ASTM D2573-01(2007)

(Test Method)Standard Test Method for Field Vane Shear Test in Cohesive Soil

Standard Test Method for Field Vane Shear Test in Cohesive Soil

SCOPE

1.1 This test method covers the field vane test in saturated clay and silt soils for determination of undrained shear strength. Knowledge of the nature of the soil in which each vane test is to be made is necessary for assessment of the applicability and interpretation of the test. The test is not applicable for sandy soils which may allow drainage during the test.

1.2 This test method addresses testing on land and for testing in drill holes or by self drilling or continuous push methods from the ground surface. This method does not address specifically marine testing where special test requirements or variations in equipment may be required. The user is referred to ASTM STP 1014 for additional information on in-place vane shear testing.

1.3 This method is often used in conjunction with fluid rotary drilling (D 5783) or hollow-stem augers (D 6151). Some apparatuses have the vane retracted in protective shoe for advancement and incremental testing. Sampling, such as with thin wall tubes (D 1587) is often combined with vane testing. Subsurface geotechnical explorations are reported in accordance with practice (D 5434).

1.4 Undrained shear strength and sensitivity of cohesive soils can also be measured in Unconfined Compression D 2166 and Laboratory Vane Test (D 4648).

1.5 The values stated in SI units are to be regarded as the standard. English (Imperial) units are given in parentheses.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2573 – 01 (Reapproved 2007)

Standard Test Method for

Field Vane Shear Test in Cohesive Soil

This standard is issued under the fixed designation D 2573; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method covers the field vane test in saturated 2.1 ASTM Standards:

clay and silt soils for determination of undrained shear D 653 Terminology Relating to Soil, Rock, and Contained

strength. Knowledge of the nature of the soil in which each Fluids

vane test is to be made is necessary for assessment of the D 1587 Practice for Thin-Walled Tube Sampling of Soils

applicability and interpretation of the test. The test is not for Geotechnical Purposes

applicableforsandysoilswhichmayallowdrainageduringthe D 2166 Test Method for Unconfined Compressive Strength

test. of Cohesive Soil

1.2 This test method addresses testing on land and for D 2488 Practice for Description and Identification of Soils

testing in drill holes or by self drilling or continuous push (Visual-Manual Procedure)

methods from the ground surface. This method does not D 3740 Practice for Minimum Requirements for Agencies

address specifically marine testing where special test require- Engaged in theTesting and/or Inspection of Soil and Rock

ments or variations in equipment may be required. The user is as Used in Engineering Design and Construction

referred to ASTM STP 1014 for additional information on D 4648 Test Method for Laboratory Miniature Vane Shear

in-place vane shear testing. Test for SaturatedFine-Grained Clayey Soil

1.3 This method is often used in conjunction with fluid D 5434 Guide for Field Logging of Subsurface Explora-

rotarydrilling(D 5783)orhollow-stemaugers(D 6151).Some tions of Soil and Rock

apparatuses have the vane retracted in protective shoe for D 5783 Guide for Use of Direct Rotary Drilling with

advancement and incremental testing. Sampling, such as with Water-Based Drilling Fluid for Geoenvironmental Explo-

thin wall tubes (D 1587) is often combined with vane testing. ration and the Installation of Subsurface Water-Quality

Subsurface geotechnical explorations are reported in accor- Monitoring Devices

dance with practice (D 5434). D 6151 Practice for Using Hollow-Stem Augers for Geo-

1.4 Undrained shear strength and sensitivity of cohesive technical Exploration and Soil Sampling

soilscanalsobemeasuredinUnconfinedCompressionD 2166 2.2 Other Standards:

and Laboratory Vane Test (D 4648). Recommended Standard for Field Vane Shear Test, Swed-

1.5 The values stated in SI units are to be regarded as the ish Geotechnical Society, SGF Report 2:93E, Swedish

standard. English (Imperial) units are given in parentheses. Geotechnical Institute, Linköping: www.swedgeo.se

1.6 This standard does not purport to address all of the EuroCode 7: Geotechnical Design–Part 3 Design Assisted

safety concerns, if any, associated with its use. It is the by Field Testing, ENV 1997-3:1999E, CEN

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use.

3.1.1 Forcommondefinitionsoftermsinthisstandard,refer

to Terminology D 653.

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and

Related Field Testing for Soil Evaluations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2007. Published August 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2001 as D 2573 – 01. Standards volume information, refer to the standard’s Document Summary page on

ASTM STP 1014 on Vane Shear Strength Testing in Soils (1988). the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2573 – 01 (2007)

3.1.2 sensitivity—the effect of remolding on the consistency 3.4.4 torque–T, (FL)—the measured torque (or moment)

of cohesive soil. required to rotate the vane.

3.4.5 vane area ratio–V –% —the ratio of the cross section

3.1.3 vane shear test (VST)—an in-place shear test in which

A

arodwiththinradialvanesattheendisforcedintothesoiland area of the vane to the circular area of the rotated vane

expressed as a percent (see Fig. 2).

the resistance to rotation of the rod is determined.

3.2 Definitions of Terms Specific to This Standard: 3.5 Acronyms:

3.5.1 VST—vane shear test.

3.2.1 remolded undrained shear strength—shear strength of

3.5.2 FV—field vane.

fine-grained soil in rapid loading with little or no drainage of

pore water pressure after significant failure and remolding of

4. Summary of Test Method

the initial soil structure. (Also see D 2166 and D 4648).

3.2.2 undrained shear strength—shear strength of fine-

4.1 The vane shear test consists of placing a four-bladed

grained soil (primarily clays and clayey silts) in rapid loading

vane in the undisturbed soil and rotating it from the surface to

with essentially no drainage of porewater pressure. (Also see

determine the torque required to shear a cylindrical surface

D 2166 and D 4648).

with the vane. This torque, or moment, is then converted to a

3.2.3 vane—a device with four, thin, flat metal blades or

the unit shearing resistance of the failure surface by limit

plates, fixed at an angle of 90 degrees to each other, which is

equilibrium analysis. Friction of the vane rod and instrument

inserted into the soil and then rotated about a vertical axis for

are either minimized during readings by special casings or

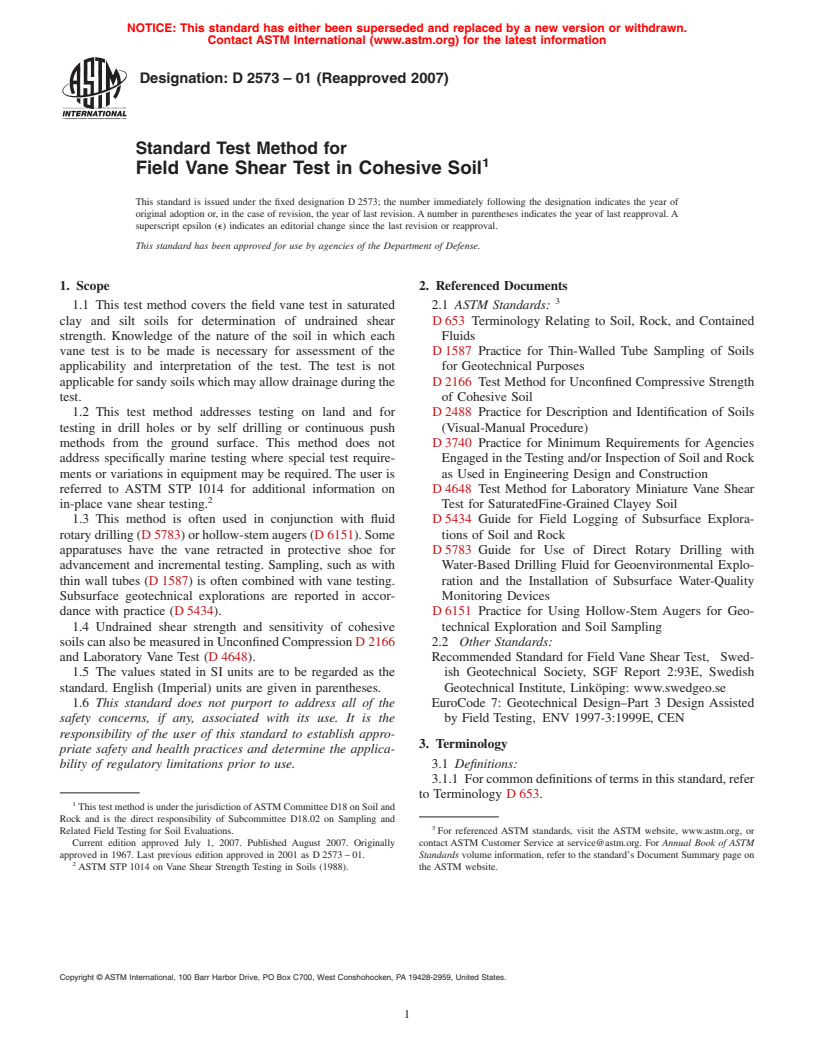

shear testing (see Fig. 1).

housing, or else accounted for and subtracted from the total

3.2.4 vane shoe—a section of drill casing and cutting bit at torque to determine the torque applied to the vane.

the end in which the vane can be retracted while drilling or

5. Significance and Use

pushing

3.3 Symbols:

5.1 This test method provides an indication of in-situ

3.3.1 In accordance with ASTM D 653.

undrainedshearstrengthoffine-grainedclaysandsiltsorother

3.3.2 shear strength, s —the maximum (undrained) resis-

u fine geomaterials such as mine tailings, organic muck, and

tance of soil to shearing stresses.

substanceswhereundrainedstrengthdeterminationisrequired.

3.4 Symbols Specific to This Standard:

The test is applicable to soils with undrained strengths of less

3.4.1 peak undrained shear strength, (s ) —the peak und-

than 200 kPa (2 tsf). Very sensitive soils can be remolded

u fv

rained shearing resistance measured during the initial rotation

during vane insertion.

of the vane in a vane shear test.

5.2 This test method is used extensively in a variety of

3.4.2 remolded undrained shear strength, (s ) —the re-

geotechnicalexplorationstoevaluaterapidloadingstrengthfor

ur fv

molded undrained shear strength is measured after five to ten

total stress analysis of saturated fine-grained clays and silts.

vane rotations in a vane shear test.

The test is routinely performed in conjunction with other field

3.4.3 sensitivity–S —the ratio of peak undrained shear and laboratory tests.

Tfv

strength to remolded undrained shear strength measured in the

5.3 The peak undrained shear resistance of the vane test is

field vane shear test: S =(s )f /(s )f . The remolded shear commonly corrected to determine the undrained shear strength

Tfv u v ur v

strength is measured after large shearing strains (see 8.7 and

for geotechnical analysis. The agency requesting the testing

9.3). must interpret these data to determine applicability for strength

analysis. It is beyond the scope of this standard to recommend

NOTE 1—Previous and existing standards have specified different

applicability of vane testing for geotechnical analysis. For

amounts of rotation, from 5 to 25 revolutions, for measurement of

information on the general use of these correction factors,

remolded strength. If sensitivity is reported, the number of revolutions

must also be reported. Sensitivity can also be measured in unconfined consult Appendix X1.

compression testing (D 2166) and laboratory vane testing (D 4648).

5.4 This method is not applicable in sands, gravels, or other

high permeability soils. With the shearing rates described in

this standard, sand lenses, if present, will allow total or partial

drainage. Soils with higher permeability, in rapid shear, can

dilate or collapse and generate negative or positive pore

pressures which may, or may not, dissipate in the shearing

process. It is important to check the soil type being tested. It is

very beneficial to sample the soil either before or after testing,

to understand the drainage conditions (permeability) of the soil

tested.

5.5 This test is often performed in drilled boreholes or with

self-push or self-drilling or pushed (vane shoe) methods. This

method also applies to hand held vane shear tests performed at

shallow depths, however, hand held equipment may be less

accurate, because it may be more difficult to maintain vane/rod

stability and verticality.

FIG. 1 Geometry of Field Vanes NOTE 2—The quality of the result produced by this standard is

D 2573 – 01 (2007)

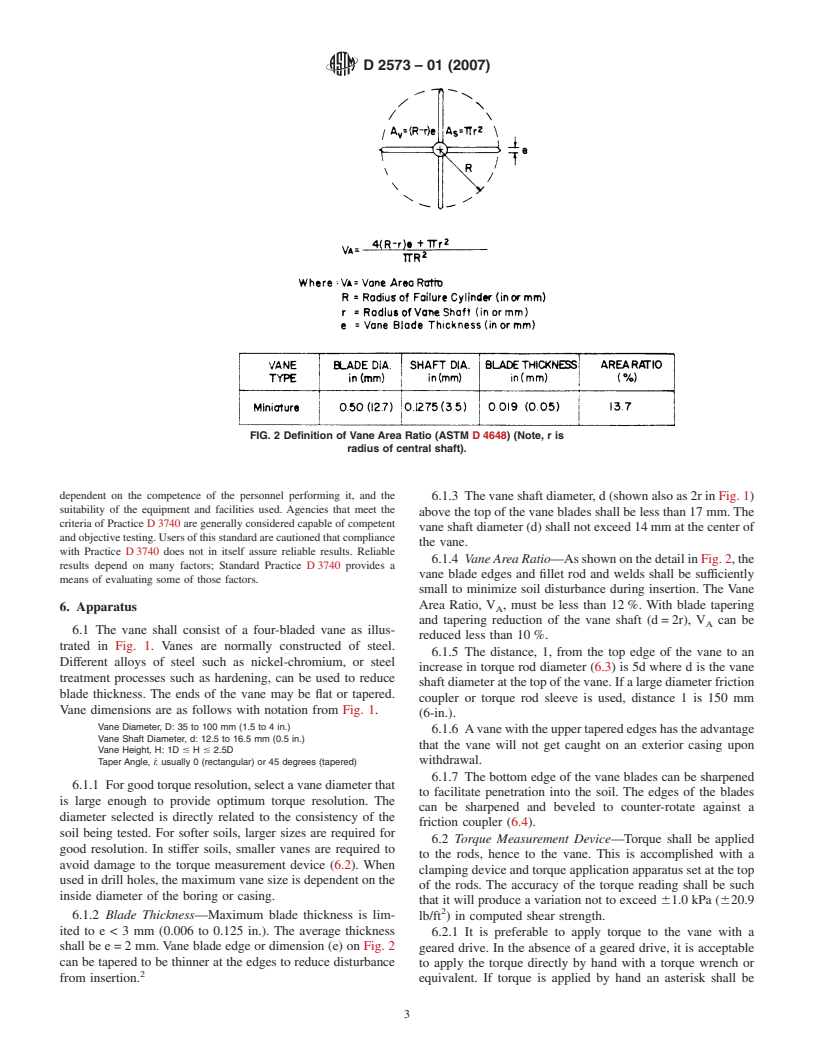

FIG. 2 Definition of Vane Area Ratio (ASTM D 4648)(Note,ris

radius of central shaft).

dependent on the competence of the personnel performing it, and the

6.1.3 The vane shaft diameter, d (shown also as 2r in Fig. 1)

suitability of the equipment and facilities used. Agencies that meet the

above the top of the vane blades shall be less than 17 mm. The

criteria of Practice D 3740 are generally considered capable of competent

vane shaft diameter (d) shall not exceed 14 mm at the center of

and objective testing. Users of this standard are cautioned that compliance

the vane.

with Practice D 3740 does not in itself assure reliable results. Reliable

6.1.4 VaneArea Ratio—AsshownonthedetailinFig.2,the

results depend on many factors; Standard Practice D 3740 provides a

vane blade edges and fillet rod and welds shall be sufficiently

means of evaluating some of those factors.

small to minimize soil disturbance during insertion. The Vane

Area Ratio, V , must be less than 12 %. With blade tapering

6. Apparatus A

and tapering reduction of the vane shaft (d = 2r), V can be

A

6.1 The vane shall consist of a four-bladed vane as illus-

reduced less than 10 %.

trated in Fig. 1. Vanes are normally constructed of steel.

6.1.5 The distance, 1, from the top edge of the vane to an

Different alloys of steel such as nickel-chromium, or steel

increase in torque rod diameter (6.3) is 5d where d is the vane

treatment processes such as hardening, can be used to reduce

shaftdiameteratthetopofthevane.Ifalargediameterfriction

blade thickness. The ends of the vane may be flat or tapered.

coupler or torque rod sleeve is used, distance 1 is 150 mm

Vane dimensions are as follows with notation from Fig. 1.

(6-in.).

Vane Diameter, D: 35 to 100 mm (1.5 to 4 in.)

6.1.6 Avanewiththeuppertaperededgeshastheadvantage

Vane Shaft Diameter, d: 12.5 to 16.5 mm (0.5 in.)

that the vane will not get caught on an exterior casing upon

Vane Height, H: 1D# H# 2.5D

Taper Angle, i: usually 0 (rectangular) or 45 degrees (tapered) withdrawal.

6.1.7 The bottom edge of the vane blades can be sharpened

6.1.1 For good torque resolution, select a vane diameter that

to facilitate penetration into the soil. The edges of the blades

is large enough to provide optimum torque resolution. The

can be sharpened and beveled to counter-rotate against a

diameter selected is directly related to the consistency of the

friction coupler (6.4).

soil being tested. For softer soils, larger sizes are required for

6.2 Torque Measurement Device—Torque shall be applied

good resolution. In stiffer soils, smaller vanes are required to

to the rods, hence to the vane. This is accomplished with a

avoid damage to the torque measurement device (6.2). When

clamping device and torque application apparatus set at the top

used in drill holes, the maximum vane size is dependent on the

of the rods. The accuracy of the torque reading shall be such

inside diameter of the boring or casing.

that it will produce a variation not to exceed 61.0 kPa (620.9

6.1.2 Blade Thickness—Maximum blade thickness is lim- lb/ft ) in computed shear strength.

ited toe<3mm (0.006 to 0.125 in.). The average thickness

6.2.1 It is preferable to apply torque to the vane with a

shall be e = 2 mm. Vane blade edge or dimension (e) on Fig. 2

geared drive. In the absence of a geared drive, it is acceptable

can be tapered to be thinner at the edges to reduce disturbance

to apply the torque directly by hand with a torque wrench or

from insertion. equivalent. If torque is applied by hand an asterisk shall be

D 2573 – 01 (2007)

placed next to the resultant shear stress and “hand torqued” amount of rotation, typically 15 degrees has occurred, and thus

shall be noted. The duration of the test shall be controlled by allows for determination of rod friction prior to the test. Use of

the requirements of 8.6. this coupling is preferred over blank rod testing for determi-

6.2.2 Some torque measurement devices are capable of nation of rod friction, because measurements are made directly

making hard copy or computer records of the load- in the soil tested.

displacement history. Other manually read systems use torque 6.5 Centralizers—For tests performed in drill holes, it will

rings and dial gauges. These automatic reading systems have benecessarytoequipthetorquerodswithcentralizerstoassure

an advantage over manually read systems, because operator a vertical push and to prevent torque rod buckling. They are

errorisreduced,andapermanentrecordofthetestisgenerated designedtosupporttherods,whileminimizinganyrodfriction

during the test. when deflected. Centralizers must be smaller in diameter than

6.3 Torque Rods—The vane shall be connected to the the drill hole. They shall be designed to allow the passage of

surface by means of steel torque rods. Typical rod diameter drill fluids.

ranges from 18 to 25 mm (0.5 to 1 in.). These rods shall have 6.6 Advancement Equipment—When used in drill holes, the

sufficient diameter such that their elastic limit is not exceeded drive head and pull-down capability of the drill rig can be used

whenthevaneisstressedtoitscapacity(Note3).Theysh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.