ASTM B539-02e1

(Test Method)Standard Test Methods for Measuring Resistance of Electrical Connections (Static Contacts)

Standard Test Methods for Measuring Resistance of Electrical Connections (Static Contacts)

SCOPE

1.1 These test methods cover equipment and techniques for measuring the resistance of static electrical connections such as wire terminations or splices, friction connectors, soldered joints, and wrapped-wire connections.

1.2 Measurements under two distinct levels of electrical loading are described. These levels are: (1) dry circuit, (2) and rated current. One or both of these levels of loading may be required in specific cases.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 It is the responsibility of the user to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: B 539 – 02

Standard Test Methods for

Measuring Resistance of Electrical Connections (Static

1

Contacts)

This standard is issued under the fixed designation B 539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Editorial changes were made throughout in April 2003.

1. Scope bulk resistance as possible in the measurement, by placing

measuring probes as close to the contact interface as practical.

1.1 These test methods cover equipment and techniques for

3.1.2 connection resistance—the resistance from the termi-

measuringtheresistanceofstaticelectricalconnectionssuchas

nation point on one end of a device containing static contacts,

wire terminations or splices, friction connectors, soldered

through the contacts to the termination point on the other end

joints, and wrapped-wire connections.

of the device. The termination point is the location on a

1.2 Measurements under two distinct levels of electrical

terminal of a device where a wire or printed circuit path

loading are described. These levels are: (1) dry circuit, (2) and

electrically connects to the terminal. This resistance is the

rated current. One or both of these levels of loading may be

value of resistance displayed by the device in a circuit

required in specific cases.

application.

1.3 This standard does not purport to address all of the

3.1.2.1 Discussion—The term contact resistance is often

safety concerns, if any, associated with its use. It is the

used in commercial literature to indicate the connection resis-

responsibility of the user of this standard to become familiar

tance displayed by the device in a standard application. In the

with all hazards including those identified in the appropriate

more rigorous usage of contact resistance, the connection

Material Safety Data Sheet for this product/material as pro-

resistance is the sum of the contact resistance plus the bulk

vided by the manufacturer, to establish appropriate safety and

resistance of leads within the device that go to the static

health practices, and determine the applicability of regulatory

contacts from the point that the leads are connected to the

limitations prior to use.

external circuitry. Measurement of contact resistance indepen-

2. Referenced Documents dent of all bulk resistance is very difficult for most commercial

devices.

2.1 ASTM Standards:

3.1.3 dry circuit—acircuitinwhichthe open-circuitvoltage

B 542 Terminology Relating to Electrical Contacts and

2

is less than or equal to 20 mV. Current is usually low in a dry

Their Use

circuit, but a low-current circuit is not necessarily a dry circuit.

E 122 Practice for Calculating Sample Size to Estimate,

When the applied voltage (open-circuit voltage) is too low to

With a Specified Tolerable Error, the Average for a

3

cause any physical changes in the contact junction, such as

Characteristic of a Lot or Process

break-down of thin insulating films or softening of contact

3. Terminology

asperities, the circuit is said to be a dry circuit.

3.1.4 open-circuit voltage—the steady-state voltage which

3.1 Definitions: see Terminology B 542 for definitions of

would appear across the contacts if they were opened.

contact resistance, film resistance, and constriction resistance.

3.1.5 static contacts—electric junctions designed for infre-

3.1.1 bulk resistance—the resistance a contact assembly

quent separation and connection, and intended to perform their

would have if it were solid metal of an identical geometry so

function only when contacting members are stationary relative

that the nominal contact area offered zero resistance. When

toeachother.Thisdefinitionincludescrimped,welded,brazed,

measuring contact resistance one attempts to include as little

riveted, or soldered joints; friction connections such as pin and

socket connectors or taper pins, twisted-wire splices; and

1

These test methods are under the jurisdiction of ASTM Committee B02 on

connections made with screws, or bolts and nuts between

Nonferrous Metals and Alloys and are the direct responsibility of Subcommittee

electrical wiring and components. The definition excludes

B02.11 on Electrical Contact Test Methods.

relay contacts, slip rings and commutators, and switches and

Current edition approved May 10, 2002. Published July 2002. Originally

published as B 539 – 70. Last previous edition B 539 – 01. circuit breakers.

2

Annual Book of ASTM Standards, Vol 02.04.

3

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

----------------------

...

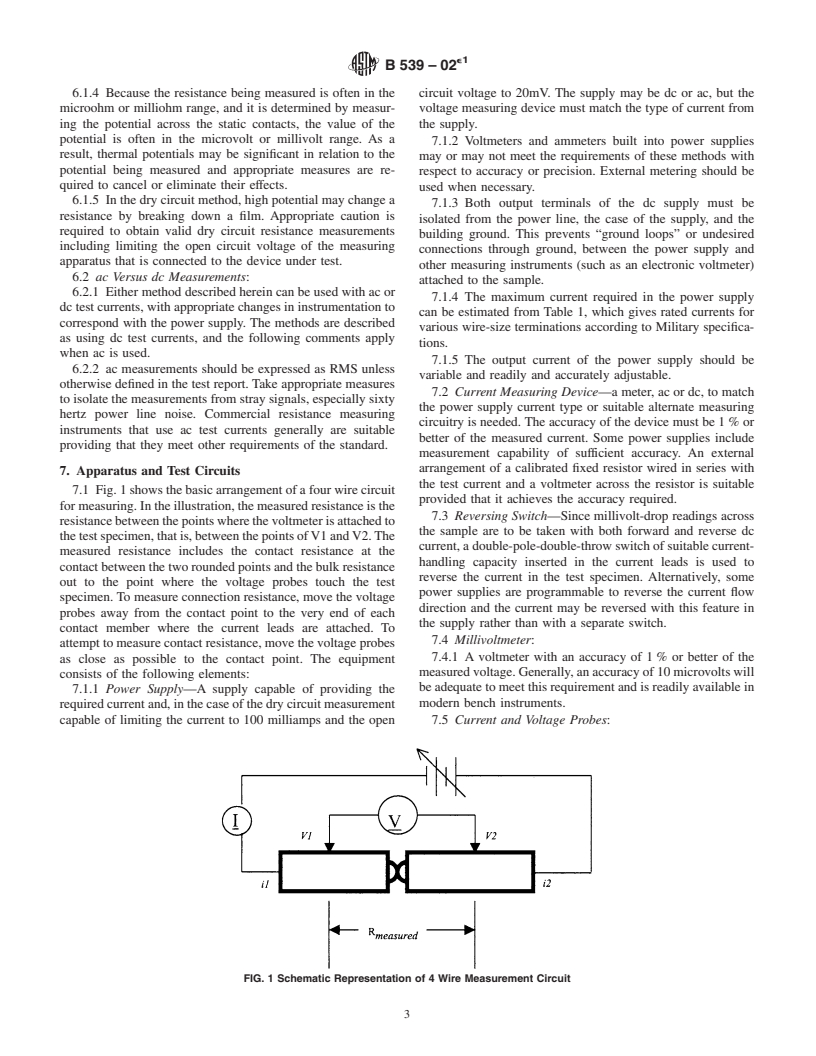

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.