ASTM D1094-07(2019)

(Test Method)Standard Test Method for Water Reaction of Aviation Fuels

Standard Test Method for Water Reaction of Aviation Fuels

SIGNIFICANCE AND USE

5.1 When applied to aviation gasoline, water reaction volume change using the technique reveals the presence of water-soluble components such as alcohols. When applied to aviation turbine fuels, water reaction interface rating using the technique is not reliable in revealing the presence of surfactants which disarm filter-separators quickly and allow free water and particulates to pass; but can reveal the presence of other types of contaminants. Other tests, such as Test Method D3948, are capable of detecting surfactants in aviation fuels.

SCOPE

1.1 This test method covers the determination of the presence of water-miscible components in aviation gasoline and turbine fuels, and the effect of these components on volume change and on the fuel-water interface.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. This standard involves the use of hazardous chemicals identified in Section 7. Before using this standard, refer to suppliers' safety labels, Material Safety Data Sheets and other technical literature.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1094 − 07 (Reapproved 2019)

Standard Test Method for

Water Reaction of Aviation Fuels

This standard is issued under the fixed designation D1094; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 Energy Institute Standard:

IP Standard Test Methods Vol 2, Appendix B, Specification

1.1 This test method covers the determination of the pres-

for Petroleum Spirits

ence of water-miscible components in aviation gasoline and

turbine fuels, and the effect of these components on volume

3. Terminology

change and on the fuel-water interface.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as

3.1.1 film, n—thin, translucent layer that does not adhere to

standard. The values given in parentheses after SI units are

the wall of the glass cylinder.

provided for information only and are not considered standard.

3.1.2 lace, n—fibers thicker than hairlike shred or of which

1.3 This standard does not purport to address all of the

more than 10 % are interlocking, or both.

safety concerns, if any, associated with its use. It is the

3.1.3 loose lace or slight scum, or both (Table 2, Rating 3),

responsibility of the user of this standard to establish appro-

n—an assessment that the fuel/buffer solution interface is

priate safety, health, and environmental practices and deter-

covered with more than 10 % but less than 50 % of lace or

mine the applicability of regulatory limitations prior to use.

scum that does not extend into either of the two layers.

This standard involves the use of hazardous chemicals identi-

fied in Section 7. Before using this standard, refer to suppliers’ 3.1.4 scum, n—layer thicker than film or that adheres to the

safety labels, Material Safety Data Sheets and other technical wall of the glass cylinder, or both.

literature.

3.1.5 shred, n—hairlike fibers of which less than 10 % are

interlocking.

2. Referenced Documents

3.1.6 shred, lace or film at interface (Table 2, Rating 2),

2.1 ASTM Standards:

n—an assessment that fuel/buffer solution interface contains

D381 Test Method for Gum Content in Fuels by Jet Evapo-

more than 50 % clear bubbles or some but less than 10 %

ration

shred, lace, film or both.

D611 Test Methods for Aniline Point and Mixed Aniline

3.1.7 tight lace or heavy scum, or both (Table 2, Rating 4),

Point of Petroleum Products and Hydrocarbon Solvents

n—an assessment that the fuel/buffer solution interface is

D1836 Specification for Commercial Hexanes

covered with more than 50 % of lace or scum, or both, that

D2699 Test Method for Research Octane Number of Spark-

extends into either of the two layers or forms an emulsion, or

Ignition Engine Fuel

both.

D2700 Test Method for Motor Octane Number of Spark-

3.1.8 water reaction interface conditions rating, n—a quali-

Ignition Engine Fuel

tative assessment of the tendency of a mixture of water and

D3948 TestMethodforDeterminingWaterSeparationChar-

aviation turbine fuel to form interface films or precipitates.

acteristicsofAviationTurbineFuelsbyPortableSeparom-

eter

3.1.9 water reaction separation rating, n—a qualitative

assessment of the tendency of insufficiently cleaned glassware

to produce emulsions or precipitates, or both, in separated fuel

This test method is under the jurisdiction of ASTM Committee D02 on

and water layers.

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.J0.05 on Fuel Cleanliness. 3.1.10 water reaction volume change, n—a qualitative indi-

Current edition approved Feb. 1, 2019. Published February 2019. Originally

cation of the presence in aviation gasoline of water-soluble

approved in 1950. Last previous edition approved in 2013 as D1094 – 07 (2013).

components.

DOI: 10.1520/D1094-07R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1094 − 07 (2019)

4. Summary of Test Method (KH PO ) in 100 mL of water. Larger volumes of the phos-

2 4

phate buffer solution may be prepared provided the concentra-

4.1 A sample of the fuel is shaken, using a standardized

tion of K HPO and KH PO in the water solution is

2 4 2 4

technique, at room temperature with a phosphate buffer solu-

equivalent to that described above. As an alternative, the

tion in scrupulously cleaned glassware. The cleanliness of the

laboratory may use a commercially prepared solution.

glass cylinder is tested. The change in volume of the aqueous

layer and the appearance of the interface are taken as the water

8. Preparation of Apparatus

reaction of the fuel.

8.1 Clean the graduated cylinder thoroughly before carrying

5. Significance and Use out this test. Only cylinders that are adequately cleaned can be

used.

5.1 When applied to aviation gasoline, water reaction vol-

8.1.1 Remove traces of oil from the graduated cylinder and

ume change using the technique reveals the presence of

stopper by flushing with hot tap water, brushing if necessary.

water-soluble components such as alcohols. When applied to

Alternatively, remove all traces of oil from the graduated

aviation turbine fuels, water reaction interface rating using the

cylinder and stopper, using either n-hexane or n-heptane or the

techniqueisnotreliableinrevealingthepresenceofsurfactants

IPpetroleumsolvent60/80.Rinsewithacetonefollowedbytap

whichdisarmfilter-separatorsquicklyandallowfreewaterand

water.

particulates to pass; but can reveal the presence of other types

8.1.2 Followingthewashingdescribedin8.1.1,immersethe

of contaminants. Other tests, such as Test Method D3948, are

cylinder and stopper in either (1) a non-ionic detergent clean-

capable of detecting surfactants in aviation fuels.

ing solution, or (2) glass cleaning solution described in 7.4.

The type of non-ionic detergent and conditions for its use need

6. Apparatus

to be established in each laboratory. The criterion for satisfac-

6.1 Graduated Glass Cylinder, glass-stoppered, 100 mL,

torycleaningshallbeamatchingofthequalityofthatobtained

with1 mLgraduations.Thedistancebetweenthe100 mLmark

with chromic acid cleaning solution. Non-ionic detergent

and the top of the shoulder of the cylinder must be within the

cleaning avoids the potential hazards and inconveniences

range from 50 mm to 60 mm.

related to handling corrosive chromic acid solutions. The latter

remains as the ref

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1094 − 07 (Reapproved 2019)

Standard Test Method for

Water Reaction of Aviation Fuels

This standard is issued under the fixed designation D1094; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 Energy Institute Standard:

IP Standard Test Methods Vol 2, Appendix B, Specification

1.1 This test method covers the determination of the pres-

for Petroleum Spirits

ence of water-miscible components in aviation gasoline and

turbine fuels, and the effect of these components on volume

3. Terminology

change and on the fuel-water interface.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as

3.1.1 film, n—thin, translucent layer that does not adhere to

standard. The values given in parentheses after SI units are

the wall of the glass cylinder.

provided for information only and are not considered standard.

3.1.2 lace, n—fibers thicker than hairlike shred or of which

1.3 This standard does not purport to address all of the

more than 10 % are interlocking, or both.

safety concerns, if any, associated with its use. It is the

3.1.3 loose lace or slight scum, or both (Table 2, Rating 3),

responsibility of the user of this standard to establish appro-

n—an assessment that the fuel/buffer solution interface is

priate safety, health, and environmental practices and deter-

covered with more than 10 % but less than 50 % of lace or

mine the applicability of regulatory limitations prior to use.

scum that does not extend into either of the two layers.

This standard involves the use of hazardous chemicals identi-

fied in Section 7. Before using this standard, refer to suppliers’ 3.1.4 scum, n—layer thicker than film or that adheres to the

wall of the glass cylinder, or both.

safety labels, Material Safety Data Sheets and other technical

literature.

3.1.5 shred, n—hairlike fibers of which less than 10 % are

interlocking.

2. Referenced Documents

3.1.6 shred, lace or film at interface (Table 2, Rating 2),

2.1 ASTM Standards:

n—an assessment that fuel/buffer solution interface contains

D381 Test Method for Gum Content in Fuels by Jet Evapo-

more than 50 % clear bubbles or some but less than 10 %

ration

shred, lace, film or both.

D611 Test Methods for Aniline Point and Mixed Aniline

3.1.7 tight lace or heavy scum, or both (Table 2, Rating 4),

Point of Petroleum Products and Hydrocarbon Solvents

n—an assessment that the fuel/buffer solution interface is

D1836 Specification for Commercial Hexanes

covered with more than 50 % of lace or scum, or both, that

D2699 Test Method for Research Octane Number of Spark-

extends into either of the two layers or forms an emulsion, or

Ignition Engine Fuel

both.

D2700 Test Method for Motor Octane Number of Spark-

3.1.8 water reaction interface conditions rating, n—a quali-

Ignition Engine Fuel

tative assessment of the tendency of a mixture of water and

D3948 Test Method for Determining Water Separation Char-

aviation turbine fuel to form interface films or precipitates.

acteristics of Aviation Turbine Fuels by Portable Separom-

eter

3.1.9 water reaction separation rating, n—a qualitative

assessment of the tendency of insufficiently cleaned glassware

to produce emulsions or precipitates, or both, in separated fuel

This test method is under the jurisdiction of ASTM Committee D02 on

and water layers.

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

3.1.10 water reaction volume change, n—a qualitative indi-

Subcommittee D02.J0.05 on Fuel Cleanliness.

Current edition approved Feb. 1, 2019. Published February 2019. Originally

cation of the presence in aviation gasoline of water-soluble

approved in 1950. Last previous edition approved in 2013 as D1094 – 07 (2013).

components.

DOI: 10.1520/D1094-07R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1094 − 07 (2019)

4. Summary of Test Method (KH PO ) in 100 mL of water. Larger volumes of the phos-

2 4

phate buffer solution may be prepared provided the concentra-

4.1 A sample of the fuel is shaken, using a standardized

tion of K HPO and KH PO in the water solution is

2 4 2 4

technique, at room temperature with a phosphate buffer solu-

equivalent to that described above. As an alternative, the

tion in scrupulously cleaned glassware. The cleanliness of the

laboratory may use a commercially prepared solution.

glass cylinder is tested. The change in volume of the aqueous

layer and the appearance of the interface are taken as the water

8. Preparation of Apparatus

reaction of the fuel.

8.1 Clean the graduated cylinder thoroughly before carrying

out this test. Only cylinders that are adequately cleaned can be

5. Significance and Use

used.

5.1 When applied to aviation gasoline, water reaction vol-

8.1.1 Remove traces of oil from the graduated cylinder and

ume change using the technique reveals the presence of

stopper by flushing with hot tap water, brushing if necessary.

water-soluble components such as alcohols. When applied to

Alternatively, remove all traces of oil from the graduated

aviation turbine fuels, water reaction interface rating using the

cylinder and stopper, using either n-hexane or n-heptane or the

technique is not reliable in revealing the presence of surfactants

IP petroleum solvent 60/80. Rinse with acetone followed by tap

which disarm filter-separators quickly and allow free water and

water.

particulates to pass; but can reveal the presence of other types

8.1.2 Following the washing described in 8.1.1, immerse the

of contaminants. Other tests, such as Test Method D3948, are

cylinder and stopper in either (1) a non-ionic detergent clean-

capable of detecting surfactants in aviation fuels.

ing solution, or (2) glass cleaning solution described in 7.4.

The type of non-ionic detergent and conditions for its use need

6. Apparatus

to be established in each laboratory. The criterion for satisfac-

6.1 Graduated Glass Cylinder, glass-stoppered, 100 mL,

tory cleaning shall be a matching of the quality of that obtained

with 1 mL graduations. The distance between the 100 mL mark

with chromic acid cleaning solution. Non-ionic detergent

and the top of the shoulder of the cylinder must be within the

cleaning avoids the potential hazards and inconveniences

range from 50 mm to 60 mm.

related to handling corrosive chromic acid solutions. The latter

remains as the reference cleaning practice and as such may

7. Reagents

function as a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1094 − 07 (Reapproved 2013) D1094 − 07 (Reapproved 2019)An American National Standard

Standard Test Method for

Water Reaction of Aviation Fuels

This standard is issued under the fixed designation D1094; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the presence of water-miscible components in aviation gasoline and turbine

fuels, and the effect of these components on volume change and on the fuel-water interface.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this The values

given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. This standard involves the use of hazardous chemicals identified in Section 7.

Before using this standard, refer to suppliers’ safety labels, Material Safety Data Sheets and other technical literature.

2. Referenced Documents

2.1 ASTM Standards:

D381 Test Method for Gum Content in Fuels by Jet Evaporation

D611 Test Methods for Aniline Point and Mixed Aniline Point of Petroleum Products and Hydrocarbon Solvents

D1836 Specification for Commercial Hexanes

D2699 Test Method for Research Octane Number of Spark-Ignition Engine Fuel

D2700 Test Method for Motor Octane Number of Spark-Ignition Engine Fuel

D3948 Test Method for Determining Water Separation Characteristics of Aviation Turbine Fuels by Portable Separometer

2.2 Energy Institute Standard:

IP Standard Test Methods Vol 2, Appendix B, Specification for Petroleum Spirits

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 film, n—thin, translucent layer that does not adhere to the wall of the glass cylinder.

3.1.2 lace, n—fibers thicker than hairlike shred or of which more than 10 % are interlocking, or both.

3.1.3 loose lace or slight scum, or both (Table 2, Rating 3), n—an assessment that the fuel/buffer solution interface is covered

with more than 10 % but less than 50 % of lace or scum that does not extend into either of the two layers.

3.1.4 scum, n—layer thicker than film or that adheres to the wall of the glass cylinder, or both.

3.1.5 shred, n—hairlike fibers of which less than 10 % are interlocking.

3.1.6 shred, lace or film at interface (Table 2, Rating 2), n—an assessment that fuel/buffer solution interface contains more than

50 % clear bubbles or some but less than 10 % shred, lace, film or both.

3.1.7 tight lace or heavy scum, or both (Table 2, Rating 4), n—an assessment that the fuel/buffer solution interface is covered

with more than 50 % of lace or scum, or both, that extends into either of the two layers or forms an emulsion, or both.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.J0.05 on Fuel Cleanliness.

Current edition approved May 1, 2013Feb. 1, 2019. Published August 2013February 2019. Originally approved in 1950. Last previous edition approved in 20072013 as

D1094D1094 – 07 (2013).–07. DOI: 10.1520/D1094-07R13.10.1520/D1094-07R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1094 − 07 (2019)

3.1.8 water reaction interface conditions rating, n—a qualitative assessment of the tendency of a mixture of water and aviation

turbine fuel to form interface films or precipitates.

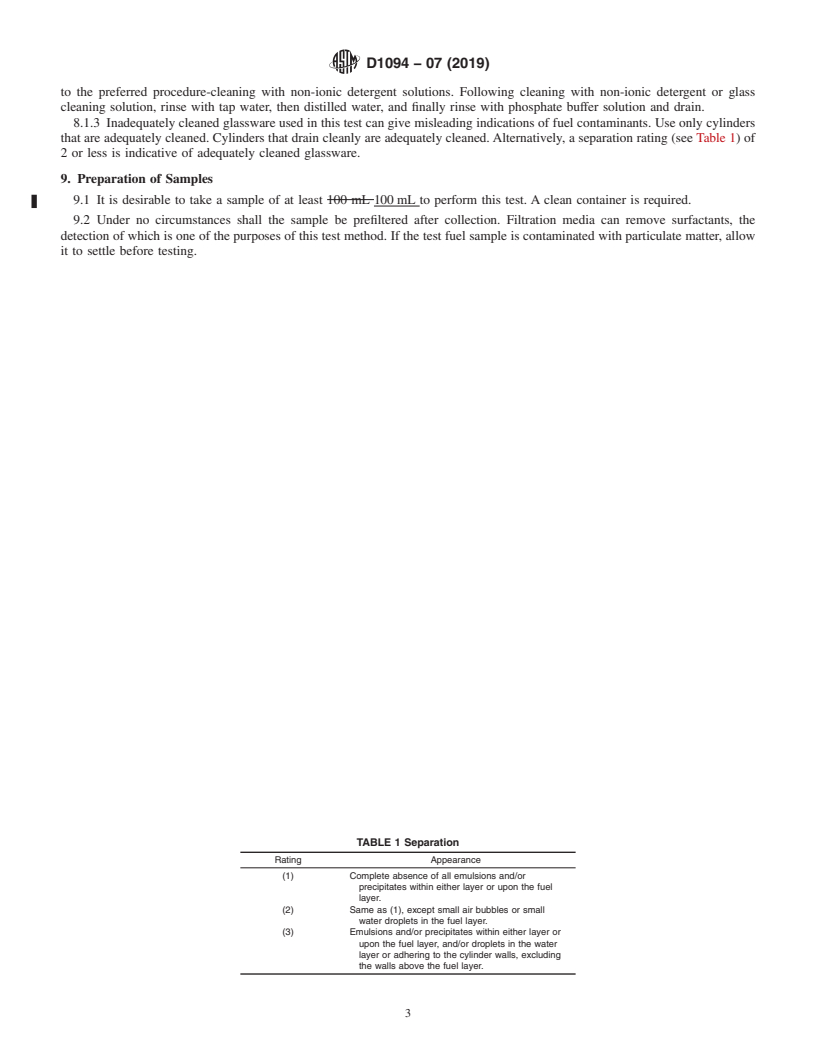

3.1.9 water reaction separation rating, n—a qualitative assessment of the tendency of insufficiently cleaned glassware to

produce emulsions or precipitates, or both, in separated fuel and water layers.

3.1.10 water reaction volume change, n—a qualitative indication of the presence in aviation gasoline of water-soluble

components.

4. Summary of Test Method

4.1 A sample of the fuel is shaken, using a standardized technique, at room temperature with a phosphate buffer solution in

scrupulously cleaned glassware. The cleanliness of the glass cylinder is tested. The change in volume of the aqueous layer and the

appearance of the interface are taken as the water reaction of the fuel.

5. Significance and Use

5.1 When applied to aviation gasoline, water reaction volume change using the technique reveals the presence of

water–solublewater-soluble components such as alcohols. When applied to aviation turbine fuels, water reaction interface rating

using the technique is not reliable in revealing the presence of surfactants which disarm filter-separators quickly and allow free

water and particulates to pass; but can reveal the presence of other types of contaminants. Other tests, such as Test Method D3948,

are capable of detecting surfactants in aviation fuels.

6. Apparatus

6.1 Graduated Glass Cylinder, glass-stoppered, 100 mL, 100 mL, with 1-mL1 mL graduations. The distance between the

100-mL100 mL mark and the top of the shoulder of the cylinder must be within the range from 5050 mm to 60 mm.60 mm.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficient purity

to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water—Unless otherwise indicated, reference to water shall be understood to mean distilled water, or water of

equivalent purity.

7.3 Acetone—(Warning—WarningFlammable.—Flammable. Health hazard.)

7.4 Glass-Cleaning Solution—Saturate concentrated sulfuric acid (H SO , sp gr 1.84) with potassium dichromate (K Cr O ) or

2 4 2 2 7

sodium dichromate (Na Cr O ). (Warning—WarningCorrosive.—Corrosive. Health hazard. Oxidizing agent.)

2 2 7

7.5 n-Hexane—Conforming to Specification D1836 or n-heptane conforming to material used in Test Methods D611, D381,

D2699, and D2700 or petroleum spirit 60/80 conforming to IP Appendix B Specification, or equivalent. (Warning—

WarningFlammable.—Flammable. Health hazard.)

7.6 Phosphate Buffer Solution (pH 7)—Dissolve 1.15 g 1.15 g of potassium monohydrogen phosphate, anhydrous (K HPO )

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.