ASTM B389-81(2020)

(Test Method)Standard Test Method for Thermal Deflection Rate of Spiral and Helical Coils of Thermostat Metal

Standard Test Method for Thermal Deflection Rate of Spiral and Helical Coils of Thermostat Metal

SIGNIFICANCE AND USE

5.1 This test method simulates, to a practical degree, the operation of the thermostat metal coil.

5.2 The thermal deflection properties of a coil may vary from lot-to-lot of thermostat metal material. This method is useful for determining the optimum thickness and length of the material for a given deflection specification.

5.3 This method is useful as a quality test to determine acceptance or rejection of a lot of thermostat metal coils.

SCOPE

1.1 This test method covers the determination of the thermal deflection rate of spiral and helical coils of thermostat metal.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B389 −81 (Reapproved 2020)

Standard Test Method for

Thermal Deflection Rate of Spiral and Helical Coils of

Thermostat Metal

This standard is issued under the fixed designation B389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope differing expansivities of the components, tends to alter its

curvature when its temperature is changed.

1.1 Thistestmethodcoversthedeterminationofthethermal

3.2 thermal deflection rate, n—the ratio of angular rotation

deflection rate of spiral and helical coils of thermostat metal.

to temperature change. It is a measure of the coil’s thermal

1.2 The values stated in inch-pound units are to be regarded

activity. It may have the units of angular degrees per degree

as standard. The values given in parentheses are mathematical

Fahrenheit, or Celsius, and is expressed by the equation

conversions to SI units that are provided for information only

D=(A −A )/(T −T ) where A and A are angular positions

2 1 2 1 2 1

and are not considered standard.

at temperature T and T respectively.

2 1

1.3 This standard does not purport to address all of the

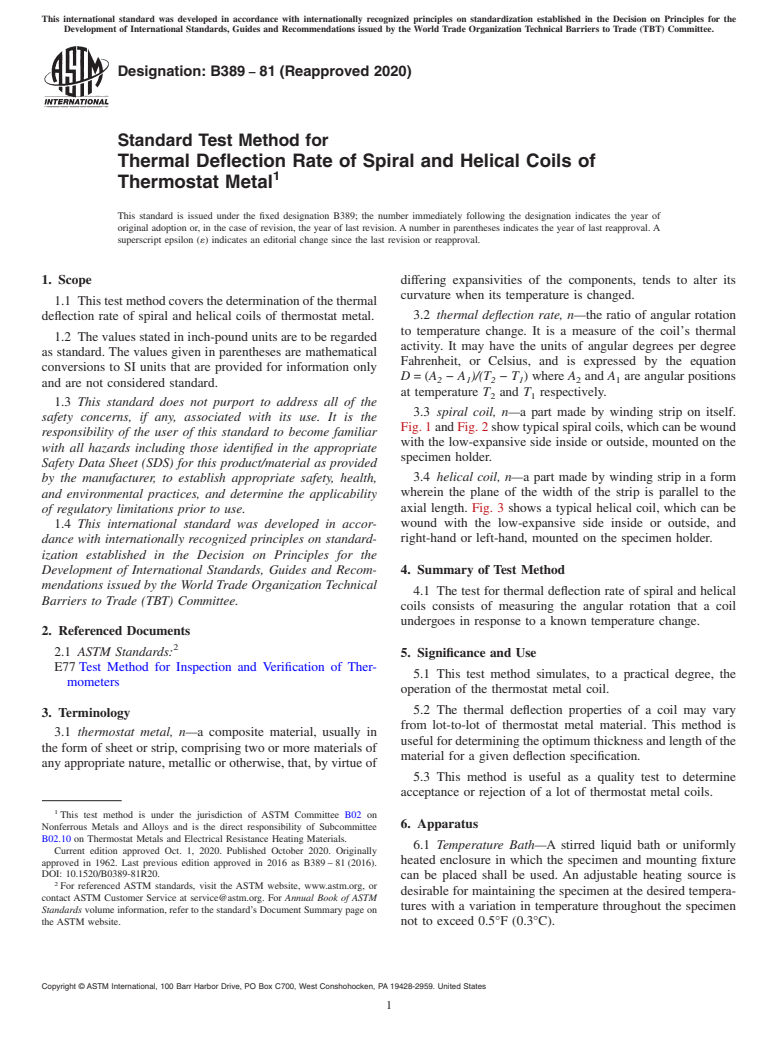

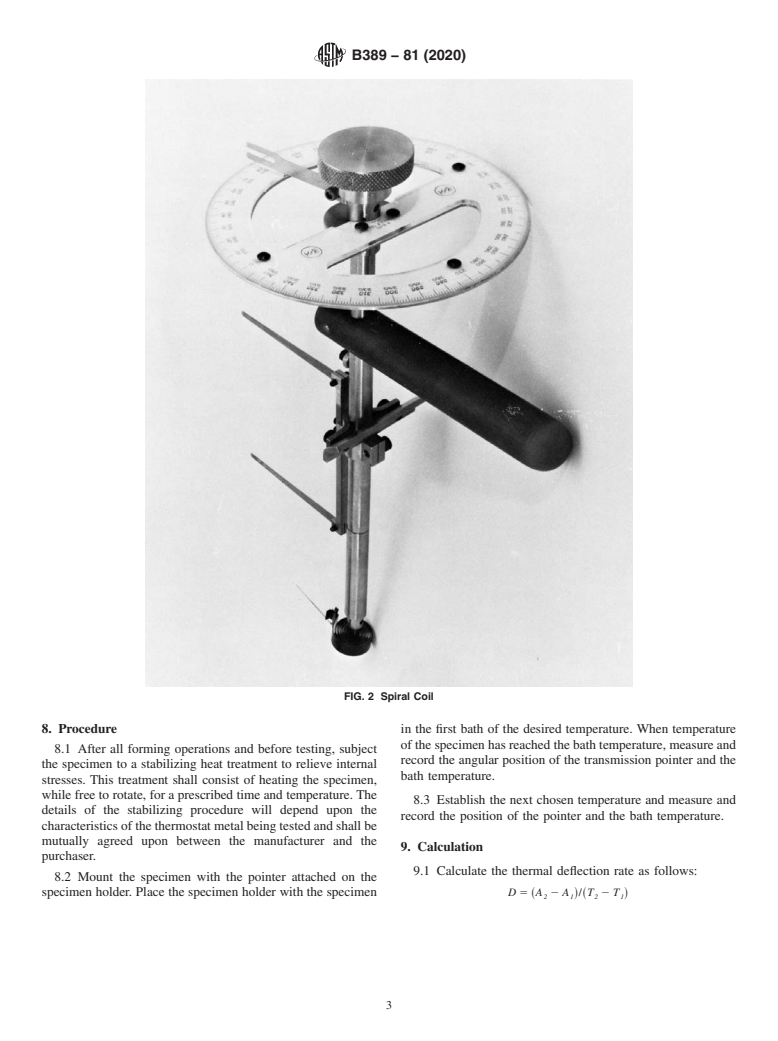

3.3 spiral coil, n—a part made by winding strip on itself.

safety concerns, if any, associated with its use. It is the

Fig. 1 and Fig. 2 show typical spiral coils, which can be wound

responsibility of the user of this standard to become familiar

with the low-expansive side inside or outside, mounted on the

with all hazards including those identified in the appropriate

specimen holder.

Safety Data Sheet (SDS) for this product/material as provided

3.4 helical coil, n—a part made by winding strip in a form

by the manufacturer, to establish appropriate safety, health,

wherein the plane of the width of the strip is parallel to the

and environmental practices, and determine the applicability

axial length. Fig. 3 shows a typical helical coil, which can be

of regulatory limitations prior to use.

wound with the low-expansive side inside or outside, and

1.4 This international standard was developed in accor-

right-hand or left-hand, mounted on the specimen holder.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Summary of Test Method

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 The test for thermal deflection rate of spiral and helical

Barriers to Trade (TBT) Committee.

coils consists of measuring the angular rotation that a coil

undergoes in response to a known temperature change.

2. Referenced Documents

2.1 ASTM Standards: 5. Significance and Use

E77 Test Method for Inspection and Verification of Ther-

5.1 This test method simulates, to a practical degree, the

mometers

operation of the thermostat metal coil.

5.2 The thermal deflection properties of a coil may vary

3. Terminology

from lot-to-lot of thermostat metal material. This method is

3.1 thermostat metal, n—a composite material, usually in

useful for determining the optimum thickness and length of the

the form of sheet or strip, comprising two or more materials of

material for a given deflection specification.

any appropriate nature, metallic or otherwise, that, by virtue of

5.3 This method is useful as a quality test to determine

acceptance or rejection of a lot of thermostat metal coils.

This test method is under the jurisdiction of ASTM Committee B02 on

6. Apparatus

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

6.1 Temperature Bath—A stirred liquid bath or uniformly

Current edition approved Oct. 1, 2020. Published October 2020. Originally

heated enclosure in which the specimen and mounting fixture

approved in 1962. Last previous edition approved in 2016 as B389 – 81 (2016).

DOI: 10.1520/B0389-81R20.

can be placed shall be used. An adjustable heating source is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

desirable for maintaining the specimen at the desired tempera-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tures with a variation in temperature throughout the specimen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. not to exceed 0.5°F (0.3°C).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B389 − 81 (2020)

and the top end allowed to rotate freely with a temperature

change. Preferably the end of the coil with the center tab shall

be considered the bottom and secured by clamping or press-

fitting the tab into a slotted arbor similar to that described in

6.4.1 for spiral coils.The depth of the slot shall be such that the

full height of the tab shall be held. If the coils do not have a

center tab, the arbor shall contain provisions for attaching the

coil with screws, rivets, or by welding. A transmission pointer

can be affixed to the top end. The center line of the coil, the

transmission pointer, and the protractor shall coincide.

6.4.3 Deviations from these procedures of holding may be

necessary when simulating the mounting used in the device for

which the coil was designed, or in cases where coils are press

fitted on arbors. In these cases, the details of mounting should

be mutually agreed upon between the manufacturer and the

purchaser.

6.5 Transmission Pointer:

6.5.1 Spiral Coils—To the outer end of the spiral coil shall

be attached a pointer that will transmit the rotation of the coil

so that it can be read on the protractor. The pointer shall be of

lightweight construction and attached to the coil by suitable

means so that the movement of these portions of the coil that

do not normally contribute to the movement of the coil with a

temperature change shall not influence the rotation of the

pointer. The pointer, when using the fixture shown in Fig. 1,

shall be so positioned that its tip shall ride slightly above the

divisions of the protractor, but shall not touch the protractor at

any time during the test. The pointer, when using the fixture

shown in Fig. 2, shall be of sufficient length so that the top may

FIG. 1 Spiral Coil

protrude from the bath when the coil is submerged.The pointer

f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.