ASTM D3222-21

(Specification)Standard Specification for Unmodified Poly(Vinylidene Fluoride) (PVDF) Molding Extrusion and Coating Materials

Standard Specification for Unmodified Poly(Vinylidene Fluoride) (PVDF) Molding Extrusion and Coating Materials

ABSTRACT

This specification covers melt processable unmodified poly(vinylidene fluoride) (PVDF) molding, extrusion and coating materials. This specification covers only virgin homopolymer prepared from vinylidene fluoride supplied in form of pellet or powder and shall be free of foreign matter. Two types covered by this specification are type I PVDF fluoroplastics and type II PVDF fluoroplastics. Detailed requirements that shall conform to this specification include peak melting endotherm, specific gravity, refractive index, limiting oxygen index, flow rate, rheological properties, tensile properties, flexural properties, impact resistance, D-C resistance, dielectric strength, dielectric constant, and dissipation factor. Preparation of compression molded specimen shall be in accordance to this specification.

SCOPE

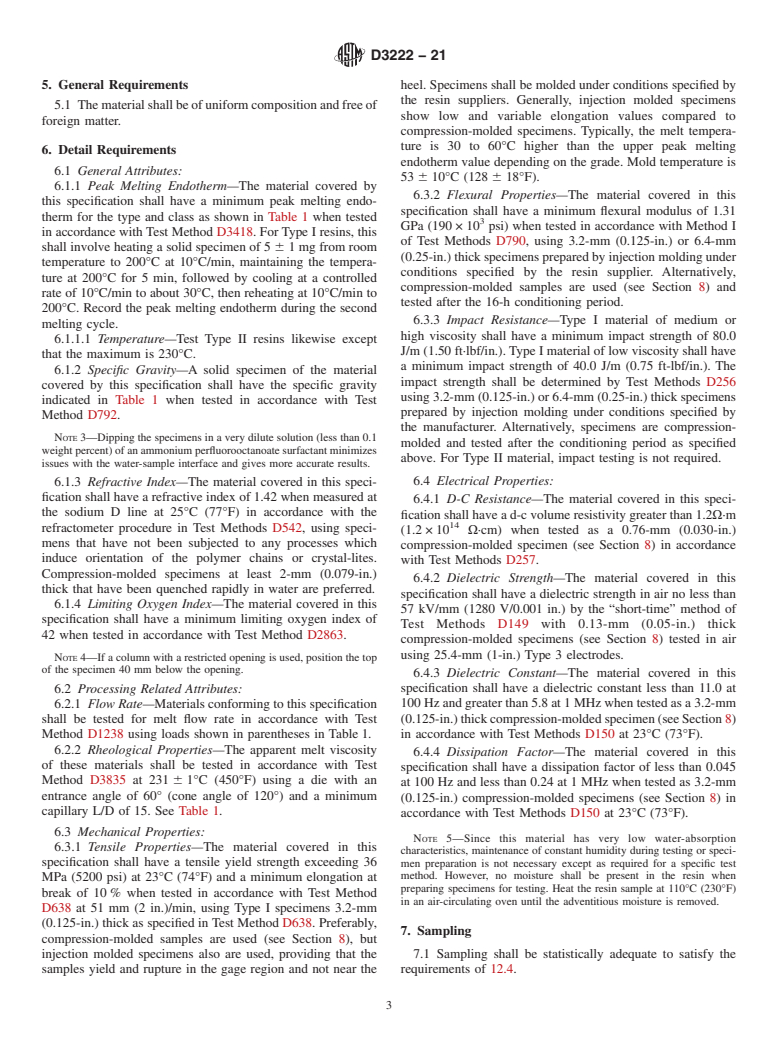

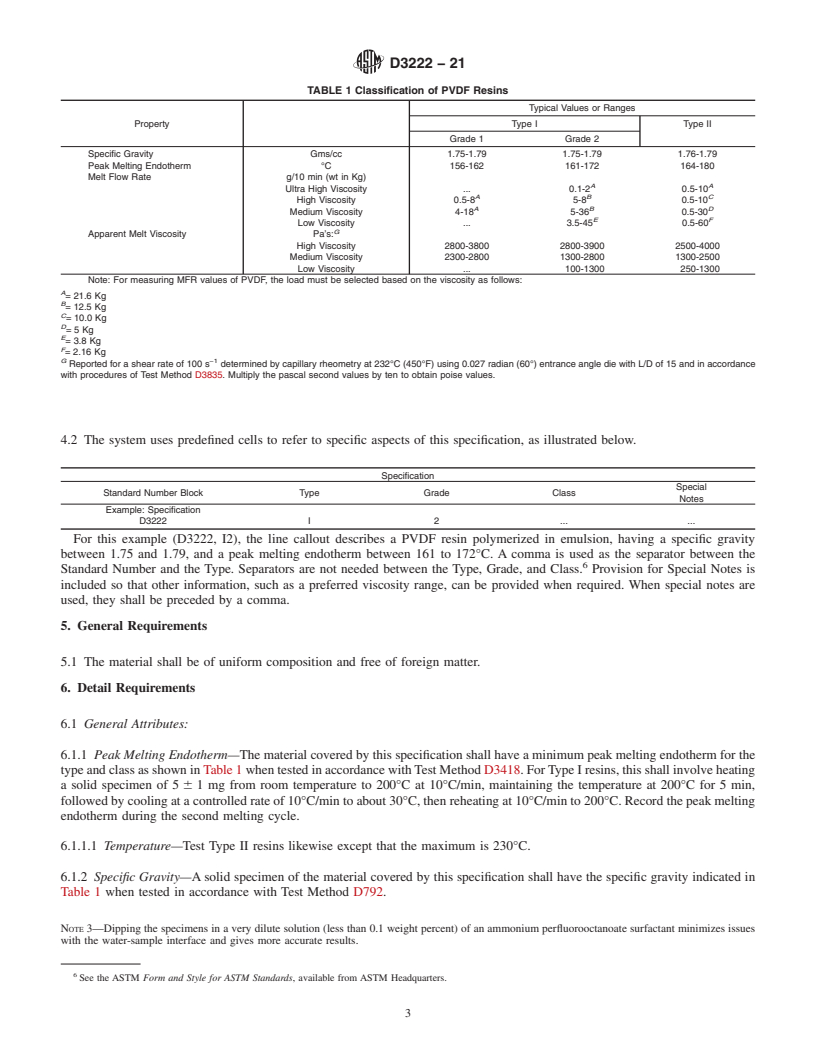

1.1 This specification covers melt processable molding and extrusion materials, as well as coating materials of poly(vinylidene fluoride) fluoroplastic, commonly abbreviated PVDF (or PVF2 in scientific literature). This specification covers thermoplastic resin materials supplied in pellet or powder form.

1.2 This specification applies only to the virgin homopolymer prepared from vinylidene fluoride, not copolymers, reinforced, filled grades or special grades with additives or treatments for modification of attributes.

1.3 The tests involved are intended to provide information for specification of unmodified PVDF homopolymer resins. It is not the purpose of this specification to provide engineering data for design purposes.

1.4 PVDF fluoroplastics melt between 156 and 180°C (312 and 356°F) and are thermally stable up to about 370°C (698°F). (Warning—Evolution of corrosive and toxic hydrogen fluoride can occur under certain conditions.)

1.5 The values stated in SI units, as detailed in IEEE/ASTM S-10, are to be regarded as the standard. The values given in parentheses are for information only.

Note 1: PVDF exhibits polymorphism.2 The type and extent of crystalline structure varies with the thermomechanical history of the sample. Specimens prepared by techniques different than prescribed in this specification can have properties that vary from the values specified.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 10.

Note 2: There is no equivalent ISO standard for this specification. Information in this specification is technically equivalent to related information in ISO 12086-1 and ISO 12086-2.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3222 −21

Standard Specification for

Unmodified Poly(Vinylidene Fluoride) (PVDF) Molding

1

Extrusion and Coating Materials

This standard is issued under the fixed designation D3222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

NOTE 2—There is no equivalent ISO standard for this specification.

1. Scope*

Information in this specification is technically equivalent to related

1.1 This specification covers melt processable molding and

information in ISO 12086-1 and ISO 12086-2.

extrusion materials, as well as coating materials of poly(vi-

1.7 This international standard was developed in accor-

nylidene fluoride) fluoroplastic, commonly abbreviated PVDF

dance with internationally recognized principles on standard-

(or PVF in scientific literature). This specification covers

2

ization established in the Decision on Principles for the

thermoplastic resin materials supplied in pellet or powder

Development of International Standards, Guides and Recom-

form.

mendations issued by the World Trade Organization Technical

1.2 This specification applies only to the virgin homopoly-

Barriers to Trade (TBT) Committee.

mer prepared from vinylidene fluoride, not copolymers,

reinforced, filled grades or special grades with additives or

2. Referenced Documents

treatments for modification of attributes. 3

2.1 ASTM Standards:

1.3 The tests involved are intended to provide information D149Test Method for Dielectric Breakdown Voltage and

for specification of unmodified PVDF homopolymer resins. It DielectricStrengthofSolidElectricalInsulatingMaterials

is not the purpose of this specification to provide engineering at Commercial Power Frequencies

data for design purposes. D150Test Methods forAC Loss Characteristics and Permit-

tivity (Dielectric Constant) of Solid Electrical Insulation

1.4 PVDF fluoroplastics melt between 156 and 180°C (312

D256Test Methods for Determining the Izod Pendulum

and356°F)andarethermallystableuptoabout370°C(698°F).

Impact Resistance of Plastics

(Warning—Evolution of corrosive and toxic hydrogen fluo-

D257Test Methods for DC Resistance or Conductance of

ride can occur under certain conditions.)

Insulating Materials

1.5 ThevaluesstatedinSIunits,asdetailedinIEEE/ASTM

D542Test Method for Index of Refraction of Transparent

S-10, are to be regarded as the standard. The values given in

Organic Plastics

parentheses are for information only.

D618Practice for Conditioning Plastics for Testing

2

D638Test Method for Tensile Properties of Plastics

NOTE 1—PVDF exhibits polymorphism. The type and extent of

crystalline structure varies with the thermomechanical history of the

D790Test Methods for Flexural Properties of Unreinforced

sample. Specimens prepared by techniques different than prescribed in

and Reinforced Plastics and Electrical Insulating Materi-

this specification can have properties that vary from the values specified.

als

1.6 This standard does not purport to address all of the

D792Test Methods for Density and Specific Gravity (Rela-

safety concerns, if any, associated with its use. It is the

tive Density) of Plastics by Displacement

responsibility of the user of this standard to establish appro-

D883Terminology Relating to Plastics

priate safety, health, and environmental practices and deter-

D1238Test Method for Melt Flow Rates of Thermoplastics

mine the applicability of regulatory limitations prior to use.

by Extrusion Plastometer

Specific precautionary statements are given in Section 10.

D2863Test Method for Measuring the Minimum Oxygen

Concentration to Support Candle-Like Combustion of

1

Plastics (Oxygen Index)

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Sept. 1, 2021. Published September 2021. Originally

3

approved in 1973. Last previous edition approved in 2020 as D3222-20. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D3222-21. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Lovinger, A. J., “Poly(Vinylidene Fluoride)” Developments in Crystalline Standards volume information, refer to the standard’s Document Summary page on

Polymers, Vol 1, Chapter 5, D. C. Bassett, Ed., Applied Science, London, 1982. the ASTM website.

*A Summary of Changes section appears

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3222 − 20 D3222 − 21

Standard Specification for

Unmodified Poly(Vinylidene Fluoride) (PVDF) Molding

1

Extrusion and Coating Materials

This standard is issued under the fixed designation D3222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers melt processable molding and extrusion materials, as well as coating materials of poly(vinylidene

fluoride) fluoroplastic, commonly abbreviated PVDF (or PVF in scientific literature). This specification covers thermoplastic resin

2

materials supplied in pellet or powder form.

1.2 This specification applies only to the virgin homopolymer prepared from vinylidene fluoride, not copolymers, reinforced, filled

grades or special grades with additives or treatments for modification of attributes.

1.3 The tests involved are intended to provide information for specification of unmodified PVDF homopolymer resins. It is not

the purpose of this specification to provide engineering data for design purposes.

1.4 PVDF fluoroplastics melt between 156 and 180°C (312 and 356°F) and are thermally stable up to about 370°C (698°F).

(Warning—Evolution of corrosive and toxic hydrogen fluoride can occur under certain conditions.)

1.5 The values stated in SI units, as detailed in IEEE/ASTM S-10, are to be regarded as the standard. The values given in

parentheses are for information only.

2

NOTE 1—PVDF exhibits polymorphism. The type and extent of crystalline structure varies with the thermomechanical history of the sample. Specimens

prepared by techniques different than prescribed in this specification can have properties that vary from the values specified.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific precautionary statements are given in Section 10.

NOTE 2—There is no equivalent ISO standard for this specification. Information in this specification is technically equivalent to related information in

ISO 12086-1 and ISO 12086-2.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Dec. 1, 2020Sept. 1, 2021. Published December 2020September 2021. Originally approved in 1973. Last previous edition approved in 20182020

as D3222 - 18a.D3222 - 20. DOI: 10.1520/D3222-20.10.1520/D3222-21.

2

Lovinger, A. J., “Poly(Vinylidene Fluoride)” Developments in Crystalline Polymers, Vol 1, Chapter 5, D. C. Bassett, Ed., Applied Science, London, 1982.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3222 − 21

2. Referenced Documents

3

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D256 Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D542 Test Method for Index of Refraction of Transparent Organic Plastics

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D1238 Test Method for Me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.