ASTM G142-98(2016)

(Test Method)Standard Test Method for Determination of Susceptibility of Metals to Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or Both

Standard Test Method for Determination of Susceptibility of Metals to Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or Both

SIGNIFICANCE AND USE

5.1 This test method provides a reliable prediction of the resistance or susceptibility, or both, to loss of material strength and ductility as a result of exposure to hydrogen-containing gaseous environments. This test method is applicable over a broad range of pressures, temperatures, and gaseous environments. The results from this test method can be used to evaluate the effects of material composition, processing, and heat treatment as well as the effects of changes in environment composition, temperature, and pressure. These results may or may not correlate with service experience for particular applications. Furthermore, this test method may not be suitable for the evaluation of high temperature hydrogen attack in steels unless suitable exposure time at the test conditions has taken place prior to the initiation of tensile testing to allow for the development of internal blistering, decarburization or cracking, or both.

SCOPE

1.1 This test method covers a procedure for determination of tensile properties of metals in high pressure or high temperature, or both, gaseous hydrogen-containing environments. It includes accommodations for the testing of either smooth or notched specimens.

1.2 This test method applies to all materials and product forms including, but not restricted to, wrought and cast materials.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G142 − 98 (Reapproved 2016)

Standard Test Method for

Determination of Susceptibility of Metals to Embrittlement in

Hydrogen Containing Environments at High Pressure, High

1

Temperature, or Both

This standard is issued under the fixed designation G142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G129 Practice for Slow Strain Rate Testing to Evaluate the

Susceptibility of Metallic Materials to Environmentally

1.1 This test method covers a procedure for determination

Assisted Cracking

of tensile properties of metals in high pressure or high

4

2.2 Military Standard:

temperature, or both, gaseous hydrogen-containing environ-

MIL-P-27201B Propellant, Hydrogen

ments. It includes accommodations for the testing of either

smooth or notched specimens.

3. Terminology

1.2 This test method applies to all materials and product

3.1 Definitions:

forms including, but not restricted to, wrought and cast

3.1.1 control test, n—a mechanical test conducted in an

materials.

environment that does not produce embrittlement of a test

1.3 The values stated in SI units are to be regarded as

material.

standard. The values given in parentheses are for information

3.1.2 hydrogen embrittlement, n—hydrogen induced crack-

only.

ing or severe loss of ductility caused by the presence of

1.4 This standard does not purport to address all of the

hydrogen in the metal.

safety concerns, if any, associated with its use. It is the

3.1.3 Other definitions and terminology related to testing

responsibility of the user of this standard to establish appro-

can be found in Terminology G15.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 Specimens of selected materials are exposed to a gas-

2

2.1 ASTM Standards: eoushydrogencontainingenvironmentathighpressureorhigh

temperature, or both, while being pulled to failure in uniaxial

D1193 Specification for Reagent Water

E4 Practices for Force Verification of Testing Machines tension. The susceptibility to hydrogen embrittlement is evalu-

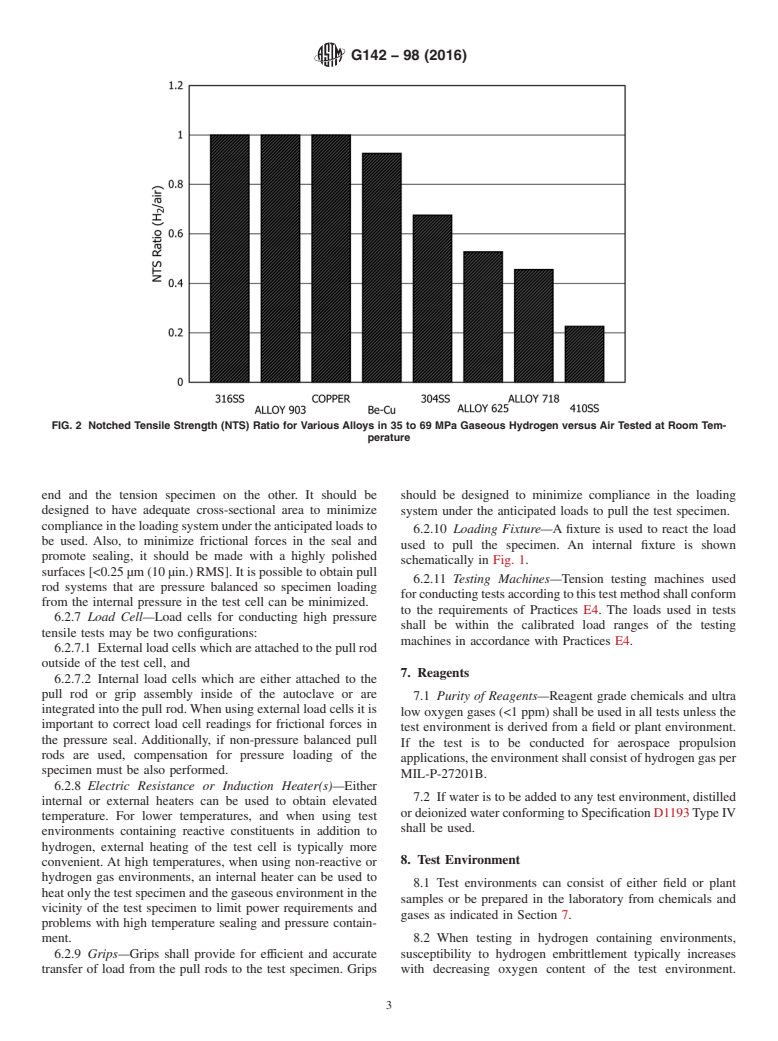

E8 Test Methods for Tension Testing of Metallic Materials ated through the determination of standard mechanical prop-

E691 Practice for Conducting an Interlaboratory Study to erties in tension (that is, yield strength, ultimate tensile

Determine the Precision of a Test Method strength, notched tensile strength, reduction in area or

G15 Terminology Relating to Corrosion and Corrosion Test- elongation, or both). Comparison of these mechanical proper-

3

ing (Withdrawn 2010) ties determined in a hydrogen-containing environment to those

G111 Guide for Corrosion Tests in High Temperature or determined in a non-embrittling environment (control test)

High Pressure Environment, or Both providesageneralindexofsusceptibilitytocrackingversusthe

material’s normal mechanical behavior.

1

This test method is under the jurisdiction of ASTM Committee G01 on

5. Significance and Use

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

Environmentally Assisted Cracking.

5.1 This test method provides a reliable prediction of the

Current edition approved May 1, 2016. Published May 2016. Originally

resistance or susceptibility, or both, to loss of material strength

approved in 1996. Last previous edition approved in 2011 as G142 – 98 (2011).

and ductility as a result of exposure to hydrogen-containing

DOI: 10.1520/G0142-98R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

gaseous environments. This test method is applicable over a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

www.astm.org. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G142 − 98 (2016)

broad range of pressures, temperatures, and gaseous environ-

ments. The results from this test method can be used to

evaluate the effects of material composition, processing, and

heat treatment as well as the effects of changes in environment

composition, temperature, and pressure. These results may or

may not correlate with service experience for particular appli-

cations. Furthermore, this test method may not

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G142 − 98 (Reapproved 2011) G142 − 98 (Reapproved 2016)

Standard Test Method for

Determination of Susceptibility of Metals to Embrittlement in

Hydrogen Containing Environments at High Pressure, High

1

Temperature, or Both

This standard is issued under the fixed designation G142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determination of tensile properties of metals in high pressure or high temperature,

or both, gaseous hydrogen-containing environments. It includes accommodations for the testing of either smooth or notched

specimens.

1.2 This test method applies to all materials and product forms including, but not restricted to, wrought and cast materials.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E4 Practices for Force Verification of Testing Machines

E8 Test Methods for Tension Testing of Metallic Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G111 Guide for Corrosion Tests in High Temperature or High Pressure Environment, or Both

G129 Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted

Cracking

4

2.2 Military Standard:

MIL-P-27201B Propellant, Hydrogen

3. Terminology

3.1 Definitions:

3.1.1 control test, n—a mechanical test conducted in an environment that does not produce embrittlement of a test material.

3.1.2 hydrogen embrittlement, n—hydrogen induced cracking or severe loss of ductility caused by the presence of hydrogen in

the metal.

3.1.3 Other definitions and terminology related to testing can be found in Terminology G15.

4. Summary of Test Method

4.1 Specimens of selected materials are exposed to a gaseous hydrogen containing environment at high pressure or high

temperature, or both, while being pulled to failure in uniaxial tension. The susceptibility to hydrogen embrittlement is evaluated

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally

Assisted Cracking.

Current edition approved March 1, 2011May 1, 2016. Published April 2011May 2016. Originally approved in 1996. Last previous edition approved in 20042011 as

G142–98(2004).G142 – 98 (2011). DOI: 10.1520/G0142-98R11.10.1520/G0142-98R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G142 − 98 (2016)

through the determination of standard mechanical properties in tension (that is, yield strength, ultimate tensile strength, notched

tensile strength, reduction in area or elongation, or both). Comparison of these mechanical properties determined in a

hydrogen-containing environment to those determined in a non-embrittling environment (control test) provides a general index of

susceptibility to cracking versus the material’s normal mechanical behavior.

5. Significance and Use

5.1 This test method provides a reliable prediction of the resistance or susceptibility, or both, to loss of material strength and

ductility as a result of exposure to hydrogen-containing gaseous environments. This test method is applicable over a broad range

of pressures, temperatures, and gas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.