ASTM D2693-02

(Specification)Standard Specification for Ethylene Glycol

Standard Specification for Ethylene Glycol

SCOPE

1.1 This specification covers ethylene glycol for use in the preparation of surface coatings.

1.2 The following applies to all specified limits in this standard; for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.3 For specific hazard information and guidance, consult the supplier's Material Safety Data Sheet.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2693 – 02

Standard Specification for

1

Ethylene Glycol

This standard is issued under the fixed designation D 2693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

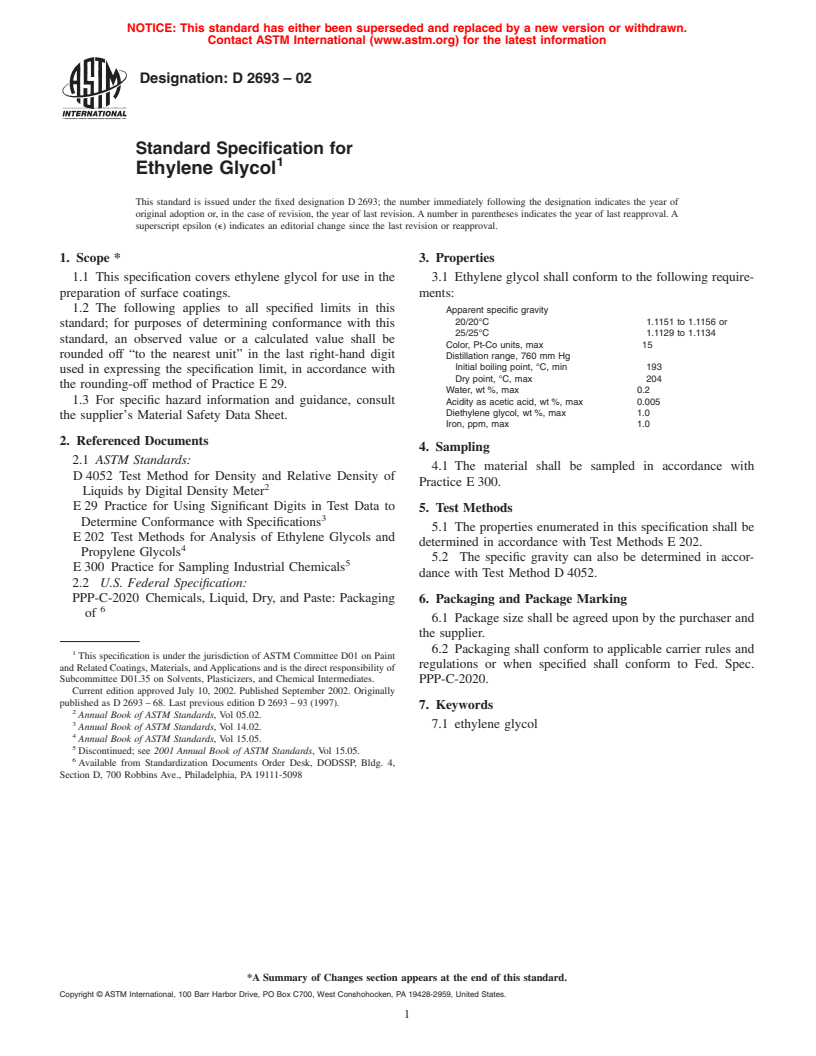

1. Scope * 3. Properties

1.1 This specification covers ethylene glycol for use in the 3.1 Ethylene glycol shall conform to the following require-

preparation of surface coatings. ments:

1.2 The following applies to all specified limits in this

Apparent specific gravity

20/20°C 1.1151 to 1.1156 or

standard; for purposes of determining conformance with this

25/25°C 1.1129 to 1.1134

standard, an observed value or a calculated value shall be

Color, Pt-Co units, max 15

rounded off “to the nearest unit” in the last right-hand digit

Distillation range, 760 mm Hg

Initial boiling point, °C, min 193

used in expressing the specification limit, in accordance with

Dry point, °C, max 204

the rounding-off method of Practice E 29.

Water, wt %, max 0.2

1.3 For specific hazard information and guidance, consult

Acidity as acetic acid, wt %, max 0.005

Diethylene glycol, wt %, max 1.0

the supplier’s Material Safety Data Sheet.

Iron, ppm, max 1.0

2. Referenced Documents

4. Sampling

2.1 ASTM Standards:

4.1 The material shall be sampled in accordance with

D 4052 Test Method for Density and Relative Density of

Practice E 300.

2

Liquids by Digital Density Meter

E 29 Practice for Using Significant Digits in Test Data to

5. Test Methods

3

Determine Conformance with Specifications

5.1 The properties enumerated in this specification shall be

E 202 Test Methods for Analysis of Ethylene Glycols and

determined in accordance with Test Methods E 202.

4

Propylene Glycols

5.2 The specific gravity can also be determined in accor-

5

E 300 Practice for Sampling Industrial Chemicals

dance with Test Method D 4052.

2.2 U.S. Federal Specification:

PPP-C-2020 Chemicals, Liquid, Dry, and Paste: Packaging

6. Packaging and Package Marking

6

of

6.1 Package size shall be agreed upon by the purchaser and

the supplier.

6.2 Packaging shall conform to applicable carrier rules and

1

This specification is under the jurisdiction of ASTM Committee D01 on Paint

regulations or when specified shall conform to Fed. Spec.

and Related Coatings, Materials, andApplic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.