ASTM D7682-10

(Test Method)Standard Test Method for Replication and Measurement of Concrete Surface Profiles Using Replica Putty

Standard Test Method for Replication and Measurement of Concrete Surface Profiles Using Replica Putty

SIGNIFICANCE AND USE

For proper bonding of overlays and coatings, it is important that a concrete surface have the correct surface profile. This test method allows one to obtain a permanent replica of the concrete surface, which can then be compared to visual profile standards, or evaluated quantitatively for profile depth. The permanent replica may also prove useful in resolving future disputes.

SCOPE

1.1 This test method is suitable for both field and laboratory use to obtain a permanent record of concrete surface profile using replica putty and to determine the depth of that surface profile.

Note 1—The procedure in this standard was developed for concrete substrates but may be appropriate for other rigid substrates.

1.2 A profile can be imparted to concrete by various methods such as blast cleaning and acid etching. The depth of the surface profile has been shown to be a factor in coating adhesion and performance.

1.3 The International Concrete Repair Institute (ICRI) provides a means of visually judging a concrete surface by use of nine different visual comparators called Concrete Surface Profiles (CSP). This standard compliments the use of these visual comparators.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7682 −10

StandardTest Method for

Replication and Measurement of Concrete Surface Profiles

Using Replica Putty

This standard is issued under the fixed designation D7682; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ICRI Document:

Technical Guideline 03732 Selecting and Specifying Con-

1.1 This test method is suitable for both field and laboratory

crete Surface Preparation for Sealers, Coatings, and Poly-

use to obtain a permanent record of concrete surface profile

mer Overlays

using replica putty and to determine the depth of that surface

profile.

3. Terminology

NOTE 1—The procedure in this standard was developed for concrete

3.1 Definitions of Terms Specific to This Standard:

substrates but may be appropriate for other rigid substrates.

3.1.1 plastic profiler, n—a device that provides a controlled

1.2 A profile can be imparted to concrete by various

means for holding and confining replica putty for placement

methods such as blast cleaning and acid etching. The depth of

onto a concrete surface.

the surface profile has been shown to be a factor in coating

3.1.2 replica coupon, n—hardened replica putty containing

adhesion and performance.

a reverse image replica of a concrete surface.

1.3 The International Concrete Repair Institute (ICRI) pro-

3.1.3 replica putty, n—a two-part, anti-stick, rapid harden-

vides a means of visually judging a concrete surface by use of

ing putty used to conform to a concrete surface and replicate

nine different visual comparators called Concrete Surface

surface profile.

Profiles (CSP). This standard compliments the use of these

3.1.4 visual comparator, n—an ICRI molded replica of a

visual comparators.

concrete surface profile that allows visual comparison to an

1.4 The values stated in SI units are to be regarded as

actual concrete surface.

standard. The values given in parentheses are for information

only.

4. Summary of Test Method

1.5 This standard does not purport to address all of the

4.1 Method A—Replica putty is used to obtain a replica

safety concerns, if any, associated with its use. It is the

coupon of a concrete surface that has been abraded or

responsibility of the user of this standard to establish appro-

roughened.Thereplicacouponisvisuallycomparedtothenine

priate safety and health practices and determine the applica-

ICRI Visual Comparators (CSP), or to a specific job standard.

bility of regulatory limitations prior to use.

4.2 Method B—Replica putty is used to obtain a replica

coupon of a concrete surface that has been abraded or

2. Referenced Documents

roughened. The replica coupon is then measured by a specially

2.1 ASTM Standards:

designed micrometer to obtain a quantitative measurement of

E177 Practice for Use of the Terms Precision and Bias in

surface profile (depth).

ASTM Test Methods

5. Significance and Use

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5.1 For proper bonding of overlays and coatings, it is

important that a concrete surface have the correct surface

profile. This test method allows one to obtain a permanent

replica of the concrete surface, which can then be compared to

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

visual profile standards, or evaluated quantitatively for profile

Subcommittee D01.46 on Industrial Protective Coatings.

depth. The permanent replica may also prove useful in resolv-

Current edition approved Dec. 1, 2010. Published December 2010. DOI:

ing future disputes.

10.1520/D7682–10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from International Concrete Repair Institute (ICRI), 3166 S. River

the ASTM website. Road, Suite 132, Des Plaines, IL 60018, http//www.icri.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

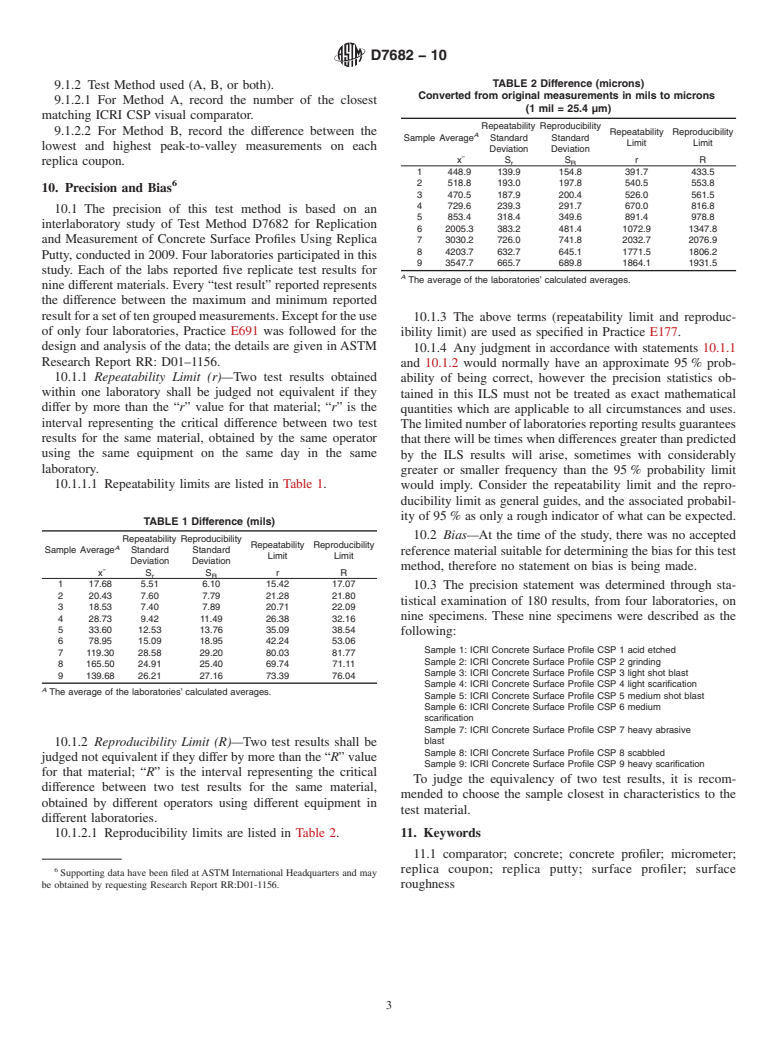

D7682−10

FIG. 1Plastic Profiler with Replica Putty on Concrete

6. Apparatus 8.1.8 Visually compare the replica coupon to the ICRI CSP

visual comparators, and determine which comparator is visu-

6.1 A set of nine ICRI CSP Comparators.

ally closest to the surface appearance of the replica coupon.

6.2 Replica putty and plastic profiler.

8.2 Method B:

6.3 A specially designed non-spring loaded micrometer

8.2.1 Follow steps 8.1.1-8.1.7 of Method A.

with a bottom anvil of at least 38 mm (1.5 in.) diameter. The

8.2.2 On each replica coupon take at least ten micrometer

upper contact point is machined flat to a diameter that will not

measurements in different locations ensuring some measure-

indent the coupon.

ments are taken in the bottoms of the valleys and some

measurements are taken on the tops of the peaks (see Fig. 2).

7. Calibration and Standardization

8.2.3 Subtract the lowest thickness measurement from the

7.1 Zero the micrometer prior to each measurement session

highest thickness measurement to determine the profile range

in accordance with the manufacturer’s instructions.

for each replica coupon.

7.2 Micrometer accuracy should be checked by measuring a

9. Report

shim of known thickness and confirming results are within the

9.1 Report the following information:

combined tolerances of both the micrometer and the shim.

9.1.1 Date, test location, and replica coupon label numbers.

8. Procedure

8.1 Method A:

8.1.1 Select a sufficient number of locations to characterize

the surface, as specified or agreed upon between the interested

parties.

8.1.2 At each location clean the surface with a brush to

remove loose material.

8.1.3 Prepare the replica putty in accordance with the

manufacturer’s instructions.

8.1.4 Place the mixed replica putty into a plastic profiler,

mounding the putty in the middle.

8.1.5 Place the plastic profiler onto the concrete, putty side

down. Step on or push the plastic profiler until the shoulders

touch the concrete surface (see Fig. 1). Do not remove the

plastic profiler.

8.1.6 After sufficient time to cure in accordance with the

manufacturer’s instructions twist the plastic profiler and re-

move it from the hardened putty (replica coupon).

8.1.7 Peel the replica coupon from the concrete surface and

number the back (smooth) side for future reference.

Thesolesourceofsupplyofthecompactors,aswellasGuideline03732known

to the committee at this time is the International Concrete Repair Institute, 3166 S.

River Road, Suite 132, Des Plaines, IL 60018. If you are aware of alternative

suppliers, please provide this information to ASTM International Head

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.