ASTM D4415-91(2000)e1

(Test Method)Standard Test Methods for Determination of Dimer in Acrylic Acid

Standard Test Methods for Determination of Dimer in Acrylic Acid

SCOPE

1.1 Test Method A --Describes a chemical (titrametric) procedure for the determination of acrylic acid dimer in acrylic acid. This procedure may be applicable to other unsaturated organic acids.

1.2 Test Method B--Describes a gas chromatographic procedure for the determination of acrylic acid dimer in acrylic acid. Other impurities may also be determined simultaneously.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D4415–91(Reapproved2000)

Standard Test Methods for

Determination of Dimer in Acrylic Acid

This standard is issued under the fixed designation D 4415; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Footnote references to commercial manufacturers were deleted editorially in November 2000.

1. Scope 3.2 Test Method B—An internal standard, n-dodecane, is

added to the sample and then introduced into a gas chromato-

1.1 Test Method A—Describes a chemical (titrametric) pro-

graph containing an appropriate capillary column for separa-

cedure for the determination of acrylic acid dimer in acrylic

tion. The separated components are measured in the column

acid. This procedure may be applicable to other unsaturated

effluent by a detector and recorded as a chromatogram. The

organic acids.

peak areas are measured and the concentration of the compo-

1.2 Test Method B—Describes a gas chromatographic pro-

nents of interest are calculated by reference to the internal

cedure for the determination of acrylic acid dimer in acrylic

standard.

acid. Other impurities may also be determined simultaneously.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 These test methods provide a measurement of the dimer

responsibility of the user of this standard to establish appro-

content of acrylic acid. The results of this measurement can be

priate safety and health practices and determine the applica-

used for specification purposes but must be on an as-shipped

bility of regulatory limitations prior to use. For specific hazard

basis since the dimer content will vary with the age and the

statements, see Section 8.

storage temperature of the acrylic acid.

2. Referenced Documents

5. Interferences

2.1 ASTM Standards:

5.1 Test Method A—If present, ester impurities present in

D 268 Guide for Sampling and Testing Volatile Solvents

the acrylic acid will be determined as dimer.

and Chemical Intermediates for Use in Paint and Related

2 5.2 Test Method B—Impurities having the same or similar

Coatings and Materials

3 retention times as the acrylic acid on the column used may

D 1193 Specification for Reagent Water

cause abnormally high results.

D 4052 Test Method for Density and Relative Density of

Liquids by Digital Density Meter

6. Apparatus

E 200 Practice for Preparation, Standardization, and Stor-

5 6.1 Test Method A:

age of Standard Solutions for Chemical Analysis

6.1.1 Pressure Bottle, 200 to 350-mL capacity, with lever-

3. Summary of Test Methods type closure and made of heat-resistant glass.

6.1.2 Container for Pressure Bottle— A suitable safety

3.1 Test Method A—The acid specimen is neutralized and

device to contain the pressure bottle. A metal container with a

the dimer (Acrylic acid dimer, CH =CH-COO-CH-CH -

2 2 2

hinged top and perforated bottom, a strong synthetic fabric or

COOH) determined by saponification and titration. Purity of

canvas bag, or a safety shield may be used.

the acid can also be determined by carrying out the first

6.1.3 Open-Top Vial,3to5-mLcapacity,ofsuchdiameterto

neutralization, quantitatively, but this is not covered in this

fit the pressure bottle.

method.

6.1.4 Buret, 100-mL capacity.

6.1.5 Buret, 50-mL capacity, calibrated.

This test method is under the jurisdiction of ASTM Committee D01 on Paint 6.1.6 Boiling Water Bath.

and Related Coatings, Materials, andApplications and is the direct responsibility of

6.2 Test Method B:

Subcommittee D01.35 on Solvents, Plasticizers and Chemical Intermediates.

6.2.1 Gas Chromatograph—Anygaschromatographhaving

Current edition approved Sept. 15, 1991. Published November 1991. Originally

a flame ionization detector (FID) or any other detector,

published as D 4415 – 84. Last previous edition D 4415 – 89.

Annual Book of ASTM Standards, Vol 06.04.

provided the system has sufficient sensitivity and stability to

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D4415–91 (2000)

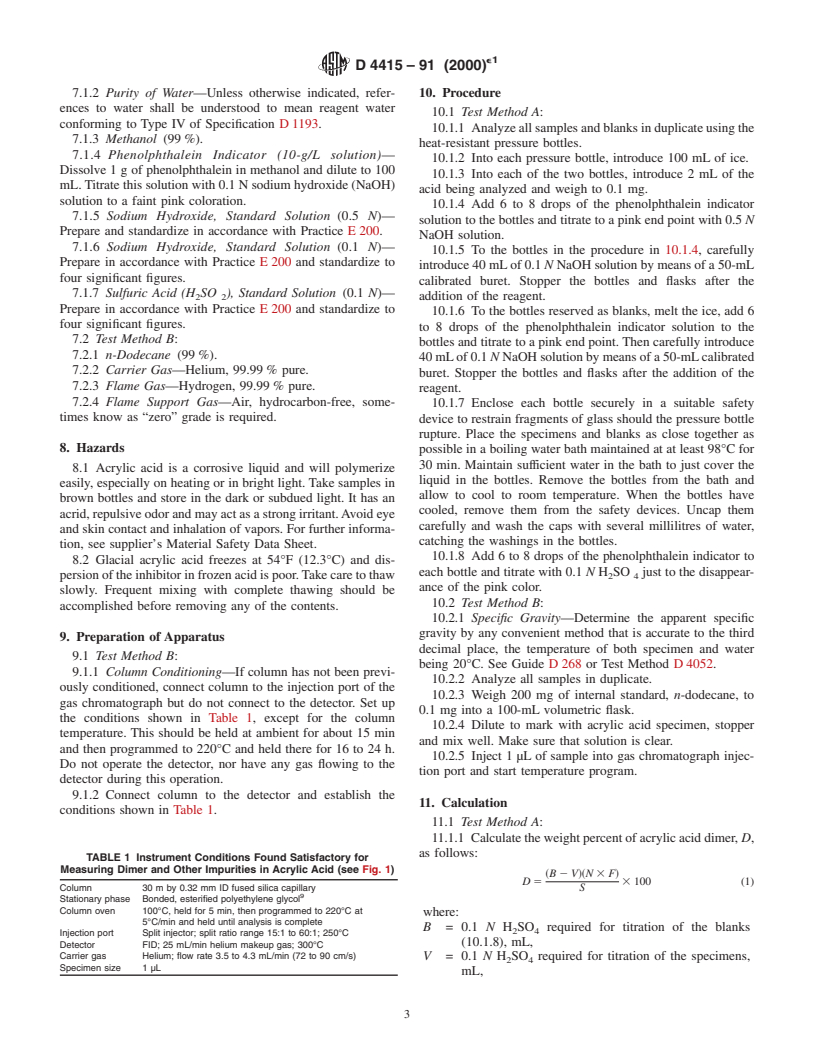

FIG. 1 Typical Chromatogram of Acrylic Acid

obtain, for a 0.01 % impurity in the specimen, a recorder 6.2.5 Gas Purifiers—The use of a gas purifier, to remove

deflection of at least 20 mm at a signal to noise ratio of at least moisture and other contaminants from the carrier gas, and an

5to1. oxygen trap or oxygen removal system is strongly recom-

6.2.1.1 The chromatograph should be capable of tempera- mended to prolong column life.

6.2.6 Volumetric Flasks, 100-mL capacity.

ture programming.

6.2.1.2 The injection port or system should be one suitable

7. Reagents and Materials

forthecapillarycolumnused.Splitinjectiontechniquesshould

7.1 Test Method A:

be used.

7.1.1 Purity of Reagents—Reagent grade chemicals shall be

6.2.2 Column—A 30 to 50-m long by 0.32-mm inside

used in all tests. Unless otherwise indicated, it is intended that

diameterfusedsilicacapillarycolumnwitha0.2to0.3-µmfilm

all reagents shall conform to the specifications of the commit-

of a bonded, esterified polyethylene glycol phase. Any other

tee on analytical reagents of the American Chemical Society,

column, capable of providing the necessary separation and

where such specifications are available. Other grades may be

precision, may be used.

used, provided it is first ascertained that the reagent is of

6.2.3 Sample Introduction System—Any system capable of

sufficiently high purity to permit its use without lessening the

introducing a representative specimen into the column. Mi-

accuracy of the determination.

crolitre syringes and autosampler systems have been used

successfully.

6.2.4 Recorder—A recording potentiometer with a full-

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

scale deflection of 1 mV, full scale response time of1sor less,

listed by the American Chemical Society, see Analar Standards for Laboratory

and sufficient sensitivity and stability to meet the requirements

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

of 6.2.1. A recording integrator or computerized data station

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

may also be used. MD.

e1

D4415–91 (2000)

7.1.2 Purity of Water—Unless otherwise indicated, refer- 10. Procedure

ences to water shall be understood to mean reagent water

10.1 Test Method A:

conforming to Type IV of Specification D 1193.

10.1.1 Analyzeallsamplesandblanksinduplicateusingthe

7.1.3 Methanol (99 %).

heat-resistant pressure bottles.

7.1.4 Phenolphthalein Indicator (10-g/L solution)—

10.1.2 Into each pressure bottle, introduce 100 mL of ice.

Dissolve1gof phenolphthalein in methanol and dilute to 100

10.1.3 Into each of the two bottles, introduce 2 mL of the

mL.Titrate this solution with 0.1 N sodium hydroxide (NaOH)

acid being analyzed and weigh to 0.1 mg.

solution to a faint pink coloration.

10.1.4 Add 6 to 8 drops of the phenolphthalein indicator

7.1.5 Sodium Hydroxide, Standard Solution (0.5 N)—

solution to the bottles and titrate to a pink end point with 0.5 N

Prepare and standardize in accordance with Practice E 200.

NaOH solution.

7.1.6 Sodium Hydroxide, Standard Solution (0.1 N)—

10.1.5 To the bottles in the procedure in 10.1.4, carefully

Prepare in accordance with Practice E 200 and standardize to

introduce 40 mLof 0.1 N NaOH solution by means of a 50-mL

four significant figures.

calibrated buret. Stopper the bottles and flasks after the

7.1.7 Sulfuric Acid (H SO ), Standard Solution (0.1 N)—

2 2 addition of the reagent.

Prepare in accordance with Practice E 200 and standardize to

10.1.6 To the bottles reserved as blanks, melt the ice, add 6

four significant figures

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.