ASTM B753-86(1998)

(Specification)Standard Specification for Thermostat Component Alloys

Standard Specification for Thermostat Component Alloys

SCOPE

1.1 This specification describes requirements for alloys to be used as components in the manufacture of bonded multi-component thermostat metal strip. More specifically it describes alloys having composition, and thermal expansion suitable for application in thermostat metal sheet and strip.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 753 – 86 (Reapproved 1998) An American National Standard

Standard Specification for

Thermostat Component Alloys

This standard is issued under the fixed designation B 753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Chemical Composition

1.1 This specification describes requirements for alloys to 5.1 The material shall be manufactured to the chemical

be used as components in the manufacture of bonded multi- compositions shown in Table 1.

component thermostat metal strip. More specifically it de- 5.2 The manufacturer will insure uniformity of composition

scribes alloys having composition, and thermal expansion throughout a heat lot to provide uniform thermal expansion and

suitable for application in thermostat metal sheet and strip. electrical resistivity properties.

2. Referenced Documents 6. Thermal Expansion Requirements

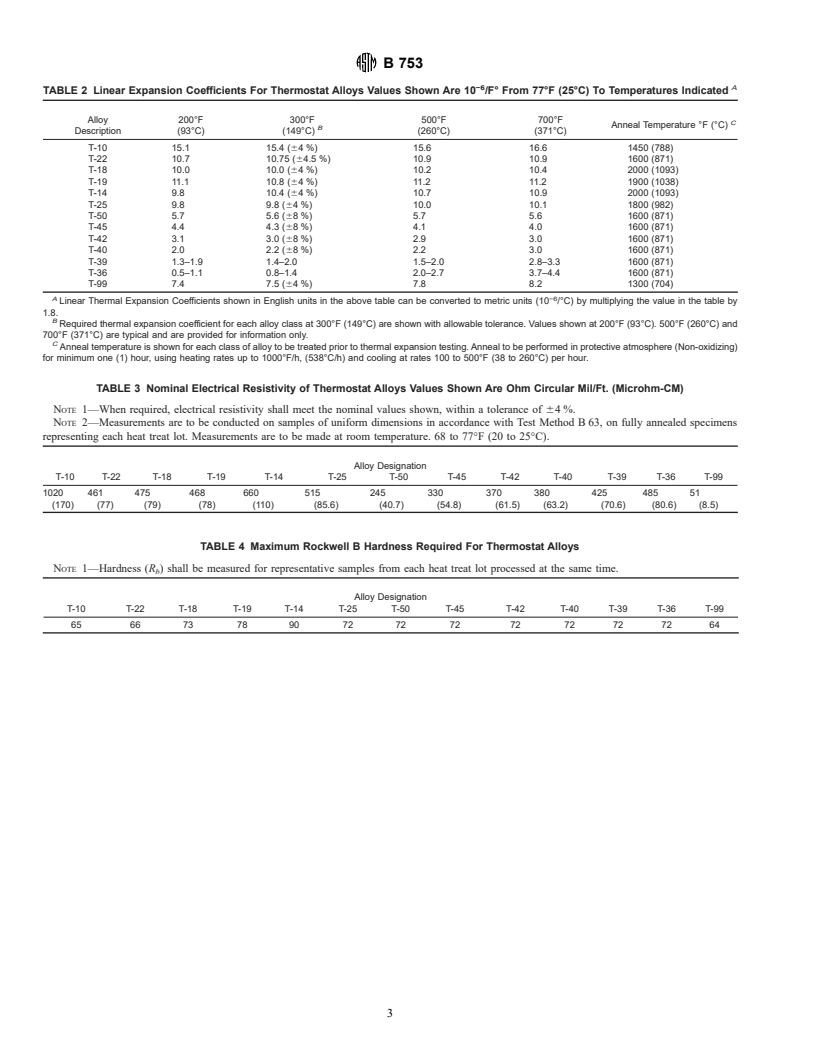

2.1 ASTM Standards: 6.1 Samples tested in accordance with 6.2 shall exhibit

A 480 Specification for General Requirements for Flat- thermal expansion properties described in Table 2.

Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and 6.2 One test sample representing each heat lot shall be

Strip machined to a suitable specimen configuration, heat treated in

B 63 Test Method for Resistivity of Metallically Conduct- accordance with instructions in Table 2, and Test Method

ing Resistance and Contact Materials E 228.

B 388 Specification for Thermostat Metal Sheet and Strip

7. Electrical Resistivity

E 18 Test Methods for Rockwell Hardness and Rockwell

Superficial Hardness of Metallic Materials 7.1 The electrical resistivity measured at room temperature

as in Test Method B 63 on suitably prepared and annealed

E 228 Test Method for Linear Thermal Expansion of Solid

Materials with a Vitreous Silica Dilatometer specimens shall conform to Table 3.

8. Temper

3. Ordering Information

3.1 Orders for this material under this specification shall 8.1 This product will be supplied in the annealed condition.

8.2 Hardness shall be measured on representative samples

include the following information:

3.1.1 Alloy type, from each heat treat lot and reported as Rockwell B hardness.

8.3 Hardness values shall conform to the requirements in

3.1.2 Size,

3.1.3 Surface finish, Table 4 tested as in Test Methods E 18.

3.1.4 Marking and packaging, and

9. Dimensions and Permissible Variations

3.1.5 Certification, if required.

9.1 Permissible variations in thickness and width shall

4. General Requirements

adhere to those described in Specification A 480. These are

shown in Table 5.

4.1 The material shall be free of scale, slivers, cracks,

seams, corrosion and other defects as best commercial practice 9.2 Edge camber shall conform to Specification A 480.

1 1

(Edge camber for widths >1- ⁄2 in. shall be a maximum ⁄4in. on

will permit. Surfaces shall be uniform and sufficiently clean so

that commonly used methods of surface preparation, or pre- any 8-ft length.)

9.3 Maximum deviation across the width of the strip at a

bond cleaning will allow bonding of the entire mating surfaces.

Since surface condition can vary for different alloys and given location shall not exceed 3 % of the nominal thickness.

9.4 Slitting burr shall be no greater than 10 % of the

because bonding practices vary, product surface condition can

be agreed upon between supplier and purchaser. thickness.

10. Certification

This test method is under the jurisdiction of ASTM Committee B-2 on

10.1 The manufacturer shall provide the purchaser with a

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.10 on Thermostat Metals. certification containing the following information:

Current edition approved Jan. 31, 1986. Published March 1986.

10.1.1 Alloy type,

Annual Book of ASTM Standards, Vol 01.03.

3 10.1.2 Specification number,

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.01. 10.1.3 Dimensions,

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 753

10.1.4 Chemical composition by heat number, 11.2.3 Heat number,

10.1.5 Coefficient thermal expansion, 11.2.4 Size,

10.1.6 Hardness, 11.2.5 Shipped weight, and

10.1.7 Quantity shipped, 11.2.6 Purchaser’s order number.

10.1.8 Purchase order number,

12. Investigation of Claims

10.1.9 Resistivity (optional), and

10.1.10 Manufacturer’s name. 12.1 Where any material fails to meet the requirements of

the specification, the material so designated shall be handled in

11. Packaging and Marking

accordance with a mutual agreement between purchaser and

11.1 Packaging and unit size shipped shall be subject to seller.

agreement between purchaser and supplier. Packaging will be

13. Keywords

sufficient to prevent damage or spoilage in transit.

11.2 Marking shall contain the following information: 13.1 alloys; chemical composition; components; controlled

11.2.1 Manufacturer’s name, thermal expansion; electrical resistivity; hardness; temper;

11.2.2 Alloy type, thermostat metal strip

TABLE 1 Suggested Compositions For Thermostat Alloys All Elements Indicated As Weight Percent

NOTE 1—Composition requirements show major elements as being nominal. These nominal requirements indicate they are to be adjusted by the

manufacturer so that the alloys meet the requirements for thermal expansion shown in Table 2. Other elements not shown, may be present in residual

amounts. These shall not be present in sufficient quantity as to significantly affect the performance in the intended application.

Alloy

T-10 T-22 T-18 T-19 T-14 T-25 T-50

Description

Carbon 0.1 max 0.12 nom 0.15 max 0.5 nom 0.5 max 0.15 max 0.15 max

Manganese 72.0 nom 0.60 max 0.80 max 1.0 nom 9.0 nom 1.0 max 0.60 max

Silicon, max 0.25 0.30 0.50 0.40 0.30 1.0 0.40

Phosphorus, max 0.030

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.