ASTM D3605-00(2005)

(Test Method)Standard Test Method for Trace Metals in Gas Turbine Fuels by Atomic Absorption and Flame Emission Spectroscopy

Standard Test Method for Trace Metals in Gas Turbine Fuels by Atomic Absorption and Flame Emission Spectroscopy

SIGNIFICANCE AND USE

Knowledge of the presence of trace metals in gas turbine fuels enables the user to predict performance and, when necessary, to take appropriate action to prevent corrosion.

SCOPE

1.1 This test method covers the determination of sodium, lead, calcium, and vanadium in Specification D 2880 Grade Nos. 1-GT and 2-GT fuels in the range from 0.1 to 2.0 mg/L. This test method is intended for the determination of oil-soluble metals and not waterborne contaminants in oil-water mixtures.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3605–00 (Reapproved 2005)

Standard Test Method for

Trace Metals in Gas Turbine Fuels by Atomic Absorption

and Flame Emission Spectroscopy

This standard is issued under the fixed designation D3605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope addedanalyteprovidesthecalibrationinformationnecessaryto

calculate the analyte content of the unaltered sample.

1.1 This test method covers the determination of sodium,

3.2 Lead is determined by atomic absorption in a premixed

lead, calcium, and vanadium in Specification D2880 Grade

air-acetylene flame, and sodium is determined by atomic

Nos. 1-GT and 2-GT fuels in the range from 0.1 to 2.0 mg/L.

absorption or atomic emission in a premixed air-acetylene

This test method is intended for the determination of oil-

flame. Calcium and vanadium are determined by atomic

soluble metals and not waterborne contaminants in oil-water

absorption or atomic emission in a premixed nitrous oxide-

mixtures.

acetylene flame.

1.2 The values stated in SI units are to be regarded as the

3.3 Most experience with this test method has been in the

standard.

atomic absorption mode, although flame emission has been

1.3 This standard does not purport to address all of the

used successfully. Details in the subsequent sections are

safety concerns, if any, associated with its use. It is the

written for the atomic absorption mode. If the flame emission

responsibility of the user of this standard to establish appro-

mode is used, minor details in the subsequent sections must be

priate safety and health practices and determine the applica-

altered to conform to standard practice for flame emission

bility of regulatory limitations prior to use.

spectroscopy. The precision statement applies only to the

2. Referenced Documents atomic absorption mode.

2.1 ASTM Standards:

NOTE 1—Some GT fuel users may wish to determine potassium in

D2880 Specification for Gas Turbine Fuel Oils

addition to other metals included in this method. Potassium can be

D4057 Practice for Manual Sampling of Petroleum and determined in a manner similar to that for sodium using a potassium

hollow cathode lamp, (unless flame emission mode is used) a wavelength

Petroleum Products

of 766.4 mm, and an appropriate organo-potassium standard. Precision

data for potassium have not been determined.

3. Summary of Test Method

3.1 The samples are prepared to conform with the require-

4. Significance and Use

ments of the method of standard additions, which is selected to

4.1 Knowledgeofthepresenceoftracemetalsingasturbine

obviate problems encountered with the direct analysis of

fuels enables the user to predict performance and, when

typical gas turbine fuels that exhibit significant variations in

necessary, to take appropriate action to prevent corrosion.

physical properties. Different, but known, amounts of analyte

are added to two portions of sample. These, together with the

5. Apparatus

unaltered sample, are burned in the flame of an atomic

5.1 Atomic Absorption Spectrophotometer, capable of mea-

absorption instrument that measures light absorption by the

suring radiation over the wavelength range from 280 to 600

atomized metals. The analysis of the sample portions with

nm. The instrument must be capable of measuring low-level

signals (approximately 1 % absorption or 0.004 absorbance

unit per mg/L vanadium). The instrument should also be

This test method is under the jurisdiction of ASTM Committee D02 on equipped as follows.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.1.1 Burner, with variable nebulizer and auxiliary oxidant

D02.03 on Elemental Analysis.

supply to reduce non-atomic absorption from unburned hydro-

Current edition approved May 1, 2005. Published May 2005. Originally

carbons which cause interferences.

approved in 1977. Last previous edition approved in 2000 as D3605 – 00. DOI:

10.1520/D3605-00R05.

5.1.1.1 Burner Head, capable of supporting a nitrous oxide-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

acetylene flame.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.1.2 Burner Head, single- or multiple-slot, capable of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. supporting an air-acetylene flame.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3605–00 (2005)

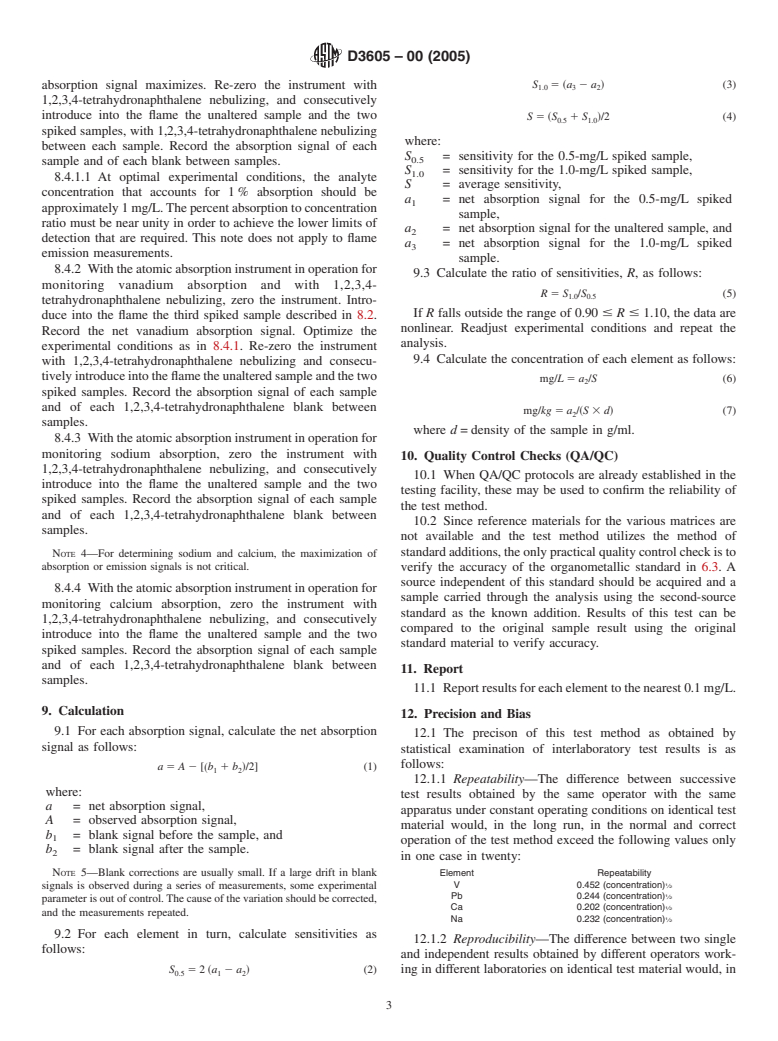

TABLE 1 Experimental Conditions

5.1.2 Electronic Detection System, capable of reading to the

nearest 0.1 % absorption or 0.0004 absorbance. Element Mode Wavelength, nm Fuel Oxidant

5.1.2.1 The text describes the measurement of absorption Na Absorption 589.6 C H air

2 2

Na Emission 589.6 C H air

2 2

signals that is, either percent absorption or absorbance. For

Pb Absorption 283.3 C H air

2 2

instruments reading in percent absorption, absorption signals

Ca Absorption 422.7 C H N O

2 2 2

Ca Emission 422.7 C H N O

of 0.1 % absorption must be measurable. For instruments

2 2 2

V Absorption 318.34–318.40 C H N O

2 2 2

reading in absorbance, signals of 0.0004 absorbance must be

V Emission 437.9 C H N O

2 2 2

measurable.

5.1.3 Hollow Cathode Lamp Power Supply, regulated to

minimize drift.

6.3 OrganometallicStandards—Oil-solublesaltsofsodium,

5.1.4 Monochromator, capable of resolving the 318.34– lead, calcium, and vanadium of known concentration.

318.40-nm vanadium doublet from the 318.54-nm vanadium 6.4 Mixed Standard—Prepare a mixed standard containing

line. 250 mg/L each of sodium, lead, calcium, and vanadium by

dissolvingtheappropriateamountsoforganometallicstandards

5.1.5 Hollow Cathode Lamps, one each for calcium, so-

in 1,2,3,4-tetrahydronaphthalene and making the required di-

dium, lead, and vanadium.

lutions. Prepare fresh daily, as needed.

NOTE 2—Electrodeless-discharge lamps can be an acceptable alterna-

tive, but the precision of this method was determined with hollow cathode

7. Sampling

lamps.

7.1 Samples shall be taken in accordance with the instruc-

5.1.6 When the instrument has flame-emission capability, tions in Practice D4057.

the emission technique can be used for the analyses of sodium,

8. Procedure

calcium, and vanadium.

8.1 Fill two clean 25-mL volumetric flasks to the line with

5.2 Volumetric Flasks, 25-mL.

sample. With the microlitre syringe add 50 µL of mixed

5.3 Glass Vials, 40-mL, screw-cap type, polyethylene-lined

standard to one flask and 100 µLto the other. Touch the needle

caps.

of the syringe to the inner wall of the flask to ensure

5.4 Syringe, 100-µL, Hamilton type or equivalent.

quantitative transfer of the standard. Invert and mix the

contents.(Thetwoflasksarenowspikedwith0.5mg/Land1.0

6. Reagents

mg/L of sodium, lead, calcium, and vanadium). Alternatively,

weigh 25.0 g of sample into each of two clean disposable glass

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in tests. Unless otherwise indicated, it is intended that all vials and add the standard in the same manner. (The two vials

are now spiked with 0.5 mg/kg and 1.0 mg/kg of sodium, lead,

reagents conform to the specifications of the Committee on

Analytical Reagents of the American Chemical Society where calcium, and vanadium.)

8.2 Prepare a third spiked sample by adding approximately

such specifications are available. Other grades may be used,

provided it is ascertained that the reagent is of sufficiently high 1mLofthemixedstandardtoapproximately25mLofsample.

This solution serves only to aid in establishing satisfactory

purity to permit its use without lessening the accuracy of the

determination. operating conditions for the atomic absorption instrument.

8.3 Establish the atomic absorption instrument operating

6.2 1,2,3,4-tetrahydronaphthalene, practical grade,

conditions, which are recommended by the manufacturer, and

analyte-sterile.

consider the following special points. Select the mode, flame

NOTE 3—Analyte-sterile 1,2,3,4-tetrahydronaphthalene can be pre-

gases, and spectral lines from the information presented in

pared by extracting a portion of tetralin with an equal amount of

Table 1.

hydrochloric acid in a covered screw-cap vial. Heat the vial on a steam

8.4 Analysis:

bath for 1 h and shake the vial for 1 h. If the acid extracted 1,2,3,4-

8.4.1 Withtheatomicabsorptioninstrumentinoperationfor

tetrahydronaphthalene and unextracted 1,2,3,4-tetrahydronaphthalene

monitoring lead absorption and with 1,2,3,4-

give

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.