ASTM C1036-91(1997)

(Specification)Standard Specification for Flat Glass

Standard Specification for Flat Glass

SCOPE

1.1 This specification covers the requirements for annealed, monolithic flat glass of rectangular shape supplied as cut sizes or stock sheets. This specification is applicable for laboratory and field evaluation only to the extent that such evaluation can be carried out in accordance with the test method(s) prescribed herein.

1.2 This specification covers the quality requirements of flat, transparent, clear and tinted glass having glossy, apparently plane and smooth surfaces. The glass is intended to be used primarily for mirrors, coatings, glazing, and general architectural or similar uses.Note 1—Reflective distortion is not addressed in this specification.Note 2—There may be blemishes or other glass quality requirements that are not addressed in this specification.

1.3 This specification covers the quality requirements of patterned or wired glasses intended to be used primarily for decorative and general glazing applications.

1.4 The dimensional values stated in metric units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1036 – 91 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Flat Glass

This standard is issued under the fixed designation C 1036; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers the quality requirements for 3.1 Definitions—For additional definitions of terms, refer to

cut sizes of flat, transparent, clear glass having glossy, appar- Terminology C 162.

ently plane and smooth surfaces for glazing, mirrors, and 3.1.1 blemishes in flat glass:

general architectural or similar uses.

NOTE 1—These definitions do not apply to in-service damage.

1.2 This specification covers the quality requirements for

3.1.1.1 crush—a lightly pitted area resulting in a dull gray

cut sizes of flat transparent tinted heat-absorbing or light-

or white appearance over the region.

reducing glass, or both, having glossy, apparently plane and

3.1.1.2 digs—deep, short scratches.

smooth surfaces. The glass is intended to be used primarily for

3.1.1.3 dirt—a small particle of foreign matter imbedded in

building construction to control the transmission of light, heat,

the glass surface.

or solar radiation, or combination thereof.

3.1.1.4 gaseous inclusions—round or elongated bubbles in

1.3 This specification covers the quality requirements for

the glass.

cut sizes of patterned and wired glasses for decorative and

3.1.1.5 knot—a transparent area of incompletely assimilated

general glazing applications.

glass.

1.4 The dimensional values stated in inch-pound units,

3.1.1.6 lines—fine cords or strings, usually on the surface of

except for thickness designations, are to be regarded as the

sheet glass.

standard.

3.1.1.7 open gaseous inclusions—bubbles at the surface of

1.5 The following safety hazards caveat pertains only to the

glass that are open, leaving a cavity in the surface.

test method portion, Section 7, of this specification. This

3.1.1.8 process surface blemishes—slight surface blemishes

standard does not purport to address all of the safety concerns,

that originated in the process that can be small particles of

if any, associated with its use. It is the responsibility of the user

foreign materials on either surface or surface irregularities.

of this standard to establish appropriate safety and health

3.1.1.9 ream—inclusions within the glass or layers or

practices and determine the applicability of regulatory limita-

strings of glass that are not homogeneous with the main body

tions prior to use.

of the glass.

2. Referenced Documents 3.1.1.10 rub—abrasion of the glass surfaces producing a

frosted appearance. A rub differs from a scratch in having

2.1 ASTM Standards:

appreciable width.

C 162 Terminology of Glass and Glass Products

3.1.1.11 scratch—any marking or tearing of the surface

E 308 Test Method for Computing the Colors of Objects by

produced in manufacturing or handling, appearing as though it

Using the CIE System

were done by a sharp or rough instrument.

E 903 Test Method for Solar Absorptance, Reflectance, and

3.1.1.12 smoke—streaked areas appearing as slight discol-

Transmittance of Materials Using Integrating Spheres

oration.

3.1.1.13 stone—any crystalline inclusion imbedded in the

glass.

This specification is under the jurisdiction of ASTM Committee C-14 on Glass

3.1.1.14 string—transparent line appearing as though a

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

thread of glass had been incorporated into the sheet.

Glass.

3.1.1.15 wave—blemishes resulting from irregularities of

Current edition approved Nov. 15, 1991. Published January 1992. Originally

e1

published as C 1036 – 85. Last previous edition C 1036 – 90 .

the surfaces of glass, making objects viewed at varying angles

Latest issue, unless otherwise specified by the agency applying Specification

appear wavy or bent.

C 1036.

3 3.1.2 vision interference angle—the acute angle included

Annual Book of ASTM Standards, Vol 15.02.

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 12.02.

C 1036

between the plane of the glass and the vertical plane perpen-

Form (Classes 1, 2, and 3)

1—Wired, polished both sides

dicular to the wall, such plane including the observer when the

2—Patterned and wired

glass is examined in accordance with 7.1.

3—Patterned

3.2 Definitions of Terms Specific to This Standard:

Quality

3.2.1 heat-absorbing glass—glass for absorbing appre- q —Decorative

q —Glazing

ciable portions of radiant energy, especially solar energy.

Finish

3.2.2 illuminant C—as defined in Test Method E 308, an

f —Patterned one side

approximate representation of average daylight. Standard illu-

f —Patterned both sides

minant C (CIE 1931) (Commission Internationale de

Mesh (Forms 1 and 2)

m —Diamond

l’Éclairage) is a gas-filled lamp of color temperature 2848 K

m —Square

used in conjunction with a liquid filter (Davis-Gibson filter) for

m —Parallel strand

converting color temperature 2856 to 6670 K.

m —Special

3.2.3 light-reducing glass—glass which is formulated to

Pattern (Forms 2 and 3)

p —Linear

reduce the transmission of light.

p —Geometric

3.2.4 light transmittance—that fraction of the incident light 3

p —Random

of a given wavelength which is not reflected or absorbed but p —Special

passes through a substance.

4.2 Intended Use of Transparent Flat Glass:

3.2.5 patterned glass—rolled flat glass having a pattern on 1

4.2.1 Mirror Select Quality,q —Intended to be coated for

one or both surfaces.

premium mirrors.

3.2.6 shading coeffıcient—for any fenestration, the ratio of

4.2.2 Mirror Quality,q —Intended to be coated for general

the rate of total solar heat gain through that type of fenestration

use mirrors.

to the total solar heat gain that would be admitted through a

4.2.3 Glazing Select Quality,q —Intended for architectural

standard single pane of 3-mm (0.12-in.) thick clear glass in the

fenestrations or other applications where distant objects are

same situation, the standard pane having a total solar transmit-

viewed through the glass by the observer.

tance value of 0.87.

4.2.4 Glazing A Quality,q —Intended for selected glazing

3.2.7 wired glass—rolled glass having a layer of meshed or

applications such as appliances or show cases where the

standard wire completely imbedded in the sheet.

observer views near objects through the glass.

4.2.5 Glazing B Quality,q —Intended for general glazing

4. Classification and Intended Use

3 4

applications that have lesser aesthetic demands than a q or q

4.1 Types, Classes, Styles, Forms, Qualities, and Finishes—

quality grade.

Glass shall be of the following types, classes, styles, forms,

4.2.6 Greenhouse Quality,q —Intended for greenhouses or

qualities, and finishes, as specified (see Section 5):

other applications where restrictions on aesthetic conditions are

4.1.1 Type I—Transparent Glass, Flat:

not required.

4.1.1.1 Class 1—Clear:

4.3 Intended Use of Patterned and Wired Flat Glasses:

Quality

4.3.1 Decorative Quality,q —Intended for use where de-

q —Mirror select

2 sign and aesthetic characteristics are major considerations.

q —Mirror

4.3.2 Glazing Quality,q —Intended for general glazing

q —Glazing select

q —Glazing A

where functional or aesthetic characteristics are a consideration

q —Glazing B

and where surface blemishes are not a major concern.

q —Greenhouse

4.3.3 Wired Glass—Intended for skylights and general glaz-

4.1.1.2 Class 2—Tinted, Heat-Absorbing and Light-

ing where fire retardation or glass retention in the frame are a

Reducing:

consideration.

Quality

q —Glazing select

4 5. Ordering Information

q —Glazing A

q —Glazing B

5.1 Purchasers should select the preferred options permitted

Style A—Higher light transmittance

in this specification, and include the following information in

Style B—Lower light transmittance

procurement documents:

4.1.1.3 Class 3—Tinted, Light-Reducing:

5.1.1 Title, number, and date of this specification,

Quality

5.1.2 Type, class, quality, style, and form, as requested (see

q —Glazing select

4.1),

q —Glazing A

q —Glazing B

5.1.3 Edges (see 6.1),

5.1.4 Length and width of cut size (see 6.3, 6.8.1.1, and

4.1.2 Type II—Patterned and Wired Glass, Flat:

6.8.2.1), and

Class

5.1.5 Glass thickness (see 6.3, 6.8.1.1, and 6.8.2.1).

1—Clear

2—Tinted, heat-absorbing and light-reducing (A and B applies to Class 2

5.1.6 Samples—If for any particular purpose samples with

only)

bids are necessary, they should be specifically asked for in the

Style A—Higher light transmittance

Style B—Lower light transmittance invitation for bids and the particular purpose to be served by

3—Tinted, light reducing

the bid sample should be definitely stated.

C 1036

5.2 Additional information to be specified for tinted, heat- 6.5 Quality q (Greenhouse)—Glass may contain visual

absorbing or light-reducing flat glass, or both: blemishes that are suitable for greenhouse glazing.

5.2.1 Heat-Absorbing Glass—Style and tint.

6.6 Additional Requirements for Type I, Class 2 (Tinted,

5.2.2 Light-Reducing Glass—Transmittance and tint.

Heat-Absorbing and Light-Reducing Flat Glass):

5.2.3 Availability—Heat-absorbing glass is available in a

6.6.1 Transmittance, Styles A and B—The illuminant C

variety of styles and tints, but within limitations. Combina-

(daylight) and solar transmittance shall be in accordance with

tions of all styles and tints are not possible. It is advisable that

Table 5.

before referencing glass to this specification, the authority

6.6.2 Blemishes for Type I, Class 2 (Tinted, Heat-Absorbing

applying this specification should consult with suppliers.

and Light-Reducing Flat Glass)—The type and number of

5.3 Additional information to be specified for patterned or

blemishes shall be not greater than those specified in Table 3

wired glass, or both.

and Table 4.

5.3.1 For patterned glass, pattern description, whether one

6.6.3 Tint—The tint of each class, style, and quality shall be

or both sides.

as specified. Note that the color of tinted heat-absorbing glass

5.3.2 For wired glass, surface finish, wire mesh, and pattern

is a major consideration for either design and aesthetic reasons

description, if any.

or for color matching requirements. Tinted heat-absorbing

5.3.3 Samples—If for any particular purpose samples with

glass should be viewed as installed for color comparison.

bids are necessary, such as wired glass that may contain

Colors may vary considerably among different manufacturers

numerous gaseous inclusions along the wire, they should be

and from run to run.

specifically asked for in the invitation for bids and the

particular purpose to be served by the bid sample should be

6.7 Additional Requirements for Type I, Class 3 (Tinted,

definitely stated. Light-Reducing, Flat Glass):

6.7.1 Luminous Transmittance—Light-reducing glass may

6. Requirements

be produced in a wide range of luminous transmittance values.

6.1 Edge—An edge shall be cut, ground, sanded to remove

The transmittance shall be as specified.

sharp edges only, seamed, ground and polished, beveled, or

6.7.2 Blemishes for Type I, Class 3 (Tinted, Light-Reducing,

mitered, as specified.

Flat Glass)—The type and number of blemishes shall be as

6.2 Marking—Each package of glass shall bear a label,

specified in Table 3 and Table 4.

affixed by the manufacturer, giving the manufacturer’s name or

6.7.3 Color—The color of tinted glass is a major consider-

trademark, the quality of glass, nominal thickness, and place of

ation for either design and aesthetic reasons or color matching

manufacture.

requirements. Tinted glass should be viewed as installed for

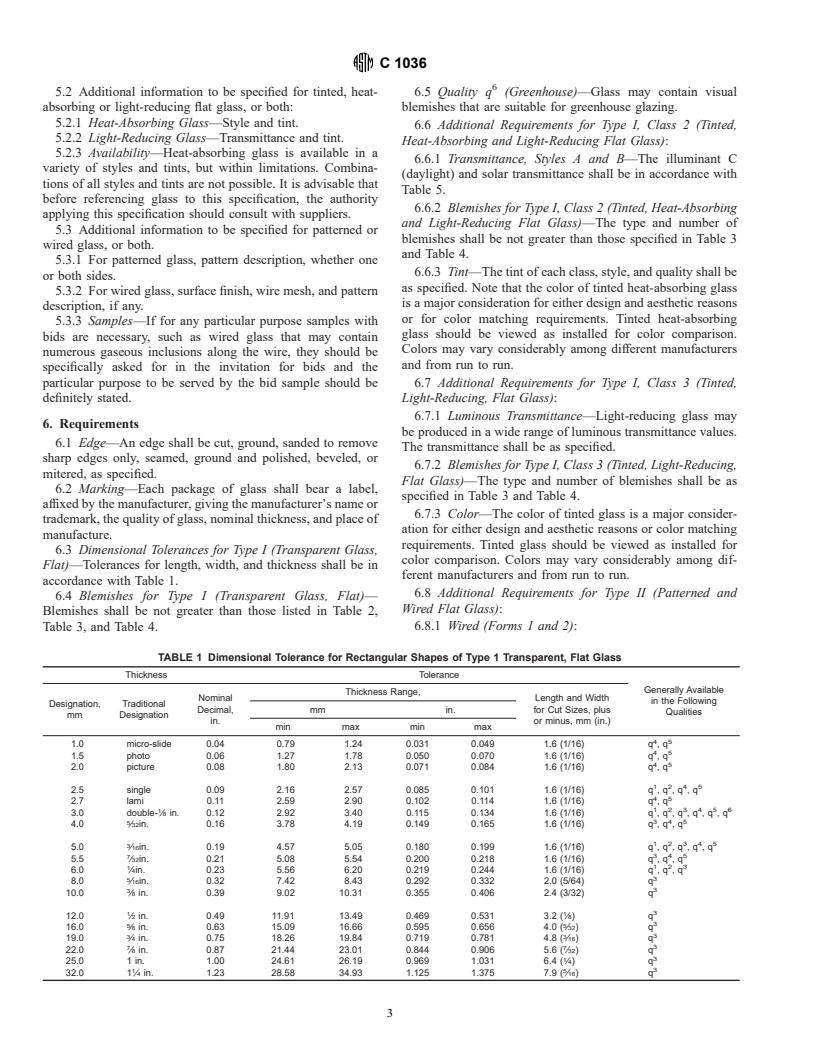

6.3 Dimensional Tolerances for Type I (Transparent Glass,

color comparison. Colors may vary considerably among dif-

Flat)—Tolerances for length, width, and thickness shall be in

ferent manufacturers and from run to run.

accordance with Table 1.

6.8 Additional Requirements for Type II (Patterned and

6.4 Blemishes for Type I (Transparent Glass, Flat)—

Wired Flat Glass):

Blemishes shall be not greater than those listed in Table 2,

Table 3, and Table 4. 6.8.1 Wired (Forms 1 and 2):

TABLE 1 Dimensional Tolerance for Rectangular Shapes of Type 1 Transparent, Flat Glass

Thickness Tolerance

Generally Available

Thickness Range,

Nominal Length and Width

in the Following

Designation, Traditional

Decimal, mm in. for Cut Sizes, plus

Qualities

mm Designation

in. or minus, mm (in.)

min max min max

4 5

1.0 micro-slide 0.04 0.79 1.24 0.031 0.049 1.6 (1/16) q ,q

4 5

1.5 photo 0.06 1.27 1.78 0.050 0.070 1.6 (1/16) q ,q

4 5

2.0 picture 0.08 1.80 2.13 0.071 0.084 1.6 (1/16) q ,q

1 2 4 5

2.5 single 0.09 2.16 2.57 0.085 0.101 1.6 (1/16) q ,q ,q ,q

4 5

2.7 lami 0.11 2.59 2.90 0.102 0.114 1.6 (1/16) q ,q

1 2 3 4 5 6

3.0 double- ⁄8 in. 0.12 2.92 3.40 0.115 0.134 1.6 (1/16) q ,q ,q ,q ,q ,q

3 4 5

4.0 ⁄32in. 0.16 3.78 4.19 0.149 0.165 1.6 (1/16) q ,q ,q

1 2 3 4 5

5.0 ⁄16in. 0.19 4.57 5.05 0.180 0.199 1.6 (1/16) q ,q ,q ,q ,q

3 4 5

5.5 ⁄32in. 0.21 5.08 5.54 0.200 0.218 1.6 (1/16) q ,q ,q

1 2 3

6.0 ⁄4in. 0.23 5.56 6.20 0.219 0.244 1.6 (1/16) q ,q ,q

8.0 ⁄16in. 0.32 7.42 8.43 0.292 0.332 2.0 (5/64) q

3 3

10.0 ⁄8 in. 0.39 9.02 10.31 0.355 0.406 2.4 (3/32) q

1 1

12.0 ⁄2 in. 0.49 11.91 13.49 0.469 0.531 3.2 ( ⁄8)q

5 5

16.0 ⁄8 in. 0.63 15.09 16.66 0.595 0.656 4.0 ( ⁄32)q

3 3

19.0 ⁄4 in. 0.75 18.26 19.84 0.719 0.781 4.8 ( ⁄16)q

7 7

22.0 ⁄8 in. 0.87 21.44 23.01 0.844 0.906 5.6 ( ⁄32)q

25.0 1 in. 1.00 24.61 26.19 0.969 1.031 6.4 ( ⁄4)q

1 5 3

32.0 1 ⁄4 in. 1.23 28.58 34.93 1.125 1.375 7.9 ( ⁄16)q

C 1036

1 2 A

TABLE 2 Glass Qualities q and q , Maximum Allowable Blemishes for Thicknesses 6.0 mm ( ⁄4in.) or Less

q , Mirror Select Quality

q , Mirror Quality

2 2 2 2

Blemishes Up to 2.5 m (25 ft ) Over 2.5 m (25 ft )

B B B B B B

Central Outer Central Outer Central Outer

Gaseous inclusions, maximum 0.8 mm 1.2 mm 1.2 mm 1.6 mm 6.4 mm 6.4 mm

C D,E D,E D,E D,E E,F E,F

1 3 3 1 1 1

size ( ⁄32 in.) ( ⁄64 in.) ( ⁄64 in.) ( ⁄16 in.) ( ⁄4 in.) ( ⁄4 in.)

Open or translucent gaseous none 0.4 mm 0.4 mm 0.8 mm 6.4 mm 6.4 mm

C D,E D,E D,E E,F E,F

1 1 1 1 1

inclusions, maximum size ( ⁄64 in.) ( ⁄64 in.) ( ⁄32 in.) ( ⁄4 in.) ( ⁄4 in.)

Knots, dirt, and stones, none 0.4 mm 0.4 mm 0.8 mm 0.8 mm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.