ASTM E2801-11(2020)

(Test Method)Standard Test Method for Evaluating Emergency Response Robot Capabilities: Mobility: Confined Area Obstacles: Gaps

Standard Test Method for Evaluating Emergency Response Robot Capabilities: Mobility: Confined Area Obstacles: Gaps

SIGNIFICANCE AND USE

5.1 A main purpose of using robots in emergency response operations is to enhance the safety and effectiveness of emergency responders operating in hazardous or inaccessible environments. The testing results of the candidate robot shall describe, in a statistically significant way, how reliably the robot is able to negotiate the specified types of obstacles, and thus provide emergency responders sufficiently high levels of confidence to determine the applicability of the robot.

5.2 This test method addresses robot performance requirements expressed by emergency responders and representatives from other interested organizations. The performance data captured within this test method are indicative of the testing robot’s capabilities. Having available a roster of successfully tested robots with associated performance data to guide procurement and deployment decisions for emergency responders is consistent with the guideline of “Governments at all levels have a responsibility to develop detailed, robust, all-hazards response plans” as stated in National Response Framework.

5.3 This test apparatus is scalable to constrain robot maneuverability during task performance for a range of robot sizes in confined areas associated with emergency response operations. Variants of the apparatus provide minimum lateral clearance of 2.4 m (8 ft) for robots expected to operate around the environments such as cluttered city streets, parking lots, and building lobbies; minimum lateral clearance of 1.2 m (4 ft) for robots expected to operate in and around the environments such as large buildings, stairwells, and urban sidewalks; minimum lateral clearance of 0.6 m (2 ft) for robots expected to operate within the environments such as dwellings and work spaces, buses and airplanes, and semi-collapsed structures; minimum lateral clearance of less than 0.6 m (2 ft) with a minimum vertical clearance adjustable from 0.6 m (2 ft) to 10 cm (4 in.) for robots expected to deploy through breech...

SCOPE

1.1 Purpose:

1.1.1 The purpose of this test method is to quantitatively evaluate a teleoperated ground robot’s (see Terminology E2521) capability of crossing horizontal gaps in confined areas.

1.1.2 Robots shall possess a certain set of mobility capabilities, including negotiating obstacles, to suit critical operations such as emergency responses. A horizontal gap with an unknown edge condition is a type of obstacle that exists in emergency response and other environments. These environments often pose constraints to robotic mobility to various degrees. This test method specifies apparatuses, procedures, and metrics to standardize this testing.

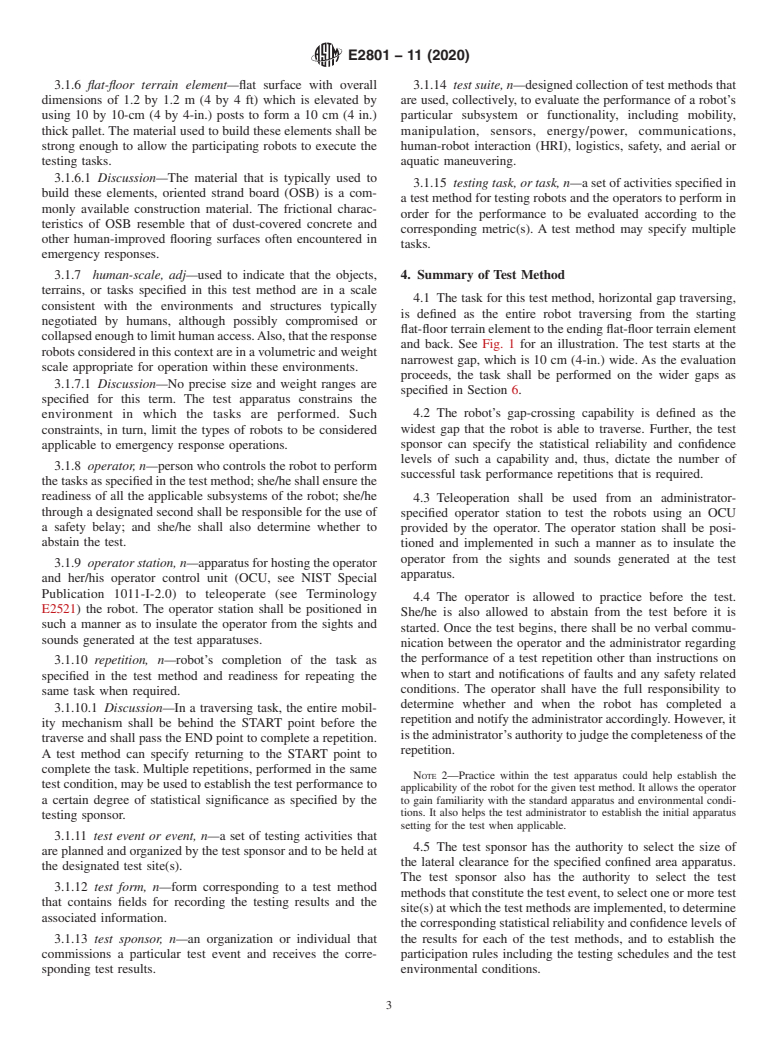

1.1.3 The test apparatuses are scalable to provide a range of lateral dimensions to constrain the robotic mobility during task performance. Fig. 1 shows three apparatus sizes to test robots intended for different emergency response scenarios.

FIG. 1 Mobility: Confined Area Obstacles: Gaps Apparatuses

1.1.4 Emergency response ground robots shall be able to handle many types of obstacles and terrain complexities. The required mobility capabilities include traversing gaps, hurdles, stairs, slopes, various types of floor surfaces or terrains, and confined passageways. Yet additional mobility requirements include sustained speeds and towing capabilities. Standard test methods are required to evaluate whether candidate robots meet these requirements.

1.1.5 ASTM Task Group E54.08.01 on Robotics specifies a mobility test suite, which consists of a set of test methods for evaluating these mobility capability requirements. This confined area gap test method is a part of the mobility test suite. The apparatuses associated with the test methods challenge specific robot capabilities in repeatable ways to facilitate comparison of different robot models as well as particular configurations of similar robot models.

1.1.6 The mobility test suite quantifies elemental mobility...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E2801 −11 (Reapproved 2020)

Standard Test Method for

Evaluating Emergency Response Robot Capabilities:

Mobility: Confined Area Obstacles: Gaps

This standard is issued under the fixed designation E2801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope comparison of different robot models as well as particular

configurations of similar robot models.

1.1 Purpose:

1.1.6 The mobility test suite quantifies elemental mobility

1.1.1 The purpose of this test method is to quantitatively

capabilities necessary for ground robots intended for emer-

evaluate a teleoperated ground robot’s (see Terminology

gency response applications. As such, users can use either the

E2521) capability of crossing horizontal gaps in confined

entire suite or a subset based on their particular performance

areas.

requirements. Users are also allowed to weight particular test

1.1.2 Robots shall possess a certain set of mobility

methods or particular metrics within a test method differently

capabilities, including negotiating obstacles, to suit critical

based on their specific performance requirements. The testing

operations such as emergency responses.Ahorizontal gap with

results should collectively represent an emergency response

an unknown edge condition is a type of obstacle that exists in

ground robot’s overall mobility performance. These perfor-

emergency response and other environments. These environ-

mance data can be used to guide procurement specifications

ments often pose constraints to robotic mobility to various

and acceptance testing for robots intended for emergency

degrees. This test method specifies apparatuses, procedures,

response applications.

and metrics to standardize this testing.

1.1.3 The test apparatuses are scalable to provide a range of

NOTE 1—Additional test methods within the suite are anticipated to be

lateral dimensions to constrain the robotic mobility during task

developed to address additional or advanced robotic mobility capability

requirements, including newly identified requirements and even for new

performance. Fig. 1 shows three apparatus sizes to test robots

application domains.

intended for different emergency response scenarios.

1.1.4 Emergency response ground robots shall be able to

1.2 Performing Location—This test method shall be per-

handle many types of obstacles and terrain complexities. The

formed in a testing laboratory or the field where the specified

required mobility capabilities include traversing gaps, hurdles,

apparatus and environmental conditions are implemented.

stairs, slopes, various types of floor surfaces or terrains, and

1.3 Units—The values stated in SI units are to be regarded

confined passageways. Yet additional mobility requirements

as the standard.The values given in parentheses are not precise

include sustained speeds and towing capabilities. Standard test

mathematical conversions to inch-pound units. They are close

methods are required to evaluate whether candidate robots

approximate equivalents for the purpose of specifying material

meet these requirements.

dimensions or quantities that are readily available to avoid

1.1.5 ASTM Task Group E54.08.01 on Robotics specifies a

excessive fabrication costs of test apparatuses while maintain-

mobility test suite, which consists of a set of test methods for

ing repeatability and reproducibility of the test method results.

evaluating these mobility capability requirements. This con-

These values given in parentheses are provided for information

fined area gap test method is a part of the mobility test suite.

only but are not considered standard.

The apparatuses associated with the test methods challenge

specific robot capabilities in repeatable ways to facilitate

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

This test method is under the jurisdiction of ASTM Committee E54 on

mine the applicability of regulatory limitations prior to use.

Homeland Security Applications and is the direct responsibility of Subcommittee

E54.09 on Response Robots.

1.5 This international standard was developed in accor-

Current edition approved Jan. 1, 2020. Published January 2020. Originally

dance with internationally recognized principles on standard-

approved in 2011. Last previous edition approved in 2011 as E2801 – 11. DOI:

10.1520/E2801-11R20. ization established in the Decision on Principles for the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2801−11 (2020)

FIG. 1Mobility: Confined Area Obstacles: Gaps Apparatuses

Development of International Standards, Guides and Recom- 3.1.3 administrator, n—person who conducts the test—The

mendations issued by the World Trade Organization Technical administrator shall ensure the readiness of the apparatus, the

Barriers to Trade (TBT) Committee.

test form, and any required measuring devices such as stop-

watch and light meter; the administrator shall ensure that the

2. Referenced Documents

specified or required environmental conditions are met; the

2.1 ASTM Standards:

administrator shall notify the operator when the safety belay is

E2521 Terminology for Evaluating Response Robot Capa-

available and ensure that the operator has either decided not to

bilities

use it or assigned a person to handle it properly; and the

E2592 Practice for Evaluating Response Robot Capabilities:

administratorshallcalltheoperatortostartandendthetestand

Logistics: Packaging for Urban Search and Rescue Task

record the performance data and any notable observations

Force Equipment Caches

during the test.

2.2 Other Standards:

3.1.4 emergency response robot, or response robot, n—a

National Response Framework U.S. Department of Home-

3 robot deployed to perform operational tasks in an emergency

land Security

response situation.

NIST Special Publication 1011-I-2.0 Autonomy Levels for

3.1.4.1 Discussion—Aresponserobotisadeployabledevice

Unmanned Systems (ALFUS) Framework Volume I:

intended to perform operational tasks at operational tempos

Terminology, Version 2.0

during emergency responses. It is designed to serve as an

3. Terminology

extension of the operator for gaining improved remote situ-

ational awareness and for projecting her/his intent through the

3.1 Definitions:

equipped capabilities. It is designed to reduce risk to the

3.1.1 Terminology E2521 lists additional definitions rel-

evant to this test method. operator while improving effectiveness and efficiency of the

3.1.2 abstain, v—prior to starting a particular test method, mission.Thedesiredfeaturesofaresponserobotinclude:rapid

the robot manufacturer or designated operator shall choose to

deployment; remote operation from an appropriate standoff

enter the test or abstain.Any abstention shall be granted before distance; mobility in complex environments; sufficiently hard-

the test begins. The test form shall be clearly marked as such,

enedagainstharshenvironments;reliableandfieldserviceable;

indicating that the manufacturer acknowledges the omission of

durable or cost effectively disposable, or both; and equipped

theperformancedatawhilethetestmethodwasavailableatthe

with operational safeguards.

test time.

3.1.5 fault condition—during the performance of the task(s)

3.1.2.1 Discussion—Abstentions may occur when the robot

as specified by the test method, a certain condition may occur

configuration is neither designed nor equipped to perform the

thatrendersthetaskexecutiontobefailedandsuchacondition

tasks as specified in the test method. Practices within the test

is called a fault condition. Fault conditions result in a loss of

apparatus prior to testing should allow for establishing the

credit for the partially completed repetition. The test time

applicability of the test method for the given robot.

continues until the operator determines that she/he can not

continueandnotifiestheadministrator.Theadministratorshall,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

then, pause the test time and add a time-stamped note on the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test form indicating the reason for the fault condition.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3.1.5.1 Discussion—Faultconditionsincluderoboticsystem

Available from Federal Emergency Management Agency (FEMA), P.O. Box

malfunction, such as de-tracking, and task execution problems,

10055, Hyattsville, MD 20782-8055, http://www.fema.gov.

4 such as excessive deviation from a specified path or failure to

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. recognize a target.

E2801−11 (2020)

3.1.6 flat-floor terrain element—flat surface with overall 3.1.14 test suite, n—designed collection of test methods that

dimensions of 1.2 by 1.2 m (4 by 4 ft) which is elevated by are used, collectively, to evaluate the performance of a robot’s

using 10 by 10-cm (4 by 4-in.) posts to form a 10 cm (4 in.) particular subsystem or functionality, including mobility,

thick pallet. The material used to build these elements shall be manipulation, sensors, energy/power, communications,

strong enough to allow the participating robots to execute the human-robot interaction (HRI), logistics, safety, and aerial or

testing tasks. aquatic maneuvering.

3.1.6.1 Discussion—The material that is typically used to

3.1.15 testing task, or task, n—a set of activities specified in

build these elements, oriented strand board (OSB) is a com-

a test method for testing robots and the operators to perform in

monly available construction material. The frictional charac-

order for the performance to be evaluated according to the

teristics of OSB resemble that of dust-covered concrete and

corresponding metric(s). A test method may specify multiple

other human-improved flooring surfaces often encountered in

tasks.

emergency responses.

3.1.7 human-scale, adj—used to indicate that the objects, 4. Summary of Test Method

terrains, or tasks specified in this test method are in a scale

4.1 The task for this test method, horizontal gap traversing,

consistent with the environments and structures typically

is defined as the entire robot traversing from the starting

negotiated by humans, although possibly compromised or

flat-floor terrain element to the ending flat-floor terrain element

collapsedenoughtolimithumanaccess.Also,thattheresponse

and back. See Fig. 1 for an illustration. The test starts at the

robotsconsideredinthiscontextareinavolumetricandweight

narrowest gap, which is 10 cm (4-in.) wide. As the evaluation

scale appropriate for operation within these environments.

proceeds, the task shall be performed on the wider gaps as

3.1.7.1 Discussion—No precise size and weight ranges are

specified in Section 6.

specified for this term. The test apparatus constrains the

4.2 The robot’s gap-crossing capability is defined as the

environment in which the tasks are performed. Such

widest gap that the robot is able to traverse. Further, the test

constraints, in turn, limit the types of robots to be considered

sponsor can specify the statistical reliability and confidence

applicable to emergency response operations.

levels of such a capability and, thus, dictate the number of

3.1.8 operator, n—person who controls the robot to perform

successful task performance repetitions that is required.

thetasksasspecifiedinthetestmethod;she/heshallensurethe

readiness of all the applicable subsystems of the robot; she/he

4.3 Teleoperation shall be used from an administrator-

through a designated second shall be responsible for the use of

specified operator station to test the robots using an OCU

a safety belay; and she/he shall also determine whether to

provided by the operator. The operator station shall be posi-

abstain the test.

tioned and implemented in such a manner as to insulate the

operator from the sights and sounds generated at the test

3.1.9 operator station, n—apparatusforhostingtheoperator

apparatus.

and her/his operator control unit (OCU, see NIST Special

Publication 1011-I-2.0) to teleoperate (see Terminology

4.4 The operator is allowed to practice before the test.

E2521) the robot. The operator station shall be positioned in

She/he is also allowed to abstain from the test before it is

such a manner as to insulate the operator from the sights and

started. Once the test begins, there shall be no verbal commu-

sounds generated at the test apparatuses.

nication between the operator and the administrator regarding

the performance of a test repetition other than instructions on

3.1.10 repetition, n—robot’s completion of the task as

when to start and notifications of faults and any safety related

specified in the test method and readiness for repeating the

conditions. The operator shall have the full responsibility to

same task when required.

determine whether and when the robot has completed a

3.1.10.1 Discussion—In a traversing task, the entire mobil-

repetitionandnotifytheadministratoraccordingly.However,it

ity mechanism shall be behind the START point before the

istheadministrator’sauthoritytojudgethecompletenessofthe

traverse and shall pass the END point to complete a repetition.

repetition.

A test method can specify returning to the START point to

complete the task. Multiple repetitions, performed in the same

NOTE 2—Practice within the test apparatus could help establish the

test condition, may be used to establish the test performance to

applicability of the robot for the given test method. It allows the operator

a certain degree of statistical significance as specified by the to gain familiarity with the standard apparatus and environmental condi-

tions. It also helps the test administrator to establish the initial apparatus

testing sponsor.

setting for the test when applicable.

3.1.11 test event or event, n—a set of testing activities that

4.5 The test sponsor has the authority to select the size of

are planned and organized by the test sponsor and to be held at

the lateral clearance for the specified confined area apparatus.

the designated test site(s)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.