ASTM C1234-98

(Test Method)Standard Practice for Preparation of Oils and Oily Waste Samples by High-Pressure, High-Temperature Digestion for Trace Element Determinations

Standard Practice for Preparation of Oils and Oily Waste Samples by High-Pressure, High-Temperature Digestion for Trace Element Determinations

SCOPE

1.1 This test method describes a high-pressure, high-temperature digestion technique using the high-pressure asher (HPA) for preparation of oils and oily waste specimens for determination of up to 28 different elements by inductively coupled plasma-atomic emission plasma spectroscopy (ICP-AES), cold-vapor atomic absorption spectroscopy (CVAAS), and graphite furnace atomic absorption spectroscopy (GFAAS). Oily and high-percentage organic waste streams from nuclear and non-nuclear manufacturing processes can be successfully prepared for trace element determinations by ICP-AES, CVAAS, and GFAAS. This method is applicable to the determination of total trace elements in these mixed wastes. Specimens prepared by this method can be used to characterize organic mixed waste streams received by hazardous waste treatment incinerators and for total element characterization of the waste streams.

1.2 This test method is applicable only to organic waste streams that contain radioactivity levels that do not require special personnel or environmental protection from radioactivity or other acute hazards.

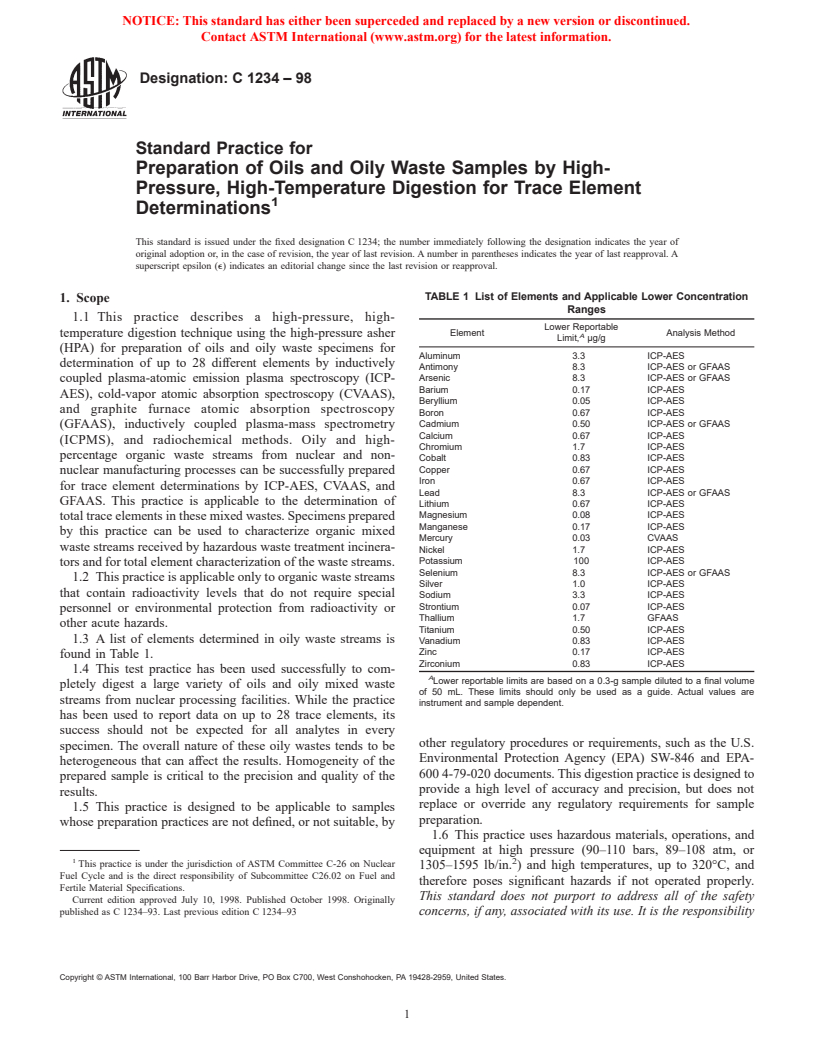

1.3 A list of elements determined in oily waste streams is found in Table 1.

1.4 This test method has been used successfully to completely digest a large variety of oils and oily mixed waste streams from nuclear processing facilities. While the method has been used to report data on up to 28 trace elements, its success should not be expected for all analytes in every specimen. The overall nature of these oily wastes tends to be heterogeneous that can affect the results. Homogeneity of the prepared sample is critical to the precision and quality of the results. Some elements, notably silver and antimony, may be recovered on a semi quantitative basis, while most results are highly quantitative.

1.5 This procedure is designed to be applicable to samples whose preparation methods are not defined, or not suitable, by other regulatory procedures or requirements, such as the U.S. Environmental Protection Agency (EPA) SW-846 and EPA-600 4-79-020 documents. This digestion method is designed to provide a high level of accuracy and precision, but does not replace or override any regulatory requirements for sample preparation.

1.6 This method uses hazardous materials, operations, and equipment at high pressure (90-110 bars, 89-108 atm, or 1305-1595 lb/in.2) and high temperatures, up to 320°C, and therefore poses significant hazards if not operated properly. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Sections 10 and 11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1234 – 98

Standard Practice for

Preparation of Oils and Oily Waste Samples by High-

Pressure, High-Temperature Digestion for Trace Element

Determinations

This standard is issued under the fixed designation C 1234; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 List of Elements and Applicable Lower Concentration

1. Scope

Ranges

1.1 This practice describes a high-pressure, high-

Lower Reportable

Element Analysis Method

temperature digestion technique using the high-pressure asher

A

Limit, μg/g

(HPA) for preparation of oils and oily waste specimens for

Aluminum 3.3 ICP-AES

determination of up to 28 different elements by inductively

Antimony 8.3 ICP-AES or GFAAS

coupled plasma-atomic emission plasma spectroscopy (ICP- Arsenic 8.3 ICP-AES or GFAAS

Barium 0.17 ICP-AES

AES), cold-vapor atomic absorption spectroscopy (CVAAS),

Beryllium 0.05 ICP-AES

and graphite furnace atomic absorption spectroscopy

Boron 0.67 ICP-AES

Cadmium 0.50 ICP-AES or GFAAS

(GFAAS), inductively coupled plasma-mass spectrometry

Calcium 0.67 ICP-AES

(ICPMS), and radiochemical methods. Oily and high-

Chromium 1.7 ICP-AES

percentage organic waste streams from nuclear and non-

Cobalt 0.83 ICP-AES

Copper 0.67 ICP-AES

nuclear manufacturing processes can be successfully prepared

Iron 0.67 ICP-AES

for trace element determinations by ICP-AES, CVAAS, and

Lead 8.3 ICP-AES or GFAAS

GFAAS. This practice is applicable to the determination of

Lithium 0.67 ICP-AES

Magnesium 0.08 ICP-AES

total trace elements in these mixed wastes. Specimens prepared

Manganese 0.17 ICP-AES

by this practice can be used to characterize organic mixed

Mercury 0.03 CVAAS

waste streams received by hazardous waste treatment incinera-

Nickel 1.7 ICP-AES

Potassium 100 ICP-AES

tors and for total element characterization of the waste streams.

Selenium 8.3 ICP-AES or GFAAS

1.2 This practice is applicable only to organic waste streams

Silver 1.0 ICP-AES

that contain radioactivity levels that do not require special

Sodium 3.3 ICP-AES

Strontium 0.07 ICP-AES

personnel or environmental protection from radioactivity or

Thallium 1.7 GFAAS

other acute hazards.

Titanium 0.50 ICP-AES

1.3 A list of elements determined in oily waste streams is

Vanadium 0.83 ICP-AES

Zinc 0.17 ICP-AES

found in Table 1.

Zirconium 0.83 ICP-AES

1.4 This test practice has been used successfully to com-

A

Lower reportable limits are based on a 0.3-g sample diluted to a final volume

pletely digest a large variety of oils and oily mixed waste

of 50 mL. These limits should only be used as a guide. Actual values are

streams from nuclear processing facilities. While the practice

instrument and sample dependent.

has been used to report data on up to 28 trace elements, its

success should not be expected for all analytes in every

other regulatory procedures or requirements, such as the U.S.

specimen. The overall nature of these oily wastes tends to be

Environmental Protection Agency (EPA) SW-846 and EPA-

heterogeneous that can affect the results. Homogeneity of the

600 4-79-020 documents. This digestion practice is designed to

prepared sample is critical to the precision and quality of the

provide a high level of accuracy and precision, but does not

results.

replace or override any regulatory requirements for sample

1.5 This practice is designed to be applicable to samples

preparation.

whose preparation practices are not defined, or not suitable, by

1.6 This practice uses hazardous materials, operations, and

equipment at high pressure (90–110 bars, 89–108 atm, or

1 2

This practice is under the jurisdiction of ASTM Committee C-26 on Nuclear

1305–1595 lb/in. ) and high temperatures, up to 320°C, and

Fuel Cycle and is the direct responsibility of Subcommittee C26.02 on Fuel and

therefore poses significant hazards if not operated properly.

Fertile Material Specifications.

This standard does not purport to address all of the safety

Current edition approved July 10, 1998. Published October 1998. Originally

published as C 1234–93. Last previous edition C 1234–93 concerns, if any, associated with its use. It is the responsibility

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1234

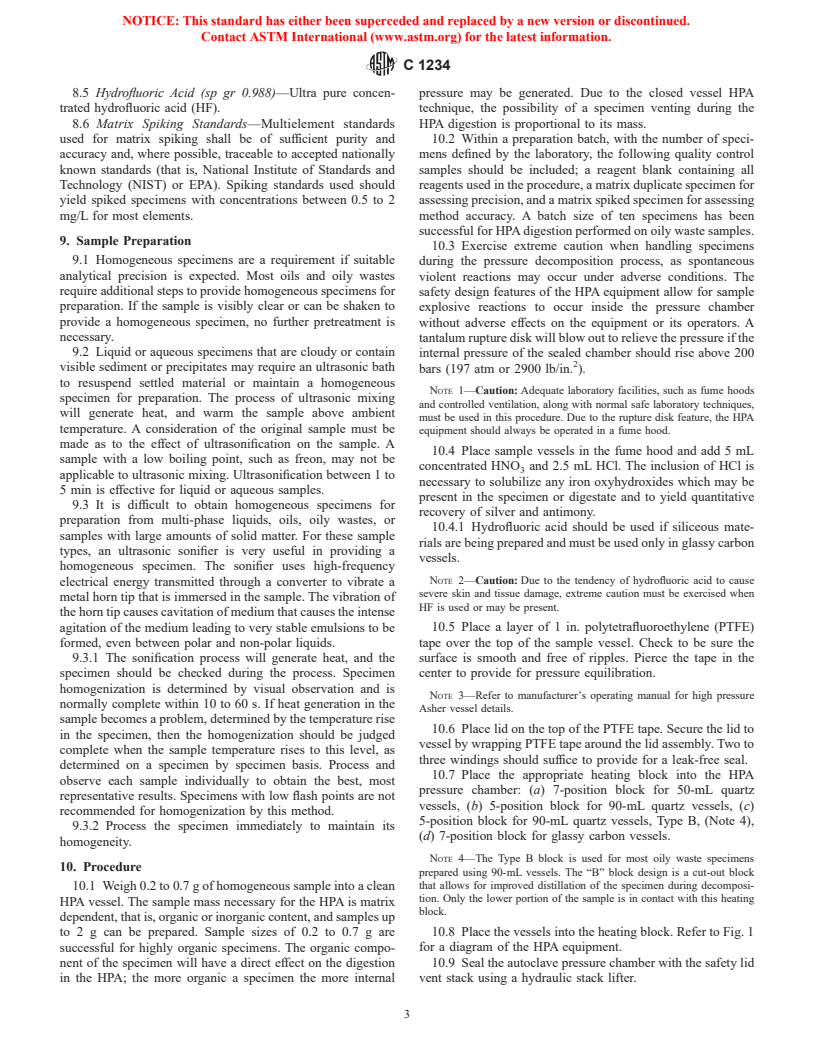

TABLE 2 HPA Temperature Program for Oils and Oily Waste

absorption or plasma emission techniques. Specimen prepara-

Samples

tion by high-pressure ashing is primarily applicable to speci-

Starting Ending

mens whose preparation by EPA SW-846 protocols is either not

Phase Time, min

Temperature,°C Temperature,°C

applicable or not defined. This sample preparation practice is

1 100 30 125

applicable for the trace element characterization of mixed oily

2 125 60 300

wastes for use by waste treatment facilities such as incinerators

3 300 60 300

425 30 25 or waste stabilization facilities.

50 0 0

6. Interferences

of the user of this standard to establish appropriate safety and

6.1 Preparation of samples for trace element determinations

health practices and determine the applicability of regulatory

is subject to matrix and chemical interferences. Although the

limitations prior to use. Specific hazard statements are given in

HPA practice is designed to totally digest most matrices, there

Sections 10 and 11.

are some matrix types that are not applicable to this practice,

for example, highly reactive substances (explosives), ex-

2. Referenced Documents

tremely flammable materials, and some silicone-based lubri-

2.1 ASTM Standards:

cants.

D 1193 Specification for Reagent Water

E 177 Practice for Use of the Terms Precision and Bias in

7. Apparatus

ASTM Test Methods

7.1 HPA High Pressure Asher —High-pressure, high-

2.2 US EPA Standards:

temperature autoclave under computer control allowing com-

Methods for Chemical Analysis of Water and Wastes,

plete digestion of difficult specimens using mineral acids. The

600/4-79-020, 1983

system includes:

Test Methods for Evaluating Solid Waste, SW-846, 3rd Ed.,

7.1.1 Compatible computer with hard drive and with one

open RS-232C serial interface.

3. Terminology

7.1.2 HPA-TC temperature controller—this device provides

the interface between the HPA autoclave and the computer by

3.1 Definitions:

3.1.1 heating block—aluminum block used to hold samples means of RS-232C serial interface.

7.1.3 HPA autoclave unit.

inside the HPA autoclave/pressure chamber.

3.1.2 HPA-TC controller—computer interface between HPA 7.1.4 HPA sample vessels, appropriate size and construction

for specimen type and mineral acid used.

autoclave and an IBM-compatible computer.

3.1.3 pressure chamber—chamber within the HPA auto- 7.2 Ultrasonic Homogenizer—Specimen homogenizer us-

ing ultrasonic disruption tip to homogenize specimens that

clave where heating block filled with samples is placed. The

cannot be mixed by hand.

chamber is designed to hold pressures up to 200 bar (197 atm

or 2900 lb/in. ) and temperatures up to 320°C.

8. Reagents and Materials

3.1.4 safety lid vent stack—top plate and cylinder that

covers the autoclave pressure chamber.

8.1 Purity of Reagents—Chemicals used in the preparation

3.1.5 sample vessel—sample container, constructed of

of spiking standards must be of ultra purity grade. Chemicals

quartz or glassy carbon, designed for use in the HPA.

and reagents used in the preparation practice must conform to

3.1.6 temperature program—software program which con-

the specifications of the Committee on Analytical Reagents of

trols the temperature ramping of the HPA during the run. The

the American Chemical Society, where such specifications are

program used for preparation of oil samples is shown in Table

available. Other grades may be used, provided it is first

2.

ascertained that the reagent is of sufficient purity to permit its

use without lessening the accuracy of the determination.

4. Summary of the Practice

8.2 Reagent Water—References to water shall be under-

4.1 Oil or oily waste specimens are digested in nitric and

stood to mean reagent water as defined by Type 1 of Specifi-

hydrochloric acids using HPA high-pressure, high-temperature

cation D 1193.

equipment. Prepared specimens of 0.2 to 0.7 g will provide

8.3 Nitric Acid (sp gr 1.42)—Ultra pure concentrated nitric

enough solution for analysis by CVAAS, ICP-AES, and

acid (HNO ).

GFAAS for up to 28 elements.

8.4 Hydrochloric Acid (sp gr 1.19)—Ultra pure concen-

trated hydrochloric acid (HCl).

5. Significance and Use

5.1 This practice is useful for preparation of difficult-to-

digest, primarily oils and oily wastes, specimens for trace

element determinations of up to 28 elements by atomic High-pressure ashing equipment manufactured by Anton Paar K. G., Graz,

Austria has been found to be satisfactory for this procedure.

“Reagent Chemicals, American Chemical Society Specifications,” Am. Chemi-

Annual Book of ASTM Standards, Vol 11.01. cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

Annual Book of ASTM Standards, Vol 14.02. the American Chemical Society, see “Reagent Chemicals and Standards,” by Joseph

Available from Superintendent of Documents, U.S. Government Printing Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

Office, Washington, DC 20402. Pharmacopeia.”

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1234

8.5 Hydrofluoric Acid (sp gr 0.988)—Ultra pure concen- pressure may be generated. Due to the closed vessel HPA

trated hydrofluoric acid (HF). technique, the possibility of a specimen venting during the

8.6 Matrix Spiking Standards—Multielement standards HPA digestion is proportional to its mass.

used for matrix spiking shall be of sufficient purity and 10.2 Within a preparation batch, with the number of speci-

accuracy and, where possible, traceable to accepted nationally mens defined by the laboratory, the following qu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.