ASTM G84-89(2005)

(Practice)Standard Practice for Measurement of Time-of-Wetness on Surfaces Exposed to Wetting Conditions as in Atmospheric Corrosion Testing

Standard Practice for Measurement of Time-of-Wetness on Surfaces Exposed to Wetting Conditions as in Atmospheric Corrosion Testing

SCOPE

1.1 This practice covers a technique for monitoring time-of-wetness (TOW) on surfaces exposed to cyclic atmospheric conditions which produce depositions of moisture.

1.2 The practice is also applicable for detecting and monitoring condensation within a wall or roof assembly and in test apparatus.

1.3 Exposure site calibration or characterization can be significantly enhanced if TOW is measured for comparison with other sites, particularly if this data is used in conjunction with other site-specific instrumentation techniques.

1.4 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

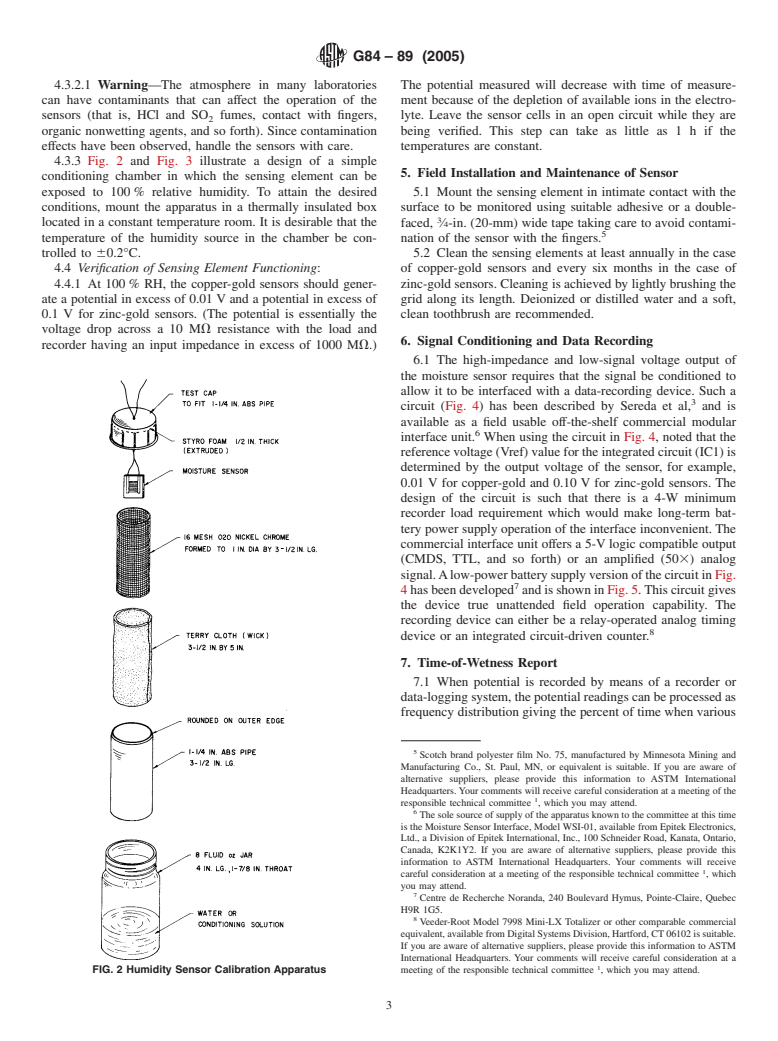

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G84–89(Reapproved2005)

Standard Practice for

Measurement of Time-of-Wetness on Surfaces Exposed to

1

Wetting Conditions as in Atmospheric Corrosion Testing

ThisstandardisissuedunderthefixeddesignationG84;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope moisture is present on the sensing element during any given

period. The fact that a potential is generated is critical to this

1.1 This practice covers a technique for monitoring time-

technique.As pertains to this practice, the absolute value of the

of-wetness (TOW) on surfaces exposed to cyclic atmospheric

potential generated is essentially of academic interest.

conditions which produce depositions of moisture.

2.2 This practice describes the moisture-sensing element,

1.2 The practice is also applicable for detecting and moni-

procedures for conditioning the elements to develop stable

toring condensation within a wall or roof assembly and in test

films on the electrodes and verifying the sensing-element

apparatus.

function, and use of the element to record TOW.

1.3 Exposure site calibration or characterization can be

significantly enhanced if TOW is measured for comparison

3. Significance and Use

with other sites, particularly if this data is used in conjunction

3.1 This practice provides a methodology for measuring the

with other site-specific instrumentation techniques.

duration of wetness on a sensing element mounted on a surface

1.4 The values stated in SI units are to be regarded as the

in a location of interest. Experience has shown that the sensing

standard.

elementreactstofactorsthatcausewetnessinthesamemanner

1.5 This standard does not purport to address all of the

as the surface on which it is mounted.

safety concerns, if any, associated with its use. It is the

3.2 Surface moisture plays a critical role in the corrosion of

responsibility of the user of this standard to establish appro-

metals and the deterioration of nonmetallics. The deposition of

priate safety and health practices and determine the applica-

moistureonasurfacecanbecausedbyatmosphericorclimatic

bility of regulatory limitations prior to use.

phenomena such as direct precipitation of rain or snow,

2. Summary of Practice condensation, the deliquescence (or at least the hygroscopic

nature) of corrosion products or salt deposits on the surface,

2.1 This practice describes a technique for detecting and

and others. A measure of atmospheric or climatic factors

recording surface moisture conditions. The moisture serves as

responsible for moisture deposition does not necessarily give

an electrolyte to generate a potential in a moisture sensing

an accurate indication of the TOW. For example, the surface

element galvanic cell that consists of alternate electrodes of

temperature of an object may be above or below both the

copper and gold, silver and platinum, or zinc and gold. The

ambient and the dew point temperatures. As a result conden-

spacing of the electrodes may be 100 to 200 µm, the width

sation will occur without an ambient meteorological indication

dimension is not considered critical (Fig. 1). However, when

that a surface has been subjected to a condensation cycle.

zinc is used as an electrode material, the effects of the

3.3 Structural design factors and orientation can be respon-

hygroscopic nature of the corrosion products on the perfor-

sible for temperature differences and the consequent effect on

mance of the sensor should be kept in mind. Also, the use of

TOW as discussed in 4.2. As a result, some surfaces may be

copper as a sensor material should be avoided in sulfur

shielded from rain or snow fall; drainage may be facilitated or

dioxide-laden atmospheres to avoid premature deterioration of

prevented from given areas, and so forth. Therefore various

the sensor’s copper substrate. The output (potential) from this

components of a structure can be expected to perform differ-

cell is fed through a signal conditioning circuit to an indicating

ently depending on mass, orientation, air flow patterns, and so

or recording device. The objective is to record the time that

forth. A knowledge of TOW at different points on large

structures can be useful in the interpretation of corrosion or

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

other testing results.

of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

3.4 In order to improve comparison of data obtained from

Corrosion.

test locations separated on a macrogeographical basis, a

Current edition approved May 1, 2005. Published May 2005. Originally

´1

approved in 1981.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.