ASTM D3749-95(2002)

(Test Method)Standard Test Method for Residual Vinyl Chloride Monomer in Poly(Vinyl Chloride) Resins by Gas Chromatographic Headspace Technique

Standard Test Method for Residual Vinyl Chloride Monomer in Poly(Vinyl Chloride) Resins by Gas Chromatographic Headspace Technique

SIGNIFICANCE AND USE

Poly(vinyl chloride) resins must contain a minimum possible amount of unreacted, or free, VCM.

This test method provides a measure of RVCM which is suitable for manufacturing control or specification acceptance purposes.

Under optimum conditions, a lower level of detection of 2 ppm by volume VCM can be detected in the headspace vapor. Using a 4-g sample, this is equivalent to about 0.02 ppm by mass RVCM in the PVC resin.

SCOPE

1.1 This test method is suitable for determining the residual vinyl chloride monomer (RVCM) content of poly(vinyl chloride) (PVC) homopolymer and copolymer resins for uses other than food contact. The range for this test, based on interlaboratory evaluation, is from 0.1 to 400 ppm RVCM.

1.2 This test method can be adapted to determinations of RVCM in a PVC copolymer resin if the Henry's Law constant at 90C for that copolymer is known.

1.3 This test method cannot be used for polymer in fused forms, such as cubes or sheets. Refer to Test Method D 4443 or Test Method D 3680 for these materials.

1.4 This test method is proposed as an alternative to EPA Method 107 for determination of vinyl chloride monomers in dry-resin samples.

1.5 The values stated SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is similar to ISO 6401-1985 in title only. The technical content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3749–95 (Reapproved 2002)

Standard Test Method for

Residual Vinyl Chloride Monomer in Poly(Vinyl Chloride)

Resins by Gas Chromatographic Headspace Technique

This standard is issued under the fixed designation D3749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope by Headspace Gas Chromatography

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method is suitable for determining the residual

Determine the Precision of a Test Method

vinyl chloride monomer (RVCM) content of poly(vinyl chlo-

2.2 Federal Standards:

ride)(PVC)homopolymerandcopolymerresinsforusesother

EnvironmentalProtectionAgencyMethod107 Determination

than food contact. The range for this test, based on interlabo-

of Vinyl Chloride Content of In-Process Waste-Water

ratory evaluation, is from 0.1 to 400 ppm RVCM.

Samples, andVinyl Chloride Content of Poly(Vinyl Chlo-

1.2 This test method can be adapted to determinations of

ride) Resin, Slurry, Wet Cake, and Latex Samples

RVCM in a PVC copolymer resin if the Henry’s Law constant

29 CFR 1919.1017 Vinyl Chloride for Regulated Levels of

at 90°C for that copolymer is known.

Exposure

1.3 This test method cannot be used for polymer in fused

2.3 ISO Standard:

forms,suchascubesorsheets.RefertoTestMethodD4443or

ISO 6401-1985 Determination of Residual Vinyl Chloride

Test Method D3680 for these materials.

Monomer in Homopolymers and Copolymers by Gas

1.4 This test method is proposed as an alternative to EPA

Chromatography

Method107 for determination of vinyl chloride monomers in

dry-resin samples.

3. Terminology

1.5 The values stated SI units are to be regarded as the

3.1 Acronyms:Acronyms:

standard.

3.1.1 VCM—Vinyl chloride monomer.

1.6 This standard does not purport to address all of the

3.1.2 RVCM—Residual vinyl chloride monomer.

safety concerns, if any, associated with its use. It is the

3.1.3 PVC—Poly(vinyl chloride).

responsibility of the user of this standard to establish appro-

3.1.4 OSHA—Occupational Safety and Health Agency.

priate safety and health practices and determine the applica-

3.1.5 FID—Flame ionization detector.

bility of regulatory limitations prior to use.

3.1.6 PID—Photoionization detector.

NOTE 1—ThistestmethodissimilartoISO6401-1985intitleonly.The

3.1.7 HED—Hall electroconductivity detector.

technical content is significantly different.

3.1.8 MHE—Multiple headspace extraction.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 The basis for this test method relates to the vapor

D3680 Test Method for ResidualVinyl Chloride Monomer

equilibriumthatisestablishedbetweenRVCM,PVCresin,and

Content of Poly(Vinyl Chloride) Resins, Compounds, and

air in a closed system. The RVCM in a PVC resin will

Copolymers by Solution Injection Technique

equilibrate in a closed vessel quite rapidly, provided that the

D4443 Test Method forAnalysis for Determining Residual

temperature of the PVC resin is maintained above the glass

Vinyl Chloride Monomer Content in PPB Range in Vinyl

transition temperature of that specific resin type.

Chloride Homo- and Co-Polymers by Headspace Gas

4.2 After sample equilibration, conventional gas chromato-

Chromatography

graphic (GC) techniques are used. A constant amount of

D4526 Practice for Determination of Volatiles in Polymers

sample headspace vapor is injected into a GC column that is

1 4

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics Annual Book of ASTM Standards, Vol 14.02.

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods. Available from the U.S. Environmental Protection Agency, Research Triangle

Current edition approved June 15, 1995. Published August 1995. Originally Park, NC27711.

published as D3749–78. Last previous edition D3749–93. This edition includes Available from the Superintendent of Documents, Government Printing Office,

revisions to Section 14. Washington, DC20402.

2 7

Annual Book of ASTM Standards, Vol 06.03. Available from American National Standards Institute, 25 W. 43rd St., 4th

Annual Book of ASTM Standards, Vol 08.03. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

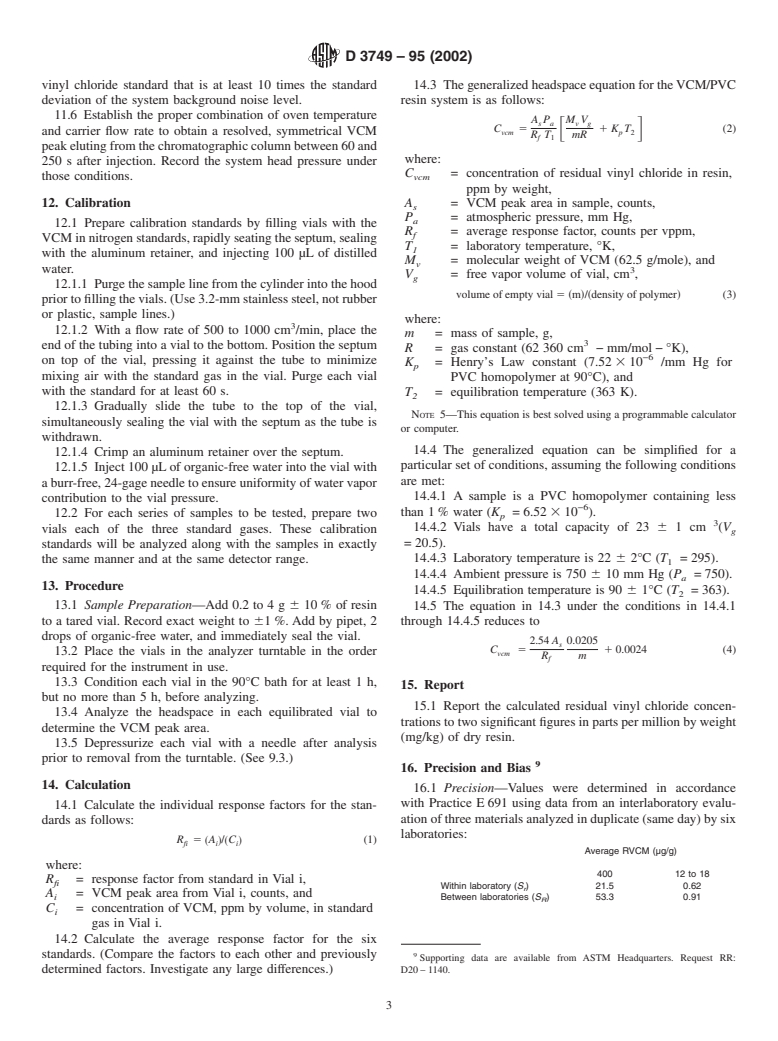

D3749–95 (2002)

packed with a liquid-coated solid support or porous polymer 8. Reagents and Materials

beads.Sampleinjectionisaccomplishedbyavailablecommer-

8.1 Standards—Cylinders of known concentrations of vinyl

cial automatic equipment. Passing through the column in a

chloride in nitrogen gas. Nominal concentrations of 5, 50, and

stream of carrier gas, the vinyl chloride monomer (VCM) is

500 ppm by volume (vppm) are needed, unless multiple

separated from other components which may be present and is

headspace extraction (MHE) is used. Lower concentration

detectedbyastandardsensingdevice.Thesignalisrecordedto

standards may be desirable for a detection limit less than 2

indicatetherelativeconcentrationoftheVCManditsretention

ppm.

time.

8.2 Nitrogen, or helium, oxygen-free, carrier gas for chro-

4.3 Refer to Practice D4526 for additional information on

matograph.

headspace gas chromatography.

8.3 Hydrogen, prepurified for FID detector.

8.4 Air, breathing grade, for FID detector.

5. Significance and Use

5.1 Poly(vinyl chloride) resins must contain a minimum

9. Hazards

possible amount of unreacted, or free, VCM.

9.1 Vinyl chloride monomer is a cancer-suspect agent and

5.2 ThistestmethodprovidesameasureofRVCMwhichis

must never be released to the laboratory atmosphere, even at

suitable for manufacturing control or specification acceptance

low ppm levels. Venting or purging of VCM mixtures must be

purposes.

held to a minimum and should be vented into a properly

5.3 Underoptimumconditions,alowerlevelofdetectionof

functioning fume hood. Refer to 29 CFR 1919.1017 for

2ppmbyvolumeVCMcanbedetectedintheheadspacevapor.

regulated levels of exposure.

Using a 4-g sample, this is equivalent to about 0.02 ppm by

9.2 Be careful not to come into contact with heated parts of

mass RVCM in the PVC resin.

thechromatograph,suchasthedetector,column,hotvials,etc.

Handle all electrical connections with care.

6. Interferences

9.3 Vials should be vented to atmospheric pressure after

6.1 Normally, the vapor above PVC resin will contain only

analysis and prior to removal from the thermostatted turntable.

air, VCM, water, small amounts of catalyst breakdown prod-

A hypodermic needle connected to a syringe containing a

ucts, and any solvents or comonomers used in polymerization.

freshly activated charcoal is suitable for this operation.

Impuritiesinthe0to1000-ppmrangewillgenerallyhaveonly

a very small influence on this equilibrium relationship.

10. Sampling and Storage

6.2 Any material that elutes from the chromatographic

10.1 Weigh and seal resin samples in the headspace vials in

column at approximately the same time as vinyl chloride will

accordance with 12.1 as soon as possible, not to exceed 24 h.

cause high RVCM results.

10.2 Resins may be stored in the sealed headspace vials for

7. Apparatus up to four weeks without loss of VCM if they are analyzed

without being reopened.

7.1 Gas Chromatograph, equipped with a flame ionization

detector (FID), photoionization detector (PID), or a Hall

11. Preparation of Gas Chromatograph

electroconductivity detector (HED) and capable of heating,

sampling, and analyzing the headspace vapors contained in 11.1 Connect carrier gas and detector gas cylinders to the

sealed vials.

chromatograph with the recommended filters and regulators as

required by the manufacturer.

NOTE 2—Automatic backflushing capability may be a desirable option

11.2 Es

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.