ASTM D4622-86(1993)

(Test Method)Standard Test Method for Rock Mass Monitoring Using Inclinometers (Withdrawn 2000)

Standard Test Method for Rock Mass Monitoring Using Inclinometers (Withdrawn 2000)

SCOPE

1.1 This test method describes the use of inclinometers for rock mass monitoring, lists some available instruments, outlines operating techniques and maintenance requirements, and presents data reduction formulas.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4622 – 86 (Reapproved 1993)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Rock Mass Monitoring Using Inclinometers

This standard is issued under the fixed designation D 4622; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ers’ specifications to determine the limitations of the particular

instrument being used.) Extend the hole at least 15 ft (4.5 m)

1.1 This test method describes the use of inclinometers for

beyond the zone of expected movement into soil or rock in

rock mass monitoring, lists some available instruments, out-

which no movement is anticipated. Make allowance for loss of

lines operating techniques and maintenance requirements, and

the bottom 5 ft (1.5 m) of the hole where sediment accumula-

presents data reduction formulas.

tion may occur. Hold casing in place with a sand backfill or a

1.2 This standard does not purport to address all of the

weak cement grout. Check casings over 50 ft (15 m) deep for

safety problems, if any, associated with its use. It is the

twist (spiraling of the interior grooves) using commercially

responsibility of the user of this standard to establish appro-

available equipment, since some of the casings may be

priate safety and health practices and determine the applica-

received with a built-in twist which would cause considerable

bility of regulatory limitations prior to use.

error in observations.

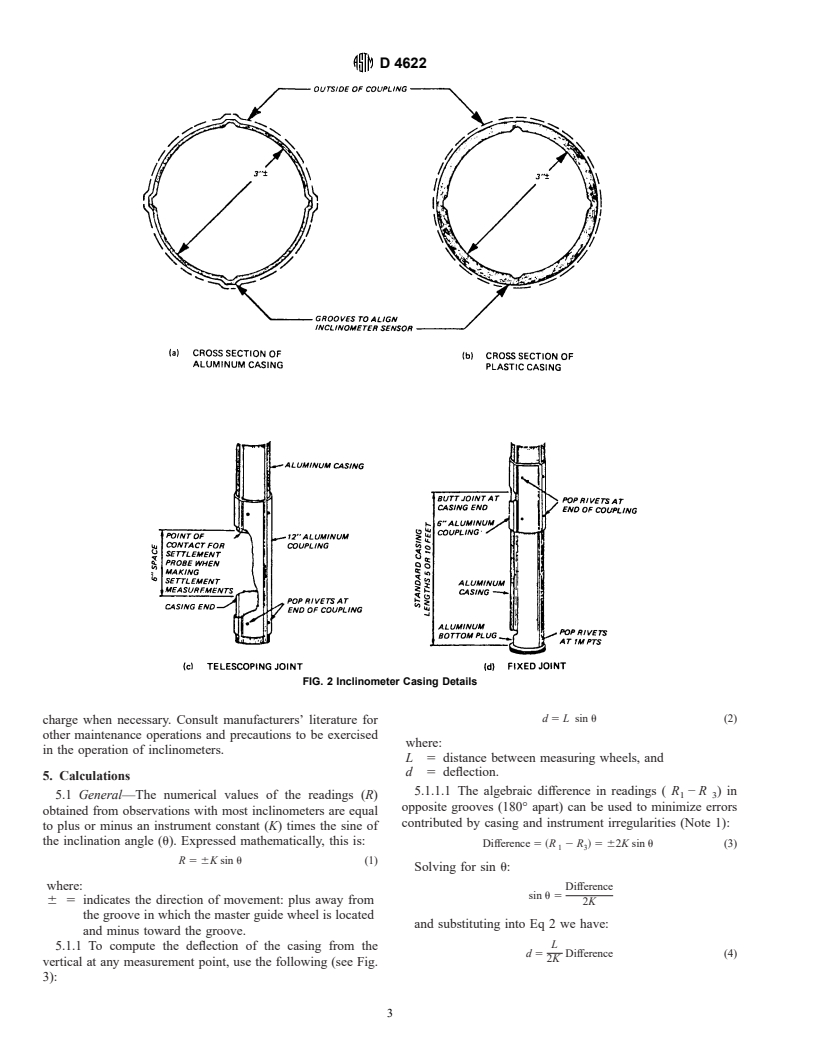

2. Significance and Use 4.1.2 Inclinometer casings are commonly installed in either

5 or 10-ft (1.5 or 3.0-m) lengths and are available in either

2.1 An inclinometer is a device for measuring the deviations

plastic or aluminum. Plastic casing joints are glued. Aluminum

perpendicular to the axis of a borehole. Deviations can be

casings are coupled with aluminum couplings and riveted (see

converted to displacements by trigonometric functions. Suc-

Fig. 2). Complete the installed casing using left and right twist

cessive measurements enable the determination of the depth,

in a compensating manner so that the grooves generally are in

magnitude, and rate of lateral movement of an unstable slope.

the same azimuth from top to bottom. For casings over 50 ft

3. Apparatus

(15 m), consider metal saddles with steel cable support for

reducing twisting. Take care to ensure that all joints are sealed

3.1 Probe-Type Inclinometer—Many types of inclinometers

since leakage can introduce fines into grooves and cause errors

are available; however, the most commonly used is the probe

in readings or plug the casings. Joints can be sealed with

type. This type consists of a control box and a probe attached

caulking and taped. Greater installation details can be obtained

to a cable which is lowered into a flexible casing in a borehole.

from manufacturers’ literature or from other sources.

In some probes, a cantilevered pendulum with resistance strain

4.1.3 Whether to use plastic or aluminum casing depends on

gages, vibrating wire, or inductive transducers is used to

the situation and the method used. Plastic casing can be

measure cantilever deflection. Other probes use the Wheat-

damaged if exposed to sunlight.

stone bridge principle, the servo accelerometer principle, or a

4.2 Observations:

differential transformer. The probe generally requires a special

4.2.1 Make initial observations after allowing sufficient time

flexible casing with four interior grooves spaced at 90°. The

for the grout around the casing to set or for the backfill to settle

electrical output from the probe is measured at the control box

where sand or gravel is used. Since computation of all

and converted to visual display, punched or magnetic tape, or

displacements is based on the position of the casing when

graphic form. Fig. 1 shows a typical inclinometer installation.

installed, verify the initial casing position with at least two

4. Procedure

separate sets of observations. Check these observations closely

to see that they agree within the accuracy of the inclinometer

4.1 Installation:

being used. Repeat observations until satisfactory agreement is

4.1.1 Install the inclinometer casing in a near-vertical hole

obtained. When initial observations are made, the top of the

that intersects the zone of suspected movement. (Measure-

casing should be located with respect to a point on the ground

ments in non-vertical holes can be made with some inclinom-

surface which is outside the zone of expected movement by

eters; however, before planning such holes, check manufactur-

conventional surveying means and its elevation determined.

4.2.2 The frequency of observations depends upon several

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

factors, the most important of which is the rate of movement.

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

Mechanics.

It is necessary to read inclinometers frequently just after

Current edition approved Oct. 31, 1986. Published December 1986.

installation and, based on these results, to adjust the interval of

For additional information see the Rock Testing Handbook, U.S. Corps of

observations. Observations should coincide with observations

Engineers, Waterways Experiment Station, Vicksburg, MI, 1978.

D 4622

FIG. 1 Typical Inclinometer Installation

of other instrumentation, such as extensometers, piezometers, readings to the top of the hole. Repeat this procedure until four

settlement devices, precipitation gages, movement surveys, sets of readings are obtained; two readings for each pair of

and the like. grooves. Make a field check by comparing the value of the sum

4.2.3 The procedure for obtaining readings with various of each set of readings (opposite grooves) and the mean of all

inclinometers may vary slightly; consult manufacturers’ litera- sets of readings for the length of the casing. When variations

ture for the current procedure for a particular instrument. greater than specified by the manufacturer are found, relocate

However, the general procedure consists of lowering the the inclinometer at that depth and take an additional reading.

inclinometer to the bottom of the borehole and beginning the Take care to ensure that readings are obtained at the same

readings, always ensuring that the inclinometer is lowered to depths eac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.