ASTM F1570-94

(Test Method)Standard Test Method for Determining the Tactile Ratio of a Membrane Switch

Standard Test Method for Determining the Tactile Ratio of a Membrane Switch

SCOPE

1.1 This test method covers the determination of the tactile response of a membrane switch as defined by tactile ratio.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1570 – 94

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Determining the Tactile Ratio of a Membrane Switch

This standard is issued under the fixed designation F 1570; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the tactile

response of a membrane switch as defined by tactile ratio.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Terminology

2.1 Definitions:

2.1.1 contact closure (make)—point at which specified re-

sistance is achieved.

2.1.2 contact force—force at contact closure.

2.1.2.1 Discussion—ideal value for F

min

2.1.3 displacement—distance traveled by the surface in

contact with the test probe.

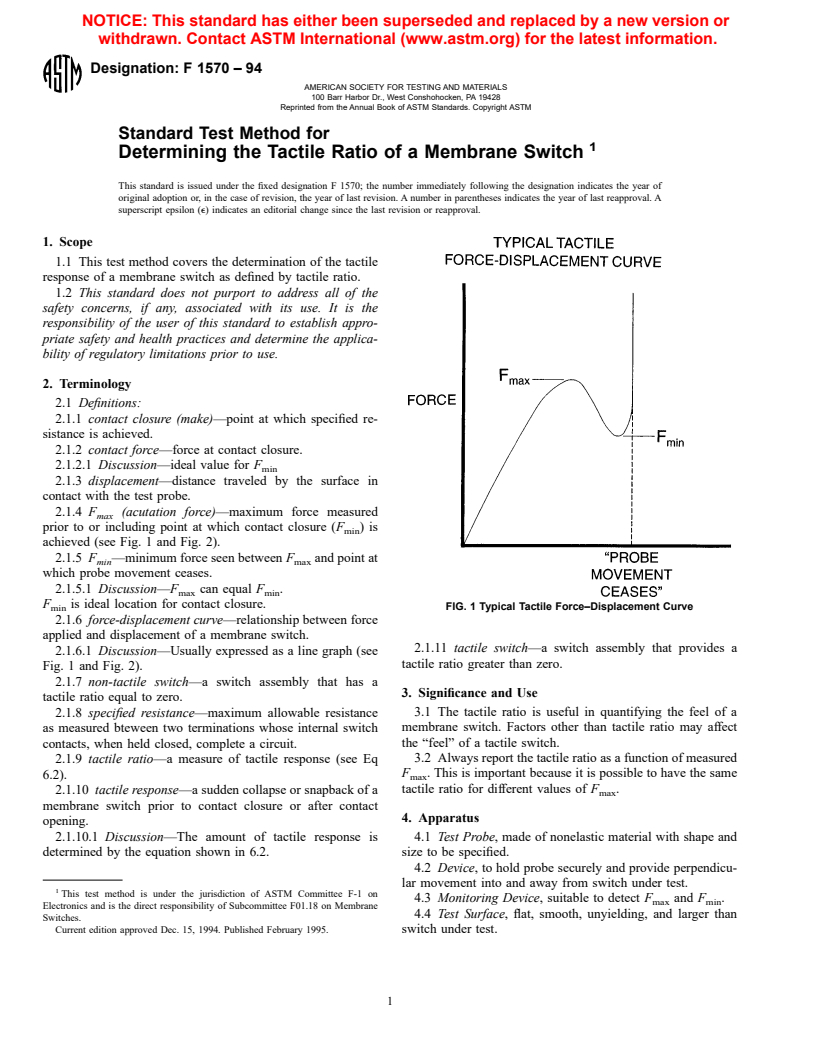

2.1.4 F (acutation force)—maximum force measured

max

prior to or including point at which contact closure (F )is

min

achieved (see Fig. 1 and Fig. 2).

2.1.5 F —minimum force seen between F and point at

min max

which probe movement ceases.

2.1.5.1 Discussion—F can equal F .

max min

F is ideal location for contact closure.

FIG. 1 Typical Tactile Force–Displacement Curve

min

2.1.6 force-displacement curve—relationship between force

applied and displacement of a membrane switch.

2.1.11 tactile switch—a switch assembly that provides a

2.1.6.1 Discussion—Usually expressed as a line graph (see

tactile ratio greater than zero.

Fig. 1 and Fig. 2).

2.1.7 non-tactile switch—a switch assembly that has a

3. Significance and Use

tactile ratio equal to zero.

2.1.8 specified resistance—maximum allowable resistance 3.1 The tactile ratio is useful in quantifying the feel of a

membrane switch. Factors other than tactile ratio may affect

as measured bteween two terminations whose internal switch

contacts, when held closed, complete a circuit. the “feel” of a tactile switch.

3.2 Always report the tactile ratio as a function of measured

2.1.9 tactile ratio—a measure of tactile response (see Eq

6.2). F . This is important because it is possible to have the same

max

tactile ratio for different values of F .

2.1.10 tactile response—a sudden collapse or snapback of a

max

membrane switch prior to contact closure or after contact

4. Apparatus

opening.

2.1.10.1 Discussion—The amount of tactile response is 4.1 Test Probe, made of nonelastic material with shape and

determined by the equation shown in 6.2.

size to be specified.

4.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.