ASTM A1006/A1006M-00

(Specification)Standard Specification for Steel Line Pipe, Black, Plain End, Laser Beam Welded

Standard Specification for Steel Line Pipe, Black, Plain End, Laser Beam Welded

SCOPE

1.1 This specification covers laser beam welded, black, plain end steel pipe for use in the conveyance of fluids under pressure. Pipe in sizes NPS 1 to 26, inclusive, with nominal wall thickness 0.750 in. [19.1 mm] or less, as given in , is included. Pipe having other dimensions, in this size range, may be furnished provided such pipe complies with all other requirements of this specification.

1.2 It is intended that the pipe be capable of being circumferentially welded in the field when welding procedures in accordance with the requirements of the applicable pipeline construction code are used.

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values in each system are not exact equivalents: therefore, each system is to be used independently of the other, without combining values in any way.

The following precautionary statement pertains to the test method portion, Section , of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 1006/A 1006M – 00

Standard Specification for

Steel Line Pipe, Black, Plain End, Laser Beam Welded

This standard is issued under the fixed designation A 1006/A 1006M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

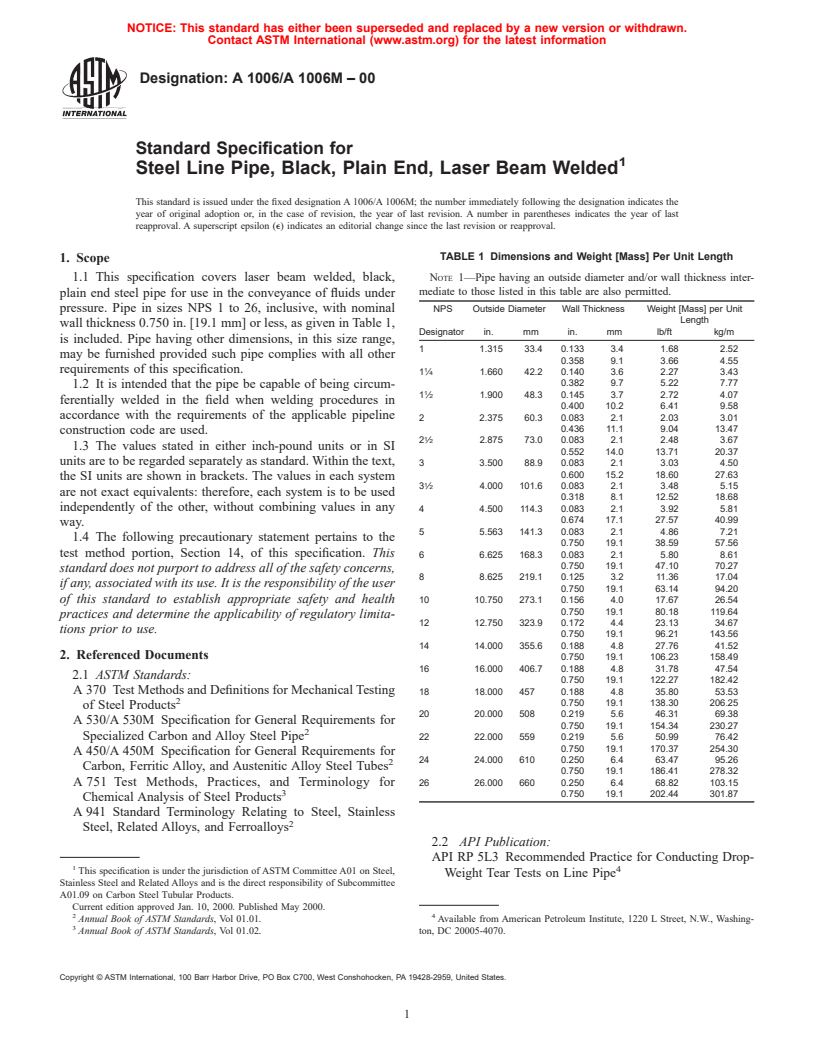

TABLE 1 Dimensions and Weight [Mass] Per Unit Length

1. Scope

1.1 This specification covers laser beam welded, black, NOTE 1—Pipe having an outside diameter and/or wall thickness inter-

mediate to those listed in this table are also permitted.

plain end steel pipe for use in the conveyance of fluids under

pressure. Pipe in sizes NPS 1 to 26, inclusive, with nominal NPS Outside Diameter Wall Thickness Weight [Mass] per Unit

Length

wall thickness 0.750 in. [19.1 mm] or less, as given in Table 1,

Designator in. mm in. mm lb/ft kg/m

is included. Pipe having other dimensions, in this size range,

1 1.315 33.4 0.133 3.4 1.68 2.52

may be furnished provided such pipe complies with all other

0.358 9.1 3.66 4.55

requirements of this specification. 1

1 ⁄4 1.660 42.2 0.140 3.6 2.27 3.43

0.382 9.7 5.22 7.77

1.2 It is intended that the pipe be capable of being circum-

1 ⁄2 1.900 48.3 0.145 3.7 2.72 4.07

ferentially welded in the field when welding procedures in

0.400 10.2 6.41 9.58

accordance with the requirements of the applicable pipeline

2 2.375 60.3 0.083 2.1 2.03 3.01

0.436 11.1 9.04 13.47

construction code are used.

2 ⁄2 2.875 73.0 0.083 2.1 2.48 3.67

1.3 The values stated in either inch-pound units or in SI

0.552 14.0 13.71 20.37

units are to be regarded separately as standard. Within the text,

3 3.500 88.9 0.083 2.1 3.03 4.50

0.600 15.2 18.60 27.63

the SI units are shown in brackets. The values in each system

3 ⁄2 4.000 101.6 0.083 2.1 3.48 5.15

are not exact equivalents: therefore, each system is to be used

0.318 8.1 12.52 18.68

independently of the other, without combining values in any 4 4.500 114.3 0.083 2.1 3.92 5.81

0.674 17.1 27.57 40.99

way.

5 5.563 141.3 0.083 2.1 4.86 7.21

1.4 The following precautionary statement pertains to the

0.750 19.1 38.59 57.56

test method portion, Section 14, of this specification. This

6 6.625 168.3 0.083 2.1 5.80 8.61

0.750 19.1 47.10 70.27

standard does not purport to address all of the safety concerns,

8 8.625 219.1 0.125 3.2 11.36 17.04

if any, associated with its use. It is the responsibility of the user

0.750 19.1 63.14 94.20

of this standard to establish appropriate safety and health 10 10.750 273.1 0.156 4.0 17.67 26.54

0.750 19.1 80.18 119.64

practices and determine the applicability of regulatory limita-

12 12.750 323.9 0.172 4.4 23.13 34.67

tions prior to use.

0.750 19.1 96.21 143.56

14 14.000 355.6 0.188 4.8 27.76 41.52

2. Referenced Documents

0.750 19.1 106.23 158.49

16 16.000 406.7 0.188 4.8 31.78 47.54

2.1 ASTM Standards:

0.750 19.1 122.27 182.42

A 370 Test Methods and Definitions for Mechanical Testing 18 18.000 457 0.188 4.8 35.80 53.53

0.750 19.1 138.30 206.25

of Steel Products

20 20.000 508 0.219 5.6 46.31 69.38

A 530/A 530M Specification for General Requirements for

0.750 19.1 154.34 230.27

Specialized Carbon and Alloy Steel Pipe

22 22.000 559 0.219 5.6 50.99 76.42

0.750 19.1 170.37 254.30

A 450/A 450M Specification for General Requirements for

24 24.000 610 0.250 6.4 63.47 95.26

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

0.750 19.1 186.41 278.32

A 751 Test Methods, Practices, and Terminology for 26 26.000 660 0.250 6.4 68.82 103.15

0.750 19.1 202.44 301.87

Chemical Analysis of Steel Products

A 941 Standard Terminology Relating to Steel, Stainless

Steel, Related Alloys, and Ferroalloys

2.2 API Publication:

API RP 5L3 Recommended Practice for Conducting Drop-

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Weight Tear Tests on Line Pipe

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved Jan. 10, 2000. Published May 2000.

2 4

Annual Book of ASTM Standards, Vol 01.01. Available from American Petroleum Institute, 1220 L Street, N.W., Washing-

Annual Book of ASTM Standards, Vol 01.02. ton, DC 20005-4070.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 1006/A 1006M

2.3 ASME Standard: 6.2 The internal and external weld protrusion resulting from

ASME Boiler and Pressure Vessel Code, Section IX, Weld- the welding process shall be removed, in accordance with the

ing and Brazing Qualifications requirements of 18.1 and 18.2.

6.3 The weld seam and its heat affected zone shall receive

3. Terminology

either a normalizing heat treatment or a continuous in-line heat

treatment in such a manner that no untempered martensite

3.1 Definitions of Terms Specific to This Standard:

remains. Complete penetration and coverage of the weld and

3.1.1 laser beam welding, n—a welding process that utilizes

the weld heat affected zone by this heat treatment shall be

a laser beam to produce melting of full thickness of edges to be

confirmed by periodic metallographic examination of weld

welded, followed by the fusion of those edges.

area cross-section specimens at least once per working shift.

3.1.2 specified outside diameter, n—the outside diameter

shown in the purchase order or in Table 1 for the applicable

7. Chemical Composition

NPS size.

7.1 The steel shall contain no more than 0.22 % carbon,

3.2 Definitions—For definitions of other terms used in this

0.015 % sulfur, and 0.025 % phosphorus, by heat and product

specification, refer to Terminology A 941.

analyses.

7.2 The steel shall contain no more than 0.0007 % boron, by

TABLE 2 Tensile Requirements

heat analysis.

A A

Grade Yield Strength, Yield Strength, Tensile Strength, 7.3 The carbon equivalent (CE) value for each heat shall not

min. max. min.

exceed 0.40 %, calculated using the product analyses and the

psi MPa psi MPa psi MPa

following equation:

35 35 000 240 65 000 450 60 000 415

Mn Si Cu Ni Cr 1 Mo 1 V 1 Cb

50 50 000 345 77 000 530 70 000 485

CE 5 C 1 F 1 1 1 1 (1)

F G

6 24 15 20 5

60 60 000 415 80 000 550 75 000 515

70 70 000 485 87 000 600 80 000 550

where:

80 80 000 550 97 000 670 90 000 620

F = a compliance factor that is dependent upon the carbon

A

Yield strength requirements are not applicable for transverse weld tests.

content, as shown below:

Carbon Content, % F Carbon Content, % F

<0.06 0.53 0.14 0.85

4. Ordering Information

0.06 0.54 0.15 0.88

0.07 0.56 0.16 0.92

4.1 Information items to be considered, if appropriate, for

0.08 0.58 0.17 0.94

inclusion in the purchase order are as follows:

0.09 0.62 0.18 0.96

0.10 0.66 0.19 0.97

4.1.1 Specification designation and year of issue,

0.11 0.70 0.20 0.98

4.1.2 Quantity (feet or metres),

0.12 0.75 0.21 0.99

4.1.3 Grades (see Table 2 or 8.6),

0.13 0.80 0.22 1.00

4.1.4 Size, either nominal (NPS) or outside diameter and

7.4 A heat analysis shall be made for each heat of steel

wall thickness,

furnished under this specification.

4.1.5 Nominal length (see 16.3),

7.5 Product analyses shall be made on at least two samples

4.1.6 End finish (plain end beveled or special, see 17.1),

from each heat of steel.

4.1.7 Bar coding (see 20.3),

7.6 All analyses shall be in accordance with Test Methods,

4.1.8 Special requirements, and

Practices, and Terminology A 751, and shall include all ele-

4.1.9 Supplementary requirements.

ments required in the carbon equivalent equation of 7.3, in

addition to titanium, phosphorus, sulfur, and boron, except that

5. General Requirements

the product analysis for boron is not required. Titanium is

5.1 Pipe furnished under this specification shall conform to

reported for information only and is not a cause for rejection.

the applicable requirements of Specification A 530/A 530M

7.7 If one or both of the product analyses representing a heat

unless otherwise provided herein.

fails to conform to the specified requirements, the heat shall be

rejected, or two additional analyses shall be made on the

6. Materials and Manufacture

sample that failed, each of which shall conform to the specified

6.1 Pipe shall be welded from one side by the laser beam

requirements.

welding process using a single pass with an appropriate

8. Tensile Property Requirements

shielding gas. The pipe shall have one longitudinal seam. The

weld shall be made in accordance with a qualified welding

8.1 The material shall conform to the requirements for

procedure as specified in ASME Boiler and Pressure Vessel

tensile properties given in Table 2 and in 8.6. The yield strength

Code, Section IX, Paragraph QW-264. The edges may be

maxima apply only to pipe NPS 8 and larger.

preheated.

8.2 The yield strength corresponding to a total extension

under load of 0.5 % of the gage length shall be determined.

8.3 A test specimen taken across the weld shall show a

tensile strength not less than the minimum tensile strength

Available from ASME International, Three Park Avenue, New York, NY

10016-5990. specified for the grade of pipe required. Test specimens shall

A 1006/A 1006M

exhibit at least 10 % elongation in 2 in. [50 mm]. This test is test specimens as required when the absorbed energy is

not required for pipe under NPS 8. expected to exceed 80 % of the full scale capacity of the testing

machine.

8.4 Transverse tension tests shall be performed on NPS 8

9.3 The minimum average absorbed energy of pipe body for

and larger and the specimens shall be taken opposite the weld.

any Charpy V-notch test shall be calculated from the equation

All transverse test specimens shall be approximately 1 ⁄2 in.

given below for pipe NPS 5 through NPS 26. Values calculated

[38 mm] wide in the gage length and shall represent the full

wall thickness of the pipe from which the specimen was cut. by this equation as less than 30 ft-lbf [40 J] shall be taken as

30 ft-lbf [40 J] minimum average.

8.5 For pipe smaller than NPS 8, longitudinal tests shall be

1.5

performed. Such tests shall be either strip specimens taken

CV ~fullsize!5 C 3 D 3 S (3)

=

approximately 90° from the weld or full section specimens, at

where:

the option of the manufacturer.

CV = minimum average value required, ft-lbf [J],

8.6 Grades intermediate to those shown in Table 2 may be

C = 0.024 [0.000 354],

furnished. For such grades, the permissible yield strength range

D = specified outside diameter, in. [mm], and

shall be as given in Table 2 for the next higher grade, and the

S = 0.72 3 specified minimum yield strength, ksi [MPa].

required minimum tensile strength shall exceed the required

NOTE 1—Charpy testing is not required on any pipe smaller than NPS

minimum yield strength by the same amount as is given in

5 or for pipe NPS 5 or larger with insufficient specified wall thickness to

Table 2 for the next higher grade.

permit at least ⁄2 size specimens to be obtained.

8.7 The minimum elongation in 2 in. [50 mm] for all grades

shall be determined by the following equation:

9.4 When subsize specimens are used, the minimum aver-

0.2 age absorbed energy shall be that specified for full size

A

e 5 C (2)

specimens multiplied by 0.67 (for ⁄3 size specimens) or 0.50

0.9

U

(for ⁄2 size specimens), rounded to the nearest whole number.

where: 9.5 Testing shall be conducted at a test temperature of 32°F

e = minimum elongation in 2 in. [50 mm], percent, [0°C], or lower.

rounded to the nearest percent, 9.6 For pipe body tests, each Charpy specimen shall exhibit

C = 625 000 [1940],

at least 75 % shear area.

2 2

A = the lesser of 0.75 in [485 mm ] and the cross-

sectional area of the tensile test specimen, based on

10. Weld Ductility Test

the specified outside diameter or the nominal speci-

10.1 Flattening Test—The flattening test shall be conducted

men width and the specified wall thickness, rounded

by tests on full section specimens of 2 in. [50 mm] minimum

2 2

to the nearest 0.01 in [1 mm ], and

length. The specimens shall be flattened cold between parallel

U = specified minimum tensile strength, psi [MPa].

plates. The weld shall be placed at 90° and at 0° from the

direction of applied force. No crack or breaks exceeding ⁄8 in.

9. Charpy V-Notch Test

[3 mm] in any direction in the weld or in the parent metal shall

9.1 Pipe body test specimens shall be taken approximately

occur on the outside surface until the distance between the

90° from the weld.

plates is less than the value of H in the following equation,

9.2 The Charpy test specimens used shall be those given in except that cracks that occur at the edges of the specimen and

2 1 1

Table 3, except that it shall be permissible to use ⁄3 or ⁄2 size are less than ⁄4 in. [6 mm] long shall not be cause for rejection:

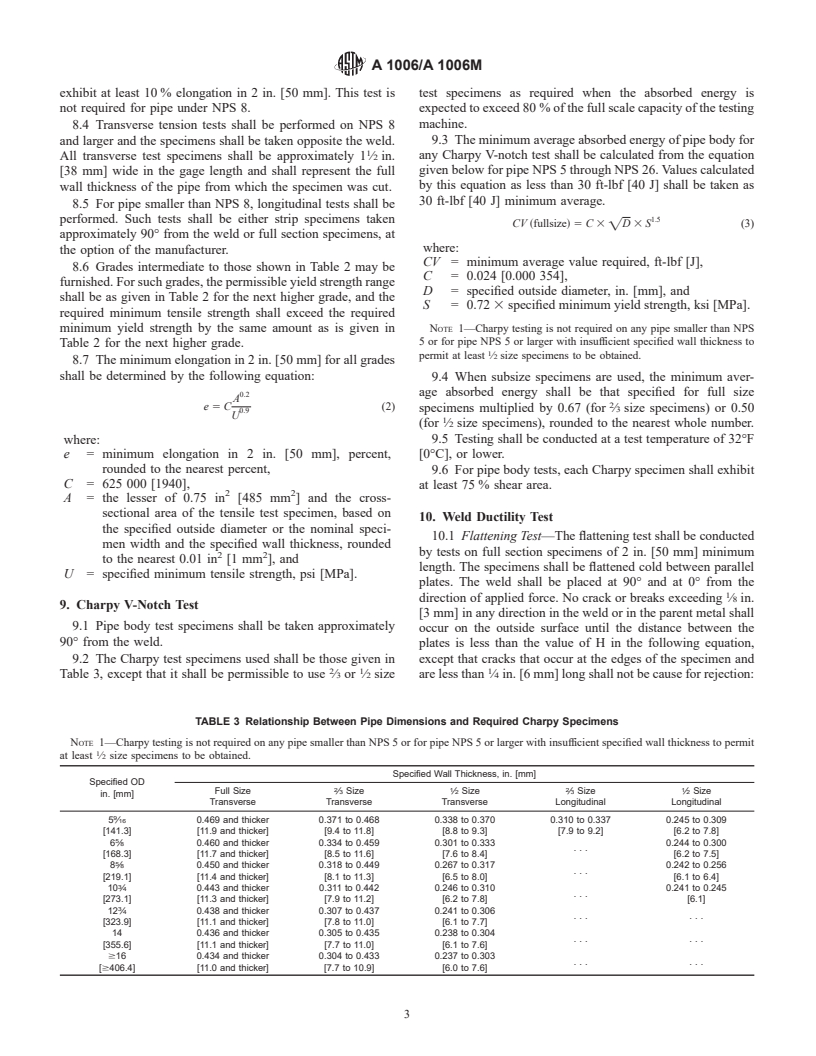

TABLE 3 Relationship Between Pipe Dimensions and Required Charpy Specimens

NOTE 1—Charpy testing is not required on any pipe smaller than NPS 5 or for pipe NPS 5 or larger with insufficient specified wall thickness to permit

at least ⁄2 size specimens to be obtained.

Specified Wall Thickness, in. [mm]

Specified OD

2 1 2 1

Full Size ⁄3 Size ⁄2 Size ⁄3 Size ⁄2 Size

in. [mm]

Transverse Transverse Transverse Longitudinal Longitudinal

5 ⁄16 0.469 and thicker 0.371 to 0.468 0.338 to 0.370 0.310 to 0.337 0.245 to 0.309

[141.3] [11.9 and thicker] [9.4 to 11.8] [8.8 to 9.3] [7.9 to 9.2] [6.2 to 7.8]

6 ⁄8 0.460 and thicker 0.334 to 0.459 0.301 to 0.333 0.244 to 0.300

...

[168.3] [11.7 and thicker] [8.5 to 11.6] [7.6 to 8.4] [6.2 to 7.5]

8 ⁄8 0.450 and thicker 0.318 to 0.449 0.267 to 0.317 0.242 to 0.256

...

[219.1] [11.4 and thicker] [8.1 to 11.3] [6.5 to 8.0] [6.1 to 6.4]

10 ⁄4 0.443 and thicker 0.311 to 0.442 0.246 to 0.310 0.241 to 0.245

...

[273.1] [11.3 and thicker] [7.9 to 11.2] [6.2 to 7.8] [6.1]

12 ⁄4 0.438 and thicker 0.307 to 0.437 0.241 to 0.306

... ...

[323.9] [11.1 and thicker] [7.8 to 11.0] [6.1 to 7.7]

14 0.436 and thicker 0.305 to 0.435 0.238 to 0.304

... ...

[355.6] [11.1 and thicker] [7.7 to 11.0] [6.1 to 7.6]

$16 0.434 and thicker 0.304 to 0.433 0.237 to 0.303

... ...

[$406.4] [11.0 and thicker] [7.7 to 10.9] [6.0 to 7.6]

A 1006/A 1006M

3.05 t

11.4 When computed test pressures are not an exact mul-

H 5 (4)

0.05 1 3 t/D!

~

tiple of 10 psi [100 kPa], they shall be rounded to the nearest

10 psi [100 kPa].

where:

11.5 The minimum hydrostatic test pressure required to

H = distance between flattening plates, in. [mm],

satisfy these requirements need not exceed 3000 psi [20 700

t = specified wall thickness, in. [mm], and

kPa]; however this does not prohibit testing at a higher pressure

D = specifie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.