ASTM D4829-95

(Test Method)Standard Test Method for Expansion Index of Soils

Standard Test Method for Expansion Index of Soils

SCOPE

1.1 This test method provides an index to the expansion potential of compacted soils when inundated with distilled water.

1.2 This test method controls variables that influence the expansive characteristics of soils and still retains a relatively simple test for practical engineering applications.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4829–95

Standard Test Method for

Expansion Index of Soils

This standard is issued under the fixed designation D4829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E11 Specification for Wire-Cloth Sieves for Testing Pur-

poses

1.1 This test method provides an index to the expansion

potential of compacted soils when inundated with distilled

3. Terminology

water.

3.1 Refer to Terminology D653 for standard definitions of

1.2 This test method controls variables that influence the

terms. Additional terms are as follows:

expansive characteristics of soils and still retains a relatively

3.2 expansionindex,EI—1000timesthedifferencebetween

simple test for practical engineering applications.

final and initial height of the specimen divided by the initial

1.3 The values stated in SI units are to be regarded as the

height.

standard. The values stated in inch-pound units are approxi-

mate.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

4.1 The specimen is compacted into a metal ring so that the

safety concerns, if any, associated with its use. It is the

degree of saturation is between 40 and 60% and the specimen

responsibility of the user of this standard to establish appro-

and the ring are placed in a consolidometer. A vertical

priate safety and health practices and determine the applica-

confining pressure of 6.9 kPa (1 lbf/in. ) is applied to the

bility of regulatory limitations prior to use.

specimen and then the specimen is inundated with distilled

2. Referenced Documents water.The deformation of the specimen is recorded for 24 h or

until the rate of deformation becomes less than 0.0005 mm/h

2.1 ASTM Standards:

(0.0002 in./h), whichever occurs first. A minimum recording

D653 Terminology Relating to Soil, Rock, and Contained

3 time of3his required.

Fluids

D698 Test Methods for Laboratory Compaction Character-

5. Significance and Use

istics of Soil Using Standard Effort (12,400 ft lbf/ft (600

3 3 5.1 The expansion index, EI, is used to measure a basic

kN-m/m ))

index property of soil and therefore, the EI is comparable to

D854 Test Method for Specific Gravity of Soils

other indices such as the liquid limit, plastic limit, and

D2216 TestMethodforLaboratoryDeterminationofWater

plasticity index of soils, as in Test Method D4318.

(Moisture) Content of Soil and Rock

5.2 The EI is not used to duplicate any particular field

D2435 Test Method for One-Dimensional Consolidation

conditionssuchassoildensity,watercontent,loading,in-place

Properties of Soils

soil structure or soil water chemistry. However, the test

D3877 Test Methods for One-Dimensional Expansion,

procedure keeps all conditions constant allowing direct corre-

Shrinkage, and Uplift Pressure of Soil-Lime Mixtures

lation of data between organizations. All organizations can

D4318 Test Method for Liquid Limit, Plastic Limit, and

benefit from these collective experiences.

Plasticity Index of Soils

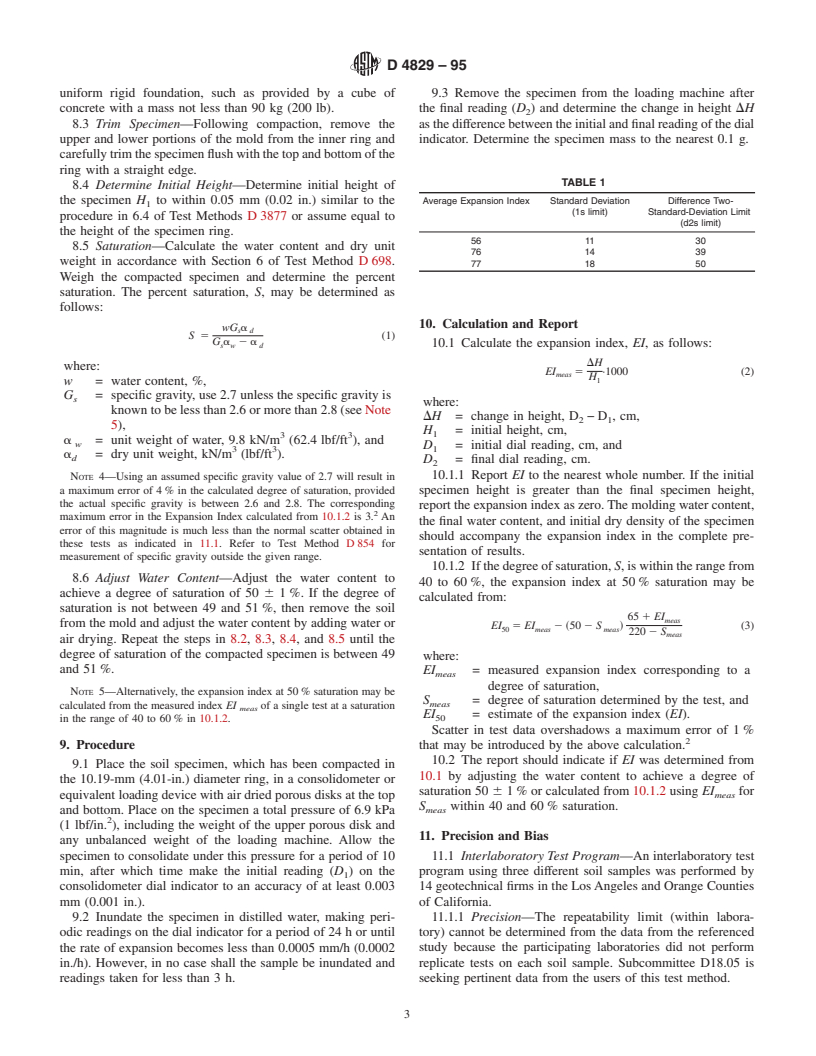

5.3 Theclassificationofapotentiallyexpansivesoilisbased

D4753 Specification for Evaluating, Selecting, and Speci-

on the following table:

fying Balances and Scales for Use in Testing Soil, Rock

Expansion Index, EI Potential Expansion

and Related Construction Materials Testing

0–20 Very Low

21–50 Low

51–90 Medium

This test method is under the jurisdiction of ASTM Committee D-18 on Soil 91–130 High

>130 Very High

and Rock and is the direct responsibility of Subcommittee D18.05 on Structural

Properties of Soils.

Current edition approved April 15, 1995. Published August 1995.

Refer to Anderson, J. N., and Lade, P. V., “The Expansion Index Test,’’

Geotechnical Testing Journal, Vol 4, No. 2, ASTM, 1981, pp. 58–67.

3 4

Annual Book of ASTM Standards, Vol 04.08. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4829–95

6. Apparatus for measuring the change in height of the specimen. The

consolidometer ring must be as specified in 6.1.

6.1 Mold—The mold shall be cylindrical in shape, made of

6.9 Porous Disks—The disks shall be smooth ground and

metal, and have the capacity and dimensions indicated in Fig.

fine enough to minimize intrusion of soil into the disks and

1. It shall have a detachable collar inscribed with a mark 5.08

shall reduce false displacements caused by seating of the

mm (2.00 in.) above the base.The lower section of the mold is

specimen against the surface of porous disks (Note 2). Such

designed to retain a removable stainless steel ring 2.54 mm (1

displacements may be significant, especially if displacements

in.)inheight,10.19mm(4.01in.)ininternaldiameter,andnot

and applied vertical pressures are small.

less than 0.31 mm (0.120 in.) in wall thickness.

6.2 Rammer—Ametal rammer having a 5.08 mm (2.00 in.)

NOTE 2—A suitable pore size is 10 µm.

diameter circular face and weighing 2.5 kg (5.5 lbf) shall be

6.9.1 Porous disks shall be air dry.

equipped with a suitable arrangement to control height of drop

6.9.2 Porous disks shall fit close to the consolidometer ring

to a free fall of 30.5 mm (12 in.) above the top of the soil. See

to avoid extrusion or punching. Suitable disk tolerances are

Test Methods D698 for specification of a suitable rammer.

described in 6.3 of Test Method D2435.

6.3 Balance—Abalance of at least 1000 g capacity meeting

the requirments of Specification D4753, Class GP2.

7. Sample Preparation

NOTE 1—For further information refer to Specification D4753.

7.1 Preparation for Sieving—If the soil sample is damp

when received from the field, dry it until it becomes friable

6.4 Drying Oven—A thermostatically controlled drying

under a trowel. Drying may be in air or by the use of drying

oven capable of maintaining a temperature of 110 6 5°C

apparatus, such that the temperature of the sample does not

(2306 9°F) for drying moisture samples.

exceed 60°C (140°F). Then thoroughly break up the aggrega-

6.5 Straight Edge—Steel straight edge 30.5 mm (12 in.) in

tions in such a manner as to avoid reducing the natural size of

length and having one bevelled edge.

individual particles.

6.6 Sieves—A 4.75-mm (No. 4) sieve conforming to the

requirements of SpecificationE11.

NOTE 3—If particles larger than 0.6 mm (0.25 in.) are potentially

6.7 Mixing Tools—Miscellaneous tools such as mixing

expansive, such as claystone, shale, or weathered volcanic rock, they may

pans, spoons, trowels, spatula, and so forth, or a suitable

be broken down so as to pass the 4.75-mm (No. 4) sieve if this is

mechanical device for thoroughly mixing the sample of soil consistent with use of the soil.

with increments of water.

7.2 Sieving—Sieve an adequate quantity of the representa-

6.8 Loading Device—Aconsolidometer or equivalent load-

tivepulverizedsoiloverthe4.75-mm(No.4)sieve.Recordthe

ing device as described in Test Method D2435 for supporting

percentage of coarse material retained on the 4.75-mm (No. 4)

andsubmergingthespecimen,forapplyingaverticalload,and

sieve and discard.

7.3 Sample—Select a representative sample of the soil with

amassofapproximately1kg(2lbf)ormorepreparedasin7.1

and 7.2.

8. Specimen Preparation

8.1 Adjust Water Content—Thoroughly mix the selected

representativesamplewithsufficientdistilledwatertobringthe

soil to approximately optimum water content as determined in

accordance with Test Method D698. The actual test method

need not be run, but experience and judgement should be used

to estimate that water content. After mixing, take a represen-

tative sample of the material for moisture determination and

sealtheremainderofthesoilinaclose-fittingairtightcontainer

for a period of at least 16 h (or overnight).Weigh the moisture

sample immediately, and dry in an oven at 110 6 5°C (230 6

9°F) for at least 12 h, or in accordance with Test Method

Le

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.