ASTM B425-11(2017)

(Specification)Standard Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825, UNS N08221, and UNS N06845) Rod and Bar

Standard Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825, UNS N08221, and <brk/>UNS N06845) Rod and Bar

ABSTRACT

This specification covers nickel-iron-chromiummolybdenum-copper alloy (UNS N08825 and UNS N08221) in the form of hot-finished and cold-drawn rounds, squares, hexagons, and rectangles. The material shall conform to the composition limits specified. The material shall conform to the mechanical properties specified. Chemical analysis, tension test, and rounding procedure shall be made in accordance to the specified requirements.

SCOPE

1.1 This specification2 covers nickel-iron-chromium-molybdenum-copper alloy (UNS N08825, UNS N08221, and UNS N06845)3 in the form of hot-finished and cold-drawn rounds, squares, hexagons, and rectangles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 12, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B425 −11 (Reapproved 2017)

Standard Specification for

Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825, UNS N08221, and

UNS N06845) Rod and Bar

This standard is issued under the fixed designation B425; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope N08825, UNS N08221, and UNS N06845) Plate, Sheet,

2 and Strip

1.1 This specification covers nickel-iron-chromium-

B880 Specification for General Requirements for Chemical

molybdenum-copper alloy (UNS N08825, UNS N08221, and

3 Check Analysis Limits for Nickel, Nickel Alloys and

UNS N06845) in the form of hot-finished and cold-drawn

Cobalt Alloys

rounds, squares, hexagons, and rectangles.

E8 Test Methods for Tension Testing of Metallic Materials

1.2 The values stated in inch-pound units are to be regarded

E29 Practice for Using Significant Digits in Test Data to

as standard. The values given in parentheses are mathematical

Determine Conformance with Specifications

conversions to SI units that are provided for information only

E1473 Test Methods for Chemical Analysis of Nickel, Co-

and are not considered standard.

balt and High-Temperature Alloys

1.3 The following precautionary caveat pertains only to the

test methods portion, Section 12, of this specification: This

3. Terminology

standard does not purport to address all of the safety problems,

3.1 Definitions of Terms Specific to This Standard:

if any, associated with its use. It is the responsibility of the user

3.1.1 bar, n—material of rectangular (flats), hexagonal, or

of this standard to become familiar with all hazards including

square solid section up to and including 10 in. (254 mm) in

those identified in the appropriate Safety Data Sheet (SDS) for

width and ⁄8 in. (3.2 mm) and over in thickness in straight

this product/material as provided by the manufacturer, to

lengths.

establish appropriate safety, health, and environmental

3.1.1.1 Discussion—Hot-worked rectangular bar in widths

practices, and determine the applicability of regulatory limi-

10in.(254mm)andundermaybefurnishedashot-rolledplate

tations prior to use.

with sheared or cut edges in accordance with Specification

1.4 This international standard was developed in accor-

B424, provided the mechanical property requirements of this

dance with internationally recognized principles on standard-

specification are met.

ization established in the Decision on Principles for the

3.1.2 rod, n—material of round solid section furnished in

Development of International Standards, Guides and Recom-

straight lengths.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Ordering Information

2. Referenced Documents

4.1 It is the responsibility of the purchaser to specify all

2.1 ASTM Standards:

requirements that are necessary for the safe and satisfactory

B424 Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS

performance of material ordered under this specification.

Examples of such requirements include, but are not limited to,

the following:

This specification is under the jurisdiction of ASTM Committee B02 on

4.1.1 ASTM designation and date of issue,

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

4.1.2 UNS number,

Current edition approved Nov. 1, 2017. Published November 2017. Originally

4.1.3 Section—Rod (round) or bar (square, hexagonal, or

approved in 1964. Last previous edition approved in 2011 as B425 – 11. DOI:

rectangular),

10.1520/B0425-11R17.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

4.1.4 Dimensions, including length,

cation SB-425 in Section II of that code.

4.1.5 Condition (see Appendix X1),

New designation established in accordance with Practice E527 and SAE

J 1086, Practice for Numbering Metals and Alloys (UNS). 4.1.6 Finish (see Appendix X1),

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.7 Quantity—Feet (or metres) or number of pieces,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.8 Certification—State if certification is required (Sec-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tion 15),

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B425−11 (2017)

A

TABLE 1 Chemical Requirements

Element UNS N08825 UNS N08221 UNS N06845

Nickel 38.0–46.0 39.0–46.0 44.0–50.0

Chromium 19.5–23.5 20.0–22.0 20.0–25.0

B

Iron 22.0 min balance balance

Manganese 1.0 1.0 0.5

Carbon 0.05 0.025 0.05

Copper 1.5–3.0 1.5–3.0 2.0–2.4

Silicon 0.5 0.5 0.5

Sulfur 0.03 0.03 0.010

Aluminum 0.2 0.2 .

Titanium 0.6–1.2 0.6–1.0 .

Molybdenum 2.5–3.5 5.0–6.5 5.0–7.0

Tungsten . . 2.0–5.0

A

Maximum unless range or minimum is given. Where ellipses (.) appear in this table, there is no requirement and analysis for the element need not be determined or

reported.

B

Element shall be determined arithmetically by difference.

TABLE 2 Mechanical Properties (Rod and Bar)

Yield Strength Elongation in 2

Tensile Strength

Alloy Condition 0.2 % offset, min, in.or50mmor

min, ksi (MPa)

D

ksi (MPa) 4 , min,%

A

UNS N08825 Annealed: 85 (586) 35 (241) 30

Hot-finished, cold–drawn

BBB

Forging Quality:

UNS N08221 All sizes annealed 79 (544) 34 (235) 30

UNS N06845 All sizes annealed 100 (690) 40 (276) 30

A

Not applicable to diameters or cross sections under ⁄32 in. (2.4 mm).

B

Forging quality is furnished to chemical requirements and surface inspection only. No tensile properties are required.

TABLE 3 Permissible Variations in Diameter or Distance Between

4.1.9 Samples for Product (Check) Analysis—State whether

Parallel Surfaces of Cold-Worked Rod and Bar

samples for product (check) analysis should be furnished (see

Permissible Variations From

Specified Dimension,

5.2), and

Specified Dimension, in. (mm)

in.

A

4.1.10 Purchaser Inspection—If purchaser wishes to wit-

(mm)

Plus Minus

ness tests or inspection of material at place of manufacture, the

Rounds: 0

1 3

purchase order must so state, indicating which test or inspec- ⁄16 (1.6) to ⁄16 (4.8), excl 0.002 (0.05)

3 1

⁄16 (4.8) to ⁄2 (12.7), excl 0 0.003 (0.08)

tions are to be witnessed (Section 13).

1 15

⁄2 (12.7) to ⁄16 (23.8), incl 0.001 (0.03) 0.002 (0.05)

15 15

Over ⁄16 (23.8) to 1 ⁄16 (49.2), incl 0.0015 (0.04) 0.003 (0.08)

5. Chemical Composition

15 1

Over 1 ⁄16 (49.2) to 2 ⁄2 (63.5), incl 0.002 (0.05) 0.004 (0.10)

Hexagons, squares, rectangles:

5.1 The material shall conform to the composition limits

⁄2 (12.7) and less 0 0.004 (0.10)

specified in Table 1. 1 7

Over ⁄2 (12.7) to ⁄8 (22.2), incl 0 0.005 (0.13)

7 1

Over ⁄8 (22.2) to 1 ⁄4 (31.8), incl 0 0.007 (0.18)

5.2 If a product (check) analysis is performed by the

Over 1 ⁄4 (31.8) to 2 (50.8), incl 0 0.009 (0.23)

purchaser, it shall be done in accordance with Specification

A

Dimensions apply to diameter of rounds, to distance between parallel surfaces of

B880 and the material shall conform to the product (check)

hexagons and squares, and separately to width and thickness of rectangles.

analysis variations defined in Table 1 of Specification B880.

variations in diameter shown in Table 3 and Table 4, except for

6. Mechanical Properties and Other Requirements

hot-worked rods ⁄2 in. (12.7 mm) in diameter and under, which

6.1 Mechanical Properties—The material shall conform to

may be out-of-round by the total permissible variations in

the mechanical properties specified in Table 2.

diameter shown in Table 4.

7. Dimensions and Permissible Variations

7.3 Corners—Cold-worked bars will have practically exact

angles and sharp corners.

7.1 Diameter, Thickness, or Width—The permissible varia-

tions from the specified dimensions as measured on the

7.4 Machining Allowances for Hot-Worked Materials—

diameter or between parallel surfaces of cold-worked rod and

When the surfaces of hot-worked products are to be machined,

barshallbeasprescribedinTable3,andofhot-workedrodand

the allowances prescribed in Table 5 are recommended for

bar as prescribed in Table 4.

normal machining operations.

7.2 Out-of-Round—Hot-worked rods and cold-worked rods 7.5 Length—The permissible variations in length of cold-

(except“forgingquality”)allsizes,instraightlengths,shallnot

worked and hot-worked rod and bar shall be as prescribed in

be out-of-round by more than one half the total permissible Table 6.

B425−11 (2017)

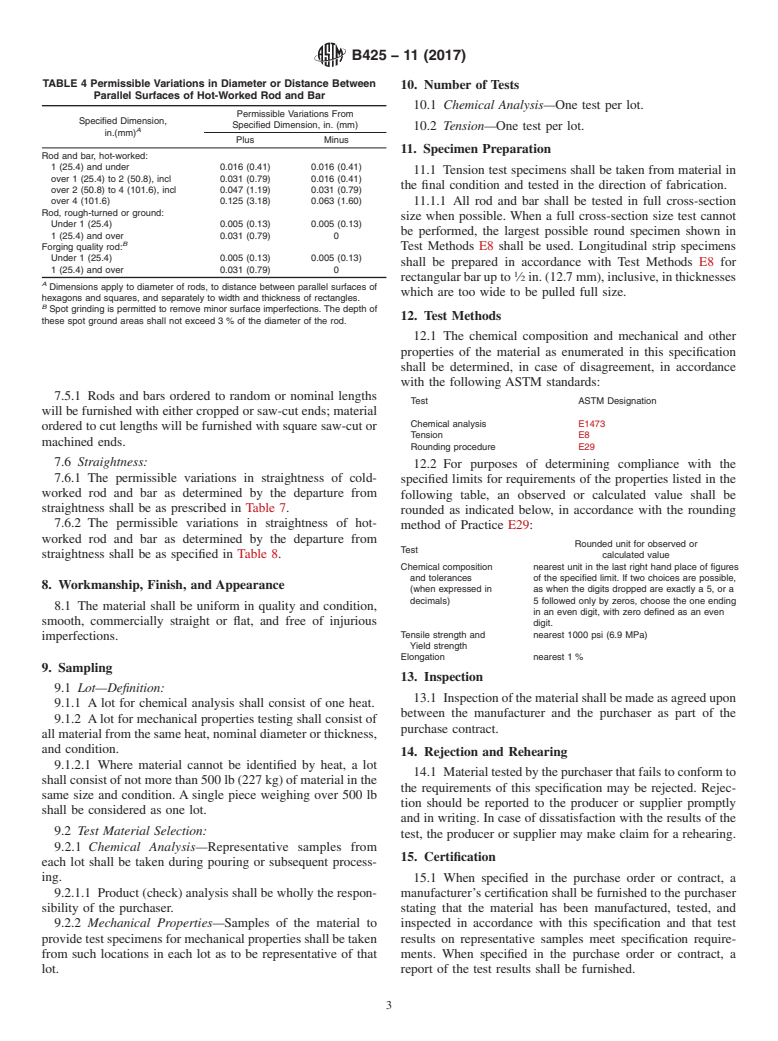

TABLE 4 Permissible Variations in Diameter or Distance Between

10. Number of Tests

Parallel Surfaces of Hot-Worked Rod and Bar

10.1 Chemical Analysis—One test per lot.

Permissible Variations From

Specified Dimension,

Specified Dimension, in. (mm)

10.2 Tension—One test per lot.

A

in.(mm)

Plus Minus

11. Specimen Preparation

Rod and bar, hot-worked:

1 (25.4) and under 0.016 (0.41) 0.016 (0.41)

11.1 Tension test specimens shall be taken from material in

over 1 (25.4) to 2 (50.8), incl 0.031 (0.79) 0.016 (0.41)

the final condition and tested in the direction of fabrication.

over 2 (50.8) to 4 (101.6), incl 0.047 (1.19) 0.031 (0.79)

over 4 (101.6) 0.125 (3.18) 0.063 (1.60) 11.1.1 All rod and bar shall be tested in full cross-section

Rod, rough-turned or ground:

size when possible. When a full cross-section size test cannot

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

be performed, the largest possible round specimen shown in

1 (25.4) and over 0.031 (0.79) 0

B

Forging quality rod:

Test Methods E8 shall be used. Longitudinal strip specimens

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

shall be prepared in accordance with Test Methods E8 for

1 (25.4) and over 0.031 (0.79) 0

rectangularbarupto ⁄2in.(12.7mm),inclusive,inthicknesses

A

Dimensions apply to diameter of rods, to distance between parallel surfaces of

which are too wide to be pulled full size.

hexagons and squares, and separately to width and thickness of rectangles.

B

Spot grinding is permitted to remove minor surface imperfections. The depth of

12. Test Methods

these spot ground areas shall not exceed 3 % of the diameter of the rod.

12.1 The chemical composition and mechanical and other

properties of the material as enumerated in this specification

shall be determined, in case of disagreement, in accordance

with the following ASTM standards:

7.5.1 Rods and bars ordered to random or nominal lengths

Test ASTM Designation

will be furnished with either cropped or saw-cut ends; material

Chemical analysis E1473

ordered to cut lengths will be furnished with square saw-cut or

Tension E8

machined ends.

Rounding procedure E29

7.6 Straightness:

12.2 For purpo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B425 − 11 B425 − 11 (Reapproved 2017)

Standard Specification for

Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825, UNS N08221, and

UNS N06845) Rod and Bar

This standard is issued under the fixed designation B425; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers nickel-iron-chromium-molybdenum-copper alloy (UNS N08825, UNS N08221, and UNS

N06845) in the form of hot-finished and cold-drawn rounds, squares, hexagons, and rectangles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 12, of this specification: This standard

does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this

standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet

(MSDS)(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety safety, health, and

healthenvironmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B424 Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825, UNS N08221, and UNS N06845) Plate, Sheet, and Strip

B880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E1473 Test Methods for Chemical Analysis of Nickel, Cobalt and High-Temperature Alloys

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bar, n—material of rectangular (flats), hexagonal, or square solid section up to and including 10 in. (254 mm) in width

and ⁄8 in. (3.2 mm) and over in thickness in straight lengths.

3.1.1.1 Discussion—

Hot-worked rectangular bar in widths 10 in. (254 mm) and under may be furnished as hot-rolled plate with sheared or cut edges

in accordance with Specification B424, provided the mechanical property requirements of this specification are met.

3.1.2 rod, n—material of round solid section furnished in straight lengths.

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Oct. 1, 2011Nov. 1, 2017. Published November 2011November 2017. Originally approved in 1964. Last previous edition approved in 20092011

as B425 – 99 (2009).B425 – 11. DOI: 10.1520/B0425-11.10.1520/B0425-11R17.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-425 in Section II of that code.

New designation established in accordance with Practice E527 and SAE J 1086, Practice for Numbering Metals and Alloys (UNS).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B425 − 11 (2017)

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for the safe and satisfactory

performance of material ordered under this specification. Examples of such requirements include, but are not limited to, the

following:

4.1.1 ASTM designation and date of issue,

4.1.2 UNS number,

4.1.3 Section—Rod (round) or bar (square, hexagonal, or rectangular),

4.1.4 Dimensions, including length,

4.1.5 Condition (see Appendix X1),

4.1.6 Finish (see Appendix X1),

4.1.7 Quantity—Feet (or metres) or number of pieces,

4.1.8 Certification—State if certification is required (Section 15),

4.1.9 Samples for Product (Check) Analysis—State whether samples for product (check) analysis should be furnished (see 5.2),

and

4.1.10 Purchaser Inspection—If purchaser wishes to witness tests or inspection of material at place of manufacture, the

purchase order must so state, indicating which test or inspections are to be witnessed (Section 13).

5. Chemical Composition

5.1 The material shall conform to the composition limits specified in Table 1.

5.2 If a product (check) analysis is performed by the purchaser, it shall be done in accordance with Specification B880 and the

material shall conform to the product (check) analysis variations defined in Table 1 of Specification B880.

6. Mechanical Properties and Other Requirements

6.1 Mechanical Properties—The material shall conform to the mechanical properties specified in Table 2.

7. Dimensions and Permissible Variations

7.1 Diameter, Thickness, or Width—The permissible variations from the specified dimensions as measured on the diameter or

between parallel surfaces of cold-worked rod and bar shall be as prescribed in Table 3, and of hot-worked rod and bar as prescribed

in Table 4.

7.2 Out-of-Round—Hot-worked rods and cold-worked rods (except “forging quality”) all sizes, in straight lengths, shall not be

out-of-round by more than one half the total permissible variations in diameter shown in Table 3 and Table 4, except for

hot-worked rods ⁄2 in. (12.7 mm) in diameter and under, which may be out-of-round by the total permissible variations in diameter

shown in Table 4.

7.3 Corners—Cold-worked bars will have practically exact angles and sharp corners.

7.4 Machining Allowances for Hot-Worked Materials—When the surfaces of hot-worked products are to be machined, the

allowances prescribed in Table 5 are recommended for normal machining operations.

7.5 Length—The permissible variations in length of cold-worked and hot-worked rod and bar shall be as prescribed in Table

6.

7.5.1 Rods and bars ordered to random or nominal lengths will be furnished with either cropped or saw-cut ends; material

ordered to cut lengths will be furnished with square saw-cut or machined ends.

A

TABLE 1 Chemical Requirements

Element UNS N08825 UNS N08221 UNS N06845

Nickel 38.0–46.0 39.0–46.0 44.0–50.0

Chromium 19.5–23.5 20.0–22.0 20.0–25.0

B

Iron 22.0 min balance balance

Manganese 1.0 1.0 0.5

Carbon 0.05 0.025 0.05

Copper 1.5–3.0 1.5–3.0 2.0–2.4

Silicon 0.5 0.5 0.5

Sulfur 0.03 0.03 0.010

Aluminum 0.2 0.2 .

Titanium 0.6–1.2 0.6–1.0 .

Molybdenum 2.5–3.5 5.0–6.5 5.0–7.0

Tungsten . . 2.0–5.0

A

Maximum unless range or minimum is given. Where ellipses (.) appear in this table, there is no requirement and analysis for the element need not be determined or

reported.

B

Element shall be determined arithmetically by difference.

B425 − 11 (2017)

TABLE 2 Mechanical Properties (Rod and Bar)

Yield Strength Elongation in 2

Tensile Strength

Alloy Condition 0.2 % offset, min, in. or 50 mm or

min, ksi (MPa)

D

ksi (MPa) 4 , min,%

A

UNS N08825 Annealed: 85 (586) 35 (241) 30

Hot-finished, cold–drawn

B B B

Forging Quality:

UNS N08221 All sizes annealed 79 (544) 34 (235) 30

UNS N06845 All sizes annealed 100 (690) 40 (276) 30

A

Not applicable to diameters or cross sections under ⁄32 in. (2.4 mm).

B

Forging quality is furnished to chemical requirements and surface inspection only. No tensile properties are required.

TABLE 3 Permissible Variations in Diameter or Distance Between

Parallel Surfaces of Cold-Worked Rod and Bar

Permissible Variations From

Specified Dimension,

Specified Dimension, in. (mm)

in.

A

(mm)

Plus Minus

Rounds: 0

1 3

⁄16 (1.6) to ⁄16 (4.8), excl 0.002 (0.05)

3 1

⁄16 (4.8) to ⁄2 (12.7), excl 0 0.003 (0.08)

1 15

⁄2 (12.7) to ⁄16 (23.8), incl 0.001 (0.03) 0.002 (0.05)

15 15

Over ⁄16 (23.8) to 1 ⁄16 (49.2), incl 0.0015 (0.04) 0.003 (0.08)

15 1

Over 1 ⁄16 (49.2) to 2 ⁄2 (63.5), incl 0.002 (0.05) 0.004 (0.10)

Hexagons, squares, rectangles:

⁄2 (12.7) and less 0 0.004 (0.10)

1 7

Over ⁄2 (12.7) to ⁄8 (22.2), incl 0 0.005 (0.13)

7 1

Over ⁄8 (22.2) to 1 ⁄4 (31.8), incl 0 0.007 (0.18)

Over 1 ⁄4 (31.8) to 2 (50.8), incl 0 0.009 (0.23)

A

Dimensions apply to diameter of rounds, to distance between parallel surfaces of

hexagons and squares, and separately to width and thickness of rectangles.

TABLE 4 Permissible Variations in Diameter or Distance Between

Parallel Surfaces of Hot-Worked Rod and Bar

Permissible Variations From

Specified Dimension,

Specified Dimension, in. (mm)

in.in.(mm)

A

(mm)

Plus Minus

Rod and bar, hot-worked:

1 (25.4) and under 0.016 (0.41) 0.016 (0.41)

over 1 (25.4) to 2 (50.8), incl 0.031 (0.79) 0.016 (0.41)

over 2 (50.8) to 4 (101.6), incl 0.047 (1.19) 0.031 (0.79)

over 4 (101.6) 0.125 (3.18) 0.063 (1.60)

Rod, rough-turned or ground:

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

1 (25.4) and over 0.031 (0.79) 0

B

Forging quality rod:

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

1 (25.4) and over 0.031 (0.79) 0

A

Dimensions apply to diameter of rods, to distance between parallel surfaces of

hexagons and squares, and separately to width and thickness of rectangles.

B

Spot grinding is permitted to remove minor surface imperfections. The depth of

these spot ground areas shall not exceed 3 % of the diameter of the rod.

7.6 Straightness:

7.6.1 The permissible variations in straightness of cold-worked rod and bar as determined by the departure from straightness

shall be as prescribed in Table 7.

7.6.2 The permissible variations in straightness of hot-worked rod and bar as determined by the departure from straightness shall

be as specified in Table 8.

8. Workmanship, Finish, and Appearance

8.1 The material shall be uniform in quality and condition, smooth, commercially straight or flat, and free of injurious

imperfections.

9. Sampling

9.1 Lot—Lot—Definition: Definition :

9.1.1 A lot for chemical analysis shall consist of one heat.

B425 − 11 (2017)

TABLE 5 Normal Machining Allowances for Hot-Worked Material

Normal Machining Allowance, in. (mm)

Finished-Machined Dimensions

Distance Between

For Rectangular Bar

for Finishes As Indicated Below,

On Diameter, Parallel Surfaces,

A

in. (mm)

for Rods for Hexagonal

On Thickness On Width

and Square Bars

B

Hot-worked:

7 1 1 1 3

Up to ⁄8 (22.2), incl ⁄8 (3.2) ⁄8 (3.2) ⁄8 (3.2) ⁄16 (4.8)

7 7 1 3 1 3

Over ⁄8 to 1 ⁄8 (22.2 to 47.6), incl ⁄8 (3.2) ⁄16 (4.8) ⁄8 (3.2) ⁄16 (4.8)

7 7 3 1 3

Over 1 ⁄8 to 2 ⁄8 (47.6 to 73.0), incl. ⁄16 (4.8) ⁄4 (6.4) . ⁄16 (4.8)

7 13 1 3

Over 2 ⁄8 to 3 ⁄16 (73.0 to 96.8), incl ⁄4 (6.4) . . ⁄16 (4.8)

13 1 3

Over 3 ⁄16 (96.8) ⁄4 (6.4) . . ⁄8 (9.5)

C

Hot-worked rods, rough-turned or rough ground:

15 1

⁄16 to 4 (23.8 to 101.6), incl in diameter ⁄16 (1.6) . . .

Over 4 to 12 (101.6 to 304.8), incl in diameter ⁄8 (3.2) . . .

A

Dimensions apply to diameter of rods, to distance between parallel surfaces of hexagonal and square bar, and separately to width and thickness of rectangular bar.

B

The allowances for hot-worked material in Table 5 are recommended for rods machined in lengths of 3 ft (0.91 m) or less and for bars machined in lengths of 2 ft (0.61

m) or less. Hot-worked material to be machined in longer lengths should be specified showing the finished cross-sectional dimension and the length in which the material

will be machined in order that the manufacturer may supply material with sufficient oversize, including allowance for out-of-straightness.

C

Applicable to 3 ft (0.91 m) max length.

TABLE 6 Permissible Variations in Length of Rods and Bars

Random mill lengths:

Random mill lengths:

Hot-worked 6 to 24 ft (1.83 to 7.31 m) long with not

more than 25 weight % between 6 and

A

9 ft (1.83 and 2.74 m)

Cold-worked 6 to 20 ft (1.83 to 6.1 m) long with not

more than 25 weight % between 6 and

10 ft (1.83 and 3.05 m).

Multiple lengths Furnished in multiples of a specified unit

length, within the length limits indicated

above. For each multiple, an allowance

of ⁄4 in. (6.4 mm) will be made for cutting,

unless otherwise specified. At the

manufacturer’s option, individual specified

unit lengths may be furnished.

Multiple lengths Furnished in multiples of a specified unit

length, within the length limits indicated

above. For each multiple, an allowance

of ⁄4 in. (6.4 mm) will be made for cutting,

unless otherwise specified. At the

manufacturer’s option, individual specified

unit lengths may be furnished.

Nominal lengths Specified nominal lengths having a range

of not less than 2 ft (610 mm) with no

B

short lengths allowed.

Cut lengths A specified length to which all rods and

bars will be cut with a permissible

variation of plus ⁄8 in. (3.2 mm), minus

0 for sizes 8 in. (203 mm) and less in

diameter or distance between parallel

surfaces. For larger sizes, the permissible

variation shall be + ⁄4 in. (6.4 mm), − 0.

A

For hot-worked sections weighing over 25 lb/ft (37 kg/m) and for smooth forged

products, all sections, short lengths down to 2 ft (610 mm) may be furnished.

B

For cold-worked rods and bars under ⁄2 in. (12.7 mm) in diameter or distance

between parallel surfaces ordered to nominal or stock lengths with a 2-ft (610-mm)

range, at least 93 % of such material shall be within the range specified; the

balance may be in shorter lengths but in no case shall lengths less than 4 ft (1220

mm) be furnished.

9.1.2 A lot for mechanical properties testing shall consist of all material from the same heat, nominal diameter or thickness, and

condition.

9.1.2.1 Where material cannot be identified by heat, a lot shall consist of not more than 500 lb (227 kg) of material in the same

size and condition. A single piece weighing over 500 lb shall be considered as one lot.

9.2 Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.