ASTM F2855-11

(Specification)Standard Specification for Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure Tubing

Standard Specification for Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure Tubing

ABSTRACT

This specification covers a Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), (CPVC AL CPVC), composite pressure tubing with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer CPVC layers are bonded to the aluminum tube by a melt adhesive. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems. This specification covers only composite tubing incorporating a continuously welded aluminum tube.

SCOPE

1.1 This specification covers a Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), (CPVC AL CPVC), composite pressure tubing with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer CPVC layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the composite tubing, the requirements and test methods for materials, the dimensions of the component layers and finished tubing, adhesion tests, hydrostatic burst and sustained pressure and thermocycling performance. Also given are the requirements and methods of marking. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems.

Note 1—The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.2 This specification covers only composite tubing incorporating a continuously welded aluminum tube. Tubing consisting of metallic layers not continuously welded together are outside the scope of this specification.

1.3 Specifications for internal bushings for use with composite tubing meeting the requirements of this specification are given in Annex A1.

Note 2—In order to assure the expected life expectancy of CPVC-AL-CPVC composite tubing by preventing corrosion of the Aluminum, a bushing meeting the requirements of Annex A1 is required to be solvent cemented into the cut ends of the CPVC-AL-CPVC tubing prior to making solvent cement joints in the piping. This bushing seals off the cut ends of the tubing preventing any contact of the AL layer with any liquids being transported by the tubing.

1.4 Tubing meeting the requirements of this standard are designed to be used with fittings and solvent cements meeting the requirements of Specification D2846/D2846M when assembled in accordance with Appendix X3.

1.5 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the tubing materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product manufacturers for their specific testing procedures prior to pneumatic testing.

Note 3—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should a system fail for any reason.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 4—Suggested hydrostatic design pressures and pressure ratings for tubing are listed in Appendix X1.

1.7 The following safety hazards caveat pertains only to the test method portion, Section 9. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2855 – 11

Standard Specification for

Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated

Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure

Tubing

This standard is issued under the fixed designation F2855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the requirements of Specification D2846/D2846M when as-

sembled in accordance with Appendix X3.

1.1 This specification covers a Chlorinated Poly(Vinyl

1.5 The products covered by this specification are intended

Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride),

for use with the distribution of pressurized liquids only, which

(CPVC AL CPVC), composite pressure tubing with a welded

are chemically compatible with the tubing materials. Due to

aluminum tube reinforcement between the inner and outer

inherent hazards associated with testing components and sys-

layers. The inner and outer CPVC layers are bonded to the

tems with compressed air or other compressed gases some

aluminum tube by a melt adhesive. Included is a system of

manufacturersdonotallowpneumatictestingoftheirproducts.

nomenclature for the composite tubing, the requirements and

Consult with specific product manufacturers for their specific

test methods for materials, the dimensions of the component

testing procedures prior to pneumatic testing.

layers and finished tubing, adhesion tests, hydrostatic burst and

sustained pressure and thermocycling performance.Also given

NOTE 3—Pressurized (compressed) air or other compressed gases

are the requirements and methods of marking.The components

contain large amounts of stored energy which present serious safety

hazards should a system fail for any reason.

covered by this specification are intended for use in residential

and commercial, hot and cold, potable water distribution

1.6 The values stated in inch-pound units are to be regarded

systems.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

NOTE 1—The text of this standard references notes and footnotes which

and are not considered standard.

provide explanatory material. These notes and footnotes (excluding those

in tables and figures) shall not be considered as requirements of the

NOTE 4—Suggested hydrostatic design pressures and pressure ratings

standard.

for tubing are listed in Appendix X1.

1.2 This specification covers only composite tubing incor-

1.7 The following safety hazards caveat pertains only to the

porating a continuously welded aluminum tube. Tubing con-

test method portion, Section 9. This standard does not purport

sisting of metallic layers not continuously welded together are

to address all of the safety concerns, if any, associated with its

outside the scope of this specification.

use. It is the responsibility of the user of this standard to

1.3 Specifications for internal bushings for use with com-

establish appropriate safety and health practices and deter-

posite tubing meeting the requirements of this specification are

mine the applicability of regulatory limitations prior to use.

given in Annex A1.

2. Referenced Documents

NOTE 2—In order to assure the expected life expectancy of CPVC-AL-

CPVC composite tubing by preventing corrosion of the Aluminum, a

2.1 ASTM Standards:

bushing meeting the requirements of Annex A1 is required to be solvent

D696 Test Method for Coefficient of Linear Thermal Ex-

cementedintothecutendsoftheCPVC-AL-CPVCtubingpriortomaking

pansion of Plastics Between Ø30°C and 30°C with a

solvent cement joints in the piping. This bushing seals off the cut ends of

Vitreous Silica Dilatometer

the tubing preventing any contact of the AL layer with any liquids being

D1600 Terminology for Abbreviated Terms Relating to

transported by the tubing.

Plastics

1.4 Tubing meeting the requirements of this standard are

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

designed to be used with fittings and solvent cements meeting

Compounds and Chlorinated Poly(Vinyl Chloride)

1 2

This specification is under the jurisdiction ofASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Feb. 1, 2011. Published February 2011. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2855–11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2855 – 11

(CPVC) Compounds 3.2.3 nominal tubing size (NTS), n—A non-dimensional

D1898 Practice for Sampling of Plastics tubing sizing convention based on copper tubing sizing, CTS,

D2122 Test Method for Determining Dimensions of Ther- dimensionsinwhichthenominalmeasuredODistheNTSsize

moplastic Pipe and Fittings plus 0.125 in. For example, NTS ⁄2 tubing has a nominal OD

D2837 TestMethodforObtainingHydrostaticDesignBasis of 0.625 in.

for Thermoplastic Pipe Materials or Pressure Design Basis

4. Classification

for Thermoplastic Pipe Products

4.1 Tubing—This specification classifies CPVC-AL-CPVC

D2846/D2846M Specification for Chlorinated Poly(Vinyl

composite tubing and CPVC bushings by a maximum continu-

Chloride) (CPVC) Plastic Hot- and Cold-Water Distribu-

ous operating condition of 100 psi (690 kPa) at 180°F (82°C)

tion Systems

1 3

and by nominal tubing sizes of ⁄2 NTS , ⁄4 NTS and 1 NTS.

D3167 Test Method for Floating Roller Peel Resistance of

4.2 Pressure Design Basis The CPVC-AL-CPVC compos-

Adhesives

ite tubing shall have an established pressure design basis at

E8/E8M Test Methods for Tension Testing of Metallic

73°F (23°C) of 800 psi (5.52 MPa) or greater and at 180°F

Materials

(82°C) of 200 psi (1.38 MPa) or greater in accordance with

F412 Terminology Relating to Plastic Piping Systems

F1281 Specification for Crosslinked Polyethylene/ Test Method D2837.

Aluminum/Crosslinked Polyethylene (PEX-AL-PEX)

5. Materials

Pressure Pipe

5.1 General—The CPVC-AL-CPVC composite tubing is

2.2 Federal Standards:

composed of an internal CPVC layer, adhesive layer, alumi-

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

num layer, adhesive layer and external CPVC layer. For tubing

2.3 Military Standards:

made to this specification, the constituent materials must meet

MIL-STD-129 Marking for Shipment and Storage

the following requirements:

2.4 NSF Standards:

5.2 Aluminum—The thickness of the aluminum layer shall

Standard No. 14 for Plastic Piping Components and Related

meetthedimensionsandtolerancegiveninTable1.Thetensile

Materials

propertiesofthealuminummaterialshallbeaminimumtensile

Standard No. 61 for Drinking Water Systems

strength of 14,600 psi (100 MPa) and an elongation of 20%

Components—Health Effects

when tested in accordance with Test Method E8/E8M.

3. Terminology

5.3 Adhesive—The adhesive that bonds the CPVC layers to

the Aluminum layer shall be of sufficient strength that no

3.1 Definitions:

debonding of the layers occurs when the CPVC-AL-CPVC

3.1.1 General—Definitions used in this specification are in

composite tubing is tested to all the requirements in Section 6

accordance with Terminology F412 and abbreviations are in

of this standard and to the requirements for Hydrostatic Burst

accordance with Terminology D1600, unless otherwise speci-

Strength and CPVC Adhesives as specified in Specification

fied. The abbreviation for Aluminum is AL.

D2846/D2846M.

3.2 Definitions of Terms Specific to This Standard:

5.4 CPVC—The CPVC compound used to make the inner

3.2.1 CPVC-AL-CPVC composite tubing, n—composite

and outer layers shall meet the requirements specified in 5.4.1

tubing produced by coextrusion or extrusion of layers of

and 5.4.2.

CPVC/Aluminum/CPVC bonded together with a melt adhe-

5.4.1 Short-Term Properties— The CPVC compound shall

sive. This construction is also known as “multilayer”.

meet the requirements of cell classification CPVC 23447 as

3.2.2 tubing, n—,For the purpose of this specification, pipe

specified in Specification D1784.

made the specific dimensions shown in Table 1.

5.4.2 Long-Term Hydrostatic Strength—The CPVC com-

pound shall have an established 180°F (82°C) hydrostatic

design stress of 500 psi (3.45 MPa) or greater in accordance

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

with Test Method D2837.

dodssp.daps.dla.mil.

5.5 Rework Material— Rework material generated from

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

CPVC-AL-CPVC composite tubing shall not be used.

Arbor, MI 48113-0140, http://www.nsf.org.

TABLE 1 Outside Diameters, Wall Thicknesses, and Tolerances for CPVC-AL-CPVC Composite Pipe

Outside Diameter, in. (mm) Inside Diameter, in. (mm) Wall Thickness, in. (mm)

Aluminum Inner CPVC Layer Outer CPVC Layer

NTS

Tolerance on Tolerance on

Average Average

Average Tolerance on Minimum Minimum

Average Average

Average

⁄2 0.625 60.003 0.448 60.003 0.017 60.002 0.025 0.025

(15.88) (0.08) (11.38) (0.08) (0.43) (0.05) (0.64) (0.64)

⁄4 0.875 60.003 0.691 60.004 0.017 60.002 0.028 0.028

(22.23) (0.08) (17.55) (0.10) (0.43) (0.05) (0.71) (0.71)

1 1.125 60.003 0.932 60.005 0.017 60.002 0.034 0.034

(28.58) (0.08) (23.67) (0.13) (0.43) (0.05) (0.86) (0.86)

F2855 – 11

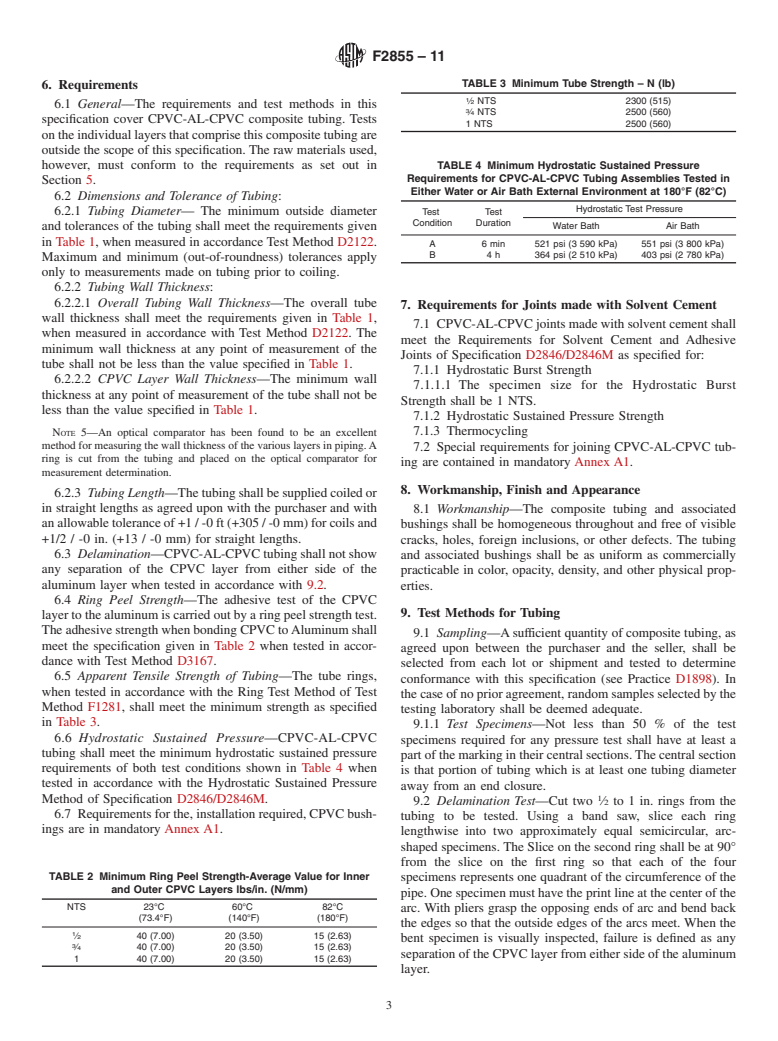

TABLE 3 Minimum Tube Strength – N (lb)

6. Requirements

⁄2 NTS 2300 (515)

6.1 General—The requirements and test methods in this

⁄4 NTS 2500 (560)

specification cover CPVC-AL-CPVC composite tubing. Tests

1 NTS 2500 (560)

ontheindividuallayersthatcomprisethiscompositetubingare

outside the scope of this specification. The raw materials used,

however, must conform to the requirements as set out in TABLE 4 Minimum Hydrostatic Sustained Pressure

Requirements for CPVC-AL-CPVC Tubing Assemblies Tested in

Section 5.

Either Water or Air Bath External Environment at 180°F (82°C)

6.2 Dimensions and Tolerance of Tubing:

Hydrostatic Test Pressure

6.2.1 Tubing Diameter— The minimum outside diameter Test Test

Condition Duration

Water Bath Air Bath

and tolerances of the tubing shall meet the requirements given

in Table 1, when measured in accordance Test Method D2122.

A 6 min 521 psi (3 590 kPa) 551 psi (3 800 kPa)

B 4 h 364 psi (2 510 kPa) 403 psi (2 780 kPa)

Maximum and minimum (out-of-roundness) tolerances apply

only to measurements made on tubing prior to coiling.

6.2.2 Tubing Wall Thickness:

6.2.2.1 Overall Tubing Wall Thickness—The overall tube

7. Requirements for Joints made with Solvent Cement

wall thickness shall meet the requirements given in Table 1,

7.1 CPVC-AL-CPVC joints made with solvent cement shall

when measured in accordance with Test Method D2122. The

meet the Requirements for Solvent Cement and Adhesive

minimum wall thickness at any point of measurement of the

Joints of Specification D2846/D2846M as specified for:

tube shall not be less than the value specified in Table 1.

7.1.1 Hydrostatic Burst Strength

6.2.2.2 CPVC Layer Wall Thickness—The minimum wall

7.1.1.1 The specimen size for the Hydrostatic Burst

thickness at any point of measurement of the tube shall not be

Strength shall be 1 NTS.

less than the value specified in Table 1.

7.1.2 Hydrostatic Sustained Pressure Strength

7.1.3 Thermocycling

NOTE 5—An optical comparator has been found to be an excellent

method for measuring the wall thickness of the various layers in piping.A

7.2 Special requirements for joining CPVC-AL-CPVC tub-

ring is cut from the tubing and placed on the optical comparator for

ing are contained in mandatory Annex A1.

measurement determination.

8. Workmanship, Finish and Appearance

6.2.3 Tubing Length—Thetubingshallbesuppliedcoiledor

in straight lengths as agreed upon with the purchaser and with

8.1 Workmanship—The composite tubing and associated

anallowabletoleranceof+1/-0ft(+305/-0mm)forcoilsand bushings shall be homogeneous throughout and free of visible

+1/2 / -0 in. (+13 / -0 mm) for straight lengths.

cracks, holes, foreign inclusions, or other defects. The tubing

6.3 Delamination—CPVC-AL-CPVC tubing shall not show and associated bushings shall be as uniform as commercially

any separation of the CPVC layer from either side of the

practicable in color, opacity, density, and other physical prop-

aluminum layer when tested in accordance with 9.2. erties.

6.4 Ring Peel Strength—The adhesive test of the CPVC

9. Test Methods for Tubing

layer to the aluminum is carried out by a ring peel strength test.

The adhesive strength when bonding CPVC toAluminum shall

9.1 Sampling—Asufficient quantity of composite tubing, as

meet the specification given in Table 2 when tested in accor-

agreed upon between the purchaser and the seller, shall be

dance with Test Method D3167.

selected from each lot or shipment and tested to determine

6.5 Apparent Tensile Strength of Tubing—The tube rings,

conformance with this specification (see Practice D1898). In

when tested in accordance with the Ring Test Method of Test

thecaseofnoprioragreement,randomsamplesselectedbythe

Method F1281, shall meet the minimum strength as specified

testing laboratory shall be deemed adequate.

in Table 3.

9.1.1 Test Specimens—Not less than 50 % of the test

6.6 Hydrostatic Sustained Pressure—CPVC-AL-CPVC

specimens required for any pressure test shall have at least a

tubing shall meet the minimum hydrostatic sustained pressure

part of the marking in their central sections.The central section

requirements of both test conditions shown in Table 4 when

is that portion of tubing which is at least one tubing diameter

tested in accordance with the Hydrostatic Sustained Pressure

away from an end closure.

Method of Specification D2846/D2846M.

9.2 Delamination Test—Cut two ⁄2 to 1 in. rings from the

6.7 Requirements for the, installation required, CPVC bush-

tubing to be tested. Using a band saw, slice each ring

ings are in mandatory Annex A1.

lengthwise into two approximately equal semicircular, arc-

shaped specimens. The Slice on the second ring shall be at 90°

from the slice on the first ring so that each of the four

TABLE 2 Minimum Ring Peel Strength-Average Value for Inner

specimens represents one quadrant of the circumference of the

and Outer CPVC Layers lbs/in. (N/mm)

pipe. One specimen must have the print line at the center of the

NTS 23°C 60°C 82°C

arc. With pliers grasp the opposing ends of arc and bend back

(73.4°F) (140°F) (180°F)

the edges s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.