Water for Exposure

for the product found within the manufacturer’s instructional

literature.

3.1.5 normal use temperatures, n—temperature range within

which it should be anticipated that the trailer may be used to

This specification is under the jurisdiction of ASTM Committee F08 and is the

direct responsibility of Subcommittee F08.10 on Bicycles.

Current edition approved Aug. 1, 2023. Published August 2023. Originally

approved in 1999. Last previous edition approved in 2015 as F1975 – 15. DOI: The last approved version of this historical standard is referenced on

10.1520/F1975-15R23. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Code of Federal Regulations, available from U.S. Government Printing Office,

the ASTM website. Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1975 − 15 (2023)

transport children. The range is from –7 6 2°C to 35 6 2°C movable components of the trailer or the bicycle that could

(–19.4 6 4.6°F to 95 6 4.6°F). cause injury, and adjustable belt(s) or other capturing devices

designed to restrain the occupant when seated.

3.1.6 occupant, n—a child or person who is restrained in a

seated position inside the trailer and whose efforts do not

4.3 Attachment—The attachment process for connecting the

contribute to the overall operation and performance of the

trailer to the bicycle shall be of a simple and secure procedure.

vehicle.

If tools are required for attachment, attaching shall be accom-

plished with common household tools.

3.1.7 restrain, v—to prevent the occupant(s) of the trailer

from leaving the seated position on the seat of the trailer by

4.4 Dimensions—The backrest shall have a minimum height

means of a restraint system (designed by the manufacturer)

of 350 mm (13.8 in.). The seated height space shall be a

when used in accordance with the manufacturer’s instructions.

minimum of 550 mm (22 in.).

3.1.8 rider, n—a person whose effort and skills contribute to

4.5 Materials:

the overall operation and performance of the vehicle.

4.5.1 All nonmetallic materials that compose structural

3.1.9 seated height space, n—a dimension of space that is

components will be subjected to either (1) 100 h of accelerated

within the protective structure of a trailer. This space is the

weathering in accordance with Method 1 of Practice G23, or

measured height of the occupant’s protective cavity, measured

(2) 60 h of accelerated weathering in accordance with Practice

from the seat bottom and along the backrest to the top of the

D4329. The material sample will then be subjected to a tensile

space allowed for occupants.

strength test with increasing load until failure. An identical

3.1.10 test dummy, n—a dummy that shall be of a design

sample of the same material, not subjected to the accelerated

consistent with the use of the trailer seat and restraint system.

weathering test, will then be subjected to the same tensile

It shall have adequate head/neck, shoulder, and arm geometry strength test. The failure load of the accelerated weathering

to ensure proper application of the upper body restraints. The

sample shall be a minimum of 60 % of the failure load of the

weight of the dummy shall be 22.7 6 1 kg (50 6 2.2 lb). The unweathered sample.

upper legs, measured perpendicularly from the dummy’s back,

4.5.2 All metallic materials of structural components shall

shall extend a minimum of 375 mm (14.8 in.). The dummy’s

be tested in accordance with the Salt Spray Test in Practice

back is the surface of the dummy that is in contact with the seat

B117 for a period of 96 h. Materials shall be placed in the test

back when the dummy is seated. The dummy’s bottom is the

environment in a condition consistent with their application on

surface of the dummy that is in contact with the seat bottom

the trailer, with surface coatings and openings sealed or open as

when the dummy is in the seated position. The weight

in normal use. After exposure to the salt spray, inspect for

distribution throughout the dummy shall result in a center of

evidence of corrosion. No corrosion beyond 20 % of the

gravity position that is 230 6 10 mm (9.1 6 0.4 in.) from the

primary wall thickness of the metal material is permitted.

dummy’s bottom and 130 6 10 mm (5.1 6 0.4 in.) from the

Painted portions shall comply with Title 16, CFR 1303.

dummy’s back when in the seated position.

4.5.3 Materials known to be a hazardous substance, as

3.1.11 tongue, n—a rigid structure or pole that extends from defined in Title 16, CFR 1500.3(b)(4)(i), shall not be used.

the frame of the trailer to the hitch of the trailer.

4.5.4 Materials other than fabrics shall not support flame

propagation in excess of the requirements of Title 16, CFR

3.1.12 useful product lifecycle, n—the allowable range of

1500.3(c)(6)(vi) when flame tested to Title 16, CFR1500.44.

time for continued use of the product from the date of

Fabrics shall achieve a Class 1 rating when tested in accor-

manufacture as described within the manufacturer’s instruc-

dance with Test Method D1230.

tional literature.

5. Test Methods

4. Requirements

5.1 Strength Tests—The dummy, or dummies, to be used in

4.1 General—A bicycle trailer shall be designed and manu-

the following tests shall comply with the dummy specification

factured in such a way that when used in accordance with the

in 3.1.10.

manufacturer’s instructions, components with which an occu-

pant may come in contact do not cause injury. Exposed 5.1.1 Restraint System Test:

surfaces shall be free from burrs, sharp edges, and points. Refer

5.1.1.1 Erect the trailer in the manufacturer’s suggested use

to Title 16, CFR 1500, Parts 48 and 49, and Title 16, CFR

configuration. Remove the trailer tongue. Restrain a dummy

1501. No openings with which the occupants’ hands can come

into each seating position in accordance with the manufactur-

in contact shall have dimensions between 6 mm (0.236 in.) and

er’s instruction for maximum occupancy.

13 mm (0.512 in.). A trailer shall be equipped with a rear

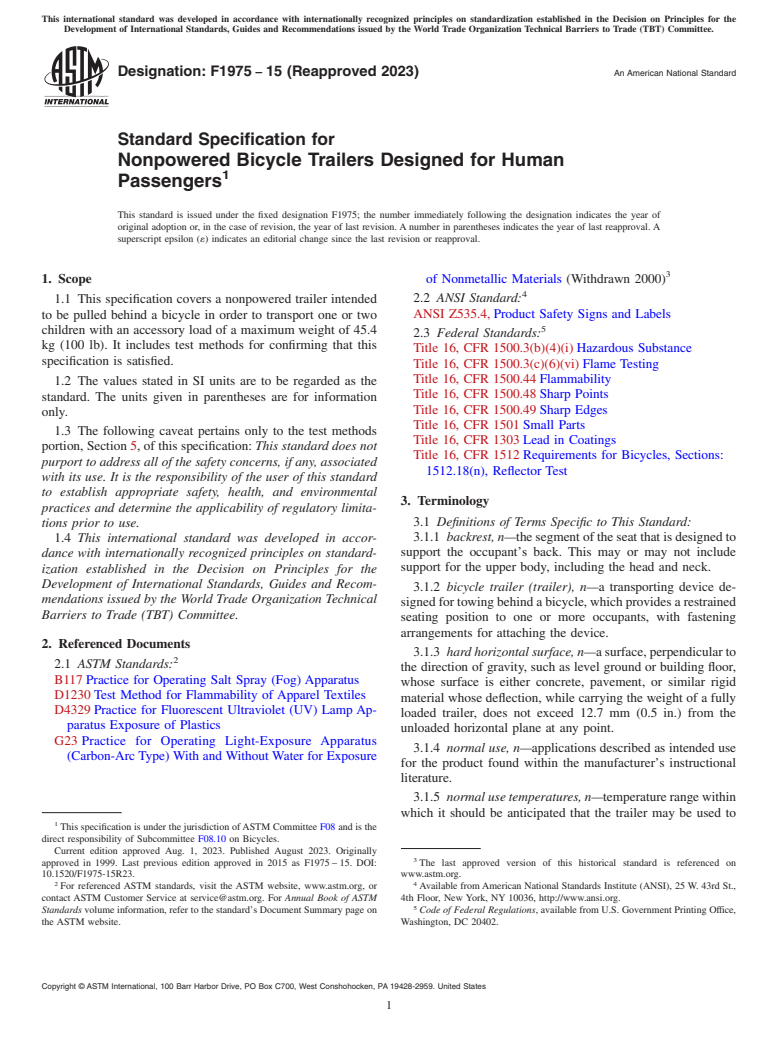

5.1.1.2 Elevate the trailer, as shown in Fig. 1, from the rear,

reflector; side reflectors are required on wheels. Refer to Title

so that the orientation toward the ground is the same as the

16, CFR 1512, Parts 16 and 18(n). The manufacturer shall warn

trailer’s direction of forward motion when attached to a bicycle

the rider that a load added to the bicycle will alter the stability

(front-most structure of the trailer is closest to the impact

and riding characteristics of the bicycle.

surface). The impact surface is a hard material, concrete or

similar. The drop height is 1.2 m (3.9 ft).

4.2 Equipment—A trailer shall be equipped with the follow-

ing equipment: seating area, footrest area, space for helmeted 5.1.1.3 By convenient method, release the trailer to drop

head, devices that protect the hands and feet from moving or onto the surface.

F1975 − 15 (2023)

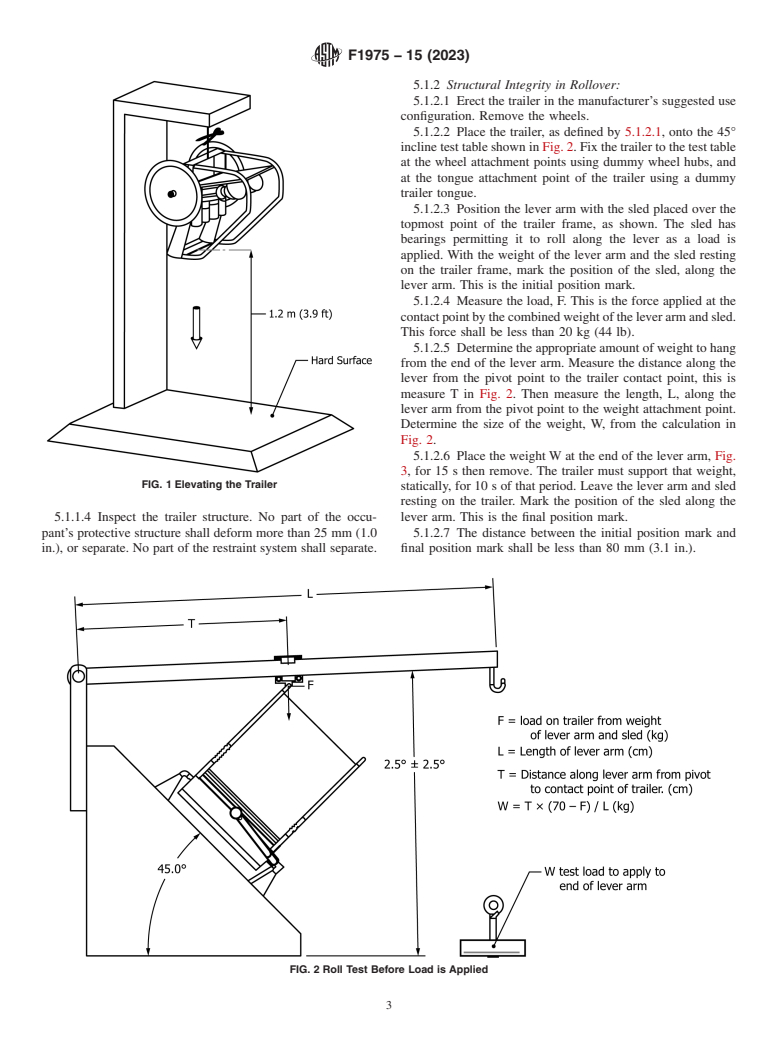

5.1.2 Structural Integrity in Rollover:

5.1.2.1 Erect the trailer in the manufacturer’s suggested use

configuration. Remove the wheels.

5.1.2.2 Place the trailer, as defined by 5.1.2.1, onto the 45°

incline test table shown in Fig. 2. Fix the trailer to the test table

at the wheel attachment points using dummy wheel hubs, and

at the tongue attachment point of the trailer using a dummy

trailer tongue.

5.1.2.3 Position the lever arm with the sled placed over the

topmost point of the trailer frame, as shown. The sled has

bearings permitting it to roll along the lever as a load is

applied. With the weight of the lever arm and the sled resting

on the trailer frame, mark the position of the sled, along the

lever arm. This is the initial position mark.

5.1.2.4 Measure the load, F. This is the force applied at the

contact point by the combined weight of the lever arm and sled.

This force shall be less than 20 kg (44 lb).

5.1.2.5 Determine the appropriate amount of weight to hang

from the end of the lever arm. Measure the distance along the

lever from the pivot point to the trailer contact point, this is

measure T in Fig. 2. Then measure the length, L, along the

lever arm from the pivot point to the weight attachment point.

Determine the size of the weight, W, from the calculation in

Fig. 2.

5.1.2.6 Place the weight W at the end of the lever arm, Fig.

3, for 15 s then remove. The trailer must support that weight,

FIG. 1 Elevating the Trailer

statically, for 10 s of that period. Leave the lever arm and sled

resting on the trailer. Mark the position of the sled along the

5.1.1.4 Inspect the trailer structure. No part of the occu- lever arm. This is the final position mark.

pant’s protective structure shall deform more than 25 mm (1.0 5.1.2.7 The distance between the initial position mark and

in.), or separate. No part of the restraint system shall separate. final position mark shall be less than 80 mm (3.1 in.).

FIG. 2 Roll Test Before Load is Applied

F1975 − 15 (2023)

FIG. 3 Roll Test During Load Application

5.2 Tipover Resistance Tests: 5.3.4 Start the test and set the motor to run at 60 6 2 rpm.

5.2.1 Tilting Procedure—Tilt the table until the uphill wheel Allow the test to run for a duration of 100 000 cycles.

starts to lift off the table. The tilt rate should be sufficiently 5.3.5 Inspect the trailer tongue, hitch, and tongue mounting

slow that the angle of the table at which the uphill tire lifts off hardware. No part of the construction shall separate or incur a

can be easily identified. fracture or crack. Repeat the horizontal hitch placement mea-

5.2.2 Single or Multiple-Occupant Trailer Test—Erect the surement of 5.3.2. The difference in this measurement, before

trailer in the manufacturer’s suggested use configuration and and after the test, shall not exceed 15 mm (0.6 in.).

inflate the tires to the trailer manufacturer’s suggested air

5.4 System Fatigue Test (Axle/Frame):

pressure. Restrain a dummy or dummies into the most onerous

5.4.1 The test equipment shall be capable of simulating the

seating position (worst case as defined by the manufacturer).

passing of the trailer over a bump. The device is a drum with

The minimum allowable tilt angle for the single-occupant

the trailer positioned so the wheel or wheels sit atop the drum

trailer is 25°.

(Fig. 6). The placement of the wheel axle shall be between 25

5.3 Coupling Security Test: and 50 mm (1.0 to 2.0 in.) rearward in the horizontal direction

5.3.1 Erect the trailer in the manufacturer’s suggested use from the highest point on the drum. The minimum width of the

configuration. Inflate the tires to the trailer manufacturer’s flywheel shall be wide enough to permit the trailer to move

suggested air pressure. Restrain a dummy into each seating side-to-side a distance of 150 mm (6 in.) in either direction.

position in accordance with the manufacturer’s instruction for The drum shall have one cleat if

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.